Seakeeper install…. 7,000 miles later

As I sat down to write this article I flashed back to an eye-opening technology experience at the 2015 Fort Lauderdale International Boat Show. My wife and I found ourselves on the Seakeeper roll stabilization demo boat in the mouth of the Port Everglades inlet with a Viking 60-foot sportfish doing circles around us throwing as big a wake as possible. Our demo ride led to a major install on our Carver motor yacht, which I can recall in vivid detail, but which also significantly improved our subsequent family voyage around the Great Loop…

By that Lauderdale show my wife and I were seriously discussing the Great Loop trip. Years before, when I started bugging her to take this “little trip” we were both in our mid-thirties with two young children and I was working very full time in financial services technology with travel most weeks. I think she felt it safe to ignore my pestering as day-dreaming.

As 2015 drew to a close my satisfaction with the work was rapidly declining and I negotiated my exit six months into the future. Suddenly, my idle day-dreaming turned into full-on possibility. If we left in the summer of 2016 our kids would be six and nine, hopefully a good time for a year of travel and home (boat) schooling. We did debate a fair amount but ultimately decided that while there were plenty of reasons not to go, we were going to give it a try.

We already owned a Carver Voyager 570. We contemplated purchasing a new boat better suited for the Great Loop, but research mainly pointed to a smaller one. With four of us on the boat we wanted the space we had and ultimately decided that our boat was as good as any.

Now on to the next issue. My wife has never been overly comfortable with the natural side-to-side rolling action of our boat. My youngest daughter, Madelyn, seemingly inherited this discomfort but without my wife’s grace in managing the discomfort. The entire summer of 2013 consisted of her chanting “Maddy go home” every time the boat rocked. So, as we walked through the boat show looking at all the pretty new boats and gadgetry, the Seakeeper booth got our attention.

I’d been intrigued by Seakeeper’s gyroscopic stabilization technology since they first started shipping product. While at the show I talked to my friend Mike Walsh from Marine Services Corp. and mentioned Seakeeper in jest, thinking it too expensive and too difficult to install.. He quickly convinced me that I should really consider it. His facility hadn’t done an install yet but he was confident they were up to the task and he was interested in taking one on.

So we circled back to the Seakeeper booth and signed up for the demo ride. We were soon heading out the inlet to meet the big Viking. When it circled us a few times, the Seakeeper handled the wake really well, but then the captain locked the gyro and the boat rolled nearly rub rail to rub rail.

At this point my wife, Laura, was holding on and not looking too happy. The captain unlocked the Seakeeper and about seven seconds later all rolling stopped; the boat rode up and down over the wake with pretty much no perceptible roll. At that moment I knew that my normally very frugal wife was sold. What I didn’t fully understand yet was how much the Seakeeper would improve our displacement cruising.

Seakeeper has now evolved to making many models for different sized boats and different power options but each is a gyroscopic stabilizer. They work by spinning a large, heavy counterweight inside of an enclosure at high RPMs, creating a spinning-top-like inertial force. In the case of our Seakeeper 9 that’s a 900 pound counterweight spinning at 9,000 RPM. A near vacuum inside the enclosure and water cooling help make this possible, but it still takes significant power.

So how does it actually work? The stabilizer is mounted in the boat so that it precesses (gyro jargon for rolling back and forth) forward and aft. This forward and aft precession produces force countering the boat’s natural tendency to roll side to side. Basically, Seakeeper is taking advantage of the same property that keeps you upright on a bicycle when the wheels are spinning. A great illustration of this property is available from the Exploratorium.

Seakeeper has developed an advanced control unit that sits in the back of the gyro enclosure above the ball. Taking input from sensors on the unit, it controls the motor that spins the counterweight as well as the hydraulic brake you can see on the right side of the unit. When you see the ball precess back and forth in an active Seakeeper video (around the 1:08 mark in this Seakeeper promotional video), you might think there’s a motor or hydraulic ram moving it around. But that’s not the case. What you’re seeing is the force of the spinning counterweight move the ball.

Because the ball can only move in one axis, fore and aft, the desire of the ball to move side to side is transferred to the mounting bracket and ultimately the hull of the boat as stabilizing force. The control unit is responsible for making sure the gyro operates safely within Seakeeper defined limits. For instance, the braking circuit can stop the gyro from precessing (which stops it from stabilizing), as well as slow its precession when it nears the end of its 140 degrees of precession.

Once we returned from Fort Lauderdale we got down to the business of figuring out how to install a roughly 1,200 pound, three foot cube in our boat. Even though Seakeeper says it doesn’t need to be centered in the boat or even particularly low, this wasn’t an easy proposition. The fuel tanks on a Carver Voyager 570 are at the aft end of the engine room, are only a little more than two feet apart, and there was no way to get the stabilizer forward of that point. So we settled on the lazarette as our install location. After some measuring, some mocking up, some head scratching, and some more measuring, a plan emerged.

We’d have to relocate the shore power isolation transformers but the gyro would fit center line aft over the steering gear. It turns out the engine room hatch was about half an inch smaller than the smallest dimension of a Seakeeper 9, so we anticipated an adventure just getting it into the boat. With a vague plan in place, even some emerging confidence that we could make this all happen, a Seakeeper 9 was ordered. As the calendar flipped to 2016 a nondescript wooden crate arrived with precious cargo inside.

Meanwhile we worked with a marine fabricator to build the needed custom bracket, and in turn the fabricator worked with a naval architect to ensure the boat’s hollow stringer structure stood up to the maximum loads the stabilizer could impose, which equate to roughly 14,000 foot pounds of torque.

It was during this stage that we encountered one limitation of working with Seakeeper. Although the company understandably requires approval review of your installation design, in our experience it does not help much in the design process. I suspect this is due to liability concerns but it’s difficult when your fabricator complains that he’s working in an information vacuum. I understand that the installer must take some responsibility in the process, but I wish Seakeeper would share more of what must be a vast trove of install knowledge.

That said, the design our fabricator ended up proposing incorporated all four main longitudinal stringers in the boat. The overall bracket starts with a u-shaped base over about a five foot section of those four stringers. In the picture above you can see the base for the center two stringers with the core box the stabilizer bolts to welded on. The outer two stringers’ base sections then bolt to this core box.

Seakeeper does specify that the bracket be glued to the structure of the boat rather than bolted. In fact, a representative described a phenomenon where the bolts can act a little like a wire cutting through butter. In other words, with the force levels involved, the bolts can become cutting instruments turning the stringer holes into slots, allowing the Seakeeper to walk and possibly worse.

So once the bracket was fabricated, it was time to glue it down to the stringers. This was a one try affair, as the adhesive used is the same used in bonding aluminum automobile structural members and, from what I understand, once cured it doesn’t let go easily. I’m not a naturally patient person and the process of creating and installing the bracket was trying.

Thankfully, the fabricator was methodical in his approach, diligently avoiding miscalculations, and we saw his success during the March, 2016 install. The process involved a couple of fork lifts, a couple of come-alongs and a porta-power to stretch the engine room hatch opening to fit the stabilizer. Actually it had to be put in on end and then rolled into place.

While it was stressful to watch this process knowing that several months of effort could have been in vain, the install ultimately went off without a hitch. Now the electrical connections needed to be made, the control system installed and the commissioning work completed.

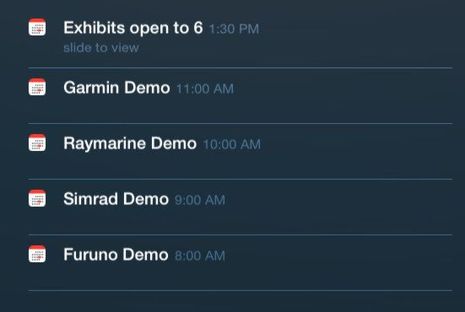

Fortunately we have a 23kw generator so the 3kw maximum draw from the Seakeeper wasn’t a major factor. Also, the control units use standard DeviceNet Micro-C connectors like NMEA-2000 networks, and I was just completing an electronics refit on the boat. So running those cables was pretty simple as all the cable chases on the boat were open and accessible.

One cloudy April day it was time to get the boat off the dock and see what the stabilizer could do. But since Have Another Day‘s winter home on the Little Calumet River is an hour plus from Lake Michigan’s potentially rough waters, we simply pulled the boat off the dock along with a 20′ skiff which we then used to throw wakes.

The wakes were no match for the Seakeeper. It precessed a few degrees, and the boat never rolled at all. The early returns, though highly incomplete, were very positive. The next test was a run out to the lake, but as Mr. Murphy would have it, we managed to pick what was likely the only flat-calm day in early April. So that’s why possibly puzzled observers saw a big Carver doing donuts and then stopping dead in its own wake. Again the boat behaved very favorably but I still didn’t feel like we knew the full capabilities of our boat and Seakeeper working together.

Actually, fully appreciating the Seakeeper took some time. Next up was finishing the lazarette install with new shelves and component dressings. Then the summer spent on the Lake was more about Great Loop preparations than extensive cruising.

But we did spend a fair amount of time at anchor and one of the great things about gyroscopic stabilizers is they work at rest. In fact, a gyro is most effective at rest and becomes less effective the faster the boat travels, and this characteristic nicely aligns with a planing hull like ours.

Have Another Day generates reasonable lateral stability on plane from the two large spinning screws underneath her. Her Achilles heel has always been at low speed where the smooth-bottomed planing hull allows a fair amount of roll. During our time at anchor and at low speed cruising around Chicago’s waterfront we had the opportunity to see and feel the stabilizer in action. We were impressed.

The boat’s pronounced tendency to roll at anchor and at low speed was nearly entirely eliminated. The worst wake or wave would only roll the boat a few degrees before she came back to a level and stable footing. Gone were the pendulum-like rolls going back and forth first with the wave and then with the resulting momentum.

On the morning of August 29th, 2016 Laura, Molly, Madelyn and I left for our Great Loop adventure. For the next two months we were on calm rivers while the stabilizer mostly just rested. But upon arrival in Mobile Bay, it was quickly back into service, and was helpful as we travelled alternately in exposed waters and the Gulf Intracoastal Waterway. It even neutralized a beam chop as we crossed the Florida panhandle to St. Petersburg on plane.

But it was in open waters ahead, and especially our crossing back from the Bahamas, that we really experienced improved comfort, even at displacement speeds.The forecast was 3-5 footers with an 11 second period, but we encountered higher waves with shorter period. This meant hours of steep five footers on our beam but the Seakeeper kept the boat flat and level even at 9 knots.

In conclusion, the Seakeeper has done what we hoped it would. A boat that we were previously comfortable cruising only on plane is now comfortable at nearly all speeds. In fact, our preferred cruising speed became 9 knots. With the new-found stability at that moderate speed everyone is more comfortable with the gentle motions of the relaxed pace. We also are able to cruise above 1 nautical mile per gallon instead of our just over 2 gallon per mile fuel burn on plane.

At the same time we can now sit at anchor comfortably without worry of rolling from waves or wake. But it’s also important to realize what the Seakeeper can’t fix. Our boat has an unfortunate tendency to pound in a head sea, for instance, and the stabilizer can’t do a thing about that. There’s also the Seakeeper 9’s $72,400 price plus the installation cost. Living on our boat for 14 months makes the investment easier to justify, and I think it will help the resale value, but I’m also realistic that resale return may be pennies or dimes on the dollar.

Overall the experiment was a success. Like every boat related decision, the finances aren’t always pretty, but the payoff our family received has been tremendous. When we finished the Great Loop last October 9th, we had enjoyed the trip even more than we ever thought we would. My once reluctant wife is now the biggest advocate of getting back on the boat and continuing to cruise. My children experienced first hand things most of their peers only have the opportunity to read about. If you want to read more about our trip we blogged the entire experience at www.haveanotherdaysgreatloop.com.

I probably don’t have to ask, but please give Ben Stein a warm welcome for his first Panbo entry ~ Old Ben

Great article! Thank you for sharing. Looking forward to doing the trip someday!

I have somehow never managed to get aboard a SeaKeeper demo, but I have many boating writer friends tell me that it is truly amazing. I particularly heard that when we gave the Seakeeper3 12v smaller boat system an award at IBEX. (Great install video here: https://youtu.be/cWovfBd1NXA )

But what I didn’t realize until now is how gyro stabilization can not only help with sickening rolls but also give fast boats a wider range of usable speeds. The cost and complexity probably makes some “salty sailors” wince, but I say COOL, and thank you, Ben S.

Great article Ben. Look forward to other articles

Great article. Can you speak a little to the electrical needs as well as the start-up and shut-down procedures.

I am under the impression that it takes quite a while to start-up and get rotating at the needed RPMs consuming a lot of power and that shut-down has a similair reguirement.

Thank You

Would be really interesting to hear a bit more on the maintenance side of SeaKeepers and other gyro stabilizers. How much work is needed, how often and how much can be be done by yourself. And what is the period between major overhauls?

Barry S, the rated power requirement is a maximum of 3kw or 3,000 watts. I typically see the stabilizer consume just under 12.5 amps (at 240v) during startup which is right at rated max. The startup or spin-up time is while the stabilizer gains RPM. When it is set to 9,000 RPM (it can also be set to spin at 7,200 RPM) it takes about 45 minutes to reach 7,650 RPM, the speed at which the ECU will let you unlock the brake and gain stabilization. Once the stabilizer is up to speed power consumption typically drops and varies between 3.5 and 12 amps depending on sea state.

Shut down consumes nearly no power. The first few minutes after turning off the electric motor the cooling pumps still run to cool the bearings. I can’t remember the exact amount of time, but it’s relatively short. The main coolant circulating pump on the stabilizer is 24v so it doesn’t require the generator be running. The spin-down can take up to 8 hours but during this time there’s no power drawn.

I don’t have any data on major overhauls. The factory reps mentioned some of their higher hour units when I asked about longevity and those numbers were impressive.

The brake system and cooling system fluids call for annual maintenance. The sacrificial anode depends on the water the boat is operated in. Other items are mostly inspect and replace as needed.

Here’s what Seakeeper provides: https://seakeeper.com/wp-content/uploads/2017/03/90426-Seakeeper_Scheduled_Maintenance_Plan-Recreational_Line.pdf

Thank you for the great article. Last summer we installed a Seakeeper 6 in a Defever 45 trawler. Since we only installed it in Sept. and have only a short time with it, we were glad to see you’re experience in large seas. As for the electrical requirements, it takes both 12/24 vdc and 120/240vac. Start up time for the stabilizer to reach effective rpm is 30-40 minutes. We start it up while under shore power and then switch to gen-set just before departing the dock. Power draw is app. 2300 watts at start-up and 1050-2300 watts while underway (depending on amount of stabilization required. While it takes about 45 min. To spool down, there is no power requirement for this. The expenses is large, but in our case not much more than fin stabilizers, plus there are no hull protrusions to snag on lobster pots.

Thanks for posting. Great article.

We have a new build 45 ft. Trawler being constructed now with one. It’s a large investment but I am glad we did it.

How long does the DC coolant pump run after you shut down? IE, if the gyro requires up to 8 hours to completely stop, I assume no pumps are needed for cooling during that duration and you can leave the boat while it’s still spinning?

Are the zincs easily accessible?

Can you do the basic annual PMs on your own during the Warranty period, or is a Seakeeper trained tech required?

On the water experiences with products are exciting to read about, thank you for sharing this with us.

Ben, do you still provide hats for first time writers?

Hats? There are hats?

I haven’t checked too carefully. I believe the pump will run for an extended period of time, maybe as long as a few hours. I have been told by Seakeeper that within about five minutes of shutting off the bearings are safe even if all power is removed. I wouldn’t hesitate to leave the boat during the spin-down period regardless of pump running or not. The zinc is pretty easy to access, on the top of the heat exchanger to the left of the ball. I know the Seakeeper literature says maintenance should be performed by a Seakeeper trained tech, I don’t know if this is a requirement or not. The brake service I believe requires some specialized tooling to properly re-pressurize the brake circuit.

Ben S.

Gary G, I would like to hear about your experiences as well. Gyro technology isn’t as proven as fins and I know many people building displacement trawlers are still spec’ing fins because they’re tried and true. I’ve seen a few passage making trawlers equipped with Seakeeper and have been curious to hear from someone who’s operated one over long distances. The one area I’ve often wondered about is that underway fins never run out of stabilizing force since they can leave a fin out catching water indefinitely, the same isn’t true for a Gyro. It’s rarely been a problem on our boat but the reality of our boat is its overall seakeeping abilities aren’t as strong so we don’t find ourselves out in some of the conditions others might.

Ben

Ben S, email me and we can discuss our SK experiences without hijacking Ben E’s great blog. Ben E, would you pls send Ben S my email.

Further, the SK 6, which is 2/3 the size of the SK 9, uses 110 vac, plus 12vdc. The water pump is a 110 vac pump, but is controlled by the 12v controller. When one shuts off the power, the water pump shuts off, but Seakeeper says this is okay. When the SK is spinning down, it is not generating heat that requires external cooling. On our SK6, it only takes 4-5 hours to spin down (my first Post said 45 min, but autocorrect took over!)

User maintenance involves periodic checking for leaves and corrosion. The big items involve changing cooling fluid (user can do) and changing the hydraulic fluid in the braking pistons. This requires a very expensive tool one can purchase from Seakeeper. You need to have Seakeeper do this task to keep in warranty, but later I see no reason a mechanically inclined user couldn’t, if you had the tool. We’re in fresh water (Great Lakes) so zincs are not too much of a concern, but they are easily reachable.

All in all, it is an easily maintained system, far easier than fins.

Not to worry about hijaking Ben’s thread. This ones actually mine, I wrote the article :-). I can provide my email off line but I think others would be interested in hearing your results.

Ben S.

Last post by Gary G, sorry

Great, well-written article.

NVH? Noise, vibration, harshness?

I suppose it could be zero, as you don’t mention it, or maybe it is all moot as a 23kw generator is running anyway? Still, it’d be interesting to hear if there is any in the wind-down process, in case the genset has been turned off.

Thanks in advance,

Yes indeedy, Dan, first-time Panbo writers still get the highly-sought-after but not-available-in-any-store Panbo long-billed cap 😉

Xavier,

You hit the nail on the head with mention of NVH potentially being moot due to the other mechanical sources of NVH. Underway or with the generator running, or really even the air conditioning, you can’t hear or feel the gyro at all. If you’re at the dock during spin-up you can hear a slight whine which is the main noise the stabilizer makes. During spin down that same slight whine can be heard during the high RPM portion of the spin down, I’d say down to about 4,000 RPM you can still hear a little bit of a whine.

I should clarify the whine isn’t disruptive in any way. The engine room is sound-shielded against two 12 liter diesels and a 23kw generator so the sounds of the stabilizer that make it through are quite minimal. We have a set of chairs directly on top of the engine room hatch. The stabilizer is directly under that hatch and the stabilizer spinning up, running or spinning down doesn’t affect conversation or being able to sit and enjoy the scenery at all.

Ben S.

Second Ben S’ comments about NVH. Our SK is in the engine room, directly under the main salon. With the generator running (8kW)(and its not too loud either) you do not hear any sounds from the gyro. When the genie is turned off at shut down, you do hear a quiet whine, but not obtrusive. The whine goes down as the spinning goes down. Actually, it is more noticeable off the boat on the dock, than inside the boat. There is no vibration whatsoever from the gyro.

Gary and Ben S, Thanks.

Another alternative is MC 2 quick gyro.

http://www.gineicomarine.com/browse.php?cid=629

These are vertical , require no external cooling, are way cheaper. Their marketing must be crap as they get no press, but to me are a better alternative from my limited reading and talk to a rep at the Sydney boat show.

I’ve been a little intrigued about what Quick has up their sleeve as well. I haven’t seen pricing data on them but I do know that a large part of the expense of ours was the installation expense. That’s more a function of the amount of force placed on the hull than anything else so I don’t expect that to change much. The cost of a thru-hull for cooling and an AC pump is pretty small.

It’s concerning to me to note the Quick -MC2X30, which is rated for roughly the same size boats as a Seakeeper 9 is very heavy. A MC2X30 is 965 kg while a Seakeeper 9 is 550kg. That’s not too surprising. Seakeeper is spinning the counterweight at 9,000 RPM while Quick is at 4,000RPM. To get the same angular momentum it’s going to require a much heavier flywheel.

Ben S.

That is a large RPM and weight delta for the other brand, but I don’t know anything about them so I can’t comment further.

Our SK5 is going in now on a new Trawler build.

Hello All,

Finally took the plunge and purchased a seakeeper for Bliss our 40′ Bendford custom pilot house trawler.

Unlike “Have Another Day” Bliss is quite small for a 40′ trawler having been built on the hull of a cascade 39 cutter sailboat. At 15 tons she has little room to accommodate both a generator and the seakeeper… So.. after thinking long and hard about how we would run the power hungry seakeeper without a generator we finally took the plunge and dumped the generator!

So… the seakeeper now sits where the generator was. The next issue that had to be solved was how to power the seakeeper with our 100HP yanmar while underway. This challenge was addressed by the installation of 2x 250 AMP alternators with external rectifiers which drive a 3kw victron inverter connected to the ouse bank. The alternators generate 400+ amps continuously (warm) although the seakeeper 5 needs only about 120amps to run once it has reached its 10,000 RPM state. Starup consumes about 180 Amps DC at 12 V… again something that the dual alternator setup can manage. We have a 2000AMP/HR AGM house battery bank that allows us run the seakeeper for 8-10 hours (50% discharge of battery bank) while at anchor. Again the dual alternator setup produces enough current to run the seakeeper while charging the house battery bank.

One problem that had to be overcome was running the engine at low RPM. at 4Hp per 100Amps the alternators can consume 16Hp which the engine will support at low RPM but not while motoring. Although designed for a dual engine setup we used a balmar centerfielder II to control the output from the alternators. We have 2 switches running to the pilot house which allow us to control the output current from the alternators. One switch disables the port alternator altogether while other switch puts the starboard alternator in small engine mode reducing the output to 50%. this allows us 4 output settings. 100/75/50/25%. While idling or motoring slowly we can reduce the alternator output to direct the engines HP to the prop.

At 2400 RPM the engine produces about 75Hp 25 of which is used to drive the boat at 7.2Knots. this leaves plenty of power (50Hp) to drive the alternators which require 16HP at max output.

This is basically a poor man’s implementation of nigel calders integrel system

https://www.victronenergy.com/blog/2018/10/03/nigel-calder-and-the-integrel-9kw-alternator-on-steroids/

https://www.integrelmarine.com

sold by Bruce Schwab Energy but not available in the USA yet.

Finally to monitor all the current that is being shipped around the boat we used a Pico system with shunts on both alternators allowing us to see the exact amount of current generated by each and to monitor the state of our large battery bank as well as the current draw by the seakeeper.

https://panbo.com/simarine-pico-good-ideas-in-battery-monitoring-more/

And… the seakeeper is amazing… our rollyboat is not so rolly anymore!

Take care.

–luis

Luis,

Wow, yours is a much more interesting install than my boring old generator based system. I love that you can run the Seakeepr at anchor on battery alone and avoid the noise, smell and fuel burn of a generator. As I was reading your description I was thinking how similar it sounded to Integrel and then you mentioned your poor man’s implementation of the same concept. The one thing I was left wondering was if you considered going to a lithium battery chemistry for the charge acceptance characteristics of those batteries. That strikes me as the only pain point in what you have built.

Ben

hi Ben,

Lithiums would be nice… I have looked into them but the cost is high. 2000Amp/Hr of Li batteries is about $25K or greater. And… Bliss uses the lead for ballast so swapping out the batteries will required adding lead to the the boat.

Having said that… Li is in my future… just not quite yet.

For now the AGMs do the job. My 7x8D + 1x4D house bank has no problem generating the amps required to run the SK5.

The integral is a fantastic concept… In doing my due diligence on the install and looking at the power curve for Bliss (provided by the designer Benford) and the power curve for the engine it is pretty obvious that a ** LOT ** of diesel HP is lost when motoring. this loss can easily be converted to DC current which is much more efficient running a genset. I did contact Niegel about installing an integral system on bliss since that is really the perfect solution. However, the system was still quite new at the time and he was not ready to sell systems in the USA. So… we went with the manual approach.

We did look long at hard at other stabilization technologies (fins, paravanes, bilge keels) but in the end Bliss with her 34′ water line is just too small for most. The bilge keeps might have worked OK but who wants all that wetted surface in the under body.

All in all a great learning experience.

we are headed up to the Canadian Maritimes (PEI) this summer and the seakeeper will be much appreciated after rolling gunnel to gunnel in the Bay of Fundi last year.

Take care.

–luis

I would like to learn more on longer period maintenance costs. Many I speak with, from users and installers, state the SK’s are great for the first year, but beyond have frequent and expensive problems.

Thank you