Max Marine Electronics, used gear with confidence

I first learned about Max Marine Electronics when Max himself served with me on an awards judging panel at the National Marine Electronics Association’s annual meeting a few years ago. Since hearing about his operations, I’ve been planning to visit the facility and see how they refurbish and sell used marine electronics. It took a while, but I recently made my way to Pompano Beach and spent the day with Max at his eponymous company.

Before we dive into the company, note that Max and I share the last name Stein. Stein isn’t a particularly rare name so it’s certainly not the first time I’ve come across another Stein. But, Max is also my brother’s name. At least in my life, another Max Stein is a rarity and required more clearly tagging their contact info to avoid the confusion I experienced on multiple occasions.

Enough about coincidences of naming, let’s talk about marine electronics and the art of keeping them alive many years after manufacturers have moved on. Sellers of used marine electronics aren’t particularly unique. I’ve come across several who seem to have steady supplies of used gear and offer it at reasonable prices. But, what makes Max Marine Electronics (MME) unique is the work they do to ensure that equipment purchased from them works and will work for the long haul.

Marine electronics have proven themselves durable and reliable. So, 10 or even 20-year-old equipment still working well isn’t unusual. But, if one component in an older navigation suite fails, boat owners may find themselves with a difficult decision. Currently available equipment won’t work with the rest of their system. So, the failure of a fifteen year old radar unit means potentially replacing the entire navigation suite. Often the only alternative is to purchase a used compatible unit. That’s where companies like Max Marine Electronics come in.

A culture of figuring it out

To understand Max Marine’s business today, I think it helps to understand the history of the company. Max traces his eCommerce roots back to 2008 and the tough economic conditions of the time. He was working in an unrelated field during the day and combing Craigslist for opportunities to make a little extra money in his off hours. He bought nearly anything he thought he could resell on eBay for more than he paid.

His scouting for profitable items took him to garage sales and it was at one he picked up a Raytheon Apelco L265 fishfinder at a minimal cost. He was stunned to find that someone would pay $260 for it. The buyer turned out to be local so he picked it up. That’s how Max learned that the buyer was a marine electronics technician purchasing the unit for a customer who just wanted a replacement unit instead of an expensive refit. This was an ah-ha moment and Max Marine Electronics traces its existence directly to that sale.

The early days of MME were about finding used gear at attractive prices and pairing that gear with buyers. Naturally, Max bought some equipment that didn’t work. In the early days that was the end for that equipment. Max started tinkering with broken gear although he says he doesn’t remember if he ever actually fixed anything. But that tinkering and desire to make the most of everything he bought would play a major role in shaping the business. Max plays down his technical abilities and credits his staff with developing their repair procedures. But, talking to Max, it’s clear he knows a lot more than he lets on. In fact, while I was visiting, Max grabbed a razor knife, cut open an Axiom and replaced the main logic module in the unit.

In the fall of 2011, Max was taking college courses and running the business on the side. MME had grown to the point that he had a decision to make. Max decided to quit school, found a 1,000-square-foot space, hired his first employee and went all in on Max Marine Electronics. In short order, the company had to add another 1,000 square feet, and it wasn’t long before they’d outgrown those spaces. That’s when Max rented a 4,800-square-foot facility in Pompano Beach.

The early growth of the company was all word of mouth. People would show up with equipment to sell. The company didn’t have relationships with installers or distributors. So, the equipment mix was pretty random. Quickly, MME began doing minor repairs of equipment they bought. They did a lot of polarizer replacements, a common repair of LCD displays exposed to sunlight. As repairs continued, MME sourced replacement screens and components. What they could buy, they bought, what they could fix, they fixed.

Steadily, the company grew and Max enjoyed a little of the success. In 2014, he bought his dream house, in 2017, he sold that house to buy a parcel of land that would become MME’s new home. It took five years and a pandemic to make it from plan to reality. In 2022, during their busiest time of year, the company moved into their 14,000 square-foot building. I visited this new headquarters and gained an appreciation for the company and its character. Currently, MME employees 25 people buying, repairing, and selling marine electronics and equipment.

Ensuring quality

As I talked with Max, a theme emerged. Max repeatedly referred to the Max Marine way, which means stepping back from a task at hand and looking at the bigger picture. That look ensures MME is operating as efficiently as possible and they’re delivering value and quality to their customers. MME doesn’t just check a single unit and make sure it works. They take what they’ve learned from working with all units of a specific model and incorporate those learnings to delivering the best product they can.

Max talked about the backlight assemblies in Raymarine E-classic MFDs. They bought a lot of them with bad display backlights. Initially, they sent the backlight assemblies to a Raymarine authorized repair facility who repaired the board and replaced failed transformers. But, the repairs were completed with factory parts. That may sound great, but in this case the factory transformer is the problem. So, MME sourced a better transformer and redesigned the backlight. Now, units repaired by MME are arguably better than stock units.

The range of repairs MME completes is impressive. During my tour I saw equipment torn down to a pile of parts and then reassembled. The range of competencies demonstrated during my tour instills confidence in the repair work they perform. Max says he hires technically skilled employees and lets them explore. Those employees routinely discover what fails in equipment and design fixes.

That exploration and discovery means broken equipment they’re unable to repair today may become repairable in the future. That creates a struggle to figure out what to keep and what to recycle. Without care and discipline, their 14,000 square-foot building could easily be filled to the brim with gear.

Handling as many pieces as MME does comes with other advantages. They’ve learned the idiosyncrasies of various models. For example, Simrad/Robertson autopilot control heads often have issues with their weather sealing. So, MME doesn’t sell one without first resealing it.

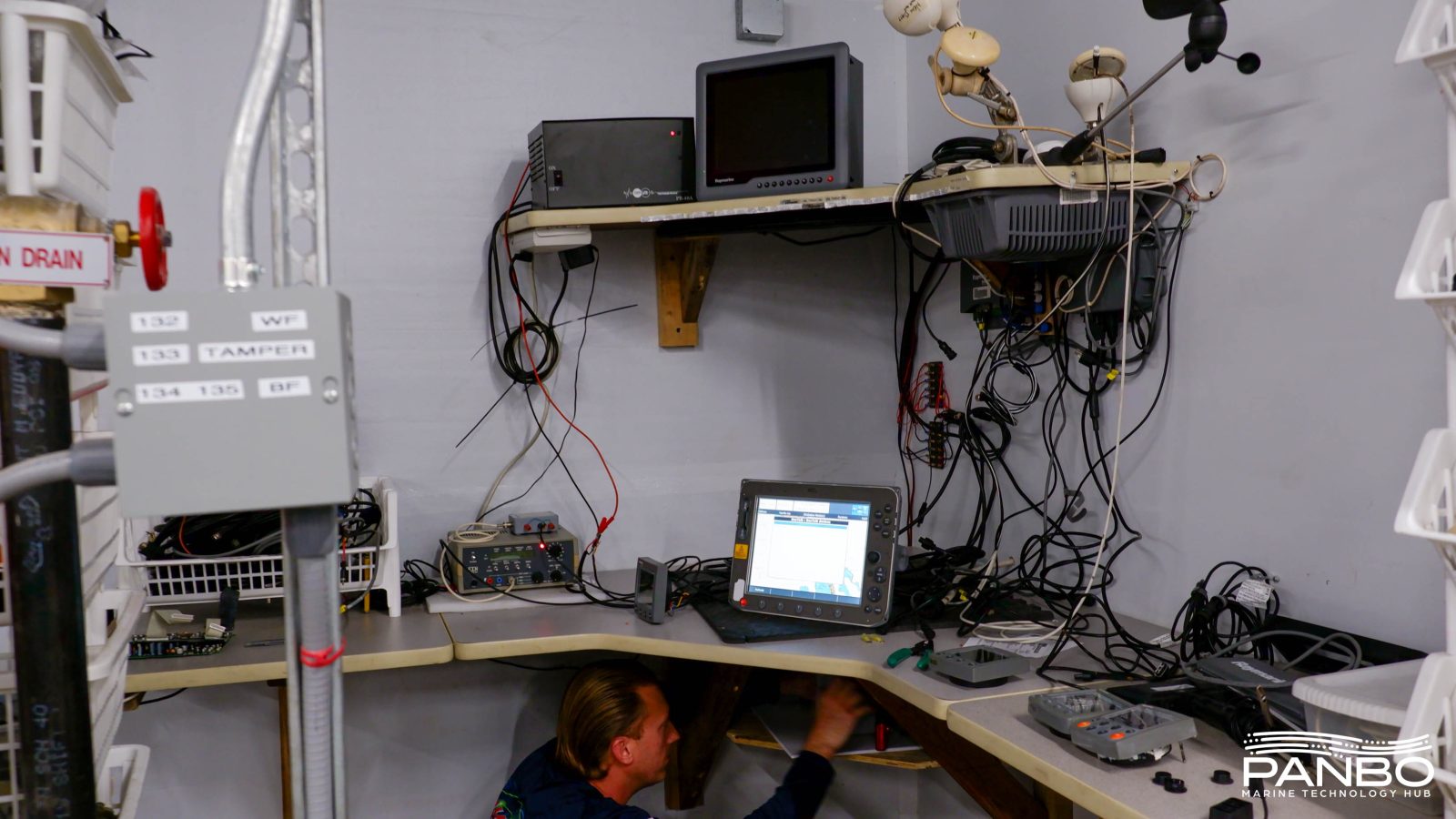

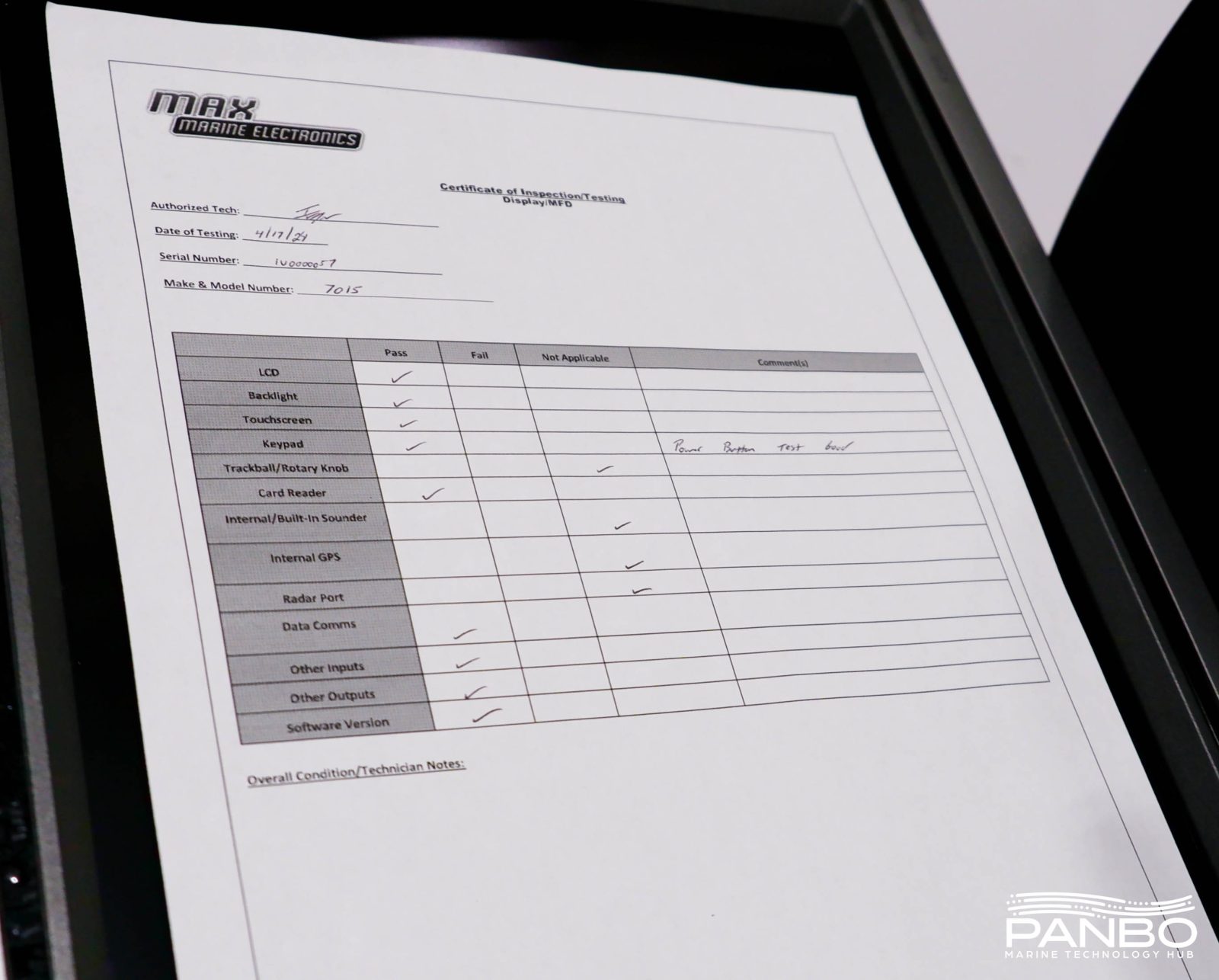

Incoming equipment is thoroughly tested; so there’s a test station right inside the front door. That test station isn’t just equipped with a power supply and a flat surface. Instead, there are NMEA 2000 and 0183 networks, sounders, transducers, and more so that equipment can be tested with sensors and other components.

It’s important to know not only that the equipment works, but all the ports and interoperability is good as well. Before a unit is sold, all these functions will be tested and software will be updated to the latest version.

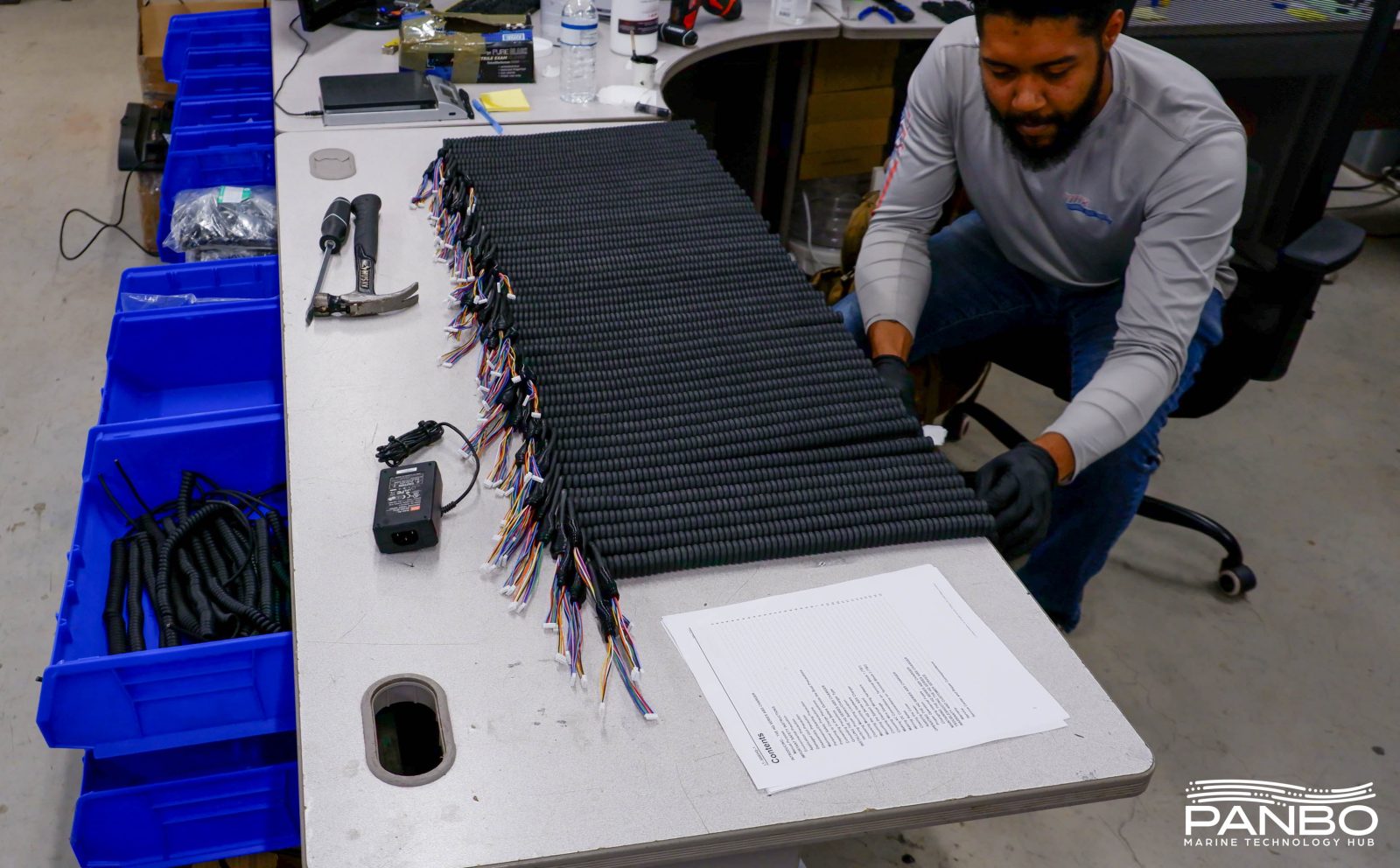

Sometimes parts just wear out beyond repair and require replacement. We’ve probably all seen a VHF microphone cable after the sun has had its way with it. In many cases, those cables simply aren’t available anymore. If you’re Max Marine, that’s not a problem. They’ve sourced replacement cables and many connectors. If they can’t get the correct connectors, they 3d print them. In the photo above, a batch of cables for several different radios and manufacturers is readied. This type of work really speaks to me. It strikes me as a great shame to replace a perfectly good radio because the cord has decayed. But, without replacements available that’s often the only choice.

MME backs their products with a 30-day return period and a 90-day warranty. Additionally, they pride themselves on their customer service. I’ve had a few conversations with boaters about MME. Every one of the boaters who interacted with them commented on their customer service (including our Ben Ellison). In fact, two of the boaters I spoke with called for help and Max answered the phone. The time he spent on the phone with them and his focus on solving their issues made an impression on both.

Sourcing the inventory

Filling a facility the size of theirs is no small feat. It probably comes as no surprise that MME’s equipment comes from numerous sources. They’ve developed a network of installers and marine electronics businesses that hold all their pulled equipment to sell to MME. In fact, some of those businesses will leverage trade-in value to win new business. Others don’t want anything to do with the used equipment they pull but refer their clients directly to MME. Additionally, MME will buy closeouts and refurbished equipment either direct from the major manufacturers or via distributors. Plus, Max isn’t afraid to bring a stack of business cards to a boat show and just walk the show explaining to exhibitors that he’d like to buy their old stuff.

When I drove over for my visit, I brought a van full of old gear I’d removed during installs I’ve completed. As it turns out, more of what I brought was broken than not. But, I got a few dollars for the working gear — and got to see MME’s testing and evaluation in action. More importantly to me, the equipment didn’t just go to a landfill. Even the broken equipment will see use. Some of it was in decent cosmetic condition, so the case parts may see service with working innards. Finally, the parts deemed surplus end up sorted into totes so they can be scrapped and recycled as well.

Final thoughts

Rest assured that although Max and I share a common last name, every nice word I’ve said about him is well-earned. I believe a company like Max Marine Electronics is an asset and a resource to the boating community. Keeping serviceable equipment working is a noble mission and they do it very well. The next time you find yourself in a pickle, you may want to give MME a call. From their knowledge of marine electronics (current and a little older) to their stock of hard-to-find components, they just might get you out of trouble.

I cannot say enough good things about Max Marine Electronics, and Max himself. As an NMEA Dealer, the ability to confidently source a vintage piece of electronics to salvage a system and save our clients from a lock stock & barrel replacement is a God send for all involved. We have been purchasing from Max since he was repairing HSB1 Pathfinder displays, and it’s wonderful to see MME grow and expand their ability to continually find solutions to keep the party going for so many applications with support that is beyond what some OEMs provide. Cheers to Max and the MME Crew; thank you for all the innovative solutions that prevent preemptive and planned obsolescence!

I just posted this article on the North Pacific Yacht Owners FB page — just spreading the word. Thanks for the wonderful article about a noble company. I have bought from Max Marine and it was definitely a positive experience.

kudos to max and team, that was agood read and a brilliant solution for a lot of people. we dont have anywhere near the market size here in australia for a company like that, so sadly our ewaste is pretty big. but it does give us some hope seeing this.

What is the process of offering equipment to MME if one does not live in Florida?

I believe if you reach out to them they will walk you through the process. My understanding is they will have you send photos and be able to make a preliminary assessment from the photos.

-Ben S.

I sent emails to Max and to Sales. No response. Suggestions??

Max along with us other dealers receive a ton of unsolicited phantom”offers” equipment removed from ships around the globe from ECDIS sytems to VDRs. I would mention you read about the article on Panbo and Ben referred you to separate your request from those other spoofs.

Orin, found your e-mail, we’ll respond to it now – we do get a ton of e-mails, some legit, some not as suggested below. Thank you!

I am impressed that Max Marine reached out to me as a result of this post. Really appreciate their interest

I’d also like to offer my compliments to Max and his crew. They do tremendous work and their customer service is outstanding. I have referred many Raymarine customers to them in need of specialty cables, parts, and even replacement MFDs that we don’t have available anymore. Many have reported back that the MME team took great care of them and got their systems back up and running. Purchasing full, new systems is just not an option for everyone and I am glad we have Max as a resource to keep boaters happy and underway! Thanks for featuring them here on on Panbo!

I’m looking to swap a 12” Simrad evo 3 with radar for the comparable Garmin unit. Is that something you do?

I suspect that is something Max Marine does, but this is just a writeup of their business. You can contact them via their contact page: https://maxmarineelectronics.com/contact-us-max-marine-electronics-inc-pompano-beach-florida/.

-Ben S.

Hello Ben, Great article . Can you help me out ? My 2004 Sabre 386 came equipped with a Raymarine C80 Chartplotter. The unit powers up but the screen remains blank. Crowley’s yacht yard in Chicago where I store the boat gave me your info to see about a repair or replacement. Please let me know if you can help. Thank you. Regards, Scott Broderick

Hi Scott,

It sounds as though the backlight may have failed on your unit. I would suggest getting in touch with Max Marine. I believe they have an option to send your failed unit in as a core and get an upgraded unit.

-Ben S.

Great, thank you for your help. Regards, Scott Broderick