NMEA 2000, power “problem” part 2

I think I got this diagram right, and I think it’s important to understand if your boat might end up with more than a few NMEA 2000 powered devices on its network. As discussed on Monday, the popular ‘light’ (or Micro) size NMEA cables only contain 22 AWG power (and data) wires. Its well insulated power wires are apparently perfectly safe (despite some internecine standards organization hubbub on that score) but they simply can not carry much DC juice very far. Electrical resistance is dependent on wire size — DC especially so (hence the fascinating “War of Currents“) — and the few DC wire tables that even include 22 guage don’t look good. Which is why some manuals, like Garmin’s below, go to some trouble regarding powertap placement…

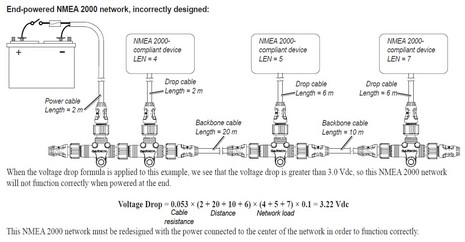

The diagram below, found in Garmin’s NMEA 2000 Fundamentals (PDF here), usefully illustrates a fairly modest N2K network that will suffer too much voltage drop at one end. Garmin goes on to show how the situation can be fixed by putting the powertap in the middle of the backbone and thus halving the effective wire runs. Not mentioned, but even better, are the split powertaps available from Maretron and elsewhere (Furuno and maybe Airmar, I think). With the split design you get two pairs of 22 AWG power wires each able to supply up to 4 amps to the backbone leg they feed. They can be switched separately, too, which might be useful if you want to leave certain devices on (GPS for security system?) and can relegate them to a particular backbone leg.

A split powertap can also be used to feed a third leg of a N2K backbone (with the wire pair headed toward the already powered leg taped off), as long as all taps are led to a common ground. That could be especially useful if you want to add something and realize you don’t have the proper juice available. But isn’t smarter to start with all the backbone power you can reasonably fit and afford? While 8-amp-per-leg Mini size NMEA cable is almost as thick as a garden hose, and very expensive, it looks like Maretron’s Mid size cable, which has regular Micro connectors, wouldn’t add a shocking cost to a backbone, if any. (Here’s a quick Google comparison: Maretron 10 meter Mid vs Garmin 10 meter vs SimNet 10 meter vs SeaTalkNG 5 meter backbone). Mid is only rated for 4 amps, like regular light cable, but its 16 AWG power wires result in much less resistance (4 Ohms versus 18 for micro wire) and hence much friendlier voltage drop calculations. Even on a small boat, a split powertap located near the load center of the backbone seems like obvious and relatively cheap future proofing.

Ben,

The original Devicenet specification called for 22 Gauge Power cores in Micro cables. The original cable designers mainly considered small, milli-amp draw sensors in factory automation systems for Micro cables.

During development meetings, we intentionally chose to only offer 18 Gauge Power wires, or larger, in our NMEA2000 Micro Cables to avoid the very problem you are describing, since marine industry sensors would necessarily be more power hungry. At least one other major partner agreed and followed.

Indeed, the cost, cable diameter, and weight savings of a 22Ga twisted pair vs. a 18Ga twisted pair for power in a NMEA2000 Micro cable is neglible in the maritime market.

Check the NMEA2000 Micro cable specifications of all the major manufacturer’s NMEA2000 Micro Cables to see what I mean.

Insider

The only ‘light’ N2K cable with greater than 22 gauge power wires that I know of is Raymarine’s SeaTalkNG. You can see the heavier wires here:

https://panbo.com/archives/2008/02/n2k_cable_mixing_not_a_big_woop.html

I couldn’t find a wire specification for Simrad SimNet wires but did notice that they spec a 5 amp fuse for the powertap and recommend heavier gauge to the tap. Garmin specifies a 3 amp fuse on its powertap, which suggests it doesn’t have much confidence in the power capacity of its N2K cable.

I did find an Airmar N2K cable brochure:

http://www.blueheronmarine.com/files/Airmar_NMEA_Accessories.pdf

But it doesn’t detail wire sizes. The Airmar powertap does look like Maretron’s — i.e. female on both sides (which means your backbone changes gender at the tap) — but it is a split feed (not stated in the brochure but I have one here and checked).

http://www.blueheronmarine.com/Detail.bok?no=5992

I think Lowrance and Furuno N2K both use 22 AWG power and data wires, but am not positive.

Apart from the power issue, it’s worth noting that when you look inside all these cable types, none seems to have the build quality and interference protection (foil around both data and power pairs, braid around everything) that the Maretron cable does. I wrote about the importance of good EMI protection last summer:

https://panbo.com/archives/2008/04/nmea_2000_smart_mixing.html

Hey Panbo… how about putting some of these specs into a wiki which you keep up to date as you review things.

The whole NMEA2K bus architecture is flawed from the very get-go. Bus based systems are very difficult to faultfind, have huge single point of failure problems. Thats where ethernet abandoned it and went hub and star. Imagine a whole boat on a NMEA2K system , distributed swictching, nav, comms control, lights etc. All this depending on a bus based system, no thanks. Its time to move to active hub and star configs, so that each device or set of devices is independant of others due to cable failure.

BTW this also solves the cable power issue.

“huge single point of failure problems”…huh?

The only one I can think of is severing the backbone cable, and the better N2K cable does not sever easily.

And separating out the power wires needed for all the little sensors around a boat is not solving a problem. The concept of power and data all in one rugged, standardized cable system is excellent, and works very well right now in many vessels.

All I’m trying to do in these entries is highlight the limitations this power distribution system so that readers plan well for growth and pay attention to quality vs cost trade offs.

POE (Power over Ethernet) is interesting, too, but also limited.

” A split powertap can also be used to feed a third leg of a N2K backbone ”

I noticed some of the power taps are female on both sides. Dosn’t that prevent a 2nd power tap from being used on the same backbone ?

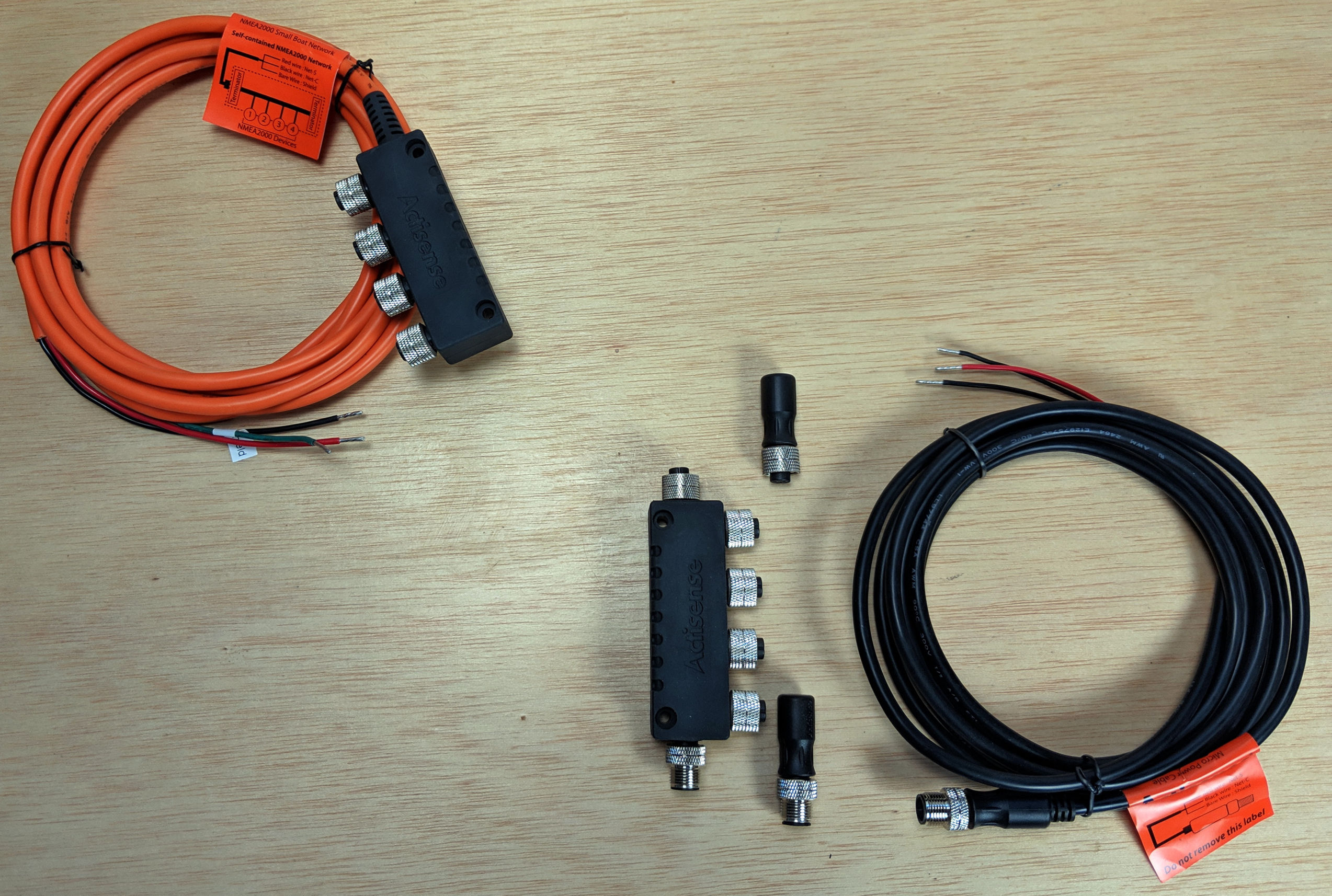

Good point, Dan. The two split powertaps I know of — Maretron’s and Airmar’s — are female on both sides. The idea, I think, is less chance of exposure to pins with live 12v in them. But at least Maretron makes simple gender changers, which make it easy to fit in a second split powertap, or retrofit a split powertap to an existing backbone which has the same gender orientation end to end.

Ethernet is generally a bad choice for any network that performs real-time data acquisition.

Fact is, ethernet is somewhat of an asynchronous network with no class-of-service or guaranteed minimum time of delivery; rather its burst-mode.

This does not work well with instrumentation. The only blessing ethernet provides is that it is very fast, so these limitations are often masked – however, there is a limit as to what speed can fix.

I disagree. With 100 or even 10mbps … what do you need class of service or guaranteed minimum delivery time for ???

Messages get to devices far faster then they do on NMEA 0183, seatalk, N2K, etc.

The realtime capabilities of N2K derive from CAN, a network used in cars and trucks for controlling electronic ignition, brakes, …. For boating, N2K is used for instrumentation and it seems vastly overdesigned for the purpose–not such a bad thing. N2K can also use parts from a much larger market, DeviceNet cable and Atmel CAN chipsets keeping costs low.

POE would be interesting but N2K is available now. That ship has already set sail.

Ben, it would be interesting for you to do a side by side price and capability comparison between a state of the art N2K installation and whatever BandG or NKE or Ockham have to offer.

awboater,

This was the big argument for Token Ring years ago. Everyone soon found out that throwing additional bandwidth at the problem with asynchronous standards is a lot easier than designing compatible synchronous networks.

Regarding the diagram in the original post:

The split powertap (on the left) is not accurate. The ground line MUST NOT be split, it MUST remain continuous.

Draw the ground line from the right hand ‘regular powertap’and draw the power line from the left hand ‘split powertap’ and you now have an accurate diagram of a split powertap.

Thanks! But there are actually two ground wires in the split taps I’ve seen, and wouldn’t doubling the effective ground flow be a good thing? In other words, doesn’t the tap solve the common ground issue just by connecting the two ground wires in the tap itself? Which I could represent with a short black connecting line under “drain wire”?

Or, connect them at either the base of the split power tap after running them thru a seperate fuse, or otherwise make sure they connect at the same ground lug back in your electrical system ? Yes ?

By extension, if you have a three segment NMEA-2000 run, you would need to discard one set of wires (don’t want to create a loop right !), and run all three ground wires back to the same ground lug with optioal fuse protection on each ? Yes ? (fuse not optional for the hot leads of course)

Without repeating my answer to this read:

https://panbo.com/forum/2009/09/switching-off-a-section-of-n2k-network.html