The ultimate LiFePO4 battery? Epoch’s 460ah powerhouse

My wife Laura reads most of my entries. She often tells me that I write about lithium batteries too much. Well, sorry but what follows will be another article about another lithium battery. If it helps, this is one hell of a battery and I think everyone considering new deep-cycle batteries for their boat should know about it and consider it. That’s doubly true in light of the significant step forward in battery safety I found when I opened the lid of my evaluation unit.

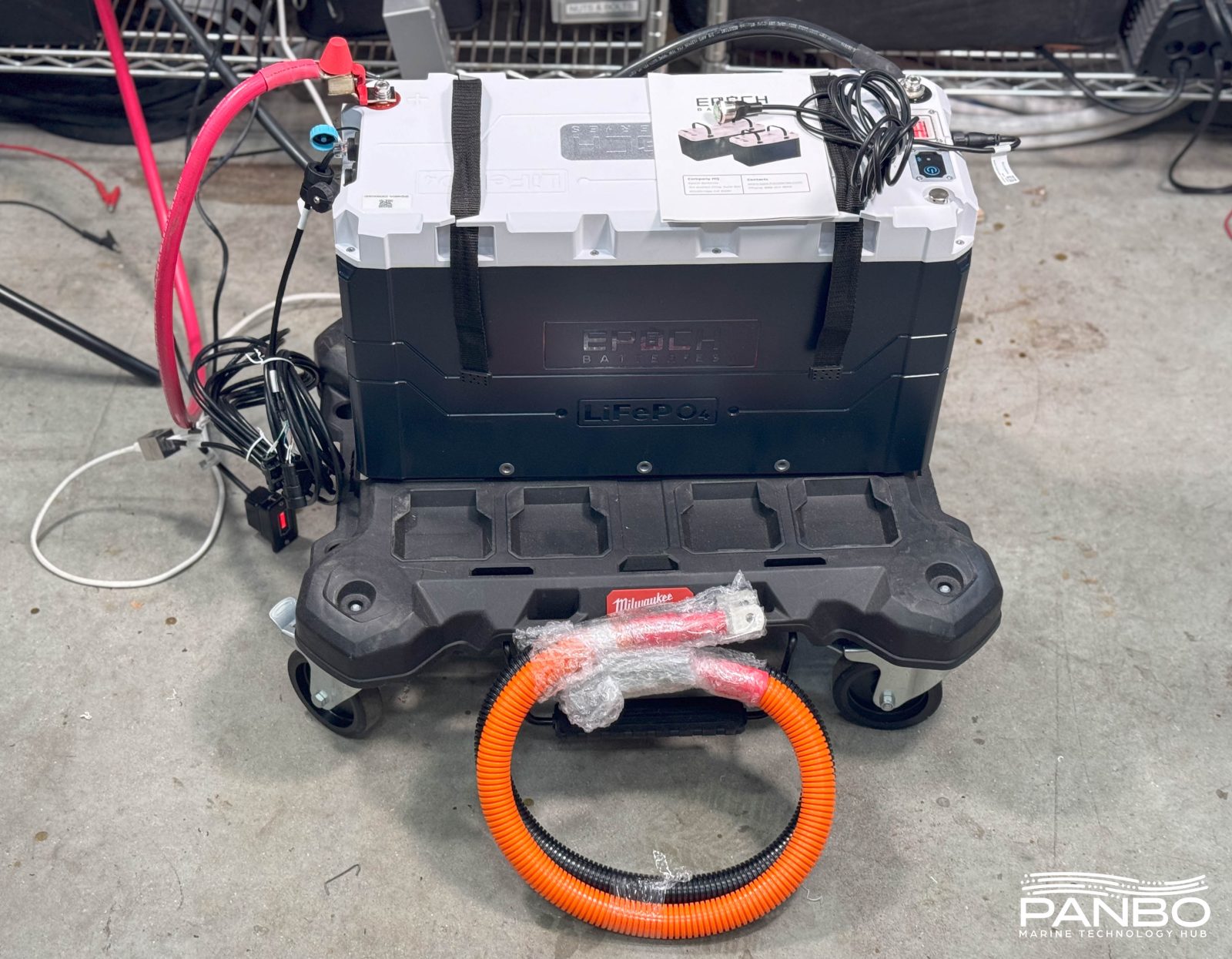

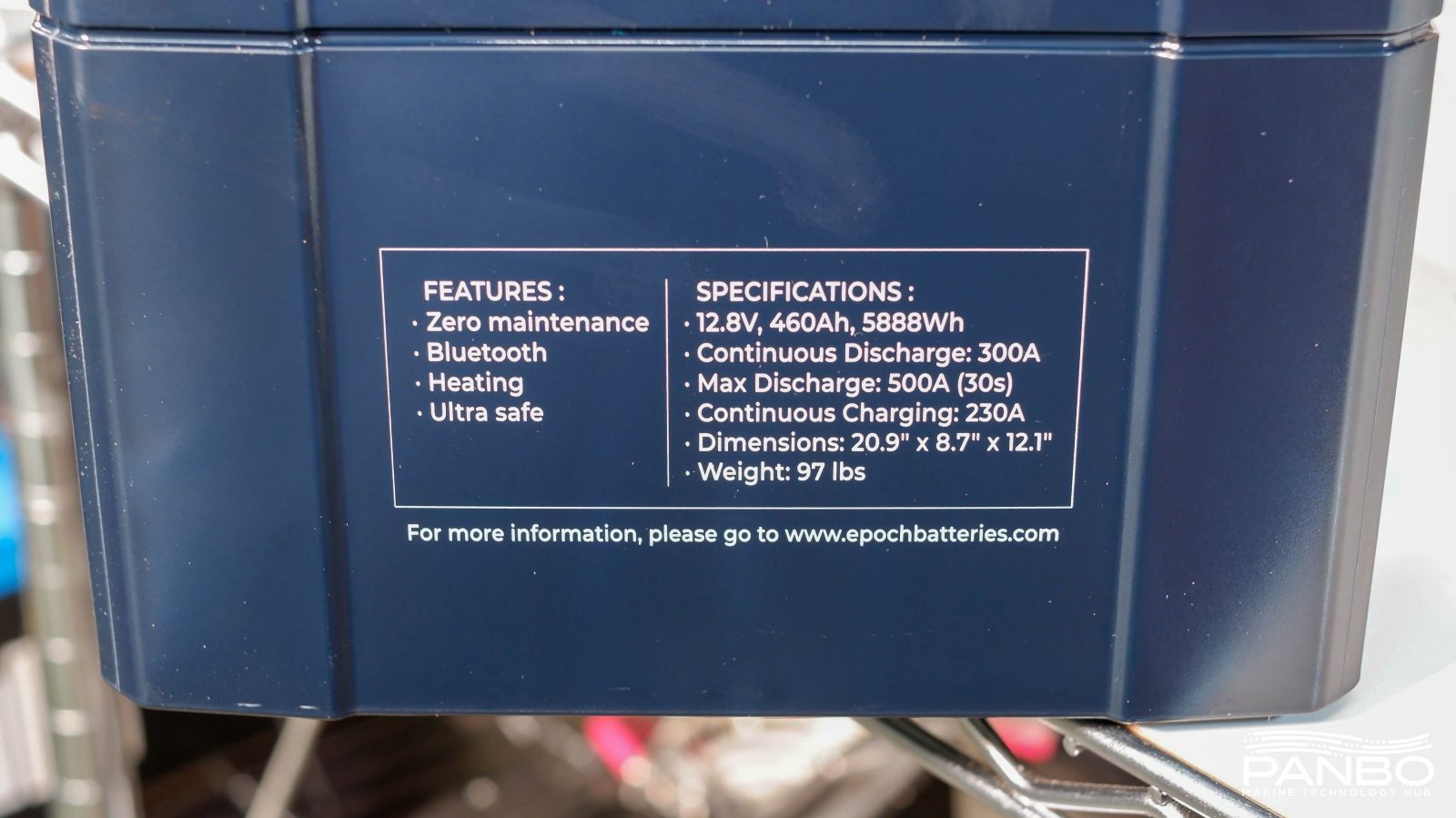

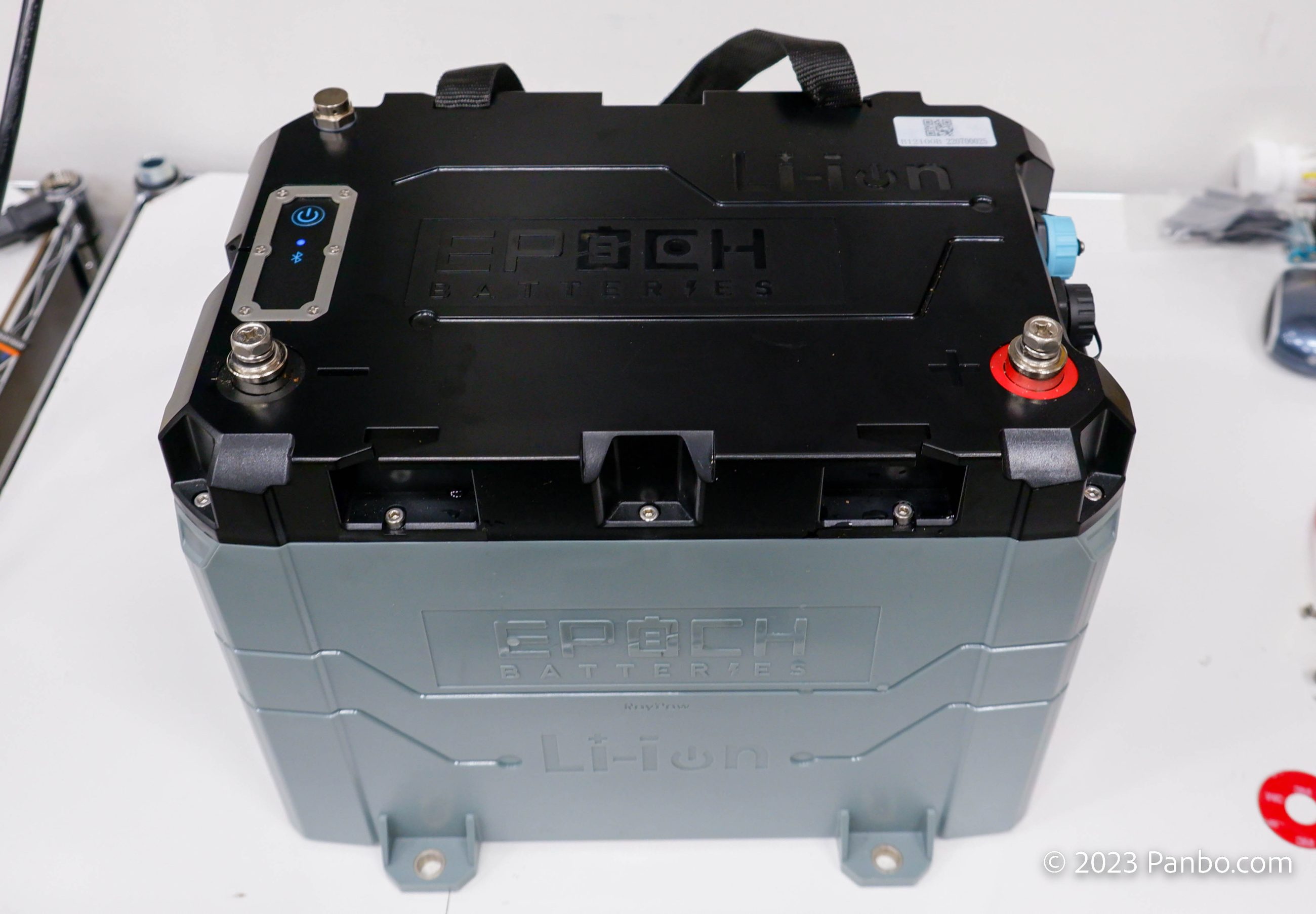

For the last several weeks I’ve been testing Epoch’s powerhouse 12-volt, 460-amp-hour, 8D sized, IP67, heated, Bluetooth, and Victron communicating battery. That’s a lot of features lined up in the name of the battery, but each of them is worth highlighting. This battery checks the box for nearly every feature I could think of wanting and adds several features I wasn’t even aware I wanted.

The battery

Each 12-volt, 460-amp-hour battery costs $1,999. The battery ships with a 10-segment LED display, remote-power switch, Victron communications cable, and mounting brackets. Although my early unit didn’t include it, I’m told that Epoch will include the custom cable required for daisy-chaining batteries to Victron systems. Lastly, my early unit did include an Anderson Power Pole to 4 AWG cable but I’m told that probably won’t be the case in the future.

If, after reading this lengthy review of the battery, you decide you would like to purchase one or more, I encourage you to use this link: https://www.epochbatteries.com/?rfsn=7030270.54d2cb and the coupon code MARINEHOWTO. The link and coupon code will earn you 10 percent off your order as well as help Rodd Collins of MarineHowTo.com. Rodd suffered a stroke and has had to shut down his marine electrical business. For those who haven’t come across his site, it is a wealth of information and Rodd is a frequent source of expertise and analysis for me.

Costs compared

| Battery | Voltage | Chemistry | Amp hours @ 20hr rate | Recommended DoD | Useable Amp hours | Useable watt hours | Cost | $/useable watt hour |

| Duracell GC2 | 6 | FLA | 215 | 50% | 107.5 | 645 | $119.88 | $0.19 |

| Kilovault HLX+ 3600 | 12 | LiFePO4 | 300 | 80% | 240 | 2880 | $1,125.00 | $0.39 |

| Epoch 460ah12v | 12 | LiFePO4 | 460 | 80% | 368 | 4416 | $1,999.00 | $0.45 |

| West Marine 8D AGM Dual Purpose | 12 | AGM | 245 | 50% | 122.5 | 1470 | $1,064.99 | $0.72 |

| Lifeline 8D deep cycle | 12 | AGM | 255 | 50% | 127.5 | 1530 | $1,164.99 | $0.76 |

| Battleborn 8D | 12 | LiFePO4 | 270 | 80% | 216 | 2592 | $2,399.00 | $0.93 |

The table above gives an overview of the cost of the Epoch 460 compared to several other options. A couple of years ago I did a writeup on the vagueries of comparing the cost of LiFePO4 batteries to other chemistries. In addition to the considerations I raised, several commenters had good points about the other factors. To keep the discussion short here, I’ll just point out I’m not comparing battery longevity (an area in which LiFePO4 has a significant advantage over any lead-based chemistry), resting voltage differences, charge acceptance rates, or charge efficiency here. The only thing I’m looking at here is a rough comparison of the cost per usable watt hour.

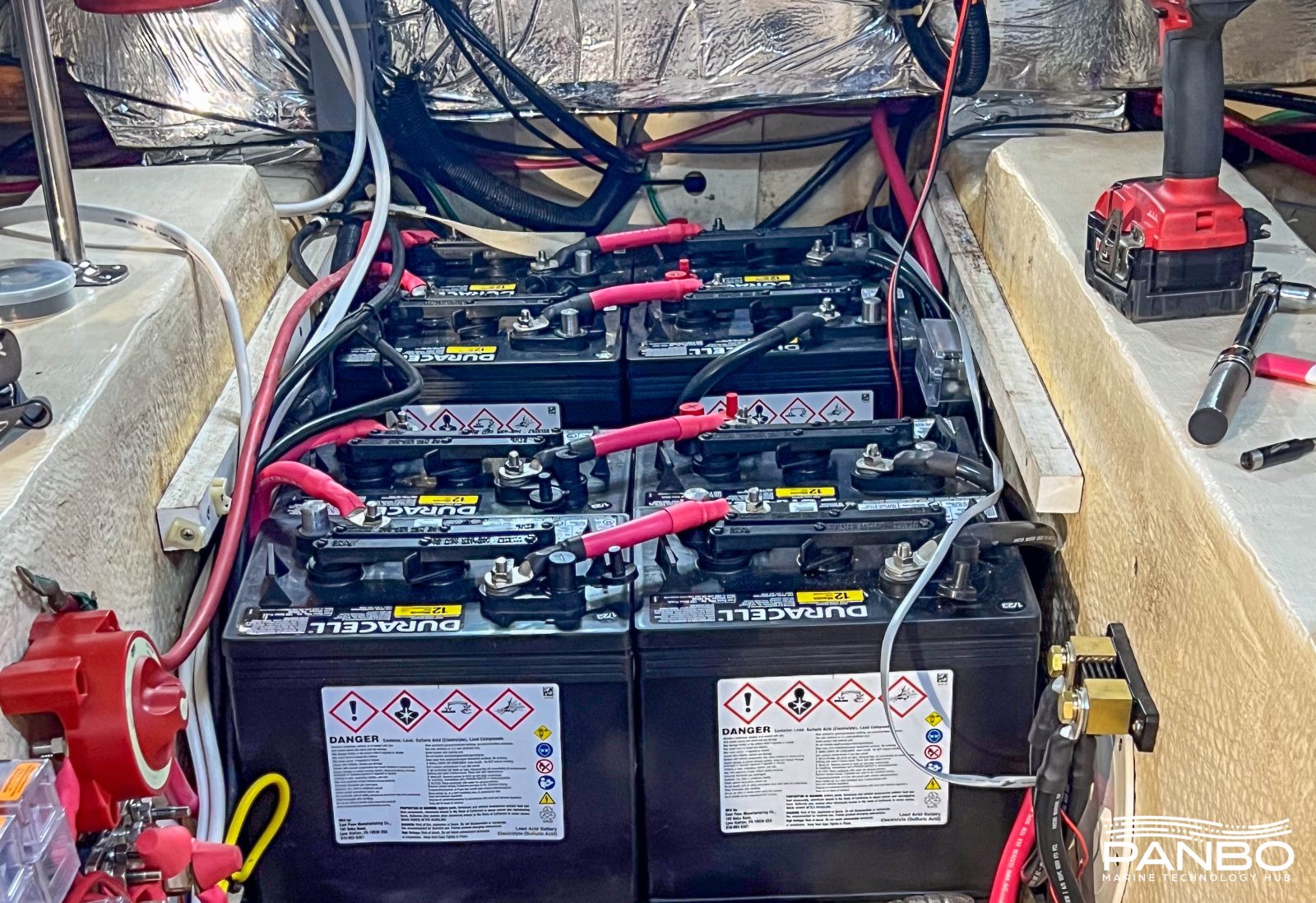

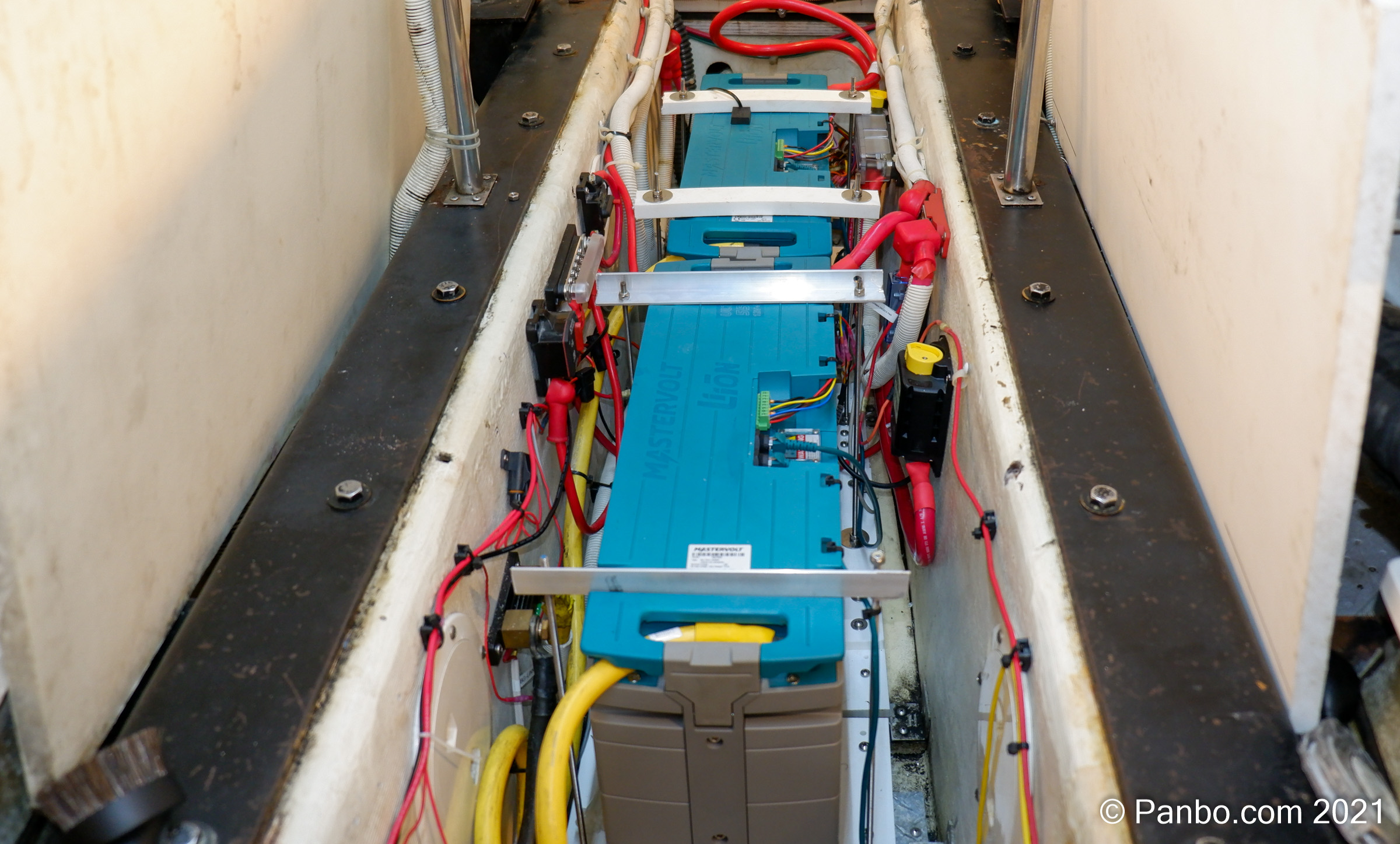

Anyone purchasing 460 amp-hour batteries is likely looking to construct a large house bank. I believe BMS-managed batteries are best deployed in, at least, pairs to ensure resiliency in the event of a BMS failure. So, if that practice is followed, the smallest battery bank possible would be a 960 total amp-hour bank with 768 amp-hours useable assuming an 80-percent depth of discharge. Let’s just compare that for a minute to a bank constructed of GC2 or 8D AGM batteries.

A pair of Epoch 460s would produce 8,832 useable watt-hours. To get the same useable watt hours from GC2 batteries we would need 13.7 GC2s. Let’s call that 14 batteries. If instead, we construct the bank from Lifeline 8D batteries, we would need 5.77 batteries. Again, we can round up to 6 batteries. As we compare costs we should also factor in the labor of installing batteries, the cost of battery cable, battery terminals, heat-shrink, and other miscellaneous supplies. For Epoch 460s, we would need a total of four cables, two positive and two negative. The GC2s would require 28 cables and the Lifeline 8D would require 12.

| Battery | Size | Cubic inches | Weight (lbs) | Useabele wh | wh / cubic inch | wh / pound |

| Duracell GC2 | 10.25×7.125×10.875″ | 794.21 | 60.5 | 645 | 0.81 | 10.66 |

| Kilovault HLX+ 3600 | 20.5x11x9.25″ | 2085.88 | 88.2 | 2880 | 1.38 | 32.65 |

| Epoch 460ah12v | 20.8×12.1×8.7″ | 2189.62 | 97 | 4416 | 2.02 | 45.53 |

| West Marine 8D AGM Dual Purpose | 20.75x11x10″ | 2282.50 | 161 | 1470 | 0.64 | 9.13 |

| Lifeline 8D deep cycle | 20.75×10.89×8.6″ | 1943.32 | 156 | 1530 | 0.79 | 9.81 |

| Battleborn 8D | 21.29×11.59×10″ | 2467.51 | 81 | 2592 | 1.05 | 32.00 |

Another frequent means of comparing LiFePO4 batteries to other chemistries is by weight and size. The table above shows the lithium chemistries all enjoy a significant advantage in watt hours per pound. The Epoch is the leader at over 45-watt hours per pound. But even the lowest density LiFePO4 battery, the battleborn at 32 wh/lb is more than three times as dense as the densest lead-acid battery. The energy density by volume isn’t quite as stark, but the Epcoh 460 is more than twice as dense as the lead acid batteries.

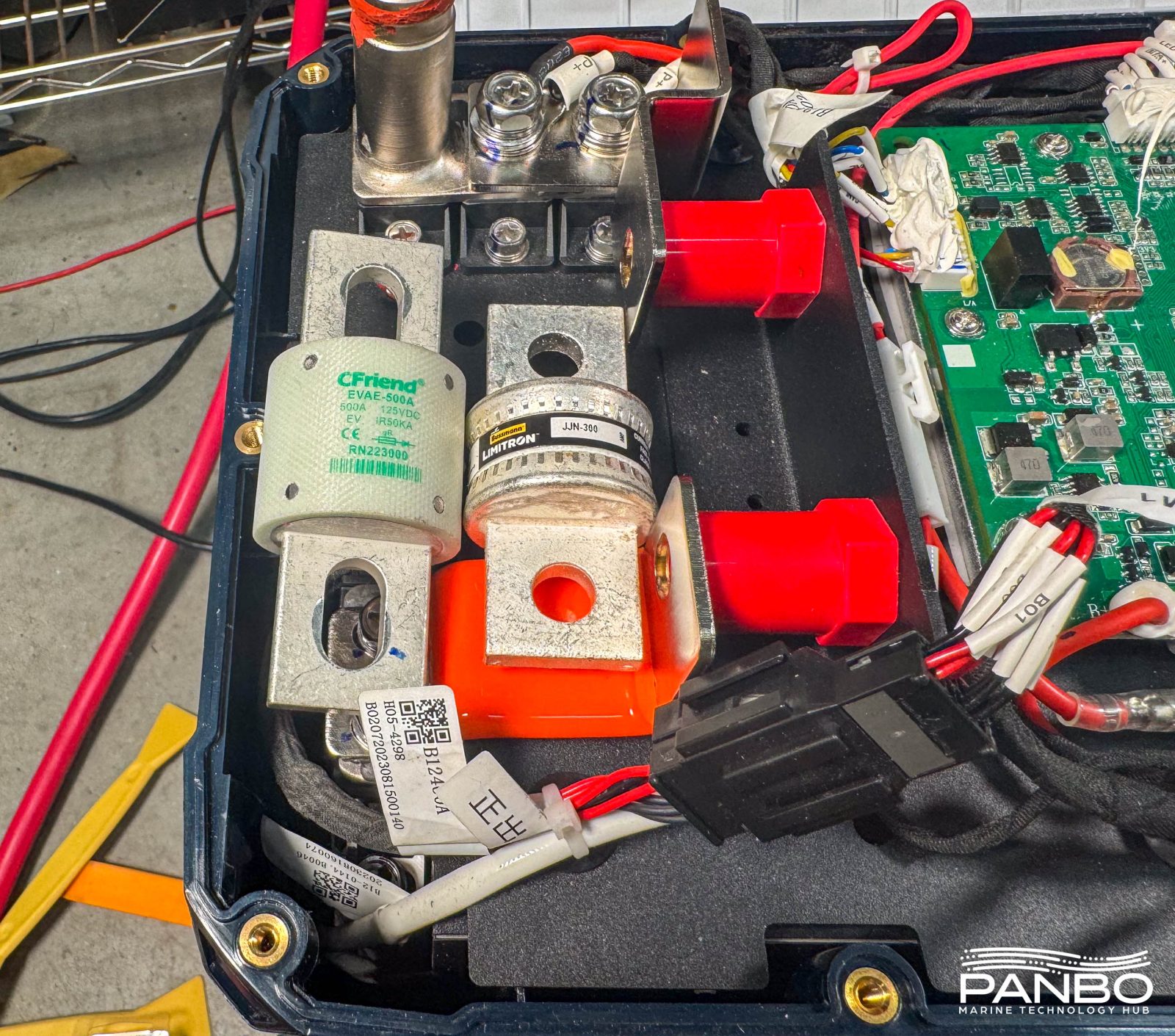

There’s a fuse, in the battery!

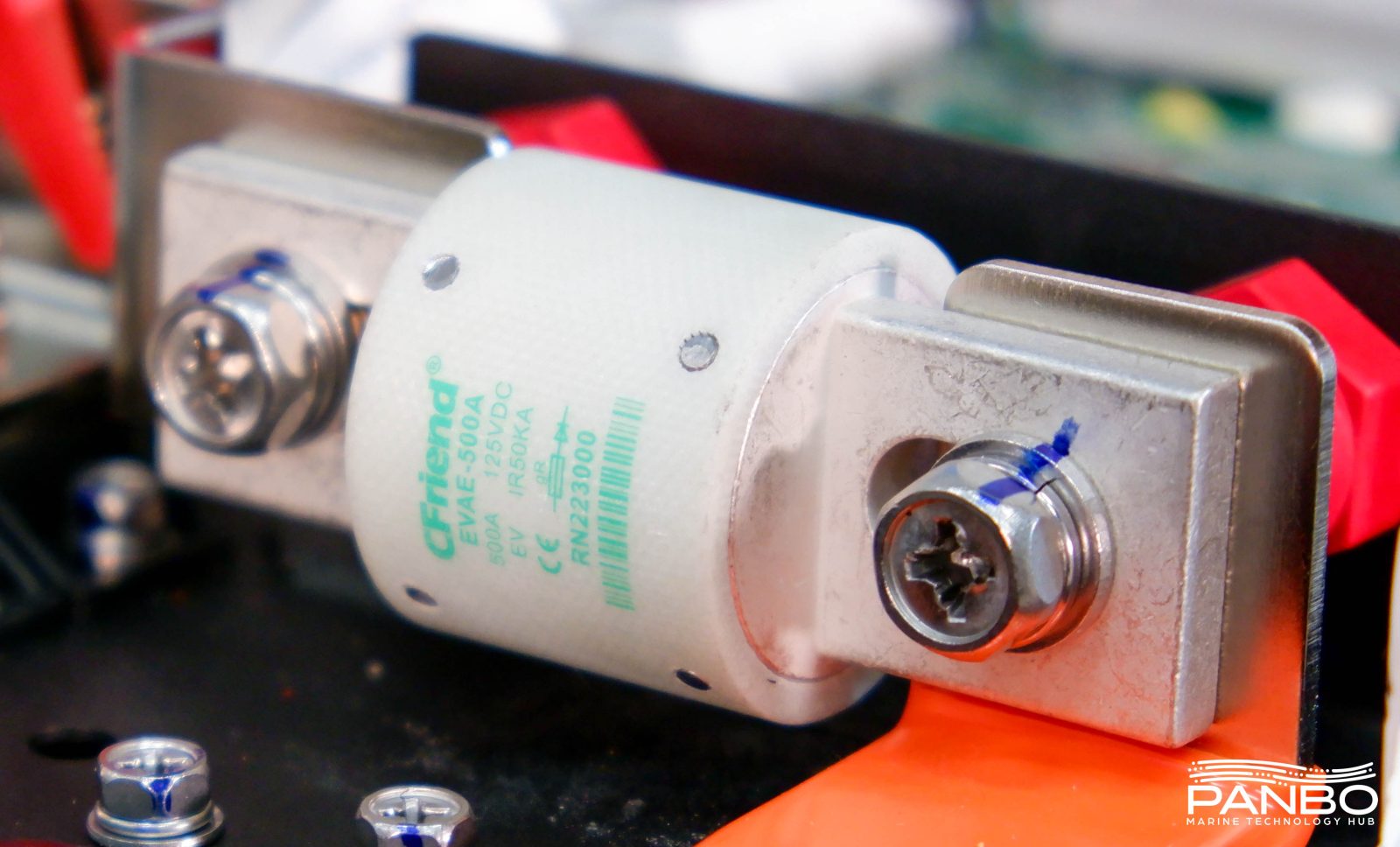

Let’s get one exciting thing out early. These batteries contain a 500 amp fuse under the cover of the battery, just before the positive post of the battery. The fuse Epoch uses is from the EV market and carries an amp interrupt capability (AIC) of 50,000 amps. That rating means that with up to 50,000 amps flowing through the fuse, it will still successfully trip to an open and safe condition.

ABYC’s electrical safety standards require a fuse with a 20,000 amp AIC. Before disassembling this battery, I’d never seen a class T rated above 20ka AIC. Thus far the only gripes I have about the fuse are that it appears difficult to source a replacement — which I’m hoping Epoch can help with by selling replacements — and I think Epoch should label the outside of the battery to warn there’s a fuse inside. That way, a boat owner won’t find themselves stumped if they accidentally trip the fuse.

But, make no mistake this fuse is a really big deal and a really good thing. By placing a high AIC fuse inside the battery, installers are now relieved of the obligation to place a physically large class T fuse as close to the batteries as possible. The combination of fuse holder size and thick cables can make this a challenge. Knowing the fuse is inside the battery, an MRBF post-top fuse holder can now be safely used. Thus, the entire system is protected via the internal fuse, and the wire off the battery is protected by an appropriately sized MRBF on the positive terminal.

One bit of bad news is that while the fuse in the battery is great, it is a different form factor than the Class T fuses we all source from Bluesea and others. The fuse in the battery has slotted holes at a wider pitch than a typical class C. I’ve been calling the fuse in the battery a class T and did in my video above, but now I think that might not be right.

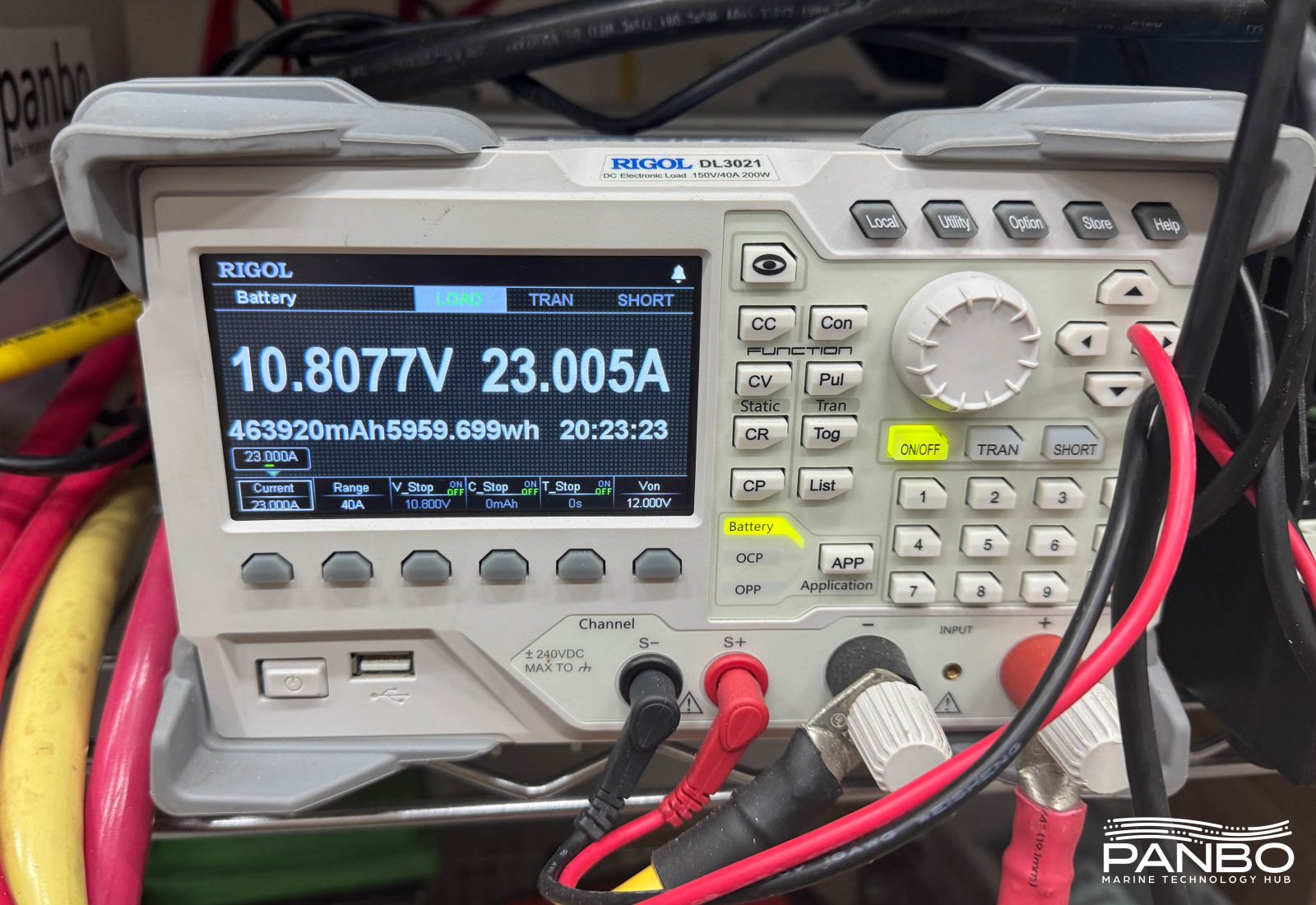

Performance

The basic performance of the 460 is pretty boring, and that’s a good thing. The battery is rated for 460 amp hours of capacity discharged over 20 hours. That means that if the battery is discharged at a fixed current (23 amps) it will deliver that over 20 hours. I’ve run at least a half-dozen such tests and it’s come out over spec each time. Voltage has been rock-solid and shows no issues whatsoever.

Perhaps the more interesting performance tests come from high discharge rates and how the battery performs. Keep in mind, this battery is rated for 300 amps of continuous discharge and 500 amps of discharge for up to 30 seconds. That’s a lot of power! At 25 C (or about 77 Fahrenheit) a Victron Multiplus II 3000 can output 2,400 watts at 93 percent efficiency. So, it shouldn’t consume more than 2,600 watts on a sustained basis. That means it will consume less than 215 amps at maximum capacity. Earlier, I mentioned I think LiFePO4 batteries should be deployed in a minimum of two batteries in parallel. Given the output ratings of these batteries, that means that even in the event of a failure of a battery, the surviving one could power all the boat’s needs.

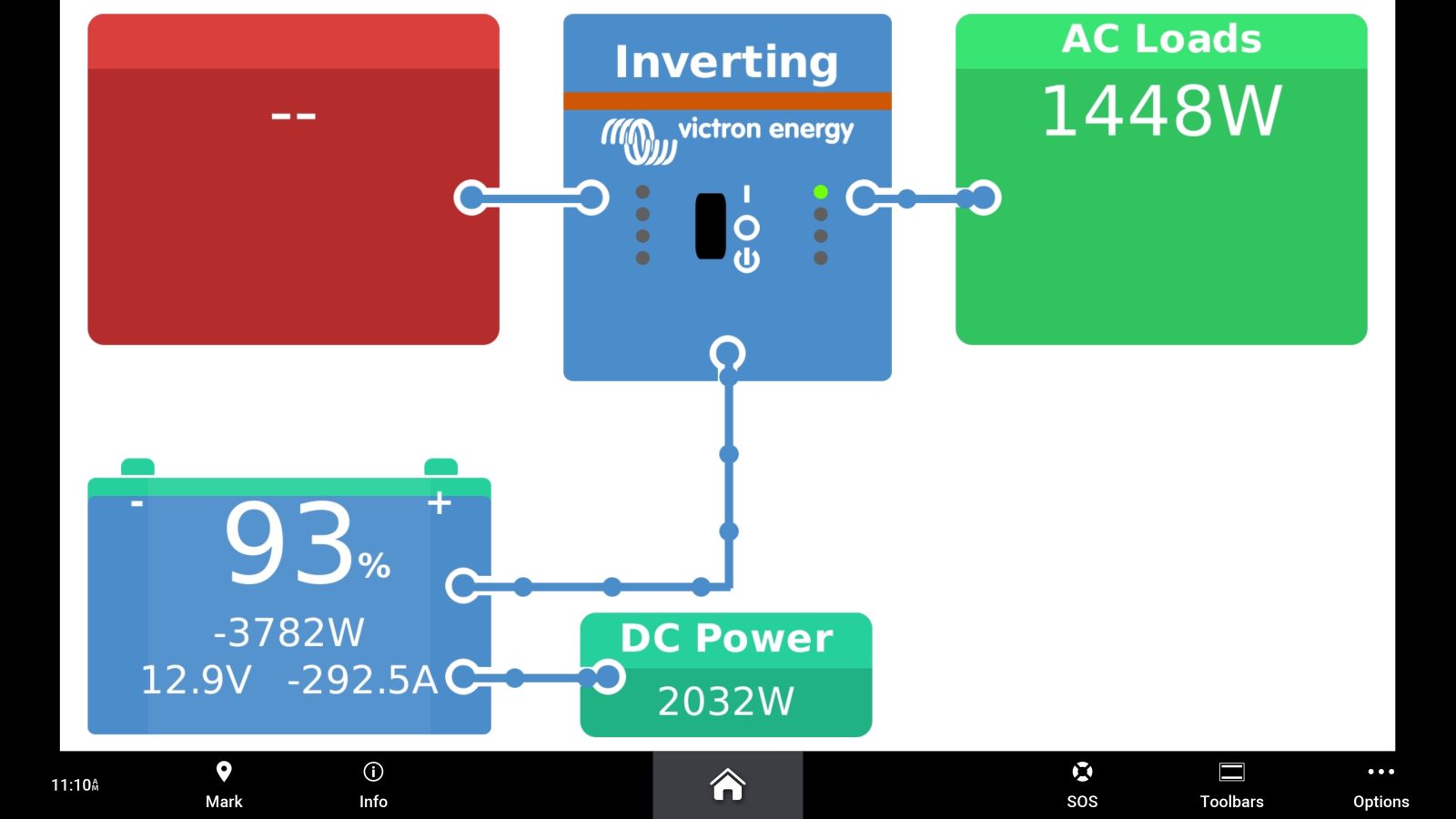

This battery has both the highest capacity and highest discharge and charge ratings of any I’ve tested. As a result, I had to beef up my load-generating abilities. I’ve typically used the MultiPlus II 2000 on the right side of the picture above. But, the 460 just shrugged at the less than 150 or so amps of load that a single inverter could generate. So, I went digging through my shelves of old gear and pulled out the behemoth Charles / Vanner IQ2600 that I pulled off Have Another Day. The two inverters were able to generate enough load to at least make the battery notice.

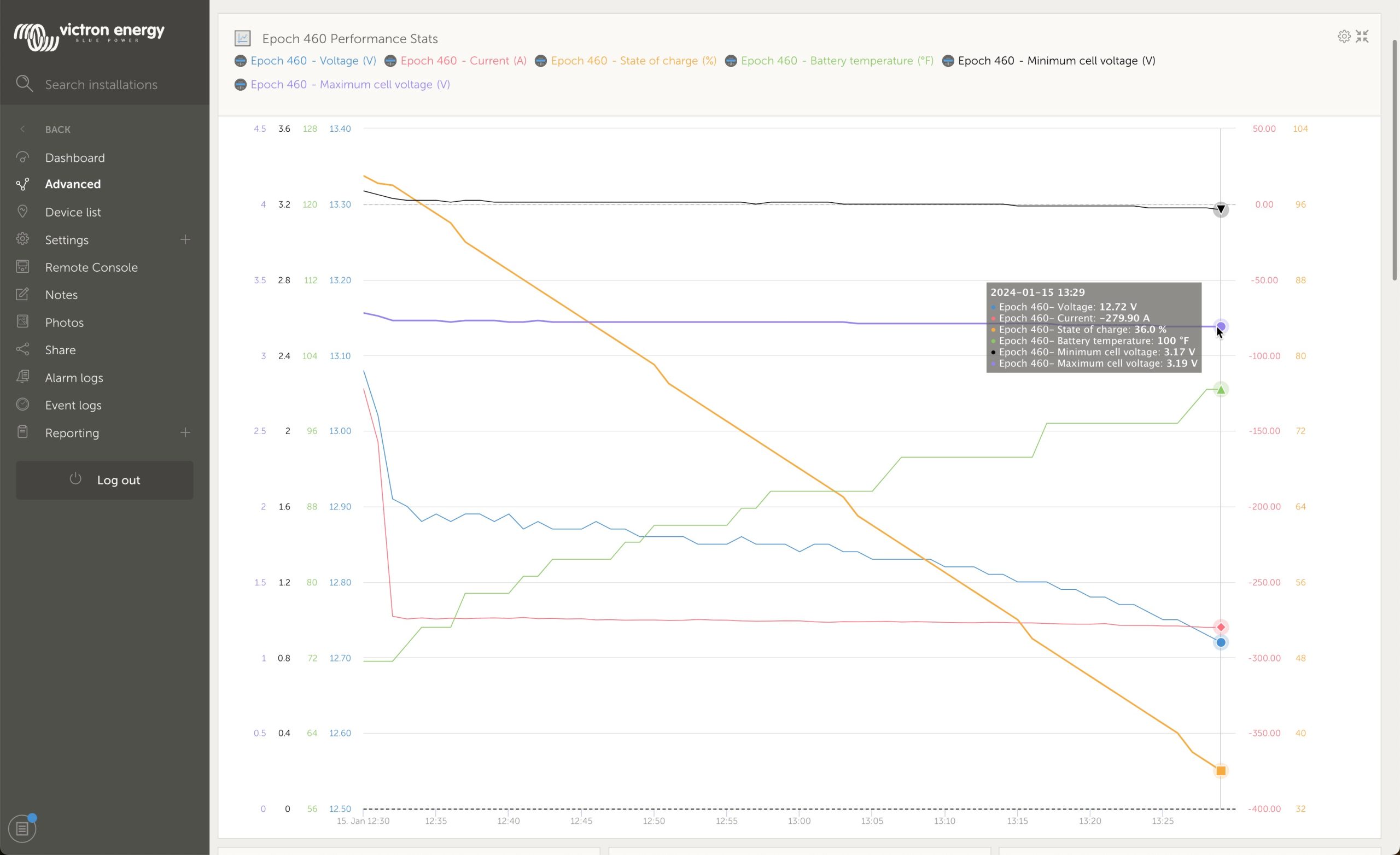

There’s a lot of data on the chart above, but shows how the battery stands up to a load. In this case, that load is about 3,500 watts of heaters. That 3,500 watts equates to around 280 amps of current at 12.7 or so volts. In the chart above, voltage is the blue line and it’s holding up nicely. When the load first hit, voltage dipped to about 12.9 volts. After 50 minutes of the load, and a drop of about 70 percent SOC, voltage is still holding over 12.7. In another good sign, the battery’s reported temperature has risen from 72 to 100 degrees during this sustained load.

I took the thermal image above after discharging the battery at just over 300 amps for about an hour and 15 minutes. As you can see, the heat sink on the top of the battery got quite warm. Interestingly, you can also see a hot spot where the fuse resides on the left side of the battery. Lastly, all the connections are pretty warm, not shocking in light of how much current they’re passing. Bear in mind that I’m pulling far more current from this single battery than is likely in most scenarios. Deployed in even a 2P configuration, it’s doubtful the battery would ever see these types of load. My testing represents worst-case scenario loads and the battery has stood up to those loads admirably.

Minimum current sensitivity

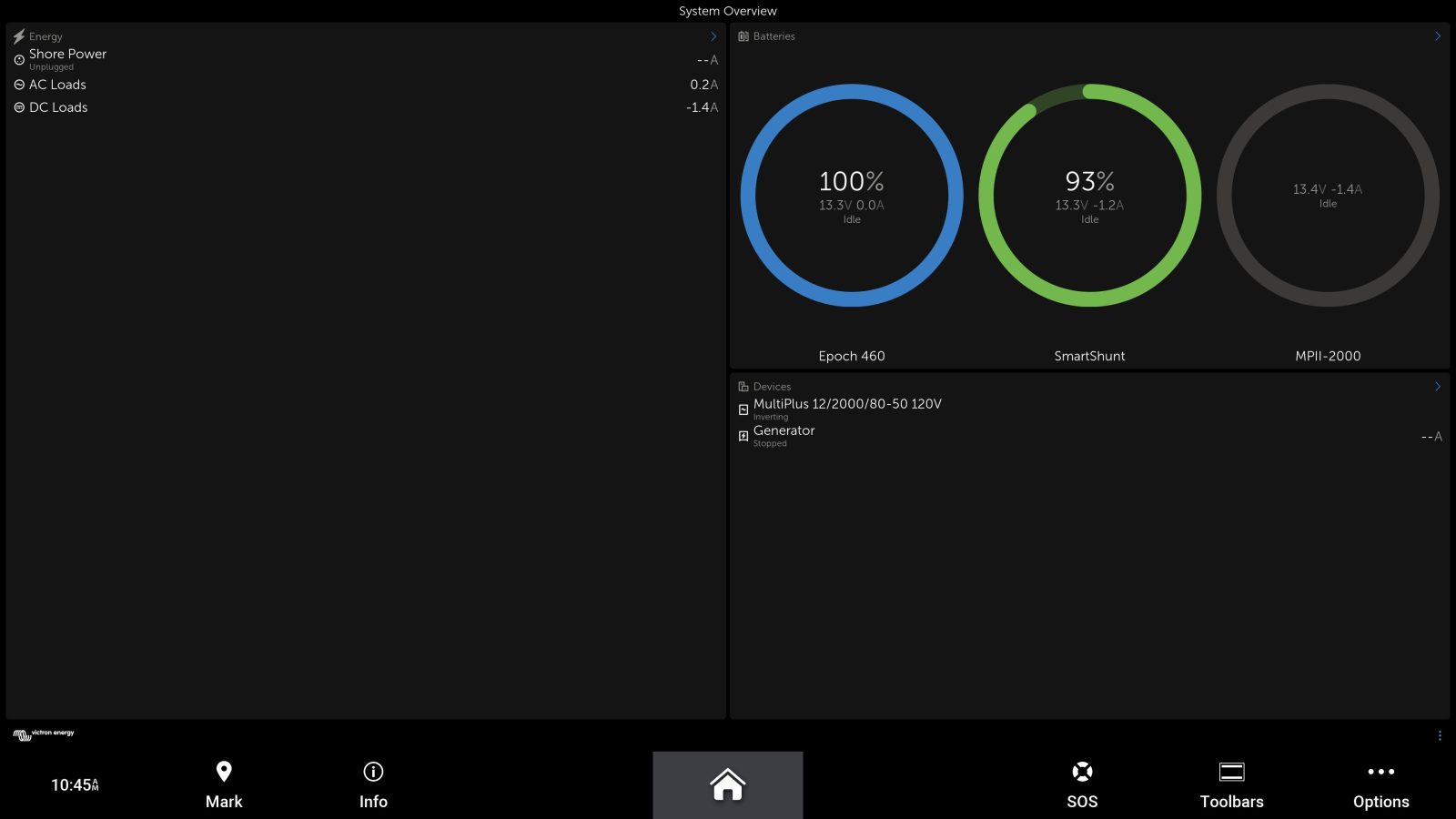

Towards the end of testing, I came across a limitation of the 460 amp-hour battery’s BMS’ measurement capabilities. It boils down to this: the battery can’t measure current draws below 1.4 amps. As a result, small current consumption simply isn’t measured by the battery. The screenshot above shows the result of not measuring a small, continuous load. In this case, it’s a 1.2 to 1.3 amp load from my two test inverters idling. I left the battery that way overnight and here’s where I ended up. The SmartShunt on my test bench correctly sees the battery at about 93 percent state of charge. But, because the battery’s BMS didn’t measure the low current draw, it still thinks the battery is at 100%.

Current flow through the battery is measured using current sensing resistors (CSR). Due to the high current handling of the battery, Epoch has to use a CSR that is capable of detecting large current. Unfortunately, especially in PCB mounted CSRs, those that have high current handling capabilities also have relatively high sensitivity floors.

I think this is a real limitation and one for any user of these batteries to understand. The battery won’t register any current below 1.4 amps. That showed up in my testing with one battery. But, imagine you’ve built a house bank of four of these batteries. Now, your loads are divided across all four batteries meaning you will need 5.6 amps to hit the sense floor of each of the four batteries. I think that’s a real enough issue to demand a Coloumb counting shunt in the mix like a Victron SmartShunt or BMV.

Connectivity

One of the major headline features of this new battery is built-in Victron communications. The 100 amp-hour batteries I tested previously have communications ports described as CANBus, but we never saw external integration with them. In fairness, I don’t believe Epoch ever promised communications with those batteries, though I thought it would come. Unlike the 100 ah batteries, this series launched with external communications working. As soon as I plugged the RJ-45 plug into the BMS.CAN port on my test Cerbo, information began flowing.

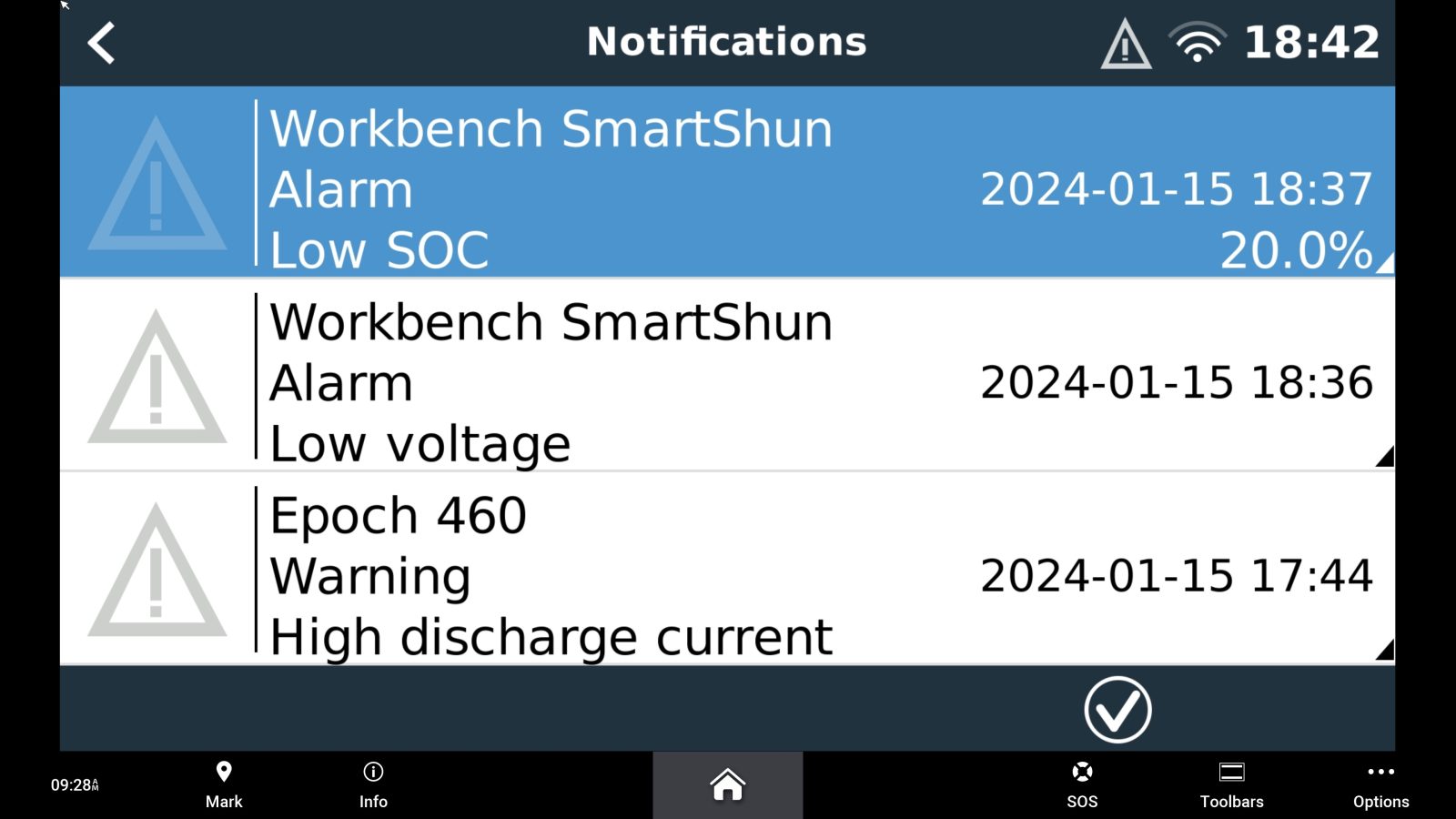

Bluetooth communications are also present and utilize the same app earlier Epoch batteries have used. The app provides the same detailed information and quick at-a-glance core health information. As I encountered with earlier batteries, the warnings and alarms the app displays are somewhat cryptic. I am fairly certain the DOC Alarm above indicates the discharge over-current alarm is active. I also triggered a COC Alarm which, I think, indicates charge over current. Because the label for both of those faults is in yellow, they’re warnings. The last screenshot shows a red fault for, I’m pretty sure, cell under voltage protection. That is a fault and has resulted in the BMS disabling discharge.

Victron integration opens many possibilities

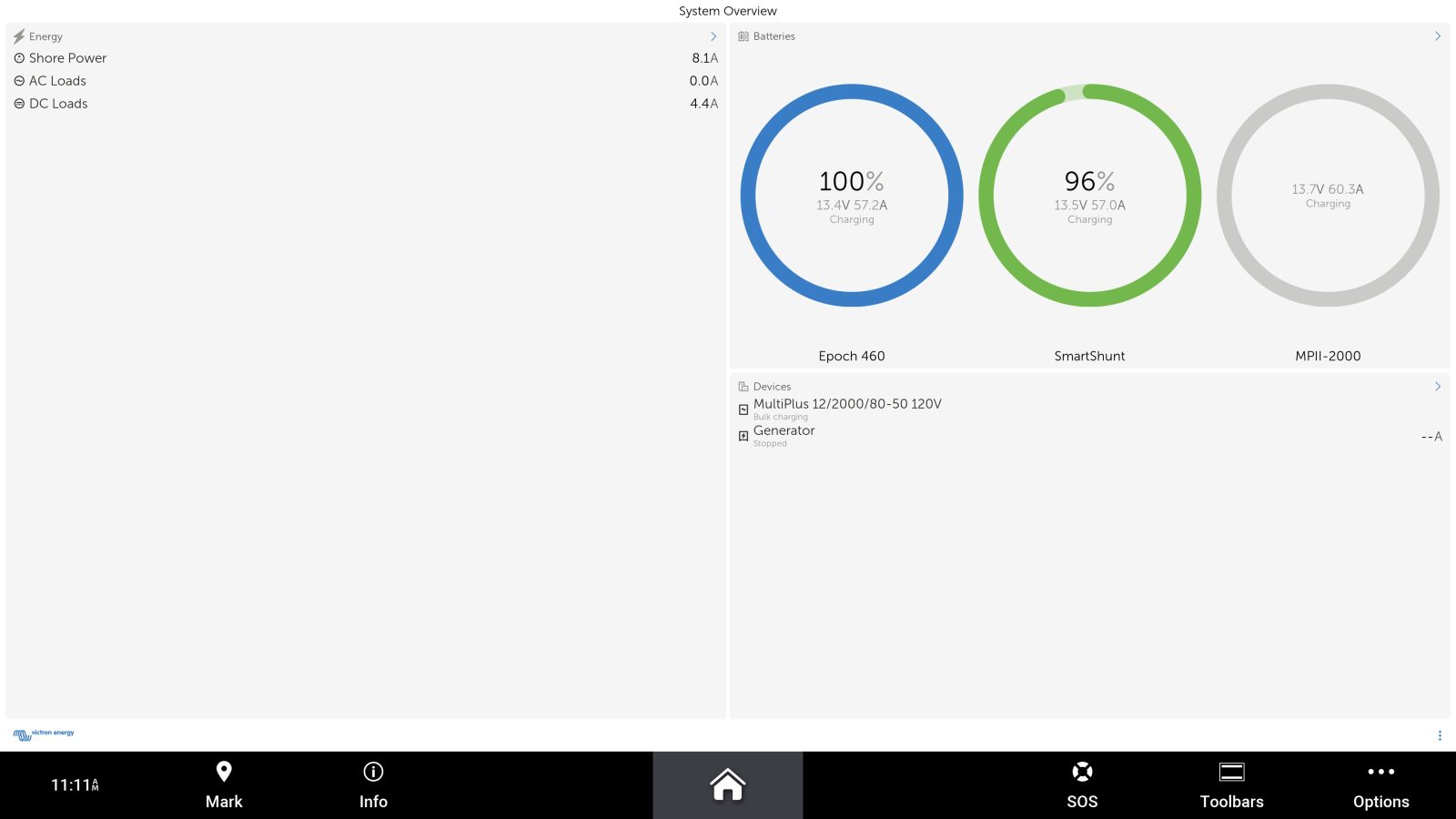

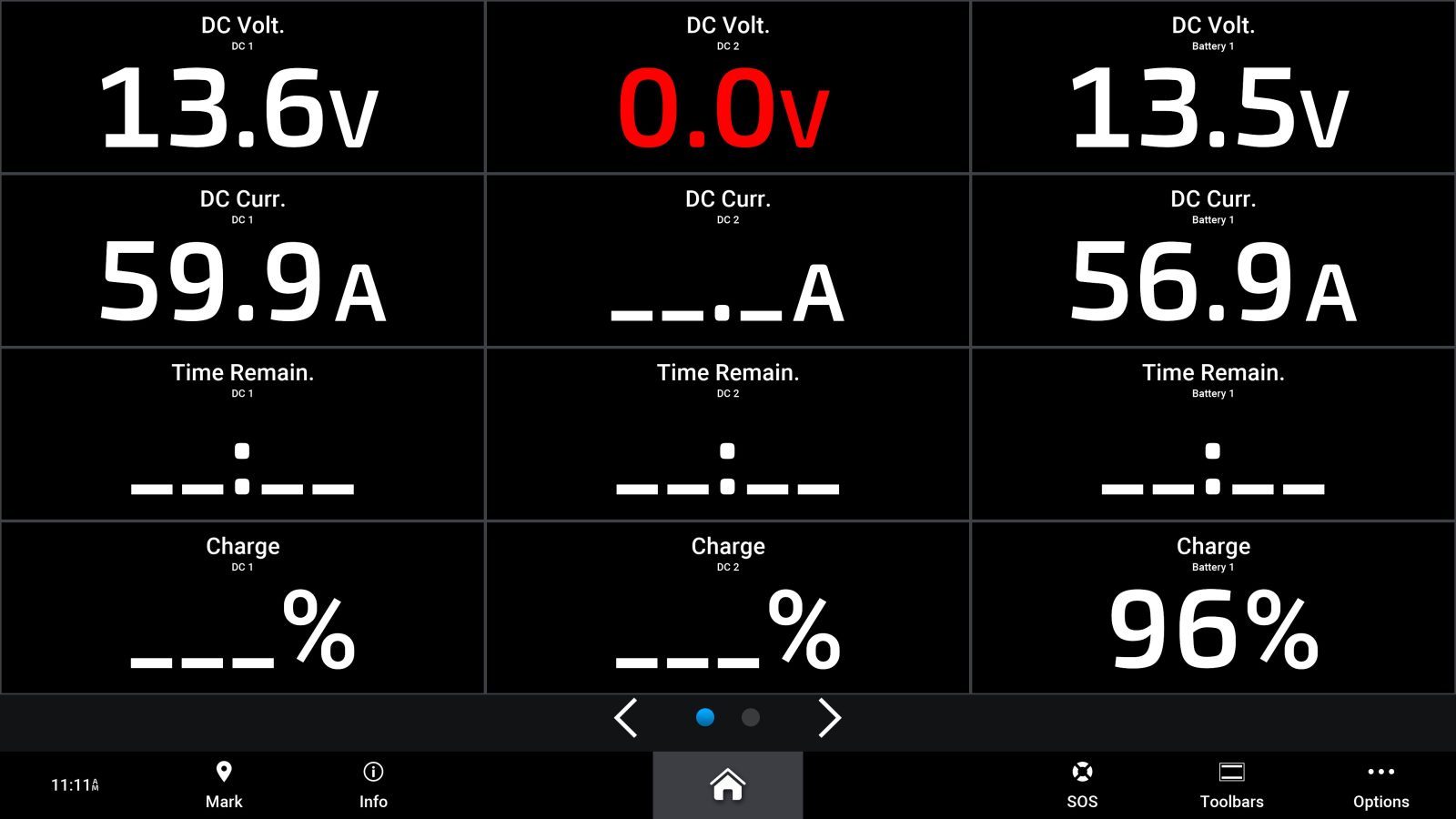

With battery data available and feeding to a Victron Venus OS device like the Cerbo, the boater has a wide-ranging choice of how to display the data. The screenshots above show several of those ways. The system overview and alarm screen use the HDMI output on the Cerbo and HDMI input on a Garmin 9219. With the display 9219 connected to the Cerbo, and a USB cable sending touch commands from the MFD to the Cerbo, you gain full display and control capabilities of the Cerbo. The second screenshot above shows Victron’s MFD app displayed on the 9219. The app leverages Garmin’s OneHelm app system to send data from the Cerbo via HTML5. Lastly, the final screenshot shows data displayed in Garmin’s native power view. This display is leveraging NMEA 2000 data delivered from the Cerbo to the MFD via Victron’s VE.CAN to NMEA 2000 cable.

Comparing available data

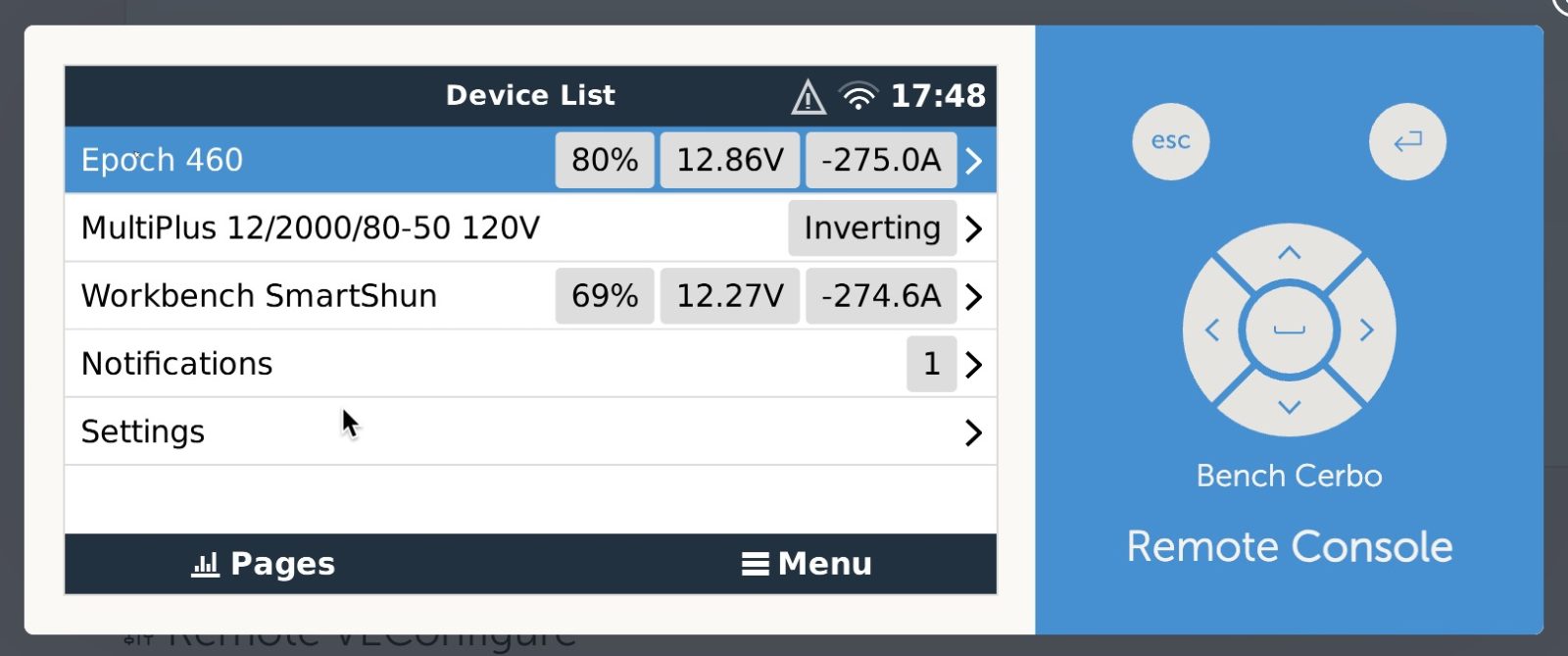

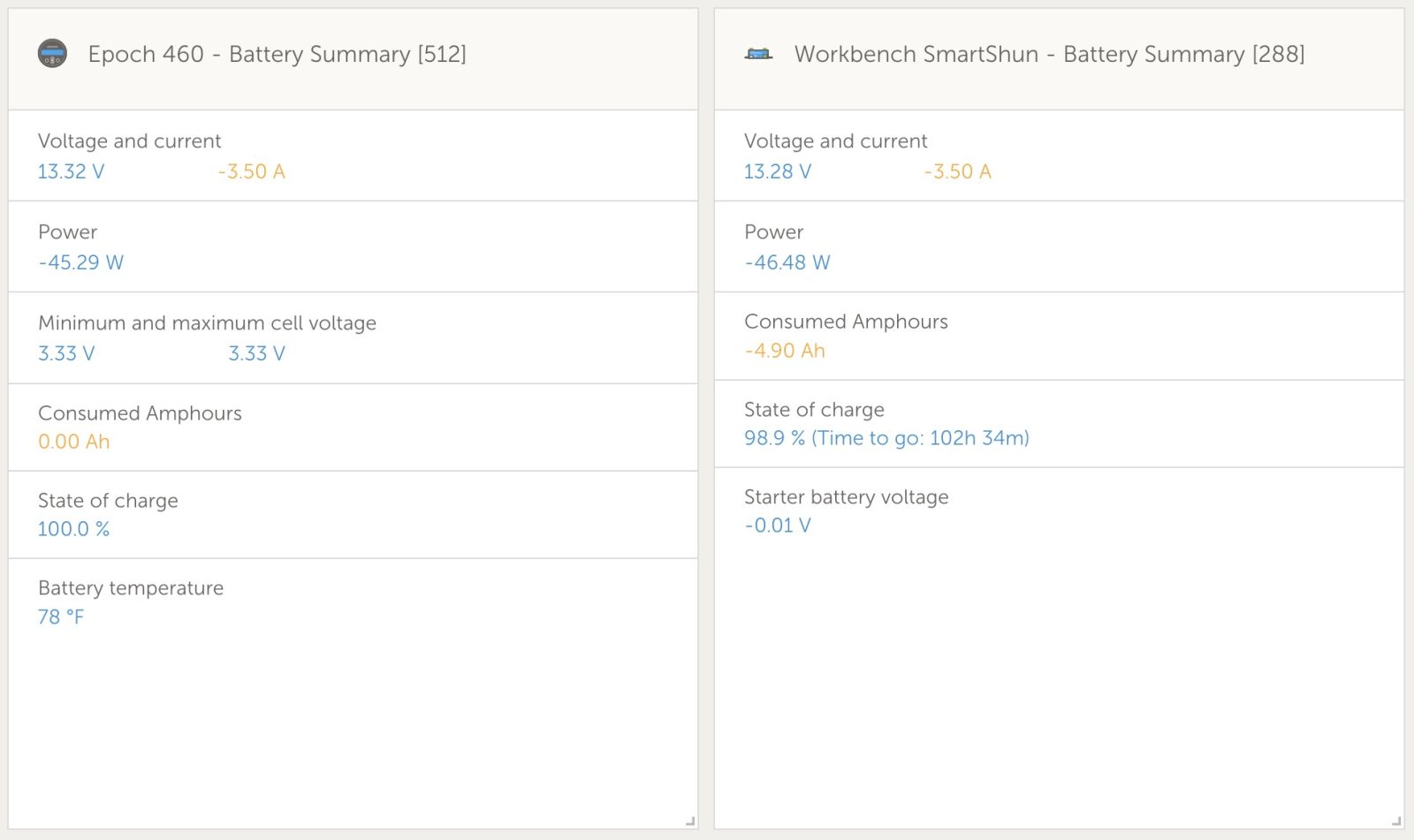

The two data boxes above compare data available via the battery’s BMS.CAN connection and via a Victron SmartShunt. The SmartShunt connects inline in the negative conductor to the battery. Both sources provide core data like voltage, current, and state of charge. But each source also provides data the other doesn’t. For example, the BMS.CAN connection from the BMS provides cell minimum and maximum voltages as well as battery temperature without an additional temperature sensor. Currently, the SmartShunt is providing runtime estimates and consumed amp hours the CAN connection isn’t. The lack of runtime data is under investigation by Epoch because they expect the battery should be providing it.

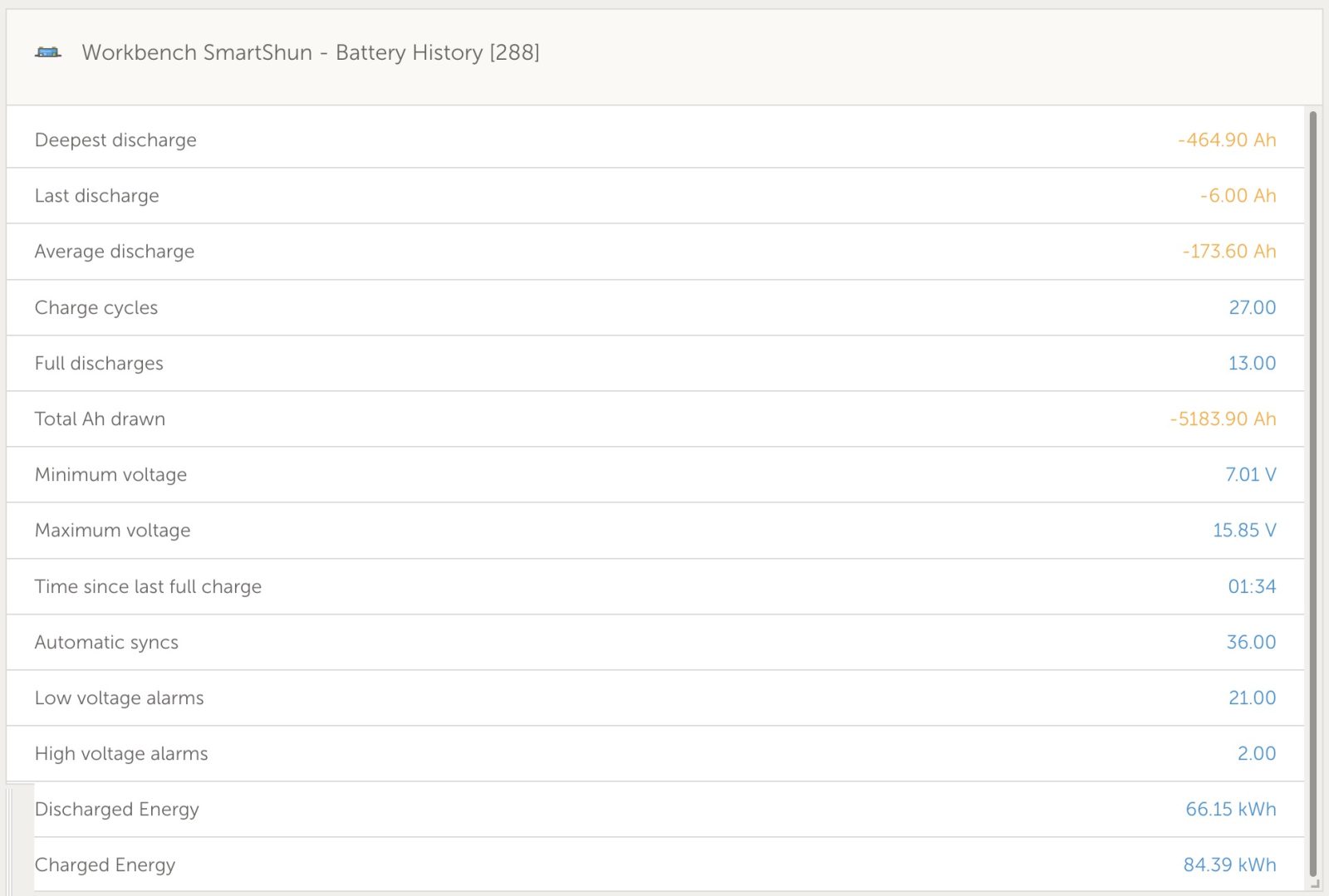

I greatly appreciate the Battery History information VRM and a SmartShunt or BMV provide. Via VRM, that information isn’t available leveraging the battery’s CAN connection. The Epoch app does provide a cycle count, but the detailed information on charged and discharged energy, time since last full charge, maximum and minimum voltages, and more are unique to Battery History. In light of the low cost of a SmartShunt, when I design systems I’m likely to still include one.

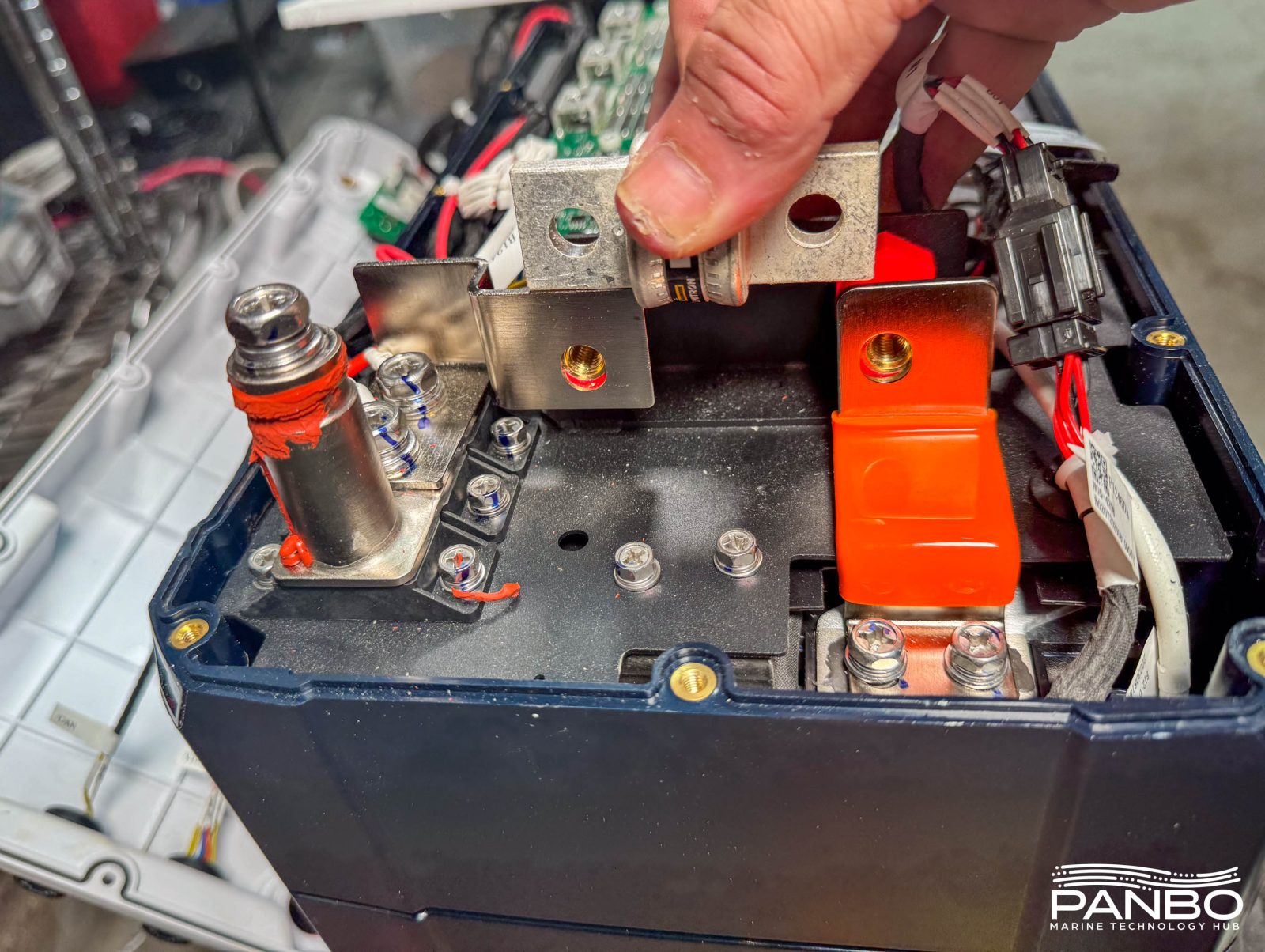

Teardown

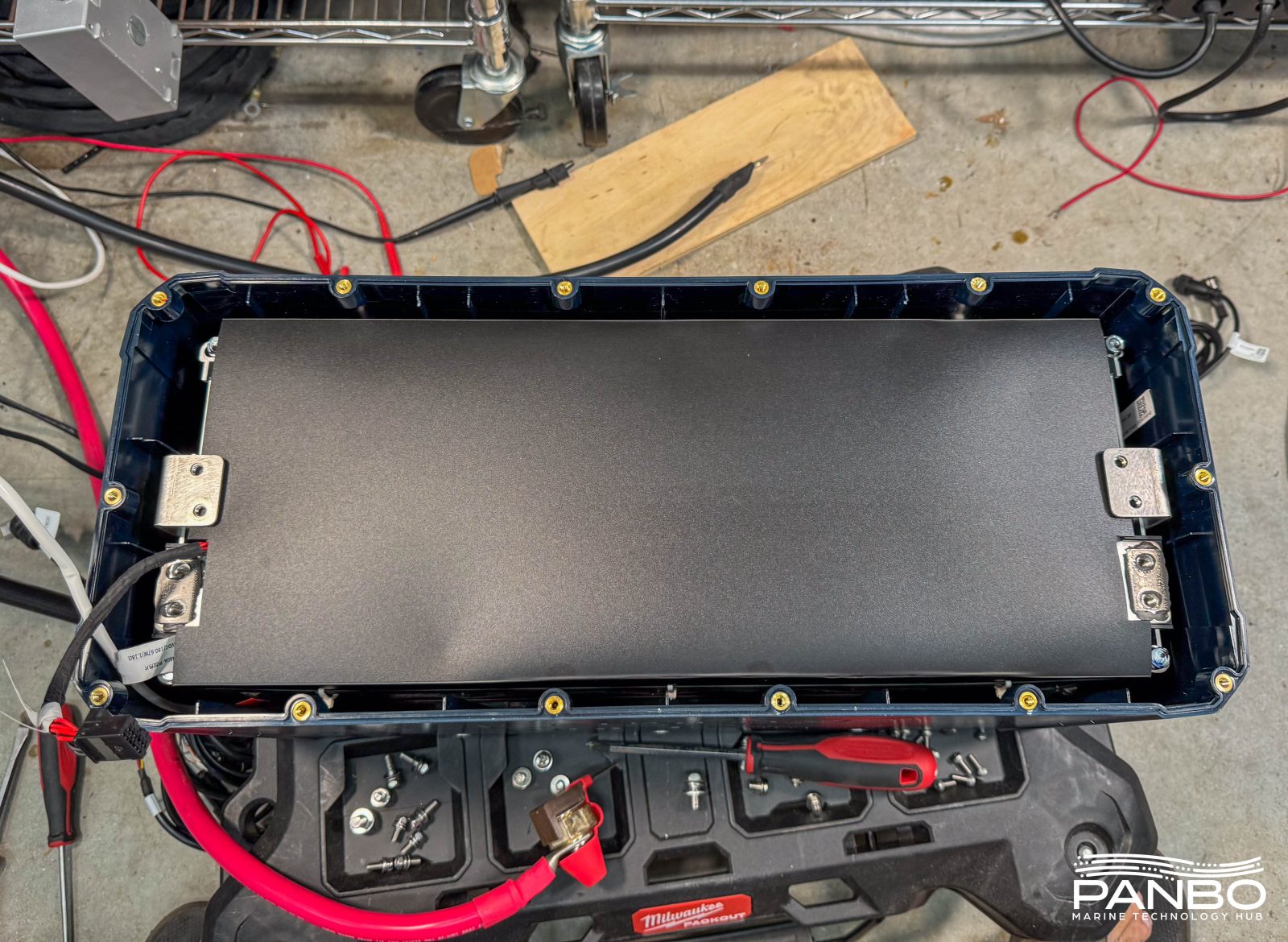

The construction of the Epoch 460 amp-hour battery is very similar to the 100 amp-hour battery. That includes a high-quality, water-resistant battery case. In the case of the 460, the top is secured by 14 hex head screws spaced around the top.

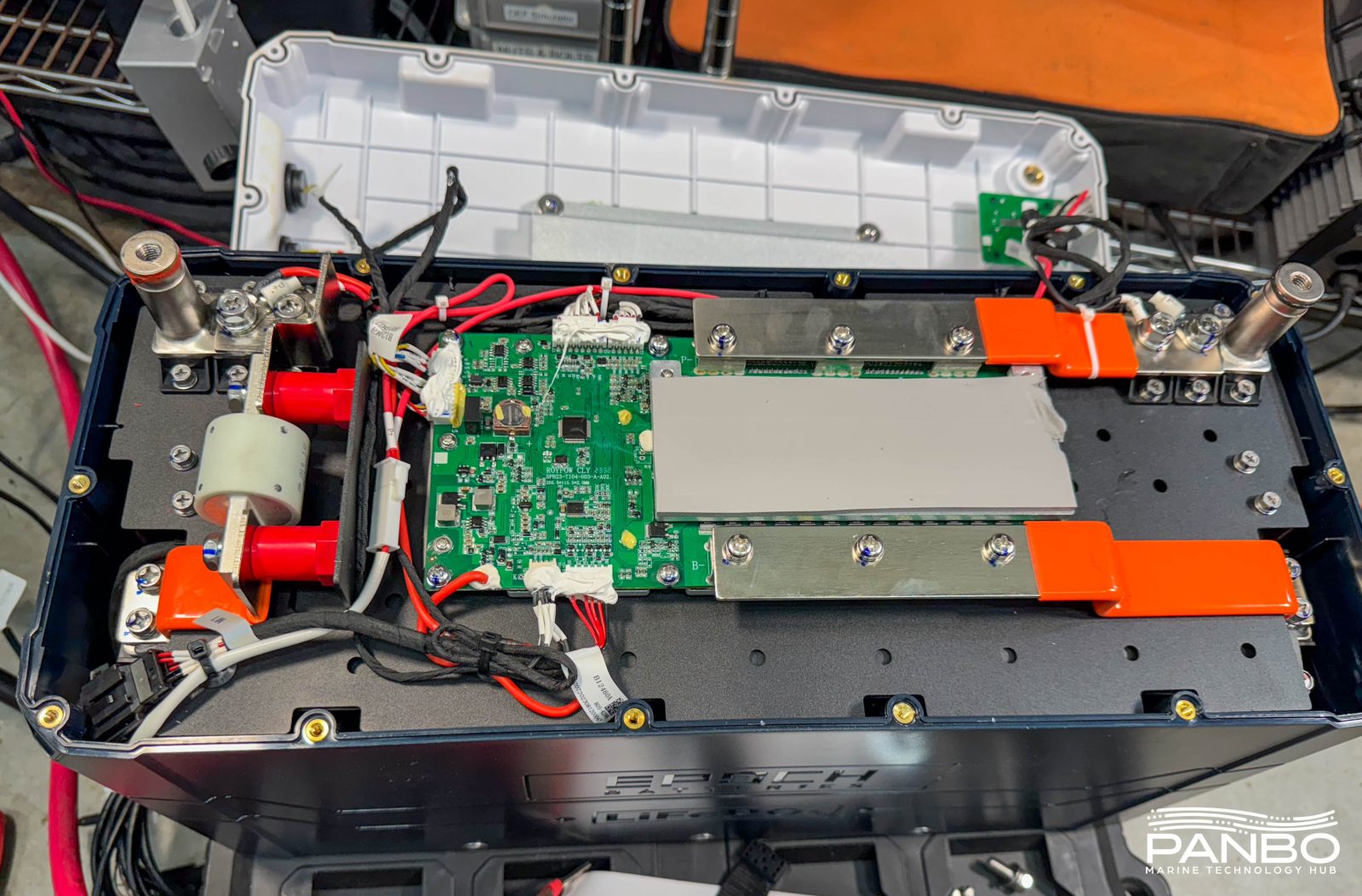

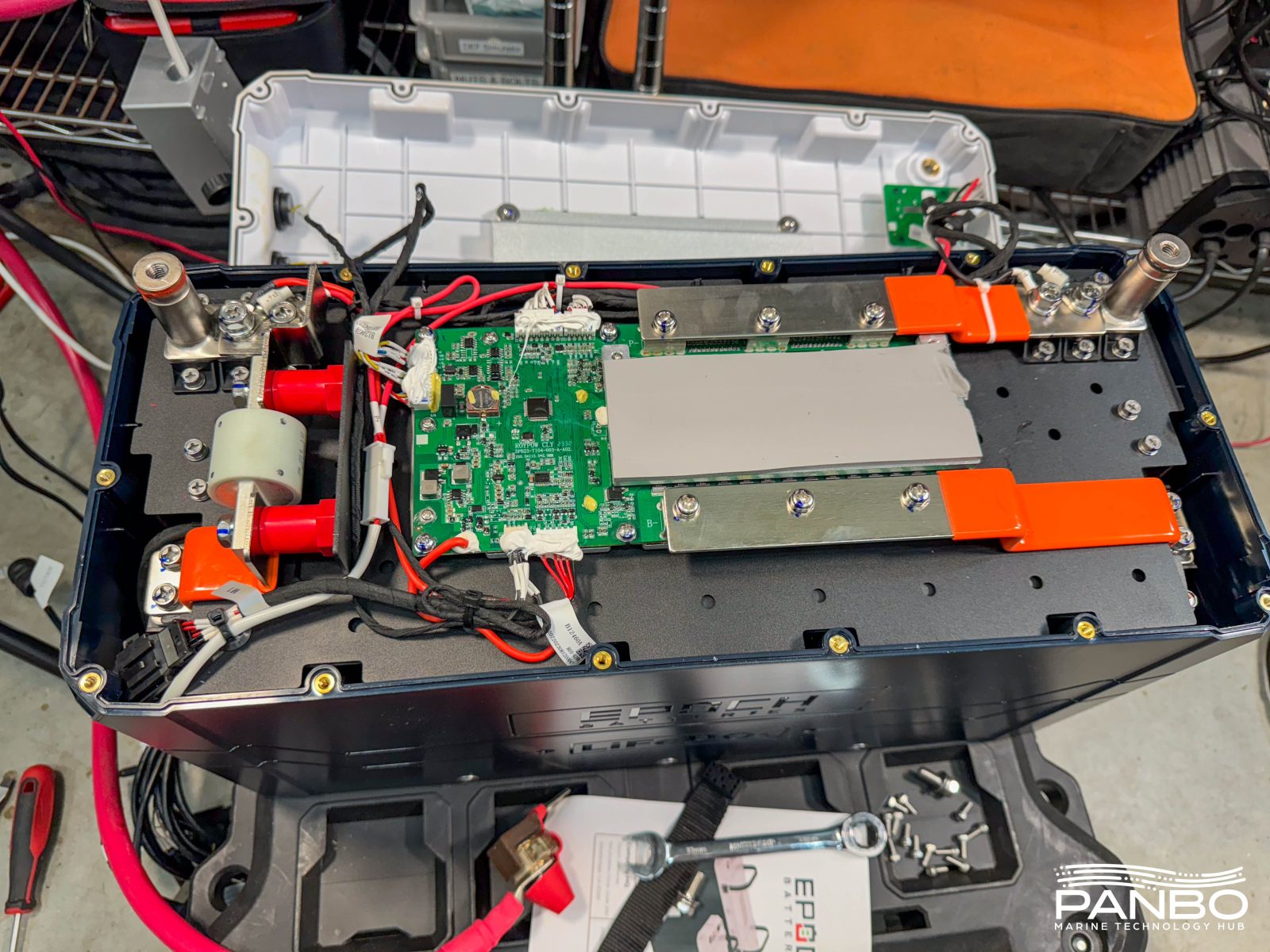

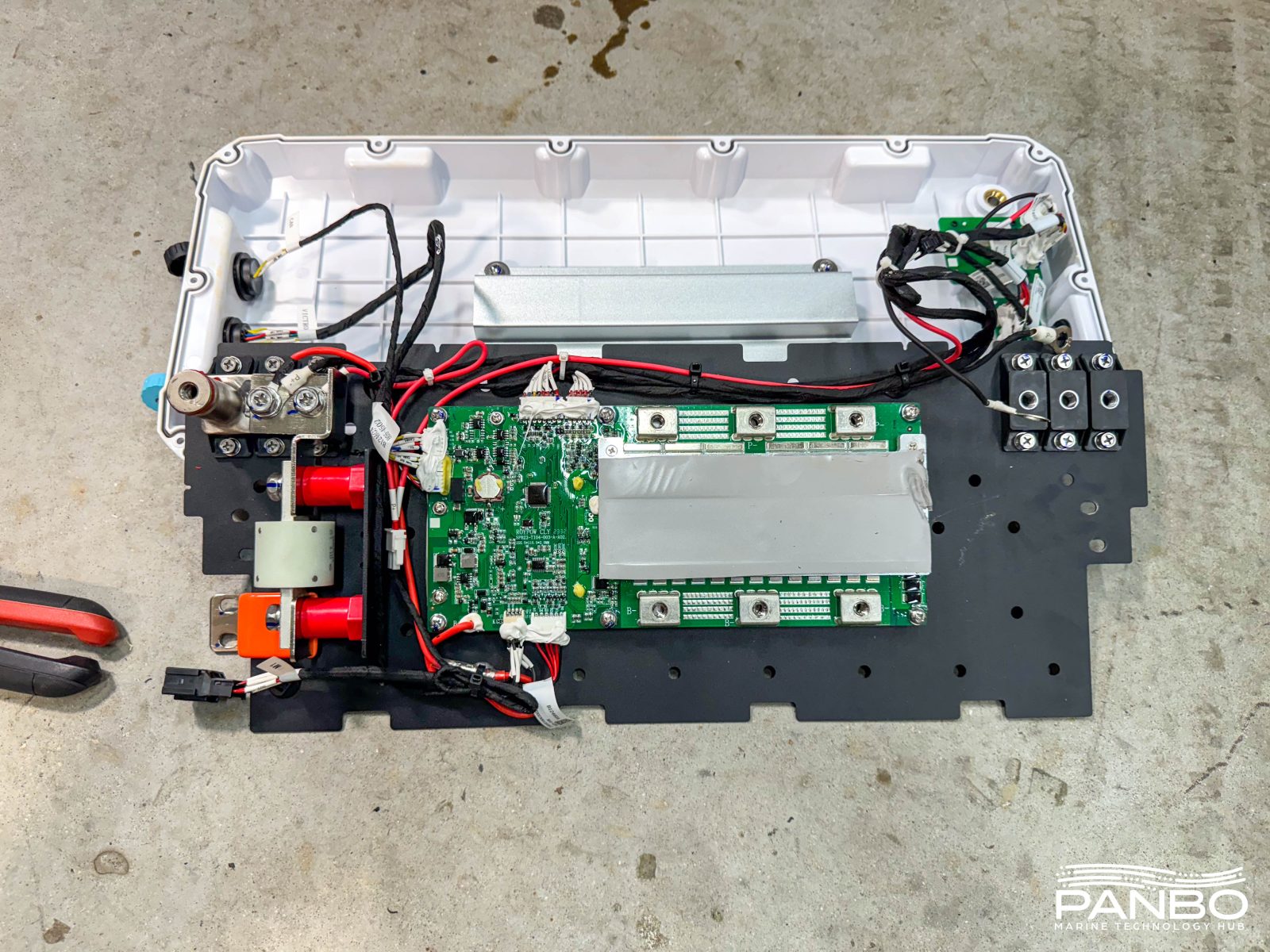

With the top screws removed, the top itself flips out of the way to reveal the BMS, bus bars, and aforementioned fuse. I’ve torn down a range of LiFePO4 batteries and Epoch’s batteries compare very favorably. The layout is clear and simple, the component quality is very high, and heck, there’s even a 500 amp class T fuse thrown in for good measure.

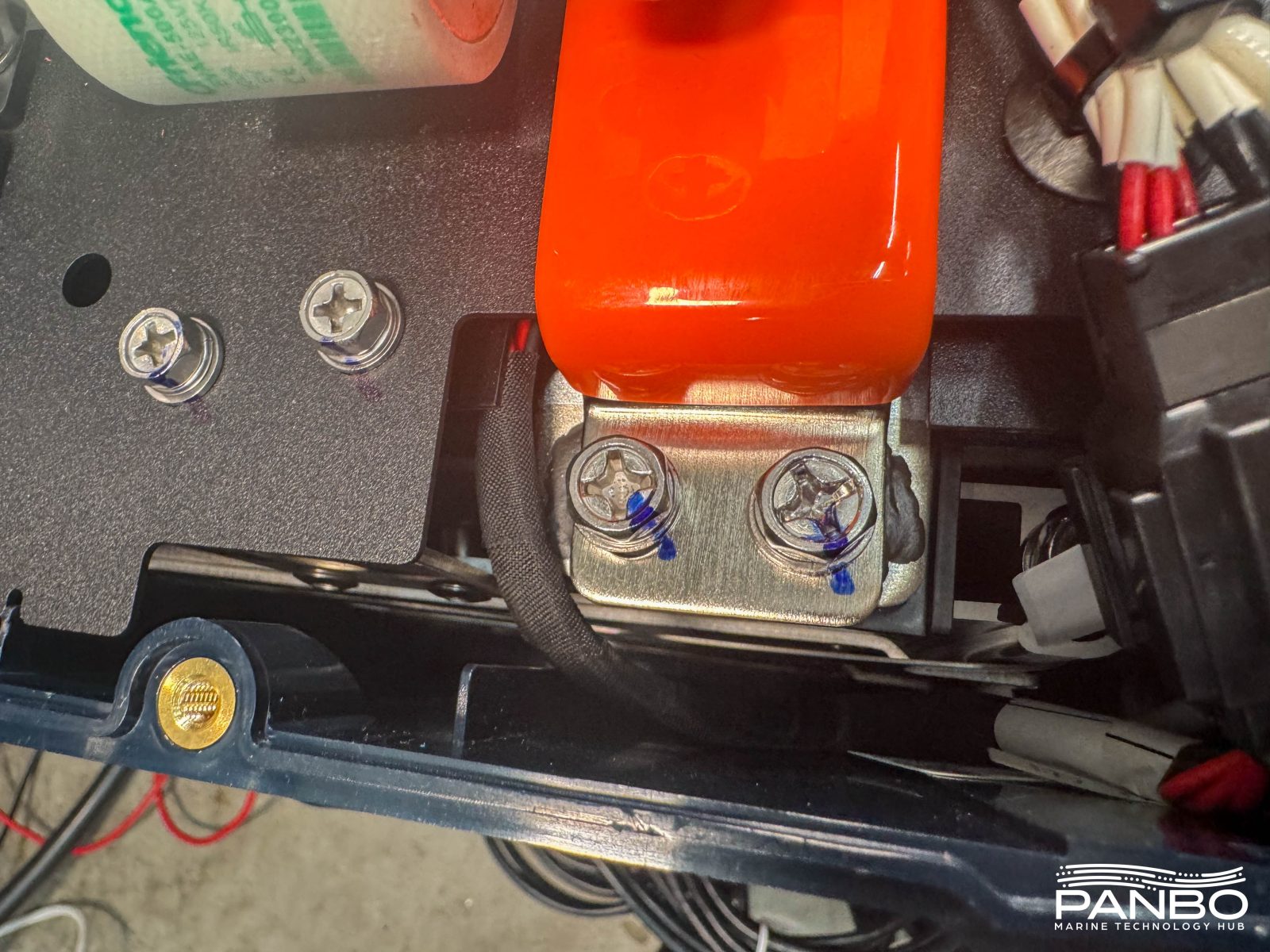

Every screw has a witness mark on it in permanent marker. These marks provide easy visual confirmation that the screws haven’t moved and are as they were at assembly. The marks on the screws securing the bus bar to the cell pack are fairly clear, but a little subtler are the marks top left above on the screws holding the top deck to the lower assembly.

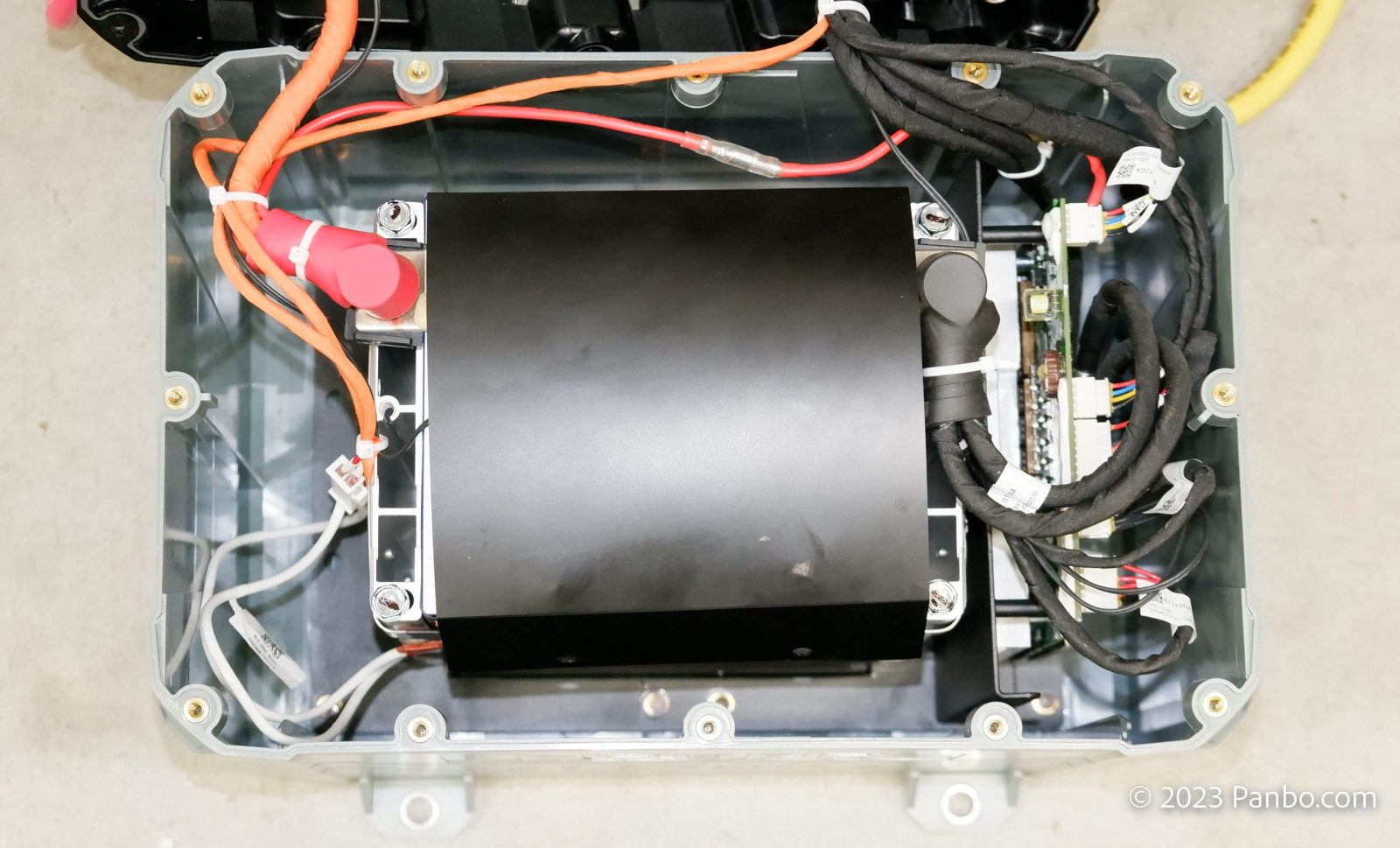

With the bus bars removed and the screws securing the upper half to the lower half, I removed the top altogether. That provides access to the cell pack which we will cover in a minute. But first, take a look at the block of thermal paste covering the FETs in the center of the image above. That paste provides a thermal pathway from the BMS’ FETs to the aluminum heatsink built into the cover. As we saw in the thermal image earlier, under heavy load, the heat sink does an efficient job removing heat from the FETs.

Cells

With the top half out of the way, we gain visibility to the cell pack below. One of the few complaints I had with the 100ah battery was the amount of wasted space in the case. The cells barely filled half the volume and left tons of empty space. That made the batteries pretty big compared to many other 100 amp hour batteries out there. There’s no such problem with the 460!

Though they’re hard to spot, there are four long bolts through the stiffeners holding the cell pack to the case. I assumed I would remove those bolts and pop the cell pack out of the case. You know what happens when you assume, right? I soon learned that in addition to the four bolts, an extremely effective adhesive holds the cells in place.

There’s nothing like seeing your shop in a video and realizing what a mess it is. I’m in the process of cleaning things up in here, but that’s another story. With the cells finally out of the case I was able to confirm the 460 seems to have the same high build quality. The aluminum stiffeners at the ends of the cells paired with tough metal strapping provide cell compression.

I’m not sure what the glue is that’s used to secure the cells to the case, but it holds extremely well. Especially considering the relatively small amount in the bottom of the case. Also, in addition to the glue, four long bolts secure through the stiffening plates at the end of the cells into the brass threaded inserts visible in the bottom of the case.

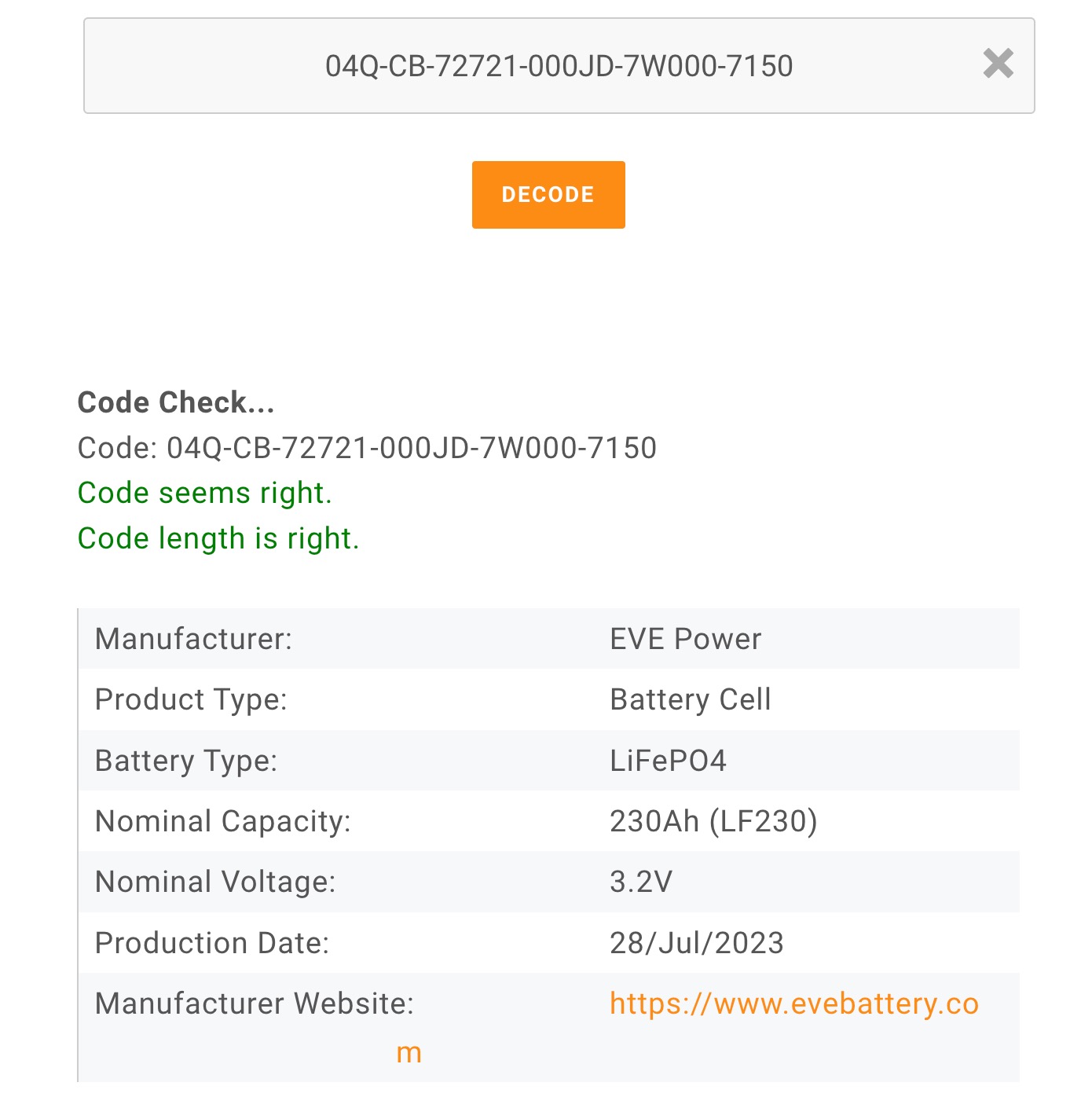

The cell QR codes are covered up by foam, but once I cut the foam away I found unobscured codes. The unobscured codes in the proper placement suggest these aren’t used or B-grade cells.

BMS

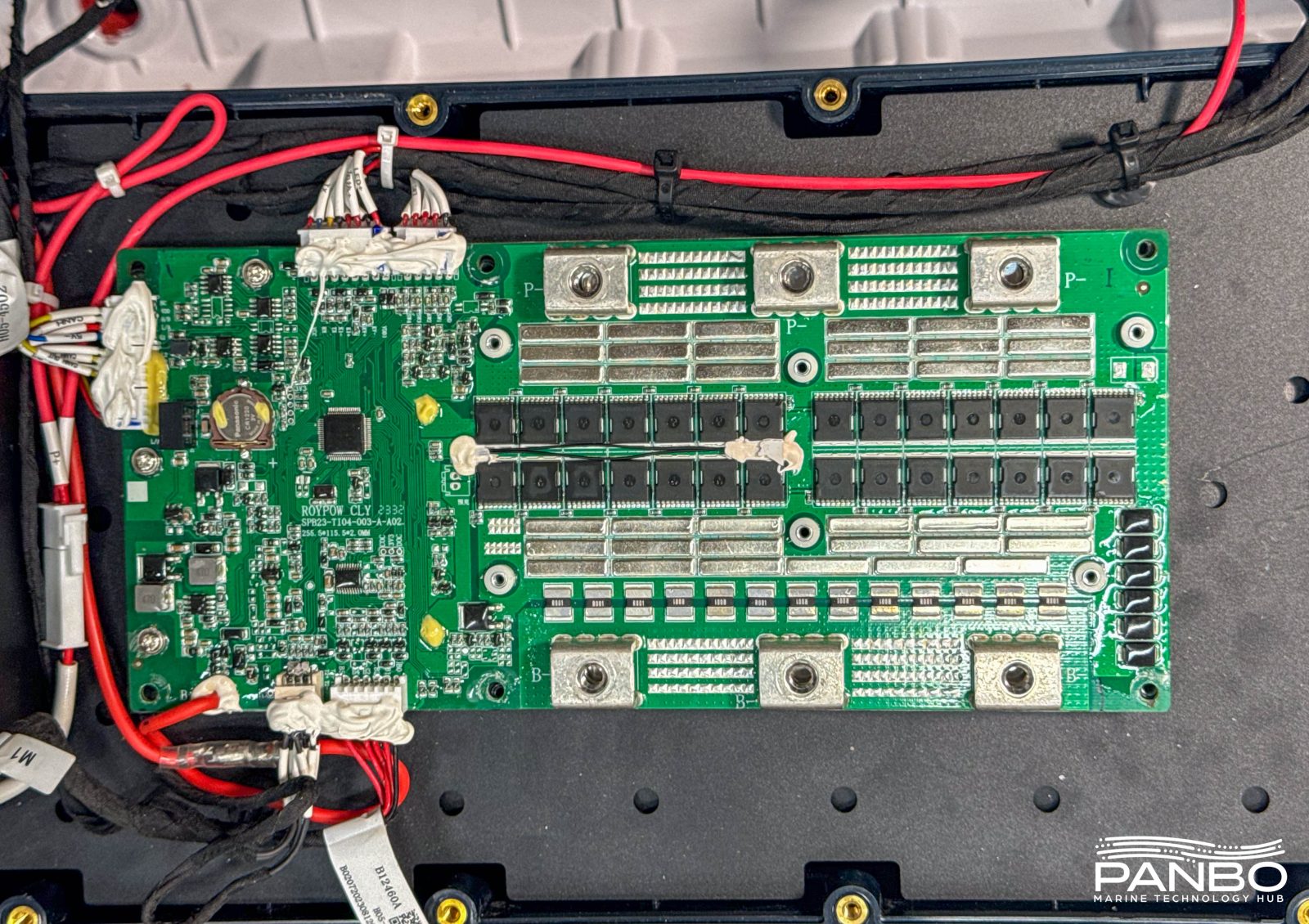

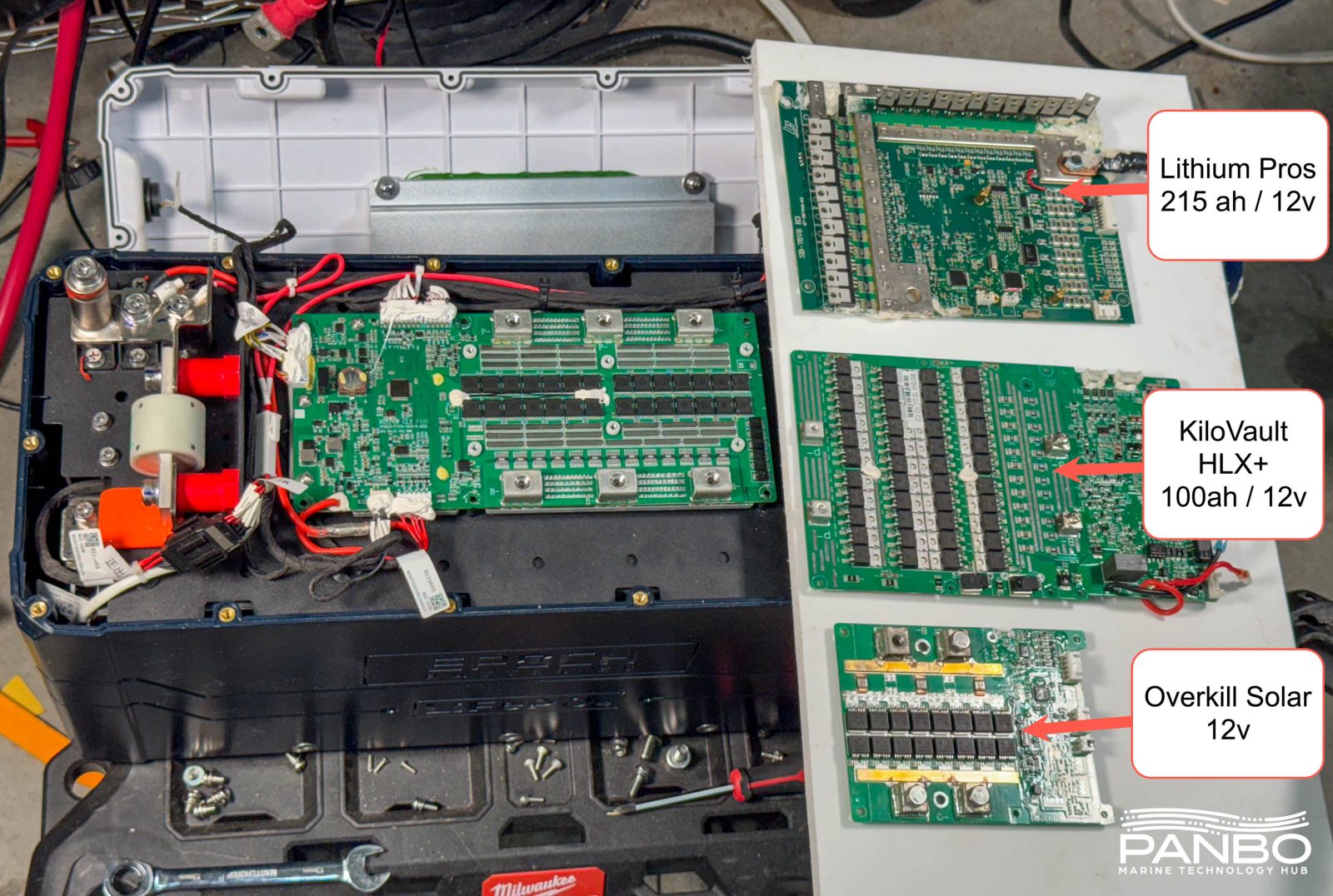

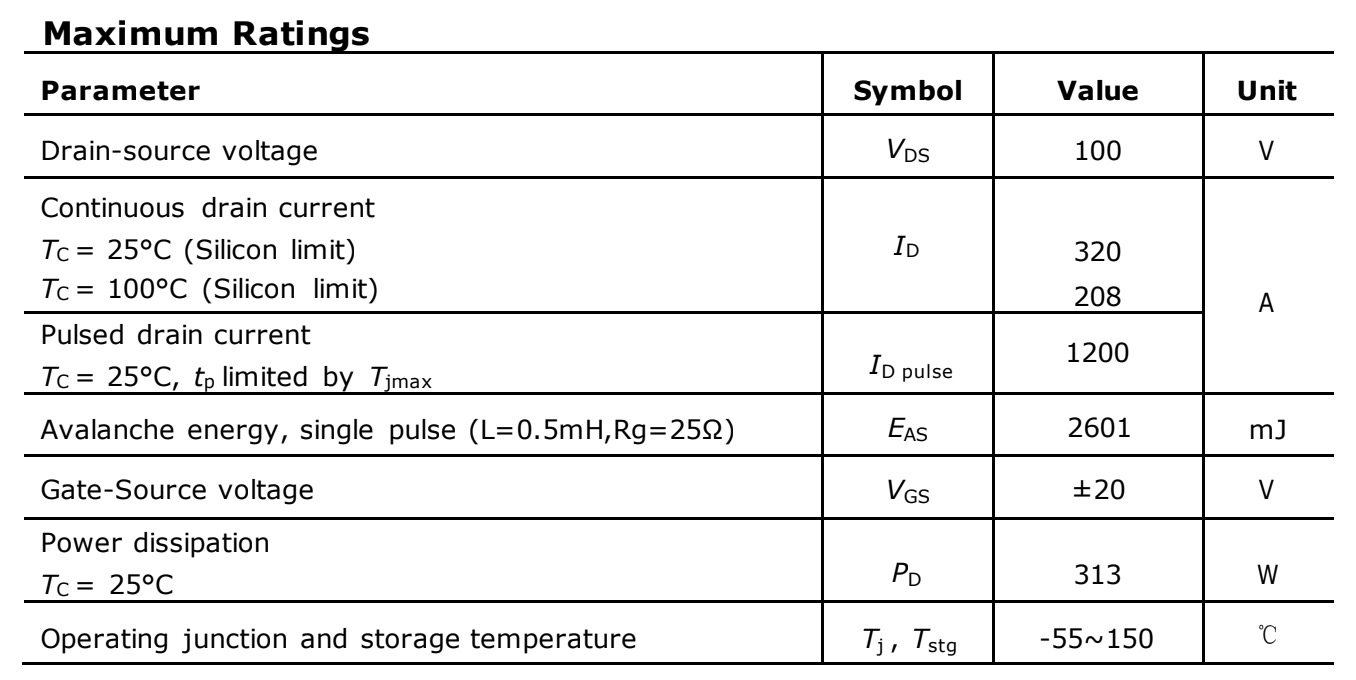

Up next I tore into the BMS to get a better look at the overall design and FET placement. There are a total of 56 FETs, 28 on the front and 28 on the rear. I believe half the FETs handle discharge loads and the other half handle charging duties. The board’s design appears robust and the components appear high quality. It’s also nice to see, like the 100 ah battery, the care taken with things like securing cables, insulation and jackets, labeling, and gluing all the connectors in place.

I’m not sure my traditional BMS comparison photo tells the full story. The current handling and durability of the FETs on this BMS appear to dwarf any others I’ve seen before.

It appears from the spec-sheet that each FET carries a max rating of 320 amps and 100 volts. But, I don’t think there’s any way the traces on the board or the FET’s ability to dissipate heat could keep up with that amount of energy. It appears each FET can dissipate the heat from a maximum of 313 watts. I’ll be the first to admit I’m over my skis trying to interpret this data. So, if any readers have a better understanding, please chime in!

Familiar goodies

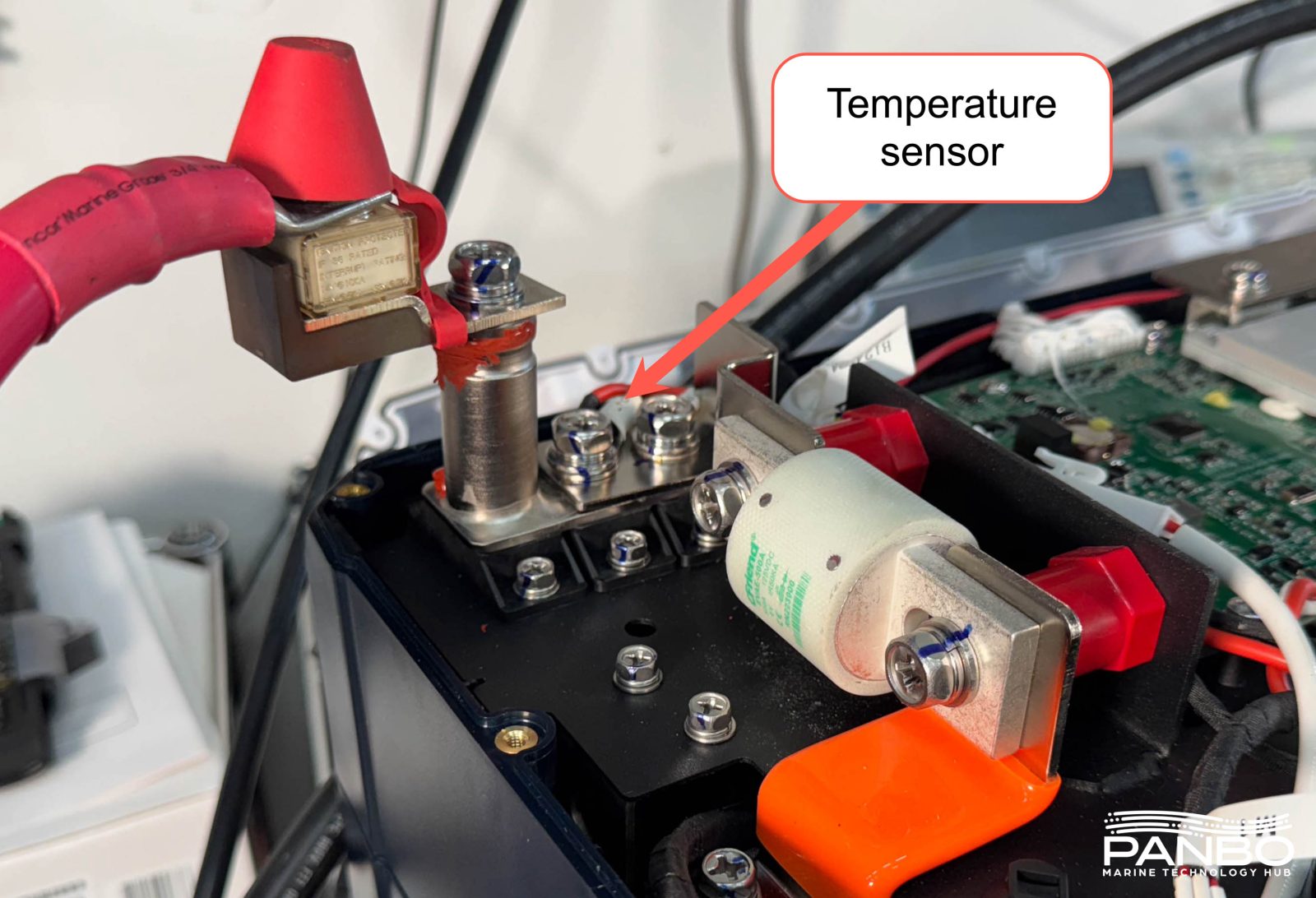

The 460 amp hour battery preserves many of the same features I appreciated in the 100 ah battery. Chief among those features are the temperature sensors on the positive and negative terminals of the battery. Prior to the 100 ah model, I’d never seen temperature sensors used like this. But once I did it seemed like such an obvious feature with so many benefits. I’ve seen the aftermath of a poor connection at a battery’s terminal. When you’re dealing with batteries that have the potential to deliver the current these do, the damage can be significant.

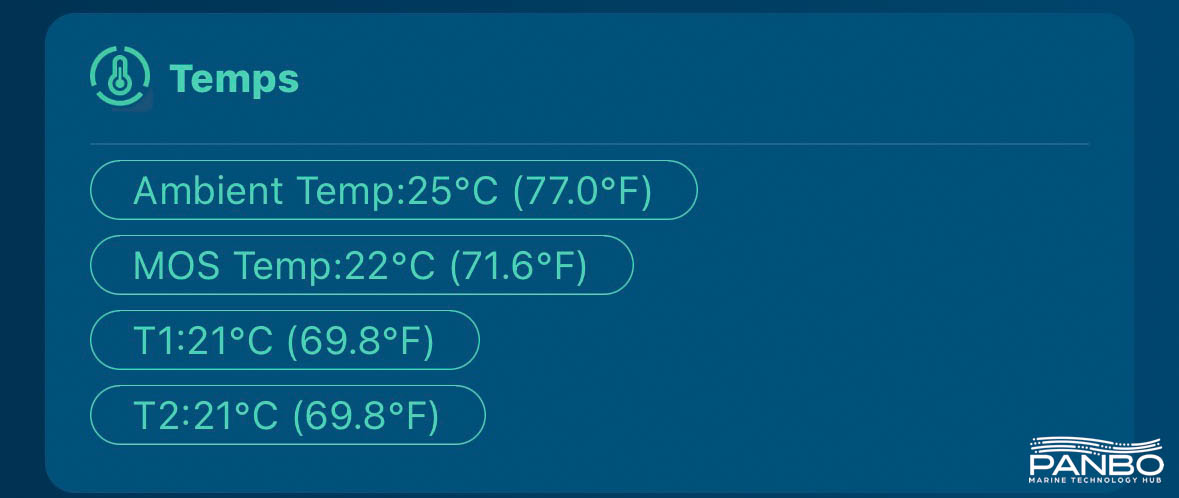

The app displays the temperature of both terminals, the temperature of the MOSFETs, and an ambient temp. I think that ambient temp is probably coming from the temperature sensor on top of the cells, but I don’t know that with certainty.

Documentation and ABYC-E13 compliance

ABYC’s E-13, the recently published safety standard for lithium batteries, spells out several requirements for compliance. In my entry on E-13, I noted that much of the standard relies on the battery manufacturer’s recommendations and requirements. Beyond extensive reliance on the battery’s manual, E-13 requires listing or approval from one of several agencies including UL, a BMS in place, and adequate water protection. There are several installation requirements and quite a few recommendations made in the notes.

So, for a battery to be able to be installed in an E-13 compliant manner, it must have a BMS, it or its cells must be approved, it must be protected from water, and the installation must follow the recommendations and requirements from the battery’s manual. The 460 meets the first three of these requirements but the current documentation doesn’t provide enough information to clear the last requirement. Several sections of E-13 reference information in the manual. In Epoch’s case, that information isn’t in the current manual. Epoch tells me they are near publishing updated literature that will provide all the required information.

Final thoughts

As I said at the beginning of this review, the Epoch 460 is one hell of a battery. It isn’t perfect and I’ve highlighted several of those imperfections. Most notably, I think the current sensing floor and data availability issues take some of the shine off the Victron communications. But, I still believe this battery provides pretty phenomenal value, safety, and performance. I would strongly recommend that if you’re going to install these batteries you add a Coloumb counting battery monitor.

I’m about to revamp the house bank on my RV and plan to leverage four 460/12s for that project. Currently, to my eye, these are the most compelling batteries available in the market. I’m excited to put a set to work and be able to report on their real-world performance.

Great article Ben. I appreciate it. I did a few testing videos and fount basically the same items. Especially the current sensing threshold. Luckily I already had a smartshunt. As a result I also think its a good idea to have one. In addition if there is ever a problem with comm cables or some other reason the Victron comms dont work you could quickly revert to using the shunt for charge and discharge control and info. Very happy with purchasing the pair of 460s for the boat.

Seeing how these go together further points to me liking them as an option. What I’m left wondering about these (and also the metal cased 300ah Epoch Essentials units) is whether orientation matters for installation. Do they have to be upright, or would they work fine laid on their sides or stood on end?

Info from Epoch is that any orientation except upside down is acceptable.

Good to know, thanks!

The OEM 500A fuse is available direct from Cfriend in China but expensive shipping or from AliExpress for around $35. Email me for info.

Has one major drawback – it’s made in China. That puts it out for me. Would be different if it was made in Taiwan.

Nearly 100% of the LiFePO4 cells on the market are made in China. You may be able to find a battery for which final assembly is outside of China, but at least the Cells will nearly certainly be made in China.

-Ben S.

I know that you reviewed installed and tested the Mastervolt MLI 12/5500 How does this stack up to that battery or the newer Mastervolt 12/6000? I know the former would cost more but wouldn’t the individual cell monitoring be worth it?… also a 460Ahr choice

Really looking forward to getting my hands on these in Australia. We have done alot of roypow installs. And roypow did say they build these batteries for epoch however the patent is owned by epoch so we won’t be seeing a roypow branded version any time soon

I looked for Epoch on Google Patents that i didn’t see anything, did Epoch say somewhere they have a patent on it? RoyPow makes a version of this battery case as well. If you Google RoyPow36v 100ah you’ll see the same enclosure. I’m guessing they just white labeled this size?

The 36v 100ah case from roypow is similar but different.

Roypow stated to me that they built the battery for epoch. Though epoch had a patent on the design “as in the technical design” I don’t know about the case. I’m not sure why you would bother putting a patent on that case . That said roypow said they wouldn’t be making their own version. I stead they have come out with a 400ah version using their case design from their 48v range

It’d be interesting to see the RoyPow version. Those guys build so many of the batteries everyone uses. I’m curious about the ability to patent a design for a battery! Never have heard of that. Thanks Moose!

Hi Ben, with regard to the FET specs, there are several things going on. First, they have these devices in parallel so they are sharing the load or charge current – while in an ideal world they would share it equally, in reality differences measured in micro- or pico- ohms will make a significant difference in how much current each device actually has to pass – so the devices are significantly over-rated for that reason. The 313 watt dissipation rating is dependent on being tied to a perfect heat sink at 25C, so in reality, they wouldn’t be able to dissipate that 313 watts for very long – and the same principle of some devices getting an unequal share applies – hence the significant over-spec.

This does bring up a question – do they really have two paths from the terminal to & from the cells, one for charge and one for discharge? If the discharge is on, does it prevent charging? (and vise-versa, of course 🙂 )

Hartley

S/V Atsa

Great info Hartley. All makes perfect sense. Your question about the sigle pathway to the cells got me thinking how the charge and discharge is controlled. From reading just now It appears many mosfets are unidirectional. So that makes sense too. Also…you can use the Roypow app to open and read the Epochs. In the Roypow app they give you the ability to turn off/on the charge and discharge mosfets with a toggle. Each side does in fact only control a single operation. I tested it several times. Pretty neat really. You can also engage the internal heater manually. One word about using non-Epoch apps. On a different battery with a JBD bms I tried the Overkill Solar bms app, which is not the oem app. It locked me out of that batteries bluetooth for some reason and I havent been able to get it working again. Even by disconnecting the bms and bluetooth module.

I was thinking the same thing about charge and discharge. Are they using diodes? I had a charger on a bat and at 13.5v the charge fets where off while the discharge fets were still on

They use a separate FETs for discharge and charge. For charging, you want to be able to turn off the FET in case of an error or if the battery pack is full. For discharge, you want to be able to turn the battery on/off and also to disable in case of an error. TI makes several battery monitoring BMS ICs that directly control the FETs.

As for MOSFETs, they block in one direction until you put a voltage on the gate. In the other direction, there is a body diode that conducts when the voltage is reversed.

While having perfect amp readings via the BMS can be useful, in practice paralleled LiFePO4’s will usually deliver differing amp flows due to variation in their internal resistance. While a common issue on low cost batteries, I’ve also noted this on a Victron battery system.. Having a battery monitor with shunt is therefore vital to monitor overall status of multi battery systems.

For me probably the biggest safety issue once fusing has been dealt with, is salt water flooding. To that end I do like a fully sealed LiFePO4 however the Epoch’s !P67 rating and construction quality looks good.

Would be interesting to know if a short circuit trips the BMS before the fuse blows? Could be a nuisance on a paralleled bank if it blew each battery’s fuse. Also from what I’ve seen the BMS and connections add considerable resistance so limit short circuit current such that external Class T fusing should be sufficient for most installations.

Finally thanks Ben for all your excellent work. I know these reviews must take huge hours to put together. Much appreciated 🙂

Typically, the BMS should detect short circuit conditions and turn off the FETs. However, if there is an issue with the BMS, then the FUSE is a last resort feature.

For now, the inclusion of an internal fuse on the battery does not automatically preclude requirements for class T fuses on the output of the battery. The AIC rating of MRBFs are only 10kA. I can’t find the let-thru current specs of the fuse they are using, but the let thru current of their fuse could easily be over 10kA (I could not find published data on the fuse they use). We will have to wait for the battery manufactures published specs to know for sure.

The article above stated its rated 50k

Here is a link to the fuse specs

https://www.hannovermesse.de/apollo/hannover_messe_2021/obs/Binary/A1089381/Fuse%20manual%201.pdf

ABYC standards only specify the AIC of the fuse. There’s no mention of a specific fuse type, form factor, etc in the standard. But, because they specify 20k amps for large banks and any size LiFePO4 bank, Class Ts have become the defacto standard as the only fuse typically used in marine applications that meets the requirement.

I’ve looked at the standard and tumbled it around in my head as well as discussed with several marine electricians. I can’t see anything in the standard that would require another high AIC fuse outside of the battery if the battery is equipped with one internally.

I think it’s worth noting that we’ve had a similar discussion previously about BMSes that interrupt the circuit in the event of over-current situations. Those discussions concluded that setup doesn’t meet the standard because in the event of a BMS malfunction, there’s nothing to provide a safety net.

-Ben S.

Thanks for the link. I have seen that data sheet. The problem is that they don’t define the let through current, so we don’t know what the short-circuit current is.

E-11.10.1.2.3.2 say that you need to have a fuse with an AIC rating of greater than 20kA if the AIC is greater than 10kA. Until we get the actual short-circuit current from EPOCH, we don’t know what type of fuse is required.

I think part of the confusion is that most people don’t understand how current limiting fuses work. Here is an article that explains what is going on.

https://www.eaton.com/content/dam/eaton/products/electrical-circuit-protection/fuses/solution-center/bus-ele-tech-lib-fuse-let-through-charts-current-limitations-charts.pdf

For what it is worth, MRBF, ANL, etc. fuses are not current limiting.

I don’t know, Andy – their wording is a bit different from what we are used to seeing, but it does sound a lot like AIC to me. “Breaking capacity: 50kA (125Vac, 220 VDC)…{with a 20 kA rating at higher voltages, which makes sense].

I would think that the ABYC was concerned that the fuse in question would interrupt the current flow, not what the peak current was before the fuse blew.

We all know that fuses are not instantaneous – if you subject them to a massive overload, they will conduct a greater-than-rated current for some (hopefully small!) amount of time, which is what you are talking about with your “current limiting” discussion. I doubt the ABYC is concerned with this at all, since all they spec is the maximum interruption rating.

If you have an MRBF or Mega and its interrupt is 6k, The Tfuse in the battery or batteries would blow well below the 6k needed to jump the gap in the Mega or MRBF, so as long as the class t is less than 6k amps (500amps in these) then AIC is achieved and a smaller fuse outside the battery is needed to correctly size for wire.

As for time – the mega or mrbf would blow quick enough to protect your wiring….. but if by chance a dead short that was big enough to exceed the AIC of the mega or MRBF, that amperage would immediately blow the class t. (it would have to be atleast 6k amps to allow current to flow…. then the time to blow with 6k amps on a 500 amp class t is pretty much instant)

The Epoch website is horrible. So far I get about 1/4 of a page to load. All the other links at the top do not do anything. I am glad their battery is better than their website.

Hmm, I have some complaints about the amount of information they make available, but I’ve never had any troubles getting the site to load.

-Ben S.

Don’t worry, like Ben says, what you find there won’t help that much–yet. (I have hope for them, but it’s a verify, then trust situation.)

I agree. The website is terrible.

I don’t experience loading issues, but the information is…let’s call it ‘lacking’ to be nice’.

The ‘Support’ has no documentation and the page directs you to their DIY Facebook Groups.

There are also a lot of inconsistencies, like flipping between whether a model is IP54 or IP67 rated in the one page.

The FAQ is a complete was of time with the vast majority of canned questions having “TBA” as the ‘answer’.

Whilst the product looks great and has a lot of good tech, they need to pull their finger out and get their customer facing side sorted out.

Any idea what parameters the onboard BMS uses to determine a ‘charge cycle’? I just recently installed my 300-V2 battery. It came 50% discharged and it drained down to 43% before i had the time to install it. The charge cycle was at ‘1’ when i received the battery. After charging to 100% it still is at ‘1 cycle’. Does anyone know if it has to be discharged below a certain SOC before it registers a new cycle? Not that its an issue. Im more curious than anything.

Joe, Its quite surprising to see the rate of cycles as you rack them up. This is something we rarely ever kept track of with lead acid batteries and we typically used our gut and the calender to determine cycles..lol. on my golf cart I have been using lithium for quite a few years. On the Original Dakotas they were “dumb” batteries so I was again estimating. But since going with Epoch I have kept an eye on cycle count and what constitutes a cycle. I still dont know. Obviously there is an algorithm that compiles, I assume, voltage deltas high and low along side event of frequency counts and determines what constitutes a single cycle. When I discharge from 100% soc to 85% and then recharge it never registers a cycle. If I do that some number of times an additional cycle appears. If I do a deep discharge and full recharge a cycle count seems to appear. Paying attention to this has led me to several loose conclusions.

1) If a battery manufacturer where less than honest you could fudge cycle life counts in a manufacturers favor. But I would think there might be a standard for what counts as a single cycle. Not sure.

2) If #1 above gives an honest account of cycles, these batterries are going to last a very long time.

3) After monitoring how slowly cycle count rises in a battery that counts them and noticing it to be much lower than my perception expected…I never actually got the number of cycles I thought I was getting out of lead acid batterries..lol.

Victron Smart Lithium/Lynx Smart BMS has 2 different “cycle” start thresholds, depending if using DVCC or not. The default for DVCC is 70% and is configurable. Without DVCC, the monitor uses 65%. In either case, one has to meet 90% on the charge to log the cycle. With node-red, or manual monitoring, one can keep the cycle counter at 0 all winter long just by keeping above the cycle start threshold or stopping charging at 89%.

Some of you have seen my consternation with the Epoch manuals/documentation or forthcomingness of the marketing there. Understanding the system is, to me, a safety issue, but I come from a world where i get checkrides every 9 months and constant training. Many boaters don’t care, or need to know, but the information should be made available…

In the state of charge meters and the BMSs I’ve worked on, we define a cycle as the total percent that you charge a battery. For example, if you charge from 50% to 80%, that would be 0.3 cycles. After you do that a couple of times, you will get up to one full cycle. I’m sure other people do it other ways.

Interesting. Thanks for replies. That makes logical sense. I’ll have to keep an eye on it out of curiosity. The battery will calendar age into oblivion probably long before it hit the max cycles anyways.

I contacted Epoch because I think this is a great battery, but as an 8D is too big for easy installation on my boat. I suggested they make a similar battery with the same features – internal fuse, victron interface – in a 4D case. The capacity would surely be less, but I’d still buy it.

I know they are working on other sizes besides the 460. As I understand it, there isn’t anything to announce yet about additional sizes. Hopefully soon.

-Ben S.

Nice review. I still don’t think you have seen a class T fuse in a battery. Isn’t class T a UL classification? 😉

The fuse is IEC gR/EV rated and I believe it is a suitable substitute for the UL class T, but it is a faith based equivalence with just a little research on the IEC standards, and asking a few electricians and experts.

These seem like really good competition in the market place if they meet your use case. I wouldn’t want to be using a lot of power in a 12v system…24v and 48v make for more efficient systems, and the limitation of 4 batteries total in the configuration just makes the stored energy budget for overnight aircon, with no expansion potential. Still, it would be doable with some compromises (read: higher temp for less duty cycle)

I hope they send you one of the cranking batteries for review when they arrive. It is a promising spec for a use case I really want–starter/windlass (maybe bowthruster) AGM replacement.

Well, Jim, as Ben S noted above, the ABYC doesn’t require a “Class T” fuse, just one with an interruption rating above 20,000 amps. The factory spec for the fuse inside the Epoch battery says it will interrupt 50,000 amos, so it would seem to be sufficient to the task. The reason we’ve been discussing “Class T” fuses is that up until now, its the only one of the commonly-available fuses that meets the ABYC requirement.

Personally, if I was about to make the jump to LIFePO4, I’d be looking at this battery pretty hard. We made the shift with Victron two years ago, when the available selection was a bit more limited 😉 Now I’m thinking about getting another Victron 12V 330ah to buck up our reserve capacity.

Hartley

S/V Atsa

Not sure I said that a class T was required…just that he still hasn’t seen a class T fuse in the epoch or any other LFP battery—yet.

Class T is a UL classification and that really nice fuse in the epoch isn’t a UL class T fuse. Like you said, it doesn’t have to be. Possibly, the reason we have been referencing class T fuses is because that is the UL class and the “A” in ABYC references American standards.—the UL.

The IEC standard for the gR class covers semiconductor devices for short circuits and overcurrent protection. Because we are protecting the circuit, the logic seems to be that so long as the wiring outside the battery is fused to protect the external wires from overcurrent, it should be safe with the internal fuse interrupting for short circuit protection in the battery power circuit.

Like you, I’m considering adding more capacity to my Victron house bank. The introduction of the Epoch/Fogstar with the JBD BMS has increased the communicating LFP competition and I think that may be a part of the reason for the recent drop in smart lithium pricing. . I sure would have looked at the epoch, but I’m pretty sure I would have gone with the Victron. At today’s pricing, I am sure I would go with the Victron.

Re:Engine Starting – I note on the specifications on the battery that the maximum discharge is only 500A(30sec). Does that spec eliminate use of this battery in boats where the house battery is used for engine starting?

Hi Gary – unless your engine is really large (or hard to crank!) you’re not going to draw anything near 500amps starting it. The fraction-of-a-second inrush current when you turn the key might approach that, but the running amps will be less. Now if you have some 1000 HP beast, you might consider different starting battery 🙂

Hartley

It’s going to depend on the engine and the battery both. I occasionally start my 3GM30F Yanmar from the LFP bank consisting of 2 200 AH batteries each rated for 150 Amps continuous discharge. The engine roars to life and the batteries don’t seem to notice. If I wasn’t a belt and suspenders type, I’d probably ditch the start battery.

My boat has a 440Hp Yanmar (6LY2A-STP of 2002 vintage) configured to start from the house battery nominaly rated at 400Ahr (4x110Ahr Firefly). I am unaware of the start current but it starts very quickly. Going to primary start battery configuration would require electrical system rewiring, so I would want the manufacturer to confirm the battery use profile to include larger engine starting capabilities.

Gary, the starter for that engine is rated at 2.5 kW, so 200amps at 12 volts – or, more likely, 250 amps at 10 volts. I would suggest telling Epoch the starter rating to get an educated answer 🙂

so interesting

Roypow has just sent me their technical manual/specs on their new 400AH 12v battery that seems to utilize the same architecture in this epoch battery they build, albiet in a very different case. about the same weight .

@Moose.

Any information on the networking side of things?

so Victron canbus connectivity is included, it has 2 network ports “same as epoch” on the front along with dip switches. interestingly though it has 4 terminals. not to sure how i can post a photo into this forum.

maybe Ben would be able to ??

Edited by Ben S. to add a photo and link to the spec sheet

https://panbo.com/wp-content/uploads/2024/02/RoyPow400ahScreengrab-aPanbo.jpg

The PDF of the spec sheet is also available here.

Thanks Moose!

End edit

I have been watching roypow. They have their trolling motor line, but nothing comparable to the 460. Although they look identical.

So roypow is the manufacture of Epoch batteries, a rather massive company seemingly always at some interesting trade expo every week around the world.

they build the 460 for epoch, however Epoch holds the patents for it, so we wont see a roypow branded 460 any time soon it seems.

however they do have the same tech available in the 48v range, and their new 400 battery seems to be a 12v version of their 48v pack. depending on the type of install it looks like the roypow will hold its own , especially if wanting to run multiple packs “up to 4”

I am sure you have seen the Fogstar Drift series which is RoyPow, as well. : https://www.fogstar.co.uk/collections/drift-pro-lifepo4-leisure-batteries

I have no idea how different Epoch’s BMS is to the Fogstar’s semi-custom JBD, but i wouldn’t doubt that they are pretty close cousins.

On you question in the next post: if they are “press to connect” plug type connections (common in server rack systems), you might think about the risk of a disconnect due to vibration, jolts, etc…you know, the things that happen in a boat. There’s two of each so the cables can carry the current with reasonably sized cable (I doubt they are tinned), but many feel (self included) that the only reason to double current carrying cables is for voltage drop mitigation and each needs to be fused and capable of carrying the entire load/charge. 12V has consequences.

Very interested in hearing opinions on the battery terminal connectors with the rp battery

Im curious if you ran across this in your testing….

I have to set absorption no higher than 14.0v to get proper charging function. At the very end of the charging cycle I find that the Epoch BMS doesn’t balance cells well and one starts to run away from the others every time. To the point of getting a cell overvoltage warning. This has happened to 4 different batteries. 14v seems to be working just fine and lets me avoid the issue.

The bms on my batteries is shutting off @ 13.8 for me

Jason,

Your comment is timely. In the last few days it has become clear that what looked like a random anomaly might be a bit more of an issue.

During my testing, I saw a few high voltage alarms as the battery neared fully charged towards the end of the absorption cycle. In conversations with Epoch, it seemed the root of the issue might have been too short of a delay on tripping a high voltage alert. The theory at the time was that perhaps as charge acceptance tapered, the inverter momentarily allowed voltage to climb and with a very short trip delay, it was generating an alarm.

Throughout my review, and continuing as we investigate what’s happening, I have been in touch with Andre, co-owner of The Yacht Rigger who recently completed an impressive install including four 460s. They also observed the high voltage alarming and decided to disconnect Victron comms in order to avoid the nuisance alerts for the boat owners. For quite a while, that seemed to be a good solution until the end of last week when the boat experienced more unusual behavior. That behavior included signs of voltage fluctuation, like intensity changes in lighting, and ultimately a fault condition that left the boat without house power.

I spent most of the day in Tampa with The Yacht Rigger visiting the boat and trying to understand what’s happening. We had a tool that is supposed to connect to the BMS’ CANBus interface and allow detailed visibility into the batteries’ operation. Unfortunately, the tool wasn’t working so we are waiting for new units. As soon as those are received we will carefully monitor the behavior of the batteries on this boat as well as my test battery and see what we can figure out about what’s happening.

The unusual part of the behavior is that it seems there is something triggering a range of Victron inverters to poorly regulate charge voltage towards the end of the charge cycle. We don’t understand this behavior yet but hope to have more clarity once we have better visibility into the BMS’ operation and parameters.

I will update this thread once I have more information. In the meantime, if others have any information from their own experience, please feel free to share it here.

-Ben S.

good to hear im not alone. That means hopefully this will get resolved by Epoch eventually.

To be more clear….

This issue has happened on two 460 units and two of the 300ah essentials units.

I had to also disconnect the Victron comms as it caused an alarm often.

So far it seems 14.0v absorption and 13.6v float is working without alarms with the Victron comms disconnected. Though now I will certainly run through a few more cycles to see if this remains ok.

On the 300ah units I had to set absorption to 13.8 or 13.9 to stop this from happening and preventing a cell to run away from the others.

My bluetooth app also only works sometimes for the 460 units. It will always show state of charge and overall voltage but not always cell voltage info. And sometimes it shows all faults for a few seconds even though the battery seems to be functioning fine.

Equipment is fully Victron aside from the batteries.

It took a lot longer than I would have liked, but here’s a video showing the full charge protection function in action.

https://youtu.be/yPFaH-b1b0Y

It seems like there are probably two factors causing the charge MOSFETS to close. First, the full charge protection feature I covered in this video. The second issue I think is impacting the batteries is cell balance at top charge. My working theory right now is that the passive balancer on the BMS can’t keep up with any large imbalance of the cells. I believe the passive balancer is capable of only 1 amp or less balance current. If that’s the case, that’s a very small adjustment against 460 amp hour cell pairs. More investigation is underway on that and I’ll report back when I know more.

-Ben S.

Precisely. I think I’m estimating 1-1.4

When I get around 2. 5 amps or less going in on a balance charge… I was able to achieve 14.0 anything more and I’d get OV. That’s how I started recommending that charge spec for balancing.

Bench top charger is great for this.

During my reading on these topics it seems that most, if not all Victron capable batteries sometimes have these same issues. One of the most used Victron capable batteries in use is the Pylontech. They are widely in use and have a several year head start on Epoch but in a non-marine capacity for off grid systems typically run at 48 volts. If you google search “Victron Pylontech over voltage” you will get tons of hits on this topic. Of course there is no guarantee these issues are exactly the same I feel like they are likely very similar. If you go to the Victron page detailing Pylontech information you can read through quite a bit of similar troubles and ways to remedy. Keep in mind Pylontech and others have these issues and they were actually “certified” by Victron back when Victron tested these things. You can see that info here https://www.victronenergy.com/live/battery_compatibility:pylontech_phantom#my_system_only_charges_the_battery_to_52v

There is potentially a few nuggets that may be applicable there. In addition I would like to ask if all of the people having these issues are running solar? There is also a train of thought in many discussions that both cell overvolt and battery overvolt may be cause by sudden spike in solar output for various reasons. That may also explain flickering lights and other anomalies. But this issue seems to have been around for a while and is pretty difficult to penetrate.

In the mean time people seem to just turn down the voltage on the DVCC. However some are reporting

Ben, when the power shut down and vessel went dark did the Epoch discharge mosfets shut down when the Victron comms were disconnected?

Jason, you said you set absorption to 14.0? Are you not using Victron comms to a Multiplus or other Victron charger? If not and you are using your lithium settings, you may double check all of your settings. If you are using the Victron cable from the Epoch to a Victron Multiplus or other capable charger then I believe absorption settings along with mos other settings are not in play.

Mathew, when you say your BMS is shutting off, are you also using a Multiplus and Victron equipment? When checking the app in this condition are both the charge and discharge mosfets off or just charge mosfets turning off?

Thanks for the feedback and I will be following to continue to learn.

This is probably a red herring, but it is easy to check… I’ve seen issues with DVCC and over voltage in other Victron configurations (no lithium) when the GX device driving the DVCC gets overloaded and slow to respond. Being overloaded will typically show up as big spikes in the d-bus round trip time metric available in the VRM graphs.

Yes when the Victron Comms cable from Epoch is connected it feeds the cerbo all the info about settings it needs. However, it became clear that this just doesnt work correctly. Alarms often about overvoltage coming from the battery to the Cerbo.

After that I disconnected the epoch cable and put in the settings manually as I usually would do. They are correct. Well…besides having to use a lower absorption and float of course.

This issue happens regardless of charge source for me. It happens on Victron solar controller, Multiplus 3000 shore power and Victron IP65 charger.

The same behavior occurred when charging the EPOCH 460 with the Zeus voltage regulator and a Balmar AT-165.

I won’t be able to test again until after the 15th.

What charge settings were you using for the the Zeus? So far in my experimenting I’m planning on a max charge voltage of 13.8.

If I recall corrrectly, I was using 14.2 bulk and 13.6 float. I’ll be back in the shop next week and will confirm.

Has anyone seen different firmware versions with the batteries. I’m seeing version 15 and 16. I emailed epoch about what the current version is and how to update, have heard nothing back

I have successfully balanced a few of these now.

First make sure your cables and everything are equal… equal torque and proper installation.

It helps if when you do your initial charge you use a bench top charger so you can monitor tail voltage and evenly get the battery properly charged for the first time.

If you have installed and only see voltages of 13.4 5 or 6 then the following will get you there.

Bring batts to below 13.3 for the highest cell. Switch inverter to invert only if you have to… and run her down. You can view it in the details section of the batteries on the Cerbo/Ekrano or app. You can do all this remotely if you need to.

Charge at 5 amps up to 13.6 then reduce the tail voltage- charging till you get alarm. Drop again. 13.2/13.3 …going that low turns off the restriction on charging. Charge up to 13.7 and hold, drop amperage to the lowest possible after house loads keeping in mind the bms will not see amperage below 1.3 amps. Use this small tail voltage to slowly bring voltage up to 13.8 then 13.9 by changing the dvcc volatge setting one tenth of a volt at a time letting batteries sit and slowly even out. Keeping the amperage as low as you can bring the voltage up .1 at a time. When you get to 13.9 go 13.95 go until you get an alarm. Repeat the whole process again. Eventually you will be seeing 14.0/14.1 usually in just a couple cycles.

I set float at 13.4 and abs 14.0 or 14.1.

Jake. Thanks for the great info and good experimentation. It makes sense. I saw these 460 owners having these issues and was wondering if I maybe I missed something on my bench testing since I wasnt having these issues prior to tearing down the bench set up. I was having them on the first 2 or 3 cycles though. But from what you are saying, and if you are correct, it seems I did something similar pretty much on accident during my bench tests. The parameters were not identical and I also discharged MUCH deeper just for testing purposes but the result may have been the same. I took the pair of 460s down to low voltage cut off or 11.1 volts and the discharge mosfets shut down output. I then charged at approximately .05c from 0% to 100% (100% was 14.2 as set in DVCC) and had no issues. I did other discharges and subsequent charges without issue as well. I am thinking this discharge and slow charge served to balance everything much closer and I never had a stray cell after this. This also seems to mirror what the guys with Pylontech batteries have seen. Just by chance I actually made a video of this portion. Ill post it below.

I think there may be another separate issue that occurs on some boats with solar regarding poorly controlled voltage and spikes, which is a Victron issue. Unfortunately this is something I have only read about so I havent tested.

Again, thanks to all for the discussion since I am still soaking up this info on best practices. Much appreciated.

https://youtu.be/oUcjefQ8TAU?si=gZVVy1d2B3PAyA8S

I think there might be some confusion about what’s happening and quite possibly more than one scenario being experienced. The issue I described above is not, I believe, caused by cell balance issues. Instead, it’s caused by the BMS turning off the charge FETs being disabled when the battery reaches 100% SOC according to the BMS. I have a video I’ll get published tomorrow that shows this occurring. As the battery reaches 100%, the Charge MOS status in the app transitions from on to off. At the same time, you can clearly see that none of the cells are out of range nor is the total battery voltage too high.

Here are two screenshots showing immediately before and after the disconnect event.

Epoch has confirmed this is done to protect the cells from overvoltage. But, disconnecting the batteries from their charge source is problematic in many systems. I think the high voltage alarms we are seeing are the result of the inverter being unable to stabilize its charge voltage without a battery connected.

I’m waiting to have some additional conversations with Epoch about this approach to protecting the battery. I understand what they’re trying to protect against: continuous high-voltage charging damaging the cells while still staying below disconnect thresholds. But, I think this approach is problematic. I believe this behavior has been used in other Epoch batteries as well as by quite a few other LiFePO4 brands.

More to come as I learn it.

-Ben S.

Ben, In the first screen shot it shows the charge mosfets on but only pulling 3.5 amps

How many amps were available for charging? Or were you just charging with 3.5A?

I was charging from a MutliPlus II with 80 amps of charging available. The battery was only accepting 3.5 amps as it was at the very tail end of its charge.

-Ben S.

Note the battery is accepting 3.5 amps if the charge MF is off. That is likely not an accurate reading.

Forgive me if I am off base or misunderstanding. I think we are all trying to wrap our head around things..lol. Myself included. The following is just thinking out loud and NOT making statements of fact.

If you were down to 3.5 amps going into the battery but had 80 amps available that would seem to imply the battery is full full. It would make sense that the battery detected this and shut down the charge mosfet. The voltage of 14.23 (an individual cell voltage of 3.55-3.60) is IMO very high. From all the research I have seen, when doing capacity tests of either individual cells or battery packs the capacity testing at various charge voltages seemed to imply anything close to 3.50 was full full full and 3.45 was 98 to 99% full. 3.65 or 14.6 from everything I have seen is extreme.

So in the operation of your system when you saw these shut downs, what was the max voltage setting in the DVCC? If it was set above 14.2 it seems the Epochs primary protections may act independently from Victron communications shutting down the charge mosfets due to an alignment issue between Victron Protocol and Epoch primary safeties. IMO all the primary protections inside an Epoch are probably active and completely independent of what that same Epochs Victron protocols are saying to a Victron system. If during operation (charging and discharging) as per Victron commands, one of those Epoch primary protections is exceeded, the battery will still act on those appropriately. I think the key is to ensure that the operating envelope of the Epoch/Victron system, when guided by the Victron protocol, never exceeds or comes close to any of the primary protections of the Epoch. In order to do that I think several things have to happen.

1) cycle the battery as Jake Archer suggested. I think the need for this is a result of very large capacity cells. This IMO stands to reason. Initial Cell balance over a capacity range of 460ah is likely far more difficult than cell balance of one that is 30ah or 100ah. And it stands to reason it may take more cycles to align things.

2) With DVCC enabled the max charge voltage must be set much lower than most people may think is correct. The community with the most experience with Victron Comms and nuisance tripping and warnings seems to be the Pylontech community. Its shocking how low the voltage Victron suggests to operate Pylontech batteries. The following is from the Victron site in their Q&A discussing system stability of Pylontech batts with Victron systems:

Q: “My system only charges the battery to 52.4V

A: When DVCC is enabled, the battery (via the CAN-bms) is responsible for the charge voltage. The Pylontech battery requests a charge voltage of 53.2V. We have however found that in practice this is too high.

The Pylontech battery has 15 cells in series, so 53.2V equates to 3.55V per cell. This is very highly charged and makes the system prone to go overvoltage.

It should also be noted that a LiFePO4 cell stores very little additional energy above 3.45V.

For this reason we opted to override the BMS and cap the voltage at 52.4V. This sacrifices almost none of the capacity and greatly improves the stability of the system.”

Extrapolating from the above numbers the above statement from Victron suggest charging a battery system to 14.2 (3.55) is ” very highly charged and makes the system prone to go overvoltage.” and they recommend using a more stable 13.96(3.49). It also almost sounds like Victron systems knows when a Pylontech battery is hooked up and Victron has overridden Pylontechs own upper charge limit for a more stable and lesser voltage. I assume this was done when Victron used to test and “certify” third party batteries, which has not been done with Epoch. Apparently Victron doesn’t do this any longer. So It would appear we (Epoch Users) will be responsible to find this more appropriate and stable upper charge voltage.

I have heard from several others that did a bunch of cycling on the 460s and ended up ok using anything from 13.8 to 14.0 with much greater stability. I did get mine to cycle with DVCC max voltage set to 14.2 ok but will likely adopt the 13.96, give or take a tenth, when the system is actually turned on after install.

I apologize if I am completely misunderstanding the issues. I think there are likely other anomalies as well that deal with solar or other systems.

Alan,

I think there are several factors you aren’t taking into account.

First, let’s talk about charge voltage. Epoch calls for a bulk voltage of 14.2 volts as listed in their spec sheet: https://cdn.shopify.com/s/files/1/0251/0484/2798/files/Epoch_B12460A_Data_Sheet.pdf?v=1701937833. They also call out a maximum charge voltage of 14.6 volts. You are correct that bringing the cells above roughly 3.5 volts each is going to result in minor differences in SOC.

For my investigation into the problems we have been seeing, I have disconnected Victron comms from the battery and used a 14.2 bulk / absoprtion with float set to 13.6.

But, what you might not be accounting for is balancing. Most BMS will balance at top charge once voltage reaches 14 volts. If the battery isn’t charged above 14 volts, the BMS won’t have an opportunity to balance them. In my mind, this is another reason that disconnecting at 100% SOC is a bad idea. Balancing continues after 100% SOC, especially if one cell is lagging behind or one is running ahead.

The other thing that I don’t think is widely understood, perhaps even by some of the BMS designers who have chosen to disconnect charge FETs at 100% SOC, is the behavior of many chargers without a battery attached. By disconnecting the charge FETs, the charge source in essence doesn’t have a destination for the power it creates. But, if that charge source is either an alternator or an inverter, it’s unlikely it can stabilize voltage without a battery present. In fact, most dedicated chargers can’t either. All these charge sources use the connected battery to smooth the peaks and valleys of their output power. In the video I plan to post tomorrow I show the result of the inverter’s output once the battery disconnects. It hunts up and down over a range of about 0.6 volts.

The output stage of the inverter simply doesn’t have enough filtering and capacitors to smooth the voltage without a battery present. I also think that hunting of voltage is the reason for the high voltage alarms raised after charging completes. The only devices typically capable of stabilizing voltages are chargers rated to run as power supplies. Like many of the current Victron chargers.

Lastly, the full SOC disconnect on the 460s is made worse by the BMS’ inability to measure small loads. The result is the BMS may believe the cells to be full prematurely after failing to measure small loads.

I suspect that what is being done in the case of the Pylontech batteries is that by preventing the battery from reaching 100% SOC, a charge FET disconnect is also being avoided. The result is no high-voltage alarms. But, the other result is that balancing is likely not occurring. But, that’s just conjecture on my part. I haven’t torn into a Pylontech battery nor have I looked carefully at their BMS setup.

-Ben S.

Ben,

I cant figure out how to directly reply under your name…lol. This forum is a bit clunky. But hopefully you’ll get the reply in your email and couple my reply to your last message.

I am definitely considering top balancing in my previous reply. In my own research and my own testing balancing was much more stable and much more consistent when bringing up the battery to 13.8 to 14.0 and much much worse when going above that. So I am assuming that whatever balancing system is in the Epoch is working in and around those voltages. But having a much harder time when going above 14.2. This video from off grid garage tests 3 different BMS’s and comes to roughly the same conclusions. Higher voltage is worse for balancing.

https://www.youtube.com/watch?v=OpEQ4fV7-ZU&list=FLZrs299orHNeLYaabqiPqeQ&index=2&t=830s&ab_channel=Off-GridGarage

I did many charge cycles on the 460s and the 300V2 as well as the 100ah and balancing was always best when keeping max charge voltage around 13.8 or so. Never went outside of .010 volts and mostly stayed between .004-.007. Even 13.3 to 13.6 seemed to stay within .004-.007 cell delta. But increase it to 14.4 or god forbid 14.6 and the disparity grew quickly. This was with various chargers. Clearly the balancing could not keep up at the higher voltages. I also believe the Epochs have active balancing that does not require an applied charge to balance but can do the balancing between cells from a higher voltage cell to a lower voltage one. No charge need be applied. That’s from my observations.

When you say “The other thing that I don’t think is widely understood, perhaps even by some of the BMS designers who have chosen to disconnect charge FETs at 100% SOC” are you saying that the BMS disconnects at 100% SOC are you meaning at 100% SOC by the SOC meters or 100% SOC as detected by voltage and current conditions? I dont think the BMS uses the SOC meter for anything from my observations. I have seen them charge well past 100% as well as discharge well below 0%.

Your observation and concerns about the charge mosfets disconnecting and having no destination for the applied power is of course the very reason not to approach the conditions where the charge mosfets would be disconnected. If the DVCC voltage was set to a very safe and reliable 13.8 as an upper limit, with or without the Victron comms hooked up, the Multiplus will pull back the current as it approaches 13.8. Balancing still occurs, 13.8 is still 99% capacity and everything seems happy.

“Lastly, the full SOC disconnect on the 460s is made worse by the BMS’ inability to measure small loads. The result is the BMS may believe the cells to be full prematurely after failing to measure small loads.”

I dont believe the SOC meters do anything from my observations and are just along for the ride and in a fairly inaccurate way. Like I said above I have seen the Epochs charge way past 100% and discharge way past 0%. Especially if the batteries have lingered in some midrange charge up and down and never being reset to 100% by way of charging to full as detected by voltage and current.

If you havent already, try cycling the battery as Jake Archer has said or do the same procedure prescribed by Victron for the Pylontech in the link I posted. Then just run the entire system hooked up with Victron comms in the loop at 13.8 max charge voltage set on the DVCC. If it does in fact run smoothly in this range and the batteries stay balanced between cells then I would consider the system up and running.

The overvoltage is from comm 512 on the VE BUS – which is from the BMS not Victron- ignore the cell voltage you are seeing, as soon as the MF shuts off the charging that cell voltage is dropping down to below the threshold and then will not allow charging until the highest cell is below 13.3.

Sidenote – The second thing that can cause the OV is ripple, so that needs to be minded as well, however that will not be the case in most faults that folks are experiencing.

If you want to confirm what I am saying … watch the Details screen on Cerbo while charging, you will see the cell voltage that is causing the alarm. Ignore your app. It only takes a split second to set. To prove this, drain the battery down and open up charging MF, then monitor on the next cycle. I have spent weeks analyzing this particular issue and characteristics of the faults and warnings that occur verifying this again and again.

Ignore the 14.6 volt charging spec, thats nonsense.

The MF are not controlled by VE, they are controlled by battery BMS, BMS is only sending voltage to VE, VE is not sending commands to the BMS. In your photo its cell 2 causing your issue. At rest you have 3.607, under charge that cell hit 3.65. while the others at 3.53 maybe hit 3.58 this would be maybe 14.3 volts for a second which is plenty high and the reason you are not seeing 14.6. You are shy of about .1 volt on each cell that is low so thats why your max V is 14.3. 14.6 would be achievable if all cells hit 3.65 at exactly the same time. Your cells in the Screenshot are hitting 14.3 due to cell imbalance. you need to see that v diff much less to achieve 14.6 (which is ridiculous to me as a goal) 14.6 means you are pumping each cell to the very max of the limit of a lith cell. Why would we want this? 14.1/14.2 is plenty full. Any more is like trying to top the tank of till its spilling over the side of the car. Its just not necessary. It would seem to me when Epoch specified charging specs they thought – “well each cell can go to 3.65 so that is 14.6 so lets put that on the charging spec sheet” this is crazy talk.

So, you are filling up, one cell hits 3.65, it triggers the MF and that is what tells the VE on comm 512 that we are full and no more voltage is accepted. The alarm is letting you know “hey, Im done!”. It is not shutting off the battery, its only shutting off charge, its actually not even doing that…your systems will load balance, but this is precisely why external alt regulation or dcdc charging with correct voltage sense is important.

Yes this is what happens in my case. The runaway cell kicks it into cell overvoltage protection. I have see the battery still charge while showing 100% SOC on the app so I don’t think its that in my case.

But even at 14.2 it does this. 14.0 doesn’t allow let it get to that point.

As for balancing Ive seen no issue there. Active cell balancing seems to happen fine UNTIL getting to the very top of the charge cycle with an absorption above 14.0. Then a stray cell happens. So if other batteries balance cells at the end of the cycle I can say this one is much more likely to go crazy past 14.0v.

As long as 14.0 causes no long term balancing issues then I guess its fine. Just not normal behavior.

Either way Victron Comms simply doesnt work right because of the reasons listed above. Its working off a BMS SOC that just isnt correct and would probably never be correct. The shunt will always be more accurate.

The packets sent via bluetooth are not capturing the “event”

Wouldnt that indicate the battery is full? And if full wouldnt you want the battery to turn off charging via the mosfets? Or are you saying you had the victron comms hooked up and the system should have throttled charge current back so as not to shut down charging by disconnect (the thing no one wants to happen with alternator charging)? If the latter what was max voltage set to in the dvcc. I see you did get to 14.23 so I assume it was set above that? One other thing I noticed is the cell variance of .075V. I noticed in the begining I had numbers like that but it seemed after some deeper discharges and lowering charge voltage in the dvcc to 14.0 I never saw much over a .015 split and the system never cut the charge mosfets. Unfortunately I have broken down my system and am not able to test any longer. Batts are at the boat and the rest is in the shop. But I am convinced that these components are not as “smart” as we hoped and it will be up to us to temper various aspects of operations. Atleast in the interim. But I may be completely misunderstanding some things too. So forgive me if I’m out in left field.

iIs one way communication to VE bus, not from it.

This is quite a simple issue. Its cell imbalance. It wouldn’t be if they set the Voltage Spec to a normal number. 14.6 is marketing. It tells the consumer the battery can handle alternator charging easier. “if we sell a battery with 14.6, more folks will buy it because most alternators charge at less than that” The problem is if you are charging to 14.6 each cell needs to be perfectly (and I mean PERFECTLY) balanced with the next one to be able to “fill all the glasses” to the tip top. like downt the .001 volt. Not happening. If you are going to expect 14.6 out of this battery you are going to be spending a ton of time wishing. Balance the battery, tail current it, get it close, charge to 14.1 and go sailing.

Furthermore, Float at 13.4 is plenty, Floating at 13.6 is stupid IMO. We dont need to keep a lith battery in a charge state when at rest. Slightly over resting voltage is plenty. The SOC number is a calculation and should be ignored. It is not what turns off charging. A cell hitting 3.65 turns off charging.

For the Victron charge sources currently running with AGM batteries, I’ve found my MPPTs have pretty stable voltage output and respond well to load changes. The voltage stability on the Multiplus when there are significant load changes on the DC side (with full batteries) is to put it nicely, total garbage. It’ll spike up or dip down by half a volt at times if there’s a big load change while it slowly adjusts the output and brings the voltage back to target. Voltage changes on the AC side cause the DC voltage to vary a bit too, just not as badly.

I’ll write more and put up some more videos as soon as I can. Right now I’m trying to finish up another review and prepare for chairing the Innovation Awards at the Miami Boat Show.

I believe we are all working on assumptions and some of those assumptions are going to turn out to be good and some are going to turn out to be bad.

First, my assumption that SOC was used to determine when the BMS enters Full Charge Protection and turns off the charge FETs appears to be bad. As both Jake and Allen mentioned above. To verify this incorrect assumption on my part, I discharged the battery slowly overnight and brought it down to about 90% SOC as measured by a SmartShunt while the BMS remained at 100%. I then charged the battery at 14.0v. The BMS allowed that charge to proceed until charge current once again reached around 3-3.5 amps and then again entered full charge protection. I recorded video of the both the app and the Victron GX console showing cell voltages. Neither source reported a cell voltage above 3.524 volts. I don’t believe there was a 0.126 volt rise inside of the update interval of these monitoring sources.

So, it appears the BMS is using some other metric to determine when to enter full charge protection. Also, I have a list from Epoch of all the error states:

“Cell OV Prot”;

“Pack OV Prot”;

“Full CHG Prot”;

“Cell UV Prot”;

“Pack UV Prot”;

“CHG OT Prot”;

“CHG UT Prot”;

“DSG OT Prot”;

“DSG UT Prot”;

“MOS OT Prot”;

“SC Prot”;

“DOC Prot”;

“COC Prot”;

“Amb. OT Prot”;

“Amb. UT Prot”;

“Temp. Fualt”;

“Voltage Fualt”;

“DSGFET Fualt”;

“CHGFET Fualt”;

“Cell Unbalance”;

“Amb. OT Alarm”;

“Amb. UT Alarm”;

“SOC Low Alarm”;

“MOS OT Alarm”;

“Cell UV Alarm”;

“Pack UV Alarm”;

“Cell OV Alarm”;

“Pack OV Alarm”;

“DOC Alarm”;

“COC Alarm”;

“DSG OT Alarm”;

“DSG UT Alarm”;

“CHG OT Alarm”;

“CHG UT Alarm”;

I think (okay assume, and we know where that’s gotten me) that if the trouble were cells passing over-voltage thresholds, we would see a “Cell OV Alarm” or “Cell OV Prot” state, not the “Full CHG Prot” fault. But, that doesn’t explain what criteria is being used for full charge protection. I’m waiting on some more info and a diagnostic tool from Epoch that may help clear this up. If that arrives today, I’ll try and get it thrown in quickly.

Once I get my review finished and schedule finalized, I’ll get to work on editing video.

-Ben S.

Yes, hopefully the Epoch tool can provide a window to observe directly what we are speculating on. Hopefully it will show set parameters so we know what we may be up against to better input parameters of our own.

Things I would like to know

*what kind of balancer

* at what voltage and deviation does balancing begin

* parameters to set overvolt, is it purely voltage or a combination of voltage and amp (tail current) almost certainly the latter. This would perfectly explain your screen shots Ben when the Epoch primary protections opened the charge mosfets at 14.2 but amperage had dropped to 3.5 when you had 80 amps available. It was full full.