Volvo Ocean 65, powered by Mastervolt Li Ion

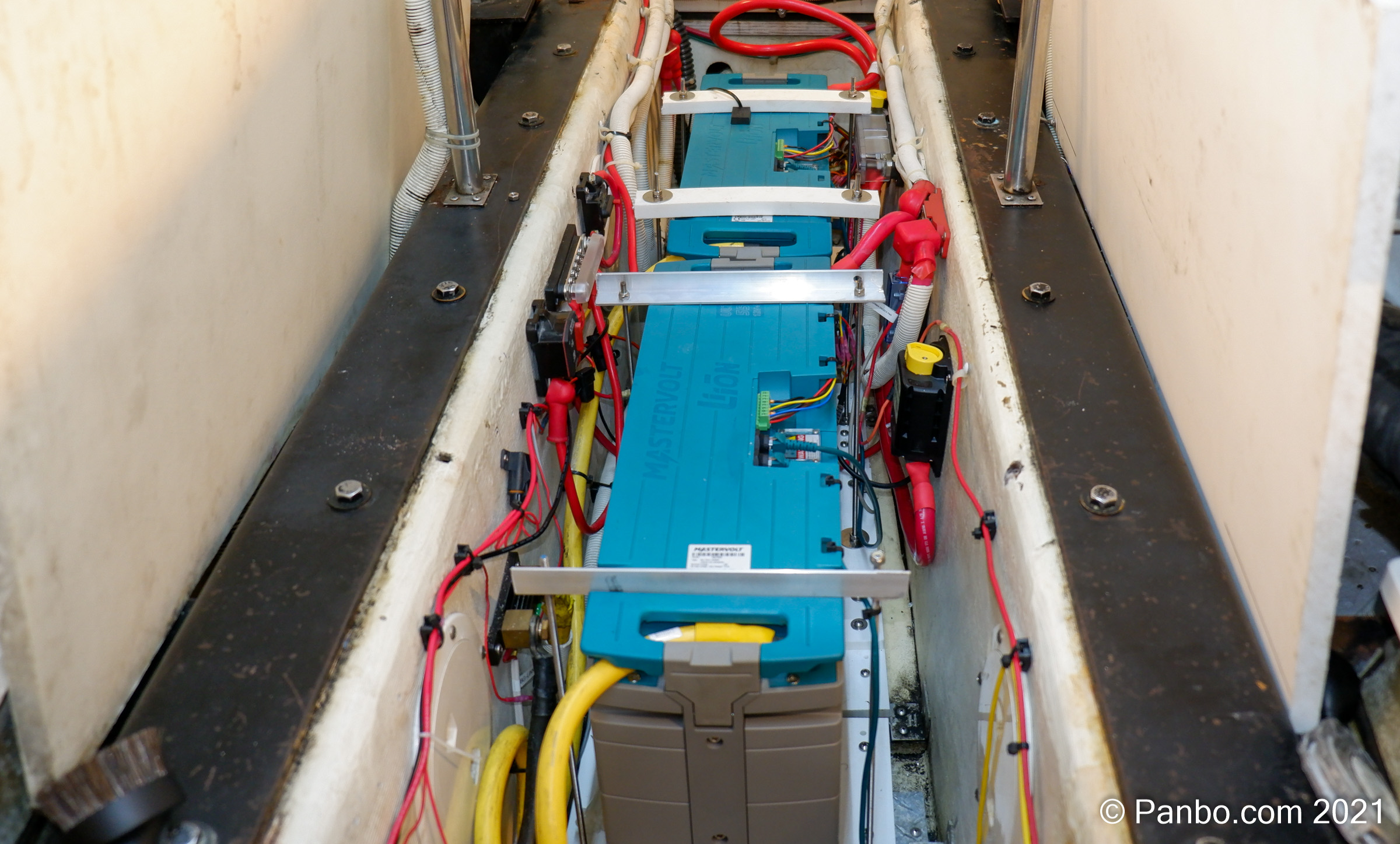

I’m happy as an oyster slow cruising Chesapeake Bay with my favorite first mate, but if I had a teleporter I surely would have jumped on an invitation to check out a Volvo Ocean 65’s systems in Newport yesterday. I doubt I would have encountered a scene as tidy as the photo above — which looks forward in the main cabin of Dongfeng with most of the engine, power, battery, and keel ram covers removed, as well as the pedestal galley — but then again all that technology has now zig-zagged almost around the planet in often demanding conditions. There’s a lot of gear on these one-design racers that has performed impressively, as best I know, but I’m particularly taken with the Mastervolt Lithium Ion battery system…

I’m happy as an oyster slow cruising Chesapeake Bay with my favorite first mate, but if I had a teleporter I surely would have jumped on an invitation to check out a Volvo Ocean 65’s systems in Newport yesterday. I doubt I would have encountered a scene as tidy as the photo above — which looks forward in the main cabin of Dongfeng with most of the engine, power, battery, and keel ram covers removed, as well as the pedestal galley — but then again all that technology has now zig-zagged almost around the planet in often demanding conditions. There’s a lot of gear on these one-design racers that has performed impressively, as best I know, but I’m particularly taken with the Mastervolt Lithium Ion battery system…

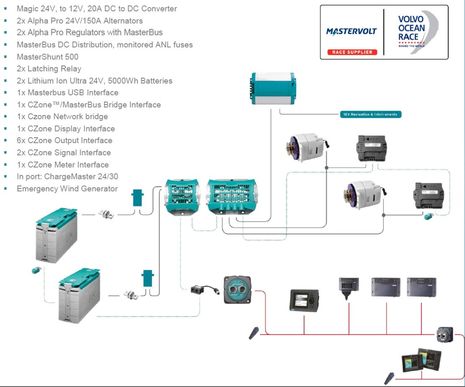

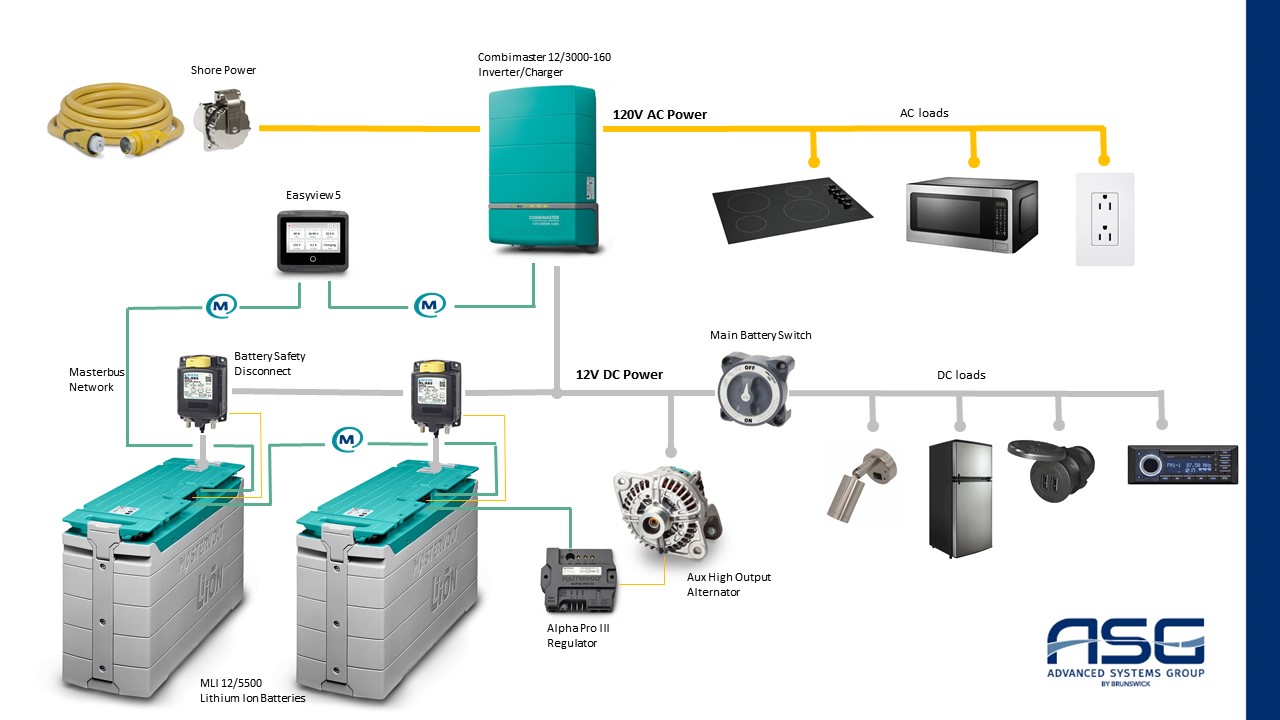

The VOR 65 power system diagram above is detailed here. The self-managing 24v batteries, alternators, regulators, shunt, fuse, DC/DC converter, and (in port) charger are all Mastervolt products, and that MasterBus subsystem bridges to sister brand CZone (NMEA 2000) for power distribution, digital switching and onboard/offboard monitoring. There was concern about overlapping lines when competitors BEP and Mastervolt both became part of Power Products a few years ago but the evidence is strong that they’ve worked things out.

The VOR 65 power system diagram above is detailed here. The self-managing 24v batteries, alternators, regulators, shunt, fuse, DC/DC converter, and (in port) charger are all Mastervolt products, and that MasterBus subsystem bridges to sister brand CZone (NMEA 2000) for power distribution, digital switching and onboard/offboard monitoring. There was concern about overlapping lines when competitors BEP and Mastervolt both became part of Power Products a few years ago but the evidence is strong that they’ve worked things out.

Here’s more detail of the twin 150 Amp alternator, twin 180 Ah Li Ion battery set up, with several of the diagrammed components in view. And note the massive swing keel rams, which are driven by an electric-hydraulic pump that is just one of several serious loads that the battery system must supply.

Here’s more detail of the twin 150 Amp alternator, twin 180 Ah Li Ion battery set up, with several of the diagrammed components in view. And note the massive swing keel rams, which are driven by an electric-hydraulic pump that is just one of several serious loads that the battery system must supply.

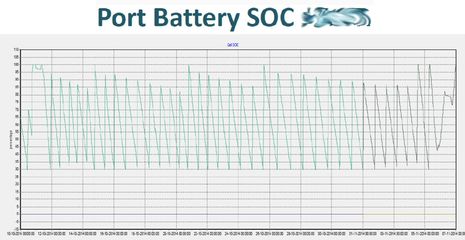

In fact, these batteries are fully cycling about three times every two days, as shown in the graph above (which you can click larger). Specifically, it shows the State of Charge for the port battery on one of the racers during the 6,500nm first leg from Alicante to Cape Town, though I believe the profiles were very similar for all 14 batteries in the fleet. At the left end you can see it being charged at the dock, but then driven down to 30% SoC and rapidly charged to 80-100% over and over again. My boat batteries can’t work that hard, and probably yours can’t either.

In fact, these batteries are fully cycling about three times every two days, as shown in the graph above (which you can click larger). Specifically, it shows the State of Charge for the port battery on one of the racers during the 6,500nm first leg from Alicante to Cape Town, though I believe the profiles were very similar for all 14 batteries in the fleet. At the left end you can see it being charged at the dock, but then driven down to 30% SoC and rapidly charged to 80-100% over and over again. My boat batteries can’t work that hard, and probably yours can’t either.

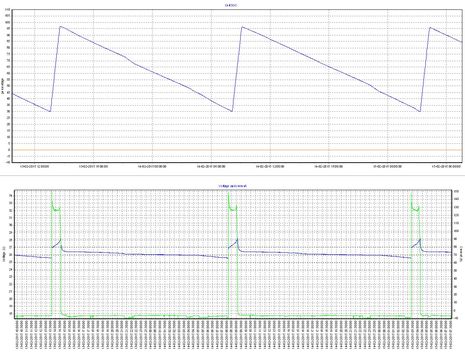

Here’s a detailed charge and discharge profile for about two days during the February Sanyo, China, to Auckland leg with SoC on top and voltage and current below. It’s the promise of Lithium Ion power storage not only writ large but delivered over Inmarsat satellite communications to VOR HQ and then to Mastervolt so their technicians might catch problem trends the racers might miss. No problems in sight, though, as the battery goes from about 97% SoC to 30% with very little voltage loss, then an alarm prompts an automated charging cycle which brings the battery back to 97% in about an hour, with the alternator pumping out close to 130 amps the whole time.

Here’s a detailed charge and discharge profile for about two days during the February Sanyo, China, to Auckland leg with SoC on top and voltage and current below. It’s the promise of Lithium Ion power storage not only writ large but delivered over Inmarsat satellite communications to VOR HQ and then to Mastervolt so their technicians might catch problem trends the racers might miss. No problems in sight, though, as the battery goes from about 97% SoC to 30% with very little voltage loss, then an alarm prompts an automated charging cycle which brings the battery back to 97% in about an hour, with the alternator pumping out close to 130 amps the whole time.

Here’s the aft nav station with some of the CZone system exposed to starboard. I like how the cables aren’t buried on a “working” boat like this, but then again, it isn’t easy to hide them. At a Miami Boat Show presentation where B&G also explained their VOR involvement, we got to talk with Alvimedica skipper Charlie Enright as they worked to windward on that same Auckland leg and the background sounds of sheet tweaks resonating through that super stiff carbon shell were scary. Enright seemed a bit on edge himself — who wouldn’t be? — but not about the power system, which he characterized as flawless. (Mastervolt applications engineer Menno Ligterink, who also helps with regular boat installs in North America, told me that the “power systems have performed outstanding so far considering the conditions they are used in. Heavy G-forces, deep discharges and a quick recharge has not compromised the performance.”)

Here’s the aft nav station with some of the CZone system exposed to starboard. I like how the cables aren’t buried on a “working” boat like this, but then again, it isn’t easy to hide them. At a Miami Boat Show presentation where B&G also explained their VOR involvement, we got to talk with Alvimedica skipper Charlie Enright as they worked to windward on that same Auckland leg and the background sounds of sheet tweaks resonating through that super stiff carbon shell were scary. Enright seemed a bit on edge himself — who wouldn’t be? — but not about the power system, which he characterized as flawless. (Mastervolt applications engineer Menno Ligterink, who also helps with regular boat installs in North America, told me that the “power systems have performed outstanding so far considering the conditions they are used in. Heavy G-forces, deep discharges and a quick recharge has not compromised the performance.”)

Besides for the Volvo 65’s, Mastervolt has thousands of their Lithium Ion batteries working on boats around the world, and their pride in the systems seems justified. There are lots of rumors around about Li Ion related boat fires, but I’ve never heard one involving these highly engineered Ultra models. A DIY lithium battery bank is possible, but only if you’re as smart about it as Bob Ebaugh is.

Besides for the Volvo 65’s, Mastervolt has thousands of their Lithium Ion batteries working on boats around the world, and their pride in the systems seems justified. There are lots of rumors around about Li Ion related boat fires, but I’ve never heard one involving these highly engineered Ultra models. A DIY lithium battery bank is possible, but only if you’re as smart about it as Bob Ebaugh is.

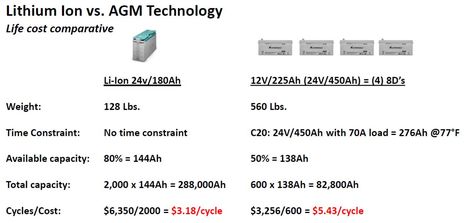

What may be more controversial is Mastervolt’s analysis of Li Ion costs versus AGM batteries, though it’s certainly a conversation starter. Gizmo’s 12v house bank, for instance, is two Deka 250 Ah 8D AGM’s that are at least 6 years old now and may well have exceeded 600 cycles (and a fair bit of owner abuse). I can tell that they are near the end of their working lives and replacing them will require more muscle than I have, but it looks like the cost will not be as bad as suggested below. But the main thing to notice about the analysis is that you really have to use your boat a lot to make it work. I don’t know how exactly many cycles the VOR 65’s will consume during their long circumnavigations, but it seems like they could use the same batteries for a couple more!

The VOR In-Port race starts at 2pm today in Newport and will be live streamed on YouTube, as will the start to Lisbon on Tuesday. If I had that teleporter — Lithium Ion powered, to be sure — I’d also like to attend PlugBoat 2015 in Holland at the end of September. But if all goes well, I’ll be back down here in Gizmo and still grinning about it.

Interesting setup, Ben – I had been wondering how they did their systems.

Are those LiIon batteries “any position” like the AGMs? I looked at their site, but they never actually said.

Also, if you converted to one from an olde AGM (like you might do..;-) what else has to be changed (AC Charger, alternator regulator, etc.)?

Ben,

Wendy Boyle & Eric Schmidts boat EQUUS sank last year at about this time.

http://www.ack.net/Equuscatchesfiresinks053014.html

The captain/crew initially claimed a fire in the battery compartment. The event quickly went silent and we could garner no further information on the event. We really can’t say if it had anything to do with the LFP system but what we do know is that it was reportedly a Mastervolt LFP system. From the initial report it originated in the battery compartment. I would love to see the results of that investigation and really don’t understand why it went silent so quickly. We are still learning about LFP for fractional “C” use, and if we sweep events like this under the rug it only creates less evidence based historical data to learn from.

I was personally aboard RAINMAKER, before she shank, talking with Chris Bailet and he told me that on the delivery trip the port Mastervolt alternator caught fire. The alternator had been replaced by the time I was there but when I crawled down into the engine bay the replacement Mastervolt alternator had no temp compensation installed and it too had a Mastervolt LFP battery system. No temp compensation, on an alternator feeding an LFP bank, is simply going to eventually be an issue. For Rainmaker it happened right out of the gate.

My main point here is that even well designed factory engineered systems need a competent installation and the charging systems feeding it need to be using safe & sane charge voltages. The physical installation and the competence level of your installer counts as much if not more than the physical factory engineered system.

-RC

im running a little 130a balmar with altenator temp sensor driving 450ah lifeline agm bank… ive noticed the regulator frequently cutting output due to maxed out altenator temps… easily visible on the ars5. i dont consider altenator temp sensor optional.

While Li battery tech is promising, it’s still immature and expensive particularly if you already have a lead acid charging infrastructure in place.

The most interesting thing to me are the “next gen” AGM batteries that use carbon foam electrode substrates and claim to be able to go to a much greater DOD without sacrificing the number of lifetime charge cycles. This could let you get away with half the number of batteries of a conventional lead acid setup with no conversion cost.

I’d love to see a writeup on those, Ben!

One of the Li Ion batteries on Vestus suffered a thermal event and burned up following their grounding this winter.

http://www.volvooceanrace.com/static/assets/content_v2/media/files/m36616_team-vestas-wind-inquiry-report-released-on-9-march-2015.pdf

Read page 60 of the report which states

The LFP batteries are reported to have started

‘smoking’ shortly before abandoning the yacht. This is believed to be as a result of their exposure or

submersion in salt water. This did raise a concern of fire and was one of the factors that influenced

the decision to abandon the yacht.

I’m not sure that I’m comfortable with a battery bank that may compound a flooding/grounding event with an exothermic reaction, smoke, or fire if it gets wet.

Another technology coming soon is Sodium-ion.

http://www.theengineer.co.uk/1020369.article?cmpid=tenews_1153164

Then lets not forget the Tesla Powerwall. I would sure like to hear from the first person that installs one in a boat.

This is just getting cooler and cooler. If you dig into the details of each of the components above, small additional features in each are designed to accomplish big things together.

Mastervolt takes the necessary systems approach to their integrated product line, but you are replacing a lot of parts and wiring in your boat to do this. I found the supporting documentation with diagrams understandable, and the website with various product options easy to navigate for someone that understand electrical systems to follow, including some options to reuse some of your existing power system components, but it seemed like the better bet was to replace everything with their product line as each component, as I stated above, has small additional features that make the total solution robust.

Since it is labor intensive to rewire and costly to design a solution one boat at a time, most of us (who can’t afford to have the right system designed), will need to wait until our next boat, one where the system was designed into a production run of boats and the labor part of the boat building process.

R, thanks for the pointer to that report – interesting for sure in many areas, and what you noted about the LFP battery burning up in that accident is certainly pertinent. Ben, if you haven’t already, download & read it, as it has a LOT to say about the charting issues that emerged from that debacle.

Dan, I suspect you are right – the cost of retrofitting literally -everything- in the charging system is prohibitive. (along with the sheer amount of work involved!) I disagree that they provide many details about what HAS to be changed vs. what would just be ‘better’. Lots of bold advertising copy & buzzwords, but little technical detail. The only existing component I could see being clearly indicated as being retainable was the alternator(s). “Features” are one thing – requirements are quite another..:)

Yes, prohibitive for a refit, but to be clear it’s not because of Mastervolt product line seeming to dominate replacing all your components. The product line is reducing the complexity, making a systems approach more doable for a very experienced person.

That Mastervolt has acquired all the components, added important features to each so they work better as a whole, and sells them in one catalog, dramatically simplifys what an experienced person taking a systems approach to using this technology, needs to think through. I can see myself doing this for my own boat, and succeeding.

An example of some cool features is in the power management features of the combo charger/inverter. You can run your HVAC off a combination of an undersized generator and your battery while at a mooring, using the battery to get past the initial high startup current of the HVAC and then topping your battery off again. This automatic capability allows you to have a smaller gen set (or even a portable HONDA generator) with less weight.

Dan, I can understand how an integrated approach to the charging & storage system is beneficial. I don’t think there is much “simplification” involved here, however, at least as far as the storage & charging part.

Note that the V65 boat has all of the same separate components that the majority of medium or larger recreational boats have (storage battery, alternator with regulator, distribution buss) but does NOT have a shore power charger or an inverter for AC equipment. Now I understand that all of the Mastervolt components talk to each other, so they are all likely to be on the same sheet of music as far as managing your energy – but it wasn’t hard for me to separately program the various components of my current *very conventional* storage & charging system to match my battery chemistry and temperature.

The V65 also has an additional 24V – 12V converter, because they really wanted the advantages of a 24V system for the larger loads, including presumably the canting keel hydraulic pumps, emergency pumps and likely any HVAC systems. Adding a whole new voltage is potentially very advantageous – but not for a retrofit (IMHO)

The only real simplification I can see is that it’s all in the same catalog..:-)

Now, if you introduce the REST of the boat’s systems, with electrical control & sensing on the same network buss as the nav/comm package – THAT is for sure a big plus worth considering – but that wasn’t what I was looking at, and simplification vs. complexity there is definitely subjective, especially looking at retrofit.

I am attracted to the claimed performance of the battery, but I’m not at all interested in gutting & rebuilding my present vessel or just chucking it and finding (or building) a new one – hence my questions.

In the Vestas Wind report it says the LFP battery was taken to the beach where it was found to have burned up.

Did the burning up happen on the beach or while still in the boat, partly submerged?

I would not rule out the battery connection cables being shorted while it was still in the boat and that would be a valid excuse for a battery burning up – but don’t lithium batteries have all kinds of protection built in?

But if it burned up just from being submerged in saltwater, that would be a major problem for me.

In Lisbon in late 2013 either my wife or I (we haven’t settled this yet) left open the hatch to the sail locker in the bow when we left for a short nighttime trip to nearby Cascais. We had strong winds and an ugly wind against current situation in the shallow water of the mouth of the Rio Tejo. When we got to Cascais, the sail locker was filled to the top with seawater. The sail locker also houses the bow thruster motor and its battery, a Victron Energy 100Ah AGM. When the locker was pumped out and rinsed with fresh water, the battery had spent close to 2 hours submerged in 3 feet of seawater. Except from a copperish look on the battery posts it was fine and it still is fine 18 months later, doing full service. Also fine was and is a Blue Sea Systems remote battery switch, BTW.

After reading this, I would hesitate to replace this battery with a LFP some day and I, too, would very much like to know more.

If there is a printed circuit board in it, that will surely malfunction if it is not encased in resin, like my phones always do when I fall in the drink from the dock. But this should fail safe and open the connection in case it gets wet. However, if it did that, that would leave the boat without power in an emergency. Not nearly as good as my AGM battery that would have provided full service while under water (if the bow thruster motor hadn’t locked up).

I have 12V/5000W on the boat. It charges very quickly and almost always full if used with 500w Watt&Sea hydrogen (+5knt boat speed). If interested drop me a line and I can take some pictures of all setup.

Laurin, I bet a lot of us (Ben included..;-) would like to see your installation! I had been looking at the Watt & Sea hydro generator system at the boat show, but hadn’t seen any “in the wild”. Apparently, Hydrovane has a kit for them that installs the generator on the Hydrovane mount, which would be very convenient for me.

Can you comment on Henning’s concerns about getting the LFP battery wet?