Update: Epoch’s 460ah battery, what we’ve learned

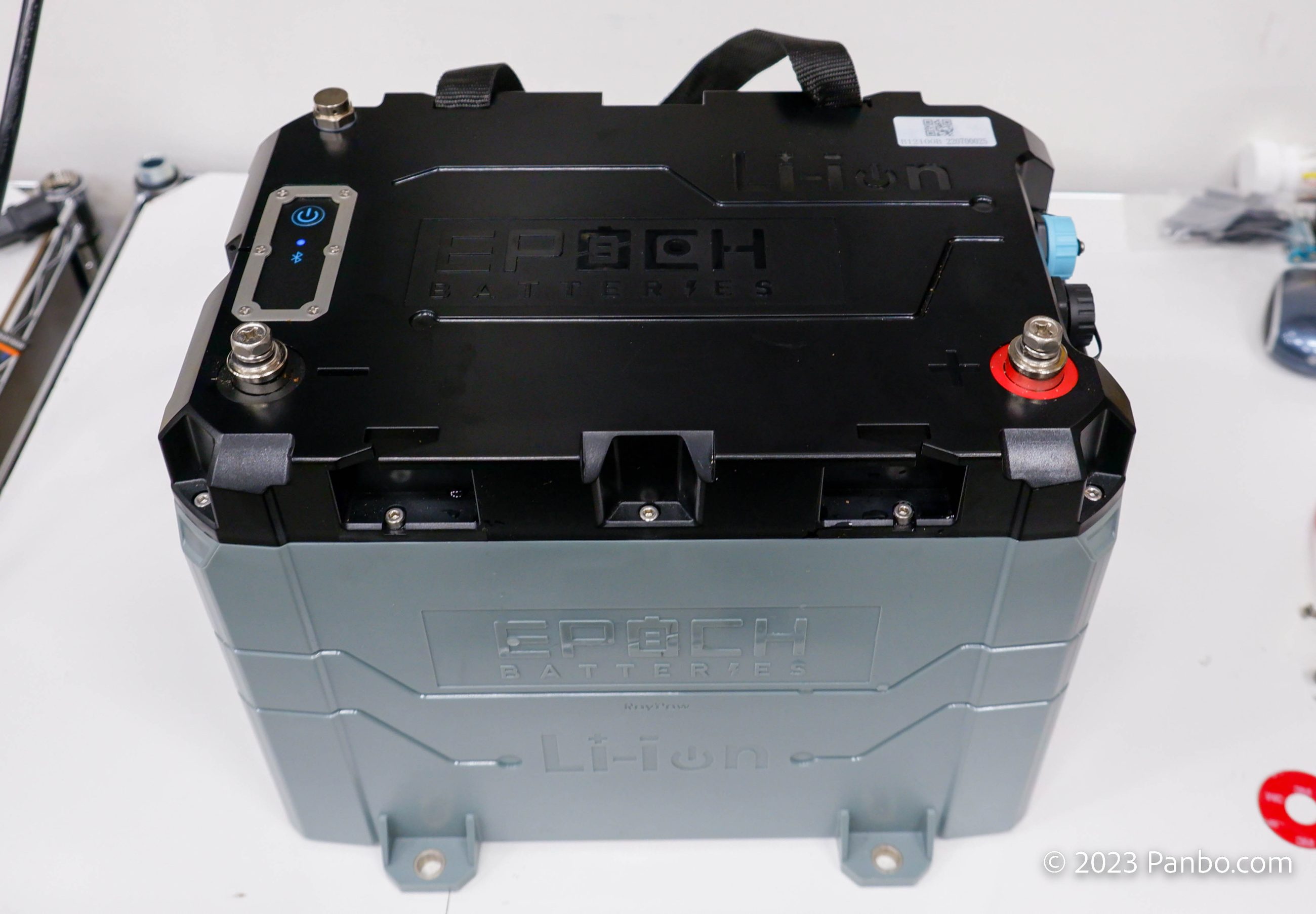

In January of this year, I published my review of the Epoch 460 amp-hour, 12 volt battery. My review was quite positive and reflected how the battery performed in my testing. But, once the battery was in the wild, reports began trickling in of troubles with some installations of the 460s. That lead to weeks of investigating the issues. At this point, I believe I have a solid command of what’s happening with these batteries and some of their limitations. While this better understanding of the batteries does serve to take a little shine off them, I still believe these are very solid batteries and capable of delivering excellent service. But, for best service, some tuning is required.

A word of warning, we’re going to get quite technical on some of the issues I’ve encountered. If my explanations fall short or I confuse anyone, please drop a comment at the bottom and let me know. I hope this entry will help people understand the issues and how to work around them,

Full charge protection

Charging LiFePO4 batteries at high voltages for extended periods of time isn’t good for them. Continuously charging LiFePO4 cells at a high voltage can cause dendrite formation. Dendrites result in reduced capacity and potential internal failures in cells. My research indicates there isn’t a clear understanding of the exact causes and prevention of dendrites, but there is a widely held understanding that overcharging LiFePO4 cells is directly linked with dendrite formation.

Most companies selling lithium iron phosphate batteries offer long warranties. In fact, the norm is for some form of warranty stretching out to ten years and beyond. As an aside, I encourage you to look at the actual terms of these warranties not just the big bold print. Many offer three to five year full replacements followed by a meager discount for the remaining years. In order to offer long warranties, battery manufacturers want to ensure the batteries will protect themselves.

The battery management systems or BMS in LiFePO4 batteries offer numerous protections for the battery. We’re familiar with quite a few of those including high and low voltage cut offs at both the pack and cell levels as well as temperature protections. But, more recently we’ve started to see, or perhaps more accurately notice, protections against high voltage charging for extended periods of time.

To protect against damaging voltage for extended periods of time, the BMS in the battery disables charging if charge voltage is observed to be above 14 volts while current acceptance is below 3.5 amps for ten seconds. It turns out this protection has been present in at least some of Epoch’s batteries for quite some time. I’ve observed the same behavior in the 100 amp hour batteries I reviewed early last year. This behavior also has a couple of potential unintended consequences, let’s take a look at each of them. Also, note that Epcoh isn’t alone in using this protection mechanism. In fact, it’s becoming increasingly common.

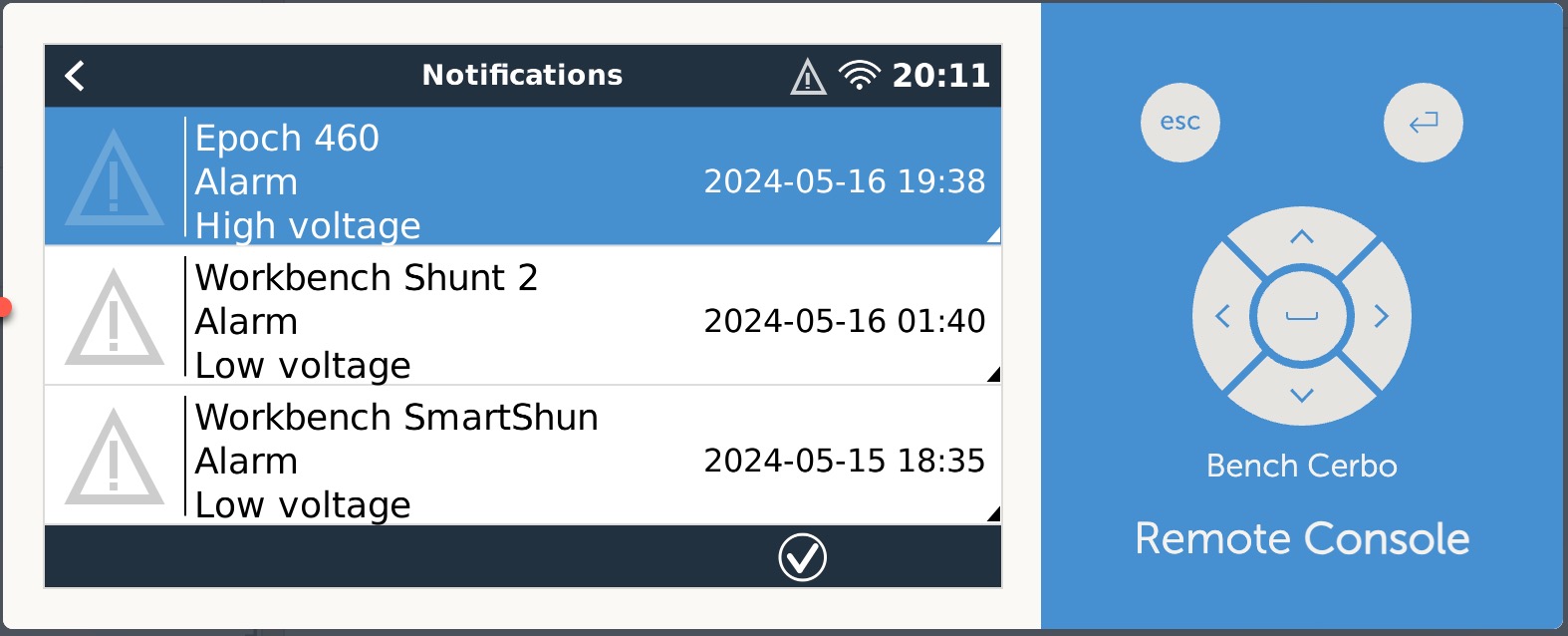

High voltage alarms

The video above demonstrates what happens when the full charge protection kicks in. If charging comes from a stabilized power source, like a lab grade DC power supply, there won’t be a spike because the power supply stabilizes its output without a battery connected. But, most people don’t charge from a bench power supply. Instead, they charge from alternators, inverter/chargers, and dedicated battery chargers. Inverter/Chargers and alternators generally depend on a connected battery to assist in stabilizing output voltage. Some battery chargers need a battery connected and some don’t.

In the case of charging from inverter/chargers and alternators, when the battery suddenly stops charging, the energy coming from the transformer or alternator needs to go somewhere. Applying Ohm’s law, we find that increasing the resistance — by opening the charge MOSFETs — results in increased voltage. The spike has a short life and decreases once the charge source reduces its output.

Unfortunately, during that spike, the battery sees high voltage and raises an alarm. In reality, this alarm is basically a nuisance, but it’s a nuisance that requires clearing the alarm on the Victron GX device to stop it from beeping.

Uneven discharging

I only have one 460 on my test bench so I haven’t been able to reproduce the issue, but I have received several reports of uneven discharging. I’ve heard reports from both boat owners and technicians who have deployed multiple 460s in parallel banks. They’ve reported circumstances where either only some batteries have entered full charge protection or one battery stays in this state longer. They then observe that the battery in full charge protection seems to carry less of the discharge load than the other batteries.

Avoiding issues

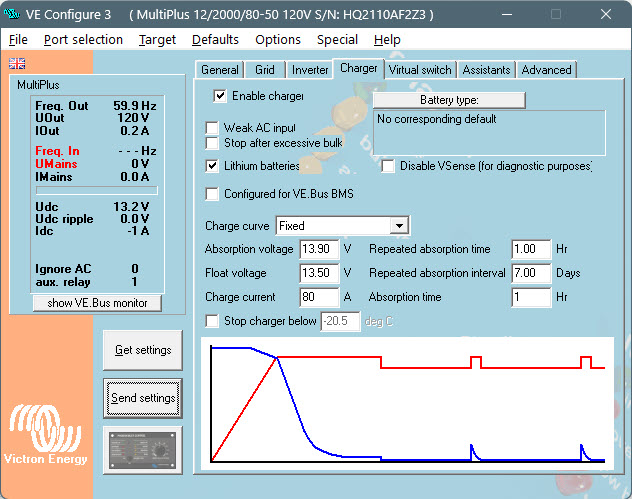

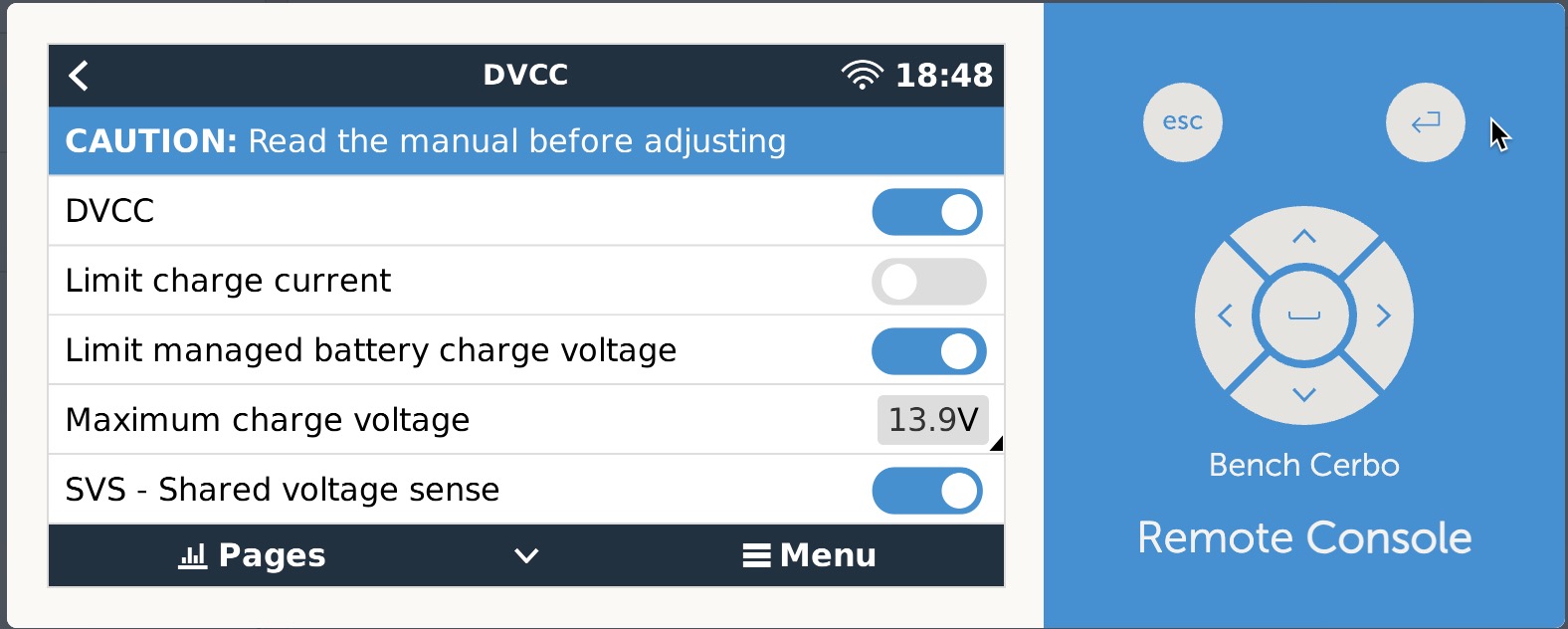

The easiest way to avoid these issues seems to be preventing the battery from entering full charge protection. To do this, we need to set our charge sources below 14 volts so the battery never enters full charge protection. This means setting the absorption voltage of your charge sources below 14 volts. Typically, that is either 13.8 or 13.9 volts depending on the stability of your charge source. I’ve used 13.9 with a MultiPlus 2000va inverter/charger without any troubles. The one caveat to this is that charging at lower absorption voltage means charging takes longer. I’m working on a comparison of both capacity and charge times based on charging voltage. I’ll post an article on that shortly.

The screenshot above shows Victron’s VE Configure connected to the MultiPlus via an MK3USB interface. But, if you don’t have an MK3USB or prefer to configure everything via a GX device, you can leverage DVCC.

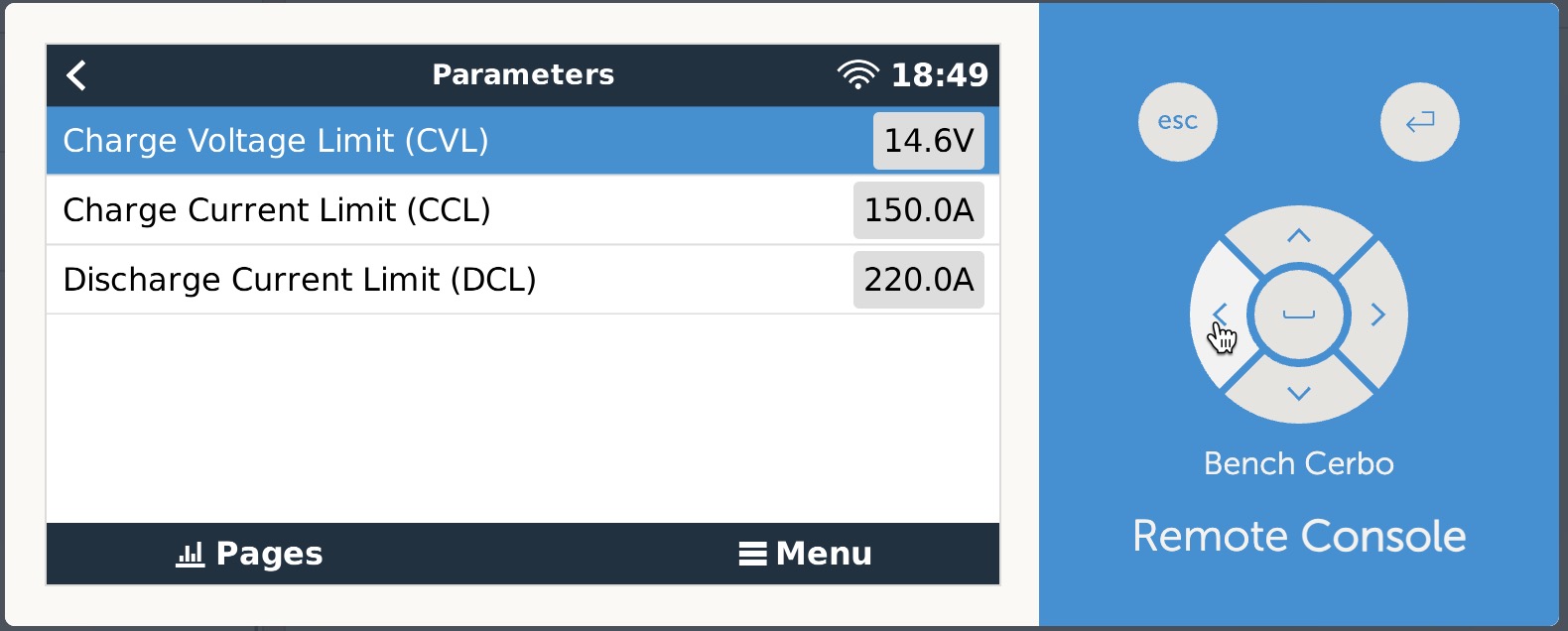

Unfortunately, there’s an issue with the DVCC parameters the battery sends. As you can see above, the battery calls for a charge limit of 14.6 volts. That was Epoch’s charge recommendation at the launch of the battery and frankly I think it’s a bad one. Curiously, Epoch hasn’t updated their documentation yet so the online manual still recommends 14.6t volts. However, their sales and support reps do provide the updated recommendation when you contact them.

14.6 votls is well above the 14 volt threshold at which low current charging is disabled. Additionally, 14.6 volts in a four cell battery like this one equates to 3.65 volts per cell. 3.65 volts also happens to be the cell overvoltage protection threshold at which the BMS will disable charging. If any the cells are out of balance at all, and with 460 amp hours of capacity, it is likely there will be some imbalance at the top of the charge curve, one of the cells will tip over 3.65v and generate a cell overvoltage protection alarm and shutdown.

The solution is to modify the global DVCC parameters for the GX instance to limit charge voltage to 13.8 or 13.9 volts. Either method accomplishes the same goal of limiting absorption voltage to below 14 volts.

SOC inaccuracies

In further testing the performance of the 460, I’ve cycled it a lot. I’ve subjected the battery to high and low current loads. I’ve left it sitting on the bench for weeks at a time and I’ve rapidly cycled the battery. Over that time, I’ve come to realize the battery’s own estimate of its state of charge (SOC) is frequently inaccurate. This isn’t new for LiFeP04 batteries with internal BMSes. In fact, I’d describe most battery management systems’ SOC measurements as suspect, at best. As I mentioned in my original review, I mentioned that the battery’s internal current sensing resistor or shunt doesn’t measure current flow below 1.4 amps. In my time with the battery, I see that current flow providing significant SOC drift.

Inaccurate SOC becomes a bigger deal when you transmit it via Victron comms and display it throughout the GX ecosystem. Fortunately, there’s a cheap and easy solution. A Victron SmartShunt is more accurate than the internal current measurement, measures an entire battery bank, and costs less than $120 at retail pricing. If you prefer the remote display of a Victron BMV-712, that’s also a good option at roughly $160 retail.

A good option without comms

I’ve just detailed a number of issues and limitations with the battery. So, you might be thinking this isn’t a good battery or you should buy something else. I don’t think that’s the case. To be fully transparent, I don’t have experience with a non-Victron battery that handles communications better. Nearly every Victron communicating battery I’ve researched has voluminous threads on forums and social media detailing trials and tribulations. To my eye, we are in a state of flux on communications between batteries and power conditioning equipment. Victron deserves kudos for being willing to work with non-Victron branded batteries. But, I also think it’s worth understanding that these integrations are pretty immature at this point. T

So, what’s the solution you ask? In my opinion — and I’ve tested it on several industry experts — the solution is really simple. Unplug the comms and use the batteries as we have been using internal BMS LiFePO4 batteries for several years. You still have the benefit of Epoch’s app via Bluetooth, you still have an excellent battery with a built-in high AIC fuse, and you still have excellent value. $1,999 for a 460 amp hour battery remains among the best prices out there and the density is difficult to beat.

Summarizing recommended settings

Just to reiterate my recommendations based on extensive experimentation, here is what I would do using an Epoch 460 amp-hour 12-volt battery. I would start by getting rid of Victron communications. Then, with the comms cable disconnected, I would go into my charge sources and set them for an absorption voltage of 13.8 or 13.9 volts and a float voltage of 13.4 or 13.5 volts. Make sure you address all your charge sources including alternators, battery chargers, inverter/chargers, and solar charge controllers. Lastly, I would add a SmartShunt or Victron BMV-712 to the bank of 460s. I believe with these basic settings, you will get good service from your batteries and enjoy reliable performance for years to come.

Thank you Ben.

This is an Excellent summary.

I have the exact setup you describe with 2 Epoch 460’s in parallel, a Victron BMV shunt and multiple charging sources set for 13.9 V Absorption & 13.45 Float. (The Victron.Direct Bluetooth network is a great way to coordinate the chargers referencing the BMV) This has been working very well maintaining decent SOC on shorepower, with no MOSFET shutdowns & good cell balancing with bulk charging.

I’ve been experimenting with seeing how high charging rates can go with my setup and despite a theoretical 330+ Amp capacity, have yet to see more than ~245 A of acceptance from this pair of batteries.

I’m not convinced that setting the bulk / absorption voltages any higher than 13.9 VDC would significantly increase charge acceptance rates but will look forward to your findings.

would you recommend those same absorption/float voltages for the 50ah Epoch? I have one connected to a Victron DC/DC charger.

Corey,

I’d check and see if you see the full charge protection fault in the app for those batteries. I’m not sure if they have the feature implemented or not. If they do, I would use these same settings.

-Ben S.

yeah, I’ve seen the fault. Very first time had me terribly confused. “Being fully charged is a fault?! I thought that was a good thing??”

Disabling Victron Comms would make hard to integrate with a Wakespeed controller. Any ideas on that?

Thanks Ben. Only thing I might add is the comms work great is using 1,2,3 or 4 in parallel or 2 in series. Beyond that the shunt is a better option IMO. And you are so right in that we are in the early stages of this. Its exciting to think of what systems will be out there in 5 years. Some kind of industry standardization might be beneficial to standardize minimum protocols for comms between batts, alternator controllers, solar and anything else.

Allen,

There is definitely room for multiple opinions. Depending on your installation design and personal preferences, there are a number of different approaches that may work better for some than others.

My reasoning for a lack of enthusiasm about comms are the following:

The first concern gets worse the more batteries you have in parallel. With a four battery bank, any load under about 5.6 amps won’t be measured. On my workbench, I frequently find the readings from the battery’s BMS quite optimistic compared to a SmartShunt also on the battery. The second concern is one I’ve seen firsthand a few times but not on my bench as I only have one battery there. The alarms concern is the most easily mitigated as I think with proper charge settings those alarms are nearly eliminated.

But, I definitely understand others may come to a different conclusion. In fact, we see several experienced and knowledgeable people here coming to a different conclusion than I’ve reached.

-Ben S.

Ben S., Very good evaluartion. An adjustable delay setting for the LVC/HVC cut-off with alert would add a safety factor as wellaslow temperature charging without heat/warming strips. Also a buffer battery to prevent the spike damage of sensitive vulnerable devices e.g. alternators.

What is a buffer battery? A diagram of such a battery and it’s full purpose please…

Charles, an additional battery(agm) that is in the alternator charging feeds would absorb the spike should the BMS envoke a shutdown disconnect of the LFPO4 bank. These also continue to power controls and other critically needed equipment e.g. nav, etc. While you straighten out what cause the event. Mine were grp 31 Agms as at the time DC chargers were still undeveloped. Understand my system was one of the first (2012) so breaking new ground. There have been many advancements since mine. However, with the exception od lithionics none include the many feature suggested, ability to program a delay, audio alarm warnings and reset that can override the BMS trigger if in a critical locatiins E.G in a narrow rock jetty lined inlet or needing to avoid a collsion. MY

BMS was custom built by Demitri who became an engineer with lithionics. Charlie Johnson et al designed my system back when 2011 and is now working in instructor training for Victron of North America and sits on the AYBC inverter specifications commitee with other players in the field.

Thanks Ben ,

Excellent testing thanks for info.

Question: is 13,8 volt sufficient to start cell balancing?

I rather would suggest to set the cell balancing threshold at 3,45 volt per cell (= 13,8 V for the battery)

And set the overall charge limit at 14,0 volt.

Victron themselves use 14,2 volt as maximum charge limit for their LiFePO4 batteries.

See also recommendations from “Andy” at “offgrid garage”, Australia

The balancing starts at 13.4. No issues here.

There ya go! Well spoken.

Personally, I like the comms.

I have my 460 batteries and in a slow process of finalizing my interconnect schematics and the mechanicals of modifying the battery compartment in my motorhome. I was going to include a Cerbo GX and use the battery comms, along with VE Direct connections to a Victron XS 12-12 50 DC-DC charger, and a Victron BMV-712 which I already have from another project. I will retain my existing Xantrex XC 2000 inverter/charger, which has custom charge profile capability and no compatible bus with the Cerbo (I assume). In addition to monitoring/control of the Victron components mentioned, The Cerbo GX was going to be used to drive a 3 time delay relay circuit to generate auto start/stop signals needed for my Onan generator. Your recommendation to not connect the Epoch 460 busses suggests eliminating the Cerbo GX in my system as well, with the auto generator start function possibly moving from a Cerbo relay output to the relay output of the BMV-712 (assuming I can program it to change state on specific SOC values). This would simplify and save $. Is there any reason I should keep the Cerbo GX in my design if the auto generator start function can be moved?

The biggest reason, in my opinion, to retain the Cerbo is off boat monitoring. Being able to see what’s happening with the system when you’re not on the boat and the rich history you get with VRM make the cost of a Cerbo worth it to me.

-Ben S.

Good point, thanks.

You have a somewhat similar system to mine, however I only have one Epoch. Curious how you are setting the absorb time with your setup?

Good Question!

From the Xantrax Freedom XC 2000 manual:

The Freedom XC transitions to the float stage if either one of the

following two conditions are met:

1. The charge current allowed by the batteries falls below the exit

current threshold, which is equal to 10% of the programmed

charge current and a minimum of 2A.

2. The Freedom XC has been in absorption for the programmed

maximum absorption time limit. The default is 6 h

I plan to set my max charge current to 80A, which is the Xantrax-recommended value and the max setting allowed. (I will have 2 batteries in parallel so they will get 40A each which is well under the Epoch specified max of 230A max and recommended 100A).

So my system will stay in absorb until Xantrax charge current is down to 8A (4A per battery), or 6hrs, whichever comes first.

It will be interesting to see how all this works out! Im trudging through enclosing my battery box and mounting the electrical components now.

Oh and there is no other mention of a programmable maximum absorption time limit in the Xantrax manual. So im assuming it isn’t programmable and will be 6hrs. Maybe the manual is in error and I will find the setting when I set everything up. I don’t know what I would set it to until the batteries go thru a few cycles anyway, with BMV-712 monitoring.

You almost need no absorption time. By the time you get to 13.85V with the bulk charging, the batteries will be at 99% SOC. Unlike Lead acid where a long absorption phase is necessary to get to 100% SOC, the low resistance of the LFP means a long absorption phase is unnecessary and if anything forces the cells into an unwelcome sustained 100% SOC.

Well, I went a bit more down this rabbit hole. I searched the Xantrax manual and could find no information for what event(s) cause transition out of float, back to bulk or absorb. In google searching I found this string (you may have to register on sprinter forum). https://sprinter-source.com/forums/index.php?threads/97947/#:~:text=The%20Freedom%20XC%20has%20been,the%20next%20stage%20of%20charging. This has ramifications on possibly over-discharging to the point of BMS shutdown using my Xantrax. In that string, one guy called Xantrax and they said float mode will be exited when battery voltage reaches 12.2V. The fact that the Xantrax has no way of knowing there are possibly loads besides battery charging, and/or to not have a programmable threshold to kick back into absorption seems to me a fundamental problem. I have plans to change engine charging control to be triggered by SOC % using my BMV-712 or Cerbo. Maybe I should investigate modifying this for the shore power mode or consider changing the charger/inverter.

Well, I hooked it all up today with the Magnum Charger and the battery was at 20% as received from Epoch. However, the charging never went into bulk but straight into absorb, which since I have the maximum absorption time set to 1 hr, the charger went into standby without the battery being fully charged. So I unplugged and plugged back in to start another absorption cycle. Guess I will have the rinse and repeat until the Epoch app shows that battery is at 13.8 ()3.45) and then let it go into standby.

Well, had a few issues yesterday getting the Magnum 2012 to charge the battery yesterday. After speaking with Magnum tech support, I found I needed to bring the battery back down to the rebulk setting to start a new charge cycle. I currently have rebulk set at 13.2 and when the new charge cycle started the and after a few seconds went immediately to absorb but the voltage was below my absorb voltage setting. So I altered the absorb time to 2.5 hours to at least get the battery charged. It reached 100% SOC in the app but the cell voltage was just getting to 3.41 volts/cell average with the target of 3.45. Now I have re-read Ben’s findings above and realize that the SOC meter in the battery can’t be relied on for good information. This morning the battery is resting at 13.32 volts or 3.331 volts/cell. There is a couple of amp draw from the Magnum.

So, I still have some research to do and place another call with Magnum. I need to find out what the voltage/time threshold is to switch to absorb since the voltage will flicker between two values (e.g., 13.7 & 13.8) for several minutes before settling on 13.8. I need to find out if it only needs to hit the 13.8 for a second to switch to absorb to it there is required time at 13.8 for the switch to occur and why it switched to absorb so quickly when the new charge cycle started.

I am also thinking that 13.2 is too high a value to trigger a new charge cycle even though Victron seems to use a rebulk offset of 0.1, which in my case would be rebulk of 13.3 volts. I am considering moving the rebulk, at least for the Magnum, to 12.8 volts. Not sure if I should do the same on my Victron Orion DC-DC charger or leave the rebulk offset the same as Victron has in their lithium iron phosphate setup. I need to better understand what the Magnum is doing prior to making any changes.

Makes me wonder, why not just get the essentials version (and add a class T fuse) if we’re not going to use the comms? Smaller and maybe even cheaper?

Epoch is now advertising an “Essentisls” battery that appears to be the same 460 Ah battery but without the Victron comms. It still has Bluetooth. Price is $1399 vs $1999 with comms. Seems like this may be just the ticket!

Excellent update based on real world (and bench!) data.

Wanting Victron integration and a different form factor, I ordered the Sun Fun Kits v5 battery after seeing the Epoch 460Ah commentary in the Facebook threads.

Perhaps you can test those when they’re back in stock?

What great timing. I have been in touch with Sun Fun Kits and they are sending me some batteries. I hope to be able to report on what I’ve found in a little bit. Indeed, their approach to Victron comms looks quite different and I’m curious to see how it works out.

-Ben S.

In most of the designs I’ve done include a Lynx BMS (if Victron batteries), CERBO, Wakespeed 500, and large alternator(s). One critical issues is the ability of the system to connect to the Alternator Controller and open the field wire prior to an emergency BMS dictated shutdown. While I strongly agrue that on a properly designed, engineered, and installed system this should never happen it does make sense to have the BMS signal it in advance and shut down the alternator field. The only internal BMS batteries we’ve installed so far that had that function built in were Lithinonics.

The comments I see on COMMS seem related to state of charge and not the primary features we use.

Not having a pre-shutdown signal with the Victron comms has been the thing I am most disappointed about. These are the best size/density that fits in the available space we have. Now I have to find some other way to protect the system in the event of a disconnect. Just can’t risk that in the middle of the ocean.

Hi David,

My solution to this issue of how to deal with a sudden MOSFET / BMS shutdown is to use DC-DC Chargers to provide charging to LFP house bank (lead acid street bank fed fire y by the alternator) thereby protecting the alternator.

In addition I plan to install an accessory DC-DC Converter powered by the start bank & connected as backup to the main DC panel (set to a voltage less than the LFP working range ~12.5 VDC). This should provide instantaneous backup power to essential instruments & engine controls etc. in the unlikely event of a sudden BMS shutdown underway.

Hi Evan,

But aren’t you then limited by the lower charge capacity of most DC-DC chargers? Are there ones that can transfer the full output of a 200+ amp alternator to fast charge a big LFP bank?

We don’t have much room for a bunch of parallel DC-DC chargers nor do we have room for a lead acid buffer bank.

That’s why I was hoping that these LFPs would give us the signals we needed for a safe alternator shutdown.

Yes. It’s a compromise.

I seriously considered changing to a Zeus external regulator but the risk of BMS shutdown was poorly mitigated in that configuration.

I instead opted for 2 x Orion XS 50 Amp chargers for ~ 100A while running the main engine drawing off a 160 Amp externally regulated Alternator.

If I’m really pressed for charging & faster capacity beyond that, I can also start the generator for an additional 200+ Amp of charging capacity.

The biggest plus to me for lithium is faster charging. How much does this negate that advantage vs higher end AGM?

I have plenty of space and weight in my trawler, and things like this make it seem like I sign up for more trouble with marginal benefit?

I have the 300Ah V2 battery and i also notice the SOC resolution is >1amp. It won’t recognize anything below that so the SOC coming from the bluetooth app is all over the place.

I’m just using a bmv-712 with a smart shunt and it has a very high resolution and seems to be extremely accurate so far.

The bluetooth app for the BMS is useful though. I have been charging at 13.8 volts and absorb for one hour. I use the app to confirm the cell voltages. By the time the absorption cycle is done the bmv monitor and the bluetooth app for the band show 99-100% SOC. From here i relly on the banc for SOC. It’s such a simple and accurate setup.

sorry typos. BMS.

Thanks for all this work and documenting all of this information. If I hadn’t found this website I would have went ahead with a typical lithium charge cycle setup and probably been at a loss as to what was wrong when issues occurred.

What would be the recommended setup for a CC/CV charge cycle. There doesn’t appear to be any “float” or “equalize” function if I use the CC/CV in my Magnum inverter rather than the “Custom Setup” charge cycle where the absorb, float and equalize are all settable parameters. Here is what I was thinking for a CC/CV charge cycle but would really like to get this community’s input on the values.

Max Amps: 100 amps

Charge Volts: 13.8 volts

End Charge: Time

Done Time: 0.5 hrs

Max Time: 1.0 hrs

Recharge: 13.1 volts

Low Battery Cut Out: 12.0 volts

Reminds me of the old saying, “no one ever got fired for buying IBM”.

Just buy Victron batteries is the conclusion we’re coming to.

Hi Ray – we bought the Victron 330ah 12V battery and the battery itself has been 110% – no issues – but the BMS board inside failed suddenly without warning of apparent cause (no actions at the time, no lightning, etc.). The effect was to turn the boat off completely – no charge, no loads – as the output signal from the battery was dead. We had to hot-wire the charge & load switches to affect a temporary recovery.

Victron (or, more specifically, the distributor and dealer – Thanks, Scott!) eventually sent me a new board which I installed myself, and this board has been working fine ever since. I have also installed a protected “battle short” switch to allow me to manually override a BMS shutdown – and a diode splitter that continues to power certain critical systems from my AGM start battery if the main battery disconnects.

My point is – even Victron can fail!

Hartley

S/V Atsa

If not a geek, the best bet is with primarily Victron equipment e.g. multiples inverters, chargers and monitors, which permit the maximum customized settings for charging etc. . All their equipment plays so well together and has great suport.

I have a question. My Epoch 460AH battery is at 53% and with the Orion XS 50 amp charger. I have the Orion trigger on with engine ignition and then it goes into float mode after about 10-15 seconds of bulk charging. Do I have a faulty Orion XS 50? My float is set to 13.5volts and the battery is still at 13.2 volts

There is some good information on battery voltage sensing under the ” AC Battery Chargers & Inverter Chargers” section near the end of the article at the below link. I am having similar issues with my Magnum Inverter/Charger where it stays in bulk for several seconds and then switches to absorb. Battery charges okay in absorb, but I would like to correct this and as of yet haven’t found a good solution.

https://marinehowto.com/lifepo4-batteries-on-boats/

Measure voltage at the Orion terminals itself at 50 A full load. The reason may be cable losses or dirty contacts.

I had to come back and re-read the SOC drift section of your write-up. Mine is way off compared to my SmartShunt. Is there a way to reset the SOC or will it reset on its own during a charge cycle? Hopefully the SOC isn’t used to determine battery shut down.

My battery went through a charge cycle last night from a low SOC (13 volts) and only achieved an 84% SOC after absorption. Question, can the SOC be reset by the user or do I have a battery issue? The cells were up to the right voltage albeit not perfectly balanced.

I’ve been playing around with comms on my 460Ah IP67 battery, and I found that you can still connect it to the Cerbo/Venus system. You just have to tell the system to not use it as “the definitive” source for charge data. Configure DVCC (if you use it) to not use the BMS. Then configure the System Settings to use the Victron shunt as the Battery Monitor. This puts most of your functionality on the shunt data, but still gives you access to the battery internal data to do with as you see fit. You can also make them both visible in VRM with another setting. I’ve got Home Assistant talking to Venus OS on a RPi Zero2W (thanks in part to another post on Panbo), and my Victron shunt, Victron 100/30 SCC and Epoch Battery all connected to Venus via “USB to X” cables. HA then gets the high/low cell voltage and temps, and some other good stuff over MODBUS/TCP from Venus. It also allows for the over/under-whatever alarms to come through from the BMS, but it doesn’t force any behaviors, such as in my case, completely shutting off the SCC when the battery goes into full charge lockout.

I’m also struggling with the cells being terribly out of balance from the factory. I think one of the ways Epoch is shaving costs is to not top-balance the cells before assembly, and just letting the BMS do it over many charge cycles. This lowers the voltage of the battery at the highest charge the BMS will allow before alerting of Full charge protection. Muy guess is that alarm is actually a cell over-voltage alarm being masked as a full charge alarm. I’m hoping that by forcing the cells to balance, by keeping a high float voltage for a few days, the battery will “open up” a little and allow a higher voltage charge. When I’m at full charge, the battery settles at 13.5V and the cells are more than 150mV out of balance between the highest and lowest cells. The other two cells are close to each other and around 50mV lower than the high cell. So I have one cell that is WAY lower voltage than all others.

I’ve set my Victron 100|30 MPPT SCC to absorb to 13.95V and float at 13.8V just for a few days, to keep the balancing circuit active, and try to wrangle this imbalance. You can see balancing activity in the app. The cells are highlighted in red when they are balancing.

I agree on everything stated here. The battery is very nice. But it definitely has some big issues. I’m really hoping that getting the cells to balance will alleviate a lot of that.

I am curious if anyone has had the opportunity to charge this battery when it is in cold temperatures. My understanding is the heaters won’t come on until it detects a charge is being attempted, but I’m not sure how long it takes to reach a temperature where a charge will be accepted. I’m also not sure how my Magnum charger will handle that situation when it attempts to bulk change. Since we are getting deeper into fall and temperatures are dropping, I’m trying to ensure I don’t need to adjust anything with my current charge configuration.

Does anyone have any information about cold temperature charging the 460ah?

I assume the high Voltage cutoff issue also applies to the 460A Essentials battery as well even though the comms issue is a mute point since the essentials doesn’t have the comms?

I’ve had one 460a essentials installed for a few months now replacing (4) Battleborn 100A batteries along with Smart Shunt and an Orion XS 50 DC/DC charger.

Manual for essentials only states charged voltage of 14.2V. not sure exactly what that means …it’s what I’ve been using in BMV setting for charged voltage and 14.2V absorb and float 13.6v.

I’d appreciate any clarity on the settings I should be using since the epoch manual doesn’t specify and I’ve never received a response from their customer support.

I will leave answering your question to someone else who is familiar with both batteries. But I am curious about how the Epoch’s performance compares to the 4 Battleborn. I almost went the Battleborn route but the Epoch 460ah seemed like it would do the same job much simpler and for a lot less money. Right now I am running a single Epoch 460ah, but this replaced six 6 volt lead acids.

If found the FB Epoch forum which answered my question. Apparently the Marine and Essential BMS’s are significantly different and the Essentials does not have the over voltage problem the Marine version has. Most are using charged voltage of 14.2V and float of 13.5V. That’s what their manual states and still the recommended values.

I replaced the <1 yr old 100A Battleborns mostly due to the smaller footprint (and far fewer cables) they required. So far performance has been fine … can't tell any difference.

(4) 100A Battleborns

https://photos.app.goo.gl/XiavvNJcrhREwbhh9

Epoch 460 Essentials

https://photos.app.goo.gl/heQ2GCuk1TzQ1eyk8

That looks like an RV. I like the marine battery but in a way it might have been simpler for me to get the Essentials version. My battery compartment is cleaned up so much with the Epoch installation, but we haven’t been out since the battery change. Can’t wait to see how it works out once we leave, but I did leave room for a second battery if I need it.

Hello, I’m new to the lithium and could use some advice on how to set up my RV system. I just got 1 Epoch 460 Essentials battery to replace 4 Lifeline AGM GPL-4CT. I have the Magnum MSH3012RV charger/inverter, the Magnum ME-ARC remote, and the Magnum PT-100 solar charger controller. The remote has 2 settings that can be used for lithium, the CC/CV and the Custom setting. Which one of these is better to use and how should it be set up?

I suggest contacting Magnum directly. I had a similar question about my 2812 inverter and they were very helpful about assisting with the correct settings.

I have the same battery and inverter however our coach has the Firefly interface vs an actual Magnum remote. I’m fairly sure you could use either setting (Lithium or the CC/CV) with the later providing more control. For the charge voltage settings you just need to set Abortion to 14.2V (Equilization also to 14.2 assuming it can’t be disabled entirely) and Float to 13.5V. These are the settings specified by Epoch directly for the Essentials battery.

You’ll also want to specify the same charge settings in the solar charge controller.

Should I have the PT controller set to “Linked”?

I am using the custom setting with an absorb voltage of 13.9 and a float (when I use it) of 13.5. Normally I set the Final Charge to Silent rather than Float so I can set the re-bulk to 13.0 volts. When I originally spoke to Magnum, they recommended not using the CC/CV but didn’t give specifics other than saying it has been “problematic”. I have also found that since the Magnum doesn’t have remote sensing, it jumps pretty quick from Bulk to Absorb and most of the charging is in Absorb. My Absorb time setting was updated accordingly to obtain a full charge. It takes some time to figure things out.

Bob’s last point is a really important one. Without remote sensing, all vales are based on the voltage leaving the inverter. It’s likely you will see some sag in there. I’d rather see as much charging as possible occur in bulk rather than absorption, so I’d be inclined to set absorbtion voltage to 14. That will likely result in the battery seeing more like 13.9 volts and hopefully keep you under the full charge protection threshold. Unfortunately, this is the needle we are left to thread with full charge protection being set down at 14 volts. It won’t help those of us with these batteries, but the updated 460 marine batteries that are on the way now will have full charge protection parameters set higher to avoid quite such a tightrope walk.

-Ben S.

Do you know if there will be any type of update for those having the current charge protection parameters?

I have not heard about any plans to change existing units in the field. I think one of the major issues is the current batteries don’t have an over the air firmware upgrade path. So, you would need someone with access to Epoch’s communication box and as far as I know that is very limited. I have one in SW FL and can help anyone in my area.

-Ben S.

Where in SWFL are you located? Just saw on Epoch’s website there is an update for the C12460A EMS and BMS. I assume that’s for the V2 of the battery.

Hi Ben,

To me the overcharging protection is why I will stick with Mastervolt Lithium batteries coupled with their chargers and alternator regulators.

It’s easy as pie to tell the Mastervolt battery to decide when it’s nearly full and then send a stop charging event to the charging sources over Masterbus. This integrated approach removes all hassle and not-fully-charging problems. This way my consumers never see a voltage spike. I get full use of my alternator + engine charging capabilities as well.

The only non-Mastervolt item that I am using is a set of Victron MPPT regulators for the solar panels, as Mastervolt doesn’t have these. These get sent the same event via a Mastervolt relay output going into the digital input on the MPPT regulators. I guess you could do the same for other charging sources of other brands, if they have a “stop charging” input.

Oh, and this is old tech in the MV world, I’ve been doing this with my Gel batteries and a Mastervolt shunt since 2010…

Kees,

There’s no question that single brand solutions with deep integration offer a lot of advantages. I think Victron offers nearly all the same advantages when using their batteries. Especially with the discreet allow to charge and allow to discharge terminals on the BMS making further integration quite straightforward.

The one disadvantage systems like Mastervolt, Victron, MG, and Lithionics come with is a larger price tag. But, sometimes you also get what you pay for…

-Ben S.

Some silly questions from a newbie. First, I understand that the Victron BMS works nicely with the Elite. Yet, do I need a Victron BMS if I can use the Epoch Software. I understand that Victron’s BMS may be far more comprehensive, but I want to dive in not deep dive in. I may be missing something which is making everyone’s eye’s roll.

Also, there is a hefty difference between the Essential and the Elite v2 when getting the 460 Ah battery. Does the extra money make sense? Maybe the internal BMS on the Elite is worth the difference because you can sidestep buying a Victron BMS?

Yes, this is all very basic, maybe misguided, but I would love to hear from better informed people.

Eric,

You don’t need (and can’t use) a Victron BMS with Epoch’s batteries. The batteries have a BMS built in. The Victron communications feature of these and other batteries allows the battery to communicate directly with the Victron ecosystem. This communication allows the battery to report on its operations to a GX device like a Cerbo, Ekrano, Venus, or Color Controller, allows the battery to communicate limits to the Victron system. Those limits cover charging voltage, charging current, and discharge current, and communicates warnings or errors from the battery to the GX device.

There are quite a few differences between the Epoch essentials and elites. These limits include IP rating for water ingress, current handling, external communications, power control and remote power switch, and gauge that displays state of charge, current voltage and current, and warnings.

Hope that helps clarify a bit.

-Ben S.