Gizmo holed, for a sonar summer

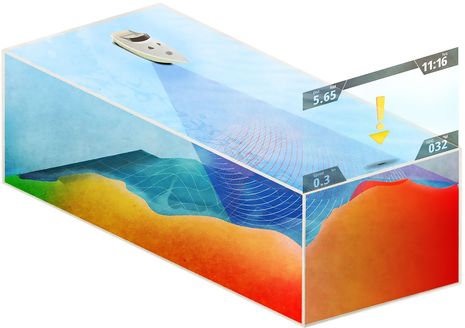

That’s a beautifully built Interphase forward looking sonar (FLS) transducer — actually two phased array transducers, one 90� vertical and one 90� horizontal, cast into the same epoxy block (hence the dual outputs). It can be used with several Interphase FLS models, but I’m looking forward to trying it with the company’s new Ultrascan PC90, discussed here last Fall. And I went to some trouble, including carefully band sawing that fairing block, to give it a good view. In fact, some may call me crazy…

Yeah, I cut three holes in Gizmo’s keel, about nine feet back from the stem. First up, obviously, is the Interphase FLS transducer. I thought about putting it off center, where it would be more protected, but the fairing block wasn’t quite deep enough to achieve the ideal vertical athwartships orientation because of Gizmo’s sharp 37� dead rise in this area. I also realized that the transducer’s epoxy-filled bronze stem is flared at the bottom, so even if I hit something hard enough to sheer the black body off, it’s unlikely the event will cause a leak. Plus I found that Gizmo’s keel area sports a pleasing solid inch of fiberglass. I went for it.

The location of the FLS transducer is nearly ideal, I think, but as for the Airmar DST800 I plan to insert in that thru-hull casing right behind it…maybe not so much. I realize that, and have other options for speed and/or depth, plus Airmar has a camera that would fit nicely in that casing if there’s just too much turbulence from the phased arrays.

Finally, further aft is a Lowrance/Simrad StructureScan side-looking transducer that’s actually designed to be transom mounted (when bolted to a stainless bracket). But Navico won’t have their StructureScan thru-hull transducer finished for a while, and I’m keen to test my theory that this technology can be useful for gunkholing. The duct tape, then, is holding in the large charge of 3M 5200 I squeezed into the offset cable hole (where I’m also using a Scanstrut Deck Seal. A little funky, yes; crazy, maybe; but it will be an interesting sonar summer. Lighting wise too…

I also drilled holes in the stern for a pair of OceanLED A6 Amphibian underwater lights, despite the major Panbo hooha on this subject. But they’re “warm white” — instead of Lauderdale blue — in deference to New England sensibilities. When adding gizmos to Gizmo, even getting gooped with 5200 while lying on my back in dank shed was big fun.

Incidentally, I’m looking for advice on the latest coatings to keep transducers clean in saltwater. Also what best for keeping barnacles off of bow thruster plastic prop, main bronze prop, and stainless rudder?

Ben, for what to put on your prop to protect it from the barnacles, take a look at what Captain Richard Rodriguez does in the San Juan Islands:

http://bitterendblog.com/?p=4465

He uses Delo grease, which seems to work well.

I have the older, bigger dual scanning interphase transducer on the port hull of my PDQ, and have just mounted a DST800 in the stbd hull, just forward of the keels in both cases. Last season in the Northern Chesapeake my depth sounders became completely covered with up to 1/2″ barnacles, in spite of several coats of Petit Transducer Paint #411179320. My old ST-50 depth transducer was able to work occasionally with that load but the interphase had conniption fits. [cotton belt term] This season I’m trying MDR Waterbase Anitfouling Transducer Paint, pn mdr-720. It drys to an abrasive or gritty texture, but I have no idea if that’s intentional or a consequence of rolling it on with a small foam roller. At least it was easy to clean up.

Since your water is colder, you will have better luck than I did.

I mounted the controller at the helm and display the Interphase via the “red box” on the video input of my Garmin 3010C.

Ben, looks great and most of all you are having fun at the same time. Tell us again how we can get a job like yours.

I have had no luck with any type of transducer anti-fowling paint.I feel fortunate though as the guy in the water stall next to me is a certified SCUBA diver and it costs me a 1/2 Gallon of Crown Royal every month (May-Sept) to keep my transducers, Rudders, props and thru hulls clean and free of growth. You should be able to find a diver in your area who does this for a living who could take care of the problem for you. The marine growth here in the PNW is at its worst May thru Sept otherwise its not that bad thru out the rest of the year.

Anyway I appreciate all your hard work you do for the boating community and enjoy all the articles you write. Keep up the good job.

The MDR Transducer Paint worked well on my depthsounder and plastic bow thruster prop last year in the Northern Chesapeake. It did not work at all on the paddle wheel (a good reason to go ultrasonic or electromagnetic!).

I’m going to try Prop Shield on the bronze prop again.

Jon

Ben,

I just finished up installing 2 Interphase FLS ‘ducers for the SE200-C and an Airmar DST800 on a 38’ sailboat, so I’ll be curious how the two units compare and would enjoy swapping notes. I’ll hopefully be powering up the system on Friday.

I’m surprised you used 5200, 3M 4200 is a much better choice for ‘ducers since they will most likely need to be removed someday, and 5200 makes that much, much harder.

Ben, that location for Airmar DST800 will be useless for depth unless you are not moving, because of the water/bubbles coming off the FLS transducer immediately in front of it. A better choice might be one of Airmar’s tilted element transducers mounted farther back in the hull on the deadrise. I’d pull DST out of there while the boat is still ashore and the hole can be filled with glass or just install a blank in the DST thruhull fitting.

Frequency interference doesn’t appear to be a problem since the FLS is at 200kHZ, the DST800 is at 235kHZ and StructureScan at 455 and 800kHZ.

We’ll see, Randy. I’ve been surprised by what you can get away with sometimes, especially at displacement speed or less. (I’ve also sometimes run same frequency transducers very close together without problems.)

That said, I won’t be too surprised if the neither sounder nor the paddlewheel speedo in the DST800 works well at this location. But, as I wrote, I already have alternatives for those sensors, and Airmar makes an underwater camera that might be perfect in that spot.

Gizmo is a test platform.

Aaron, I thought about using 4200, but given how exposed the transducer holes are, I decided to go for maximum protection. Since the transducers are right on the keel, a hard grounding on a ledge could conceivably shear all three away. I want the remains to be as tightly adhered in those holes as possible, even if it makes removing them harder.

I had to remove a transducer sleeve bedded with 5200 a few years ago, It took some of the surrounding fiberglass with it. A salesman gave me a sample of a new product last year that actually loosened 5200 on another job. I’ll have to get back with the specs. It did not appear to have affected fiberglass or marelon.

Ben, we often saw transducers placed very close to each other on high-performance center console boats where there weren’t many choices for alternate transducer locations…..where we did see interference it almost always was because the excess loops of transducer cable were laying beside each other. Interference usually went away when we got some distance between the cables.

Heard that it was “shorts” weather in Maine yesterday!

Having just completed a crawl up the ICW, I’m suddenly very interested in forward-looking depth sounders/sonars. Several times we tried to enter spots that the cruising guides pointed out as anchorages, and came to a sudden, sodden, squishy stop. Never mind the shoaling here and there.

I suspect that my requirements are very difficult to meet. Our boat draws 6’2″. I want to know whether or not, say 100′ ahead, I have 7′ of water (or more). It looks to me as though the geometry is very discouraging, particularly when the transducer is mounted on the bottom of a boat that may be pitching a bit.

So…does the technology exist to do what I want, and if so at what price?

You’re right, Larry, the geometry is tough. Soft muck is also a poor sonar target.

I don’t have either the FLS or StructureScan transducers seen above working yet, but hope to soon. I am pleasantly surprised at how well the regular DST800 transducer is working despite its “poor” positioning behind the big Interphase bump. It seems to hold bottom in several hundred feet at up to about 15 knots, and it’s great for feeling my way into shallows.

Please let us know how the transducers worked. I have used that interphase transducer in a transducer box built on the inside of the hull. The phased array transducer was shooting through 1′ to 6″ of water then 1/2″ to 3/4″ of fiberglass then through seawater to the target and back. Out to about 100′ or so I had pretty out image results, able to see channels thru reefs and even leaded crab pot line. I am now considering using the same transducer mounted on the outside of the hull on a different boat.