Clogged air conditioning condenser coils make for a hot boat

A hot room and air conditioning fans on high blowing warm air isn’t a good way to start your day. About two weeks ago I woke to just that. I knew something had to be wrong with the air conditioning but figuring out what involved a few wrong turns before finding what turned out to be a pretty obvious problem.

I’m a prima-donna when it comes to air conditioning. Though I love the water and love living on a boat I don’t love the feeling of a warm damp boat. So, little ruins my mood faster than a failure of the air conditioning. In part because of my intolerance for air conditioning problems I’ve learned to maintain and perform small repairs of my AC units. Have Another Day uses R-22 split-gas (meaning the compressors or condensers are in the engine room and the air handlers or evaporators are in accommodation spaces) Cruisair ACs. There is a 48,000 BTU condenser serving two evaporators in the salon and pilot house. The staterooms are served by 24,000 modulating (meaning it can adjust its output based upon demand) serving two evaporators, with one in the master and one in the VIP stateroom.

The salon and pilot-house evaporators are both controlled by a single thermostat in the salon and effectively operate as a single unit. The staterooms have one thermostat per evaporator where each zone can run independently. This whole system was installed in 2002 when the boat was built so the controls aren’t as sophisticated as what would be done now. As a result, the stateroom units are wired such that all they do is send a signal back to the modulating compressor indicating that their respective zones would like cold gas sent forward. These units don’t receive the normal errors for high pressure, low pressure, and low voltage that the more standard salon configuration does. I’m getting a little ahead of myself, but bear with me, these details turn out to matter as I figured out what happened.

Armed with only the knowledge the staterooms weren’t cooling I jumped down into the engine room to take stock of what was happening. I quickly discovered the unit was trying to start for a couple of seconds and then stopping. Being the pessimist I am I quickly jumped to the conclusion that the compressor has seized and I’m in for a hot and expensive day (or couple of days). In addition to finding the compressor wouldn’t start I also found it was very warm. At this point I shut the unit off and started dialing for experts. I feel very fortunate to have great network of really competent individuals. One of those people is Phil Gutowski of BoatRX who just happened to be pulling into one of the Beauforts (I’m not sure if it was South or North Carolina) after a 7 day passage from San Juan, PR. I got in touch with him and despite my contacting him while he was pulling in he was kind enough to consult on my tale of woe and provide guidance.

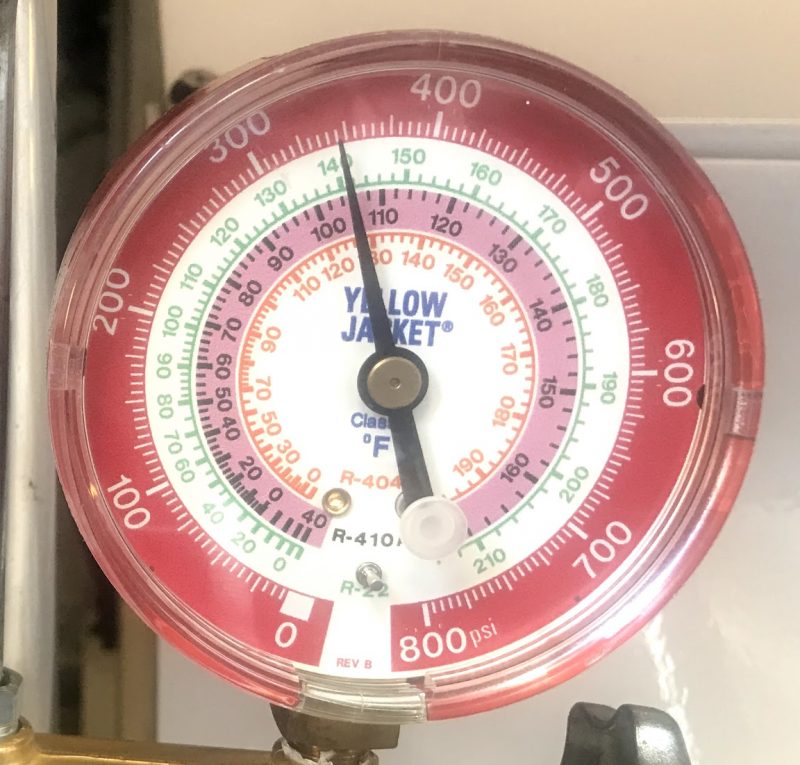

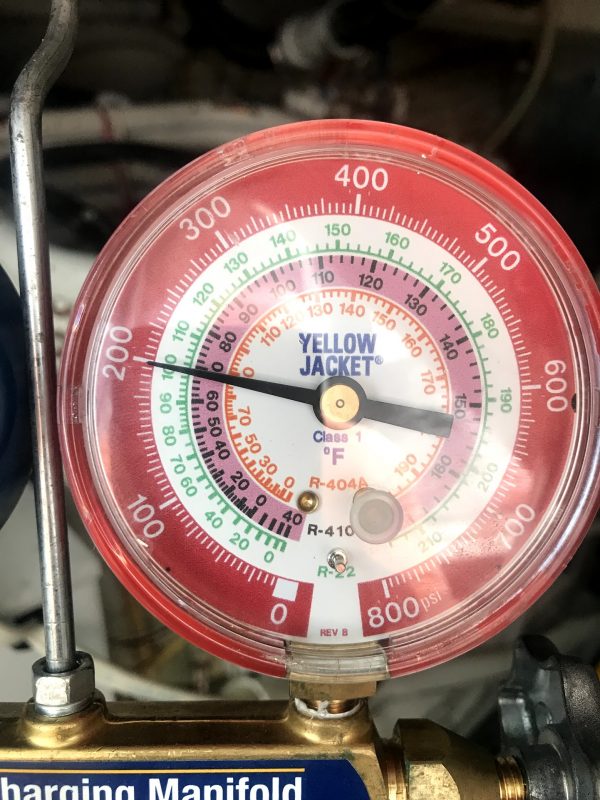

After talking to Phil and my friend Don who owns an HVAC company in the Chicago area I calmed a little and decided it was possible something less catastrophic was amiss. Fast forward through some trouble shooting to find I have a badly clogged condenser system and it’s driving very high head-pressures. On an R-22 system the head pressure should be between 200 and 300 psi. It turns out my second unit was hitting the high-pressure limit switch at 425 psi. It took longer than I would have liked to figure this out because there were some factors that lead me in the wrong direction. The biggest of which is that the salon unit shares the same water pump and condenser cooling manifolds but it wasn’t having any troubles. Ultimately, I think this was because of a small kink in the condenser discharge hose on the salon unit which constrained the already limited flow on that AC unit.

Opening my strainer revealed a shocking amount of growth and mud in the strainer. As soon as I saw this I was embarrassed that I was several hours into troubleshooting and hadn’t started here. So, with the strainer cleaned the system was fired back up. The pressures had moved down but not enough for me to think I was in the clear. So, it looked like it was time to flush the coils. Have Another Day has been a freshwater boat most of her life and while condenser coil problems do arise from time to time it’s much less common than in salt water. Hence I’ve never cleaned the coils on my AC units.

I took one look at the access to all the condenser hoses and decided I didn’t want to try and pull each of the three condenser loops apart and then reassemble them. My friend Don mentioned to me that he had just modified the plumbing on his AC condenser lines to allow him to flush his units. Using what he did as a guide I set out to find all the bronze bits I would need to build modify my plumbing to allow easy flushing of my condensers. $300 in bronze later I had what I needed and set about standing on my head in the bilge to get them all installed. In the left picture above you can see my intake plumbing. I’ve added a tee fitting, bushing and 3/4″ valve with a garden hose adapter screwed into it. In the right photo, I’ve added the same tee and valve arrangement but also a 1″ valve to close off the flow of water overboard.

When it’s time to flush the system I close the intake seacock, remove the cap from the garden hose fitting and open 3/4″ valve connected to the tee. I then make my way to the discharge side — behind the AC units with the only viable access gained by laying on top of the Seakeeper — and close the 1″ valve that stops water from being sent overboard. Now I also remove the garden hose cap and open that 3/4″ valve. Lastly, I connect hoses to both hose adapters and deposit them in a 5-gallon bucket full of Barnacle Buster.

The last modification I made was to put a toggle switch in my pump relay box to allow me to manually activate just air conditioning pump to circulate the flushing mix. This time I let that mixture circulate for about an hour and a half. During that time the mixture went from a nice light blue to jet black with lots of stuff floating in it.

After completing my flushing I was thrilled to find the head pressure sitting right at 200 psi and the units both seeming to run noticeably happier. I’ll add this to my routine maintenance list and complete a flush once every six months or so. But, this also left wondering about how to monitor this better. I don’t think most boaters carry a set of HVAC manifold gauges just in case their AC units have troubles. I looked at a few of the NMEA-2000 pressure sensors out there and couldn’t find anything capable of handling enough pressure to reliably report on this. If anyone finds one that can or if a manufacturer wanted to start making one I’d be very interested in getting my hands on four of them to ensure the health of my AC units. After all, I’m a prima-donna and I don’t want to have to go without my nice cold air conditioning.

Hi Ben, you could just put a preset pressure safety in the discharge line to a digital input. On R-22 most people go for 325 or 350 psi. Of course you wouldn’t see the pressure creep up but you would be alerted to protect your compressors. I didn’t see you mention if the compressors were shutting off on thermal overload or discharge pressure, but if the condensing units don’t have high discharge safeties you should definitely think of adding them. The compressor’s thermal overload should be it’s last line of defense.

As far as monitoring goes you could put a temperature probe on the dropleg (liquid refrigerant line leaving the condenser) to have an idea of the pressure. We have one Trane chiller that we take care of that only uses temperature probes to calculate refrigerant pressures in the system!

Joe,

I think you’re exactly right that the compressor eventually shutdown on the thermal safety. I believe what happened is that it was shutting down on high pressure but, because of the different control system with effectively just a handful of relays and a time delay unit this compressor doesn’t do what standard SMX controlled units will which is shut down until manually reset after the third high or low pressure shutdown. As a result, it was just banging off the high pressure switch until the compressor got hot enough to hit the thermal limit.

Ben

Ben, we used to live in Beaufort, SC with their hot and humid summers. With their 4 kts tidal currents, marine growth was a major issue for circulating water systems, e.g. a/c and refrigerator. We installed the water flush system design like yours and had to flush monthly to clear out the barnacles and other creatures of the deep that got sucked into the intakes. It’s good that you only need to do it every six months. BTW, how’s the Seakeeper doing? Ours is great and we use it all the time when in motion.

Ben, the first thing that jumps to my mind, for N2K monitoring, is Maretron’s FPM100. It is their six channel analog pressure transducer to N2K box. The transducers that they sell are spec’d as being compatible with refrigerant, and are available in models up to 5000psi. Now I have no hands on experience with a/c systems, so I don’t know how difficult it would be to integrate into a system. If you wanted to get real ambitious, you could use those last two channels to monitor seawater suction vacuum, or condensor back pressure. https://www.maretron.com/products/fpm100.php

I wondered about using the FPM100 too. Though I haven’t tried one, I know well from other Maretron sensors I use that you could set up alerts for higher than normal pressures and alarms for a seriously bad situation.

I’m also reminded of an elaborate custom motoryacht I once toured — https://www.lymanmorse.com/project/acadiaward-setzer-flybridge-motoryacht/ — that had some sort of electrodes in all the seacocks to kill zebra mussels. Apparently, the owner also had a fleet of commercial boats working the great rivers and feared the clogging they can cause.

https://texasinvasives.org/zebramussels/

I’m planning to reach out to Maretron and see if they think their sensors would be appropriate for use with refrigerant.

It would be very nice to be able to monitor AC health at a glance from the NMEA-2000 network.

BTW, somewhat easier is monitoring temp on the input side and output side, and then just looking at temp differential between the two, this is the approach I am planning to take. When the temp differential gets too low, it is an indication that something is off.

Ben,

I’ve been managing my Marine Air SMX systems for almost 20 years now and early on determined that some level of monitoring the health of the system, other than waiting for the compressor to shut down was required. I have effectively installed thermocouples to the suction line near the compressor on each of my condenser unites on not only the A/C units, but also the refrigeration throughout the vessel. Five on the A/C units and four for the various refrigerators. Some effort to locate the best and coldest spot on the suction line is required however it is generally near the service port on the low side.

On an R-22 system this should show a temperature of around 45 to 50 degrees F if the unit is stabilized and properly charged. It doesn’t really matter exactly what the temperature is, important is that generally it stays the same over the years and changes mean it’s time to do some maintenance.

On my boat I have installed a Maretron data collection system where I monitor 33 unique temperatures throughout the vessel including the temperature of the Trend Marine shaft seals. I have set up alarms to let me know when a device drifts to an exceedance level. I can also look back at history and see interesting correlation’s to foolish things I might done such as dragging the boat thru some mud and discovering that 30 minutes later none of my A/C units seem to be cooling properly…. Time to clean the screens!

Thanks, Cyril

I think monitoring the temp on the lines is a good idea. Flow meters on raw water intake can also be helpful, but in this situation you may have had enough flow where it wouldn’t have triggered. Also I imagine Marine AC makers could create a self diag system if they really wanted too. Some auto AC systems have a surprising amount of info in the body computers.

On the having gauges thing, after being a broke parent and having to fix my own car AC I bought a set of R134 gauges about a decade ago. Great investment, HVAC is much less a black art then most DIY people think.

I just put together a similar garden-house flush set for the 2 A/C units on my Silverton 330SB. They also share a single seawater pump, and by adding shut-offs for the hoses feeding each unit, I can flush either line effectively, plus also balance the flow between them a little better.

Ben,

Great article. I’ve been hooking a line up from the output of the pump and loop it to the output of the condenser, but requires a small pump in my bucket to circulate the solution of Barnacle Buster. I like the idea of hooking up stream of the water pump, let it do the work and cleaning it too.

I have two condensers that are fed from the one water pump, so if I did them individually, I’d need a simple way to shut the flow off for the unit not being cleaned. Or perhaps I could clean both units at one time.

Here in the FL waters where the boat lives mostly (exception of doing the loop this past year), once a year seems to be adequate.