A cool and quiet sailboat thanks to efficient air conditioning, LiFePO4 batteries, and Integrel

I work around boats pretty much every day of my life. So, what would cause me to jump in my car and drive 28 hours round trip to go see a boat? The answer: A brand new, luxury 44-foot sailboat ordered with no generator and no air conditioning. But fear not, although it was delivered without systems many regard as required, it’s now been outfitted with arguably the best air conditioning and power systems available.

The combination of highly efficient air-conditioning from Termodinimica, Victron batteries, power conversion and distribution equipment, Kilovault LiFePO4 batteries, and Integrel’s 9kw power generation solution make comfort aboard possible in a way that was a dream just a few years ago. These systems deliver comfort and quiet, without a generator.

The obvious hesitation with an all DC boat is will it stand up to extended use and cruising? I visited the boat during the commissioning stage of the myriad systems aboard. From what I saw, the systems are up to delivering on the promise of silent comfort with ample juice for many years to come.

Phil Gutowski and his company, BoatRX have carved out quite a niche designing and installing high-efficiency air conditioning systems in boats of all shapes and sizes. Phil was kind enough to write a primer on DC air conditioning for Panbo several years ago that captured the attention of many regular Panbo readers.

Phil’s article concentrated on DC air conditioners making climate control possible on vessels that previously had none. But, that’s not the case on Cinnamon Girl. Instead, the owner of this new build, 44 Jeneau Sun Odyssey has chosen advanced air conditioning, batteries, power management, and power generation in order to deliver an efficient, quiet boat that’s not dependent on a generator running to deliver comfort.

The System

Let’s start by understanding what the owner was after when he started this project: To start, the owner was clear he wanted to deliver cruising comfort without a generator. Additionally, he required full air conditioning overnight with power delivered via batteries. In order to run the air conditioning from batteries, it’s critical you can quickly replace the energy consumed from the batteries. So, fast recharging of the batteries is another requirement. The owner will install a watermaker, so power for the watermaker and other ship systems is factored in. Lastly, in addition to bulk charging sources, solar panels will also be added to the boat.

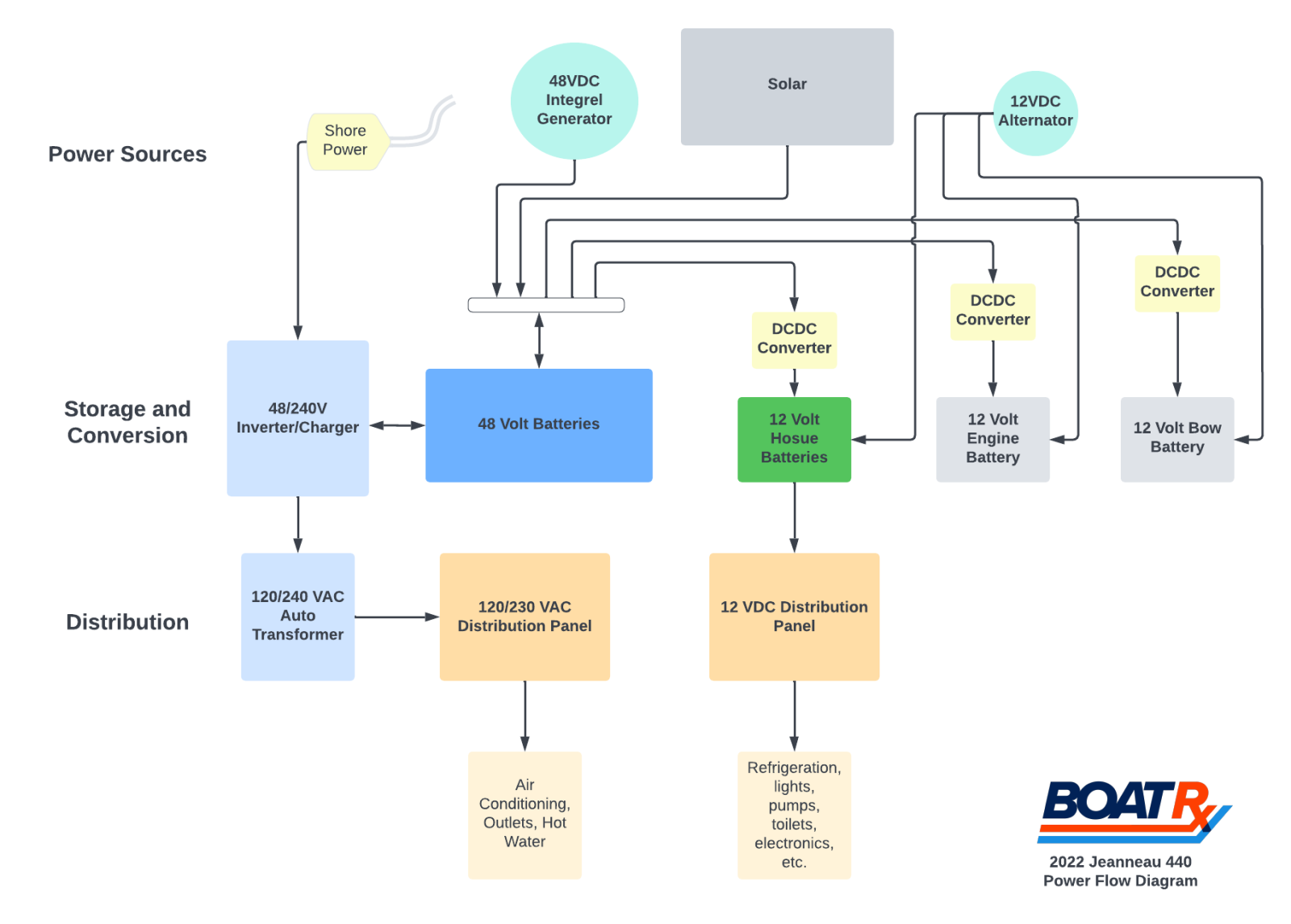

BoatRX presented three different options to the owner. Two of the options relied on all 12-volt designs with more traditional alternators. The third, and winning, proposal relies on a 48-volt battery bank that powers a large inverter. That inverter powers the air conditioning loads as well as all onboard 110-volt systems and loads. Additionally, there’s a 12-volt house bank to power all the boat’s 12-volt loads.

To really understand everything that is happening aboard Cinnamon Girl, I think we need to look at three major separate systems that make the magic happen. These systems were carefully engineered by BoatRX to work together and deliver the desired ownership experience. They are the air conditioning system from Termodinamica, the power system consisting of AC (240 volts and 120 volts) and DC systems (both 12 and 48 volts), and Integrel’s advanced 48-volt alternator system. This was a large project. Installation took several weeks and the total budget was around $135,000. The owner did mention that ordering the boat without air and a generator saved nearly half the project cost.

Power system

The final power system aboard Cinnamon Girl consists of a 120-volt / 240-volt alternating current system and a 48-volt DC house system, and a 12-volt DC house system. Additionally, there are lead-acid engine start and bow thruster batteries.

Shore power

A North American spec Jeanneau 440 comes with a single 240-volt, split-phase, 50-amp shore power inlet. Once on the boat, power is divided into two 120-volt legs and distributed throughout the boat at 120 volts.

The new air conditioning system requires 240 volts, so some changes were necessary. BoatRX modified the boat’s electrical system to directly route 240-volt power to the boat’s inverter, then to a Victron Autotransfomer and then, for house loads, back to the boat’s AC distribution panel.

The heart of the newly reconfigured AC power system is a 5000-volt-amp, 230-volt Victron Multiplus-II and a 120/240-volt, 32-amp Autotransformer. When connected to shore power, the inverter accepts a 240-volt input from shore power and outputs 230v to the Autotransformer. The Autotransformer accepts the 230-volt single-phase, 60hz output from the inverter and creates 120/240-volt 60hz split-phase output.

The combination of the Autotransformer and Multiplus-II give tremendous input power flexibility. The inverter will accept input power from 187 to 265 volts at a frequency between 45 and 65 hertz. Plus, in the event of smaller available shore power circuits, the inverter can utilize Victron’s PowerAssist to augment available power.

The only AC loads on the boat not powered via the inverter are the hot water heater and a dedicated 12-volt battery charger. The boat has to be connected to shore power for the element to heat.

House and inverter batteries

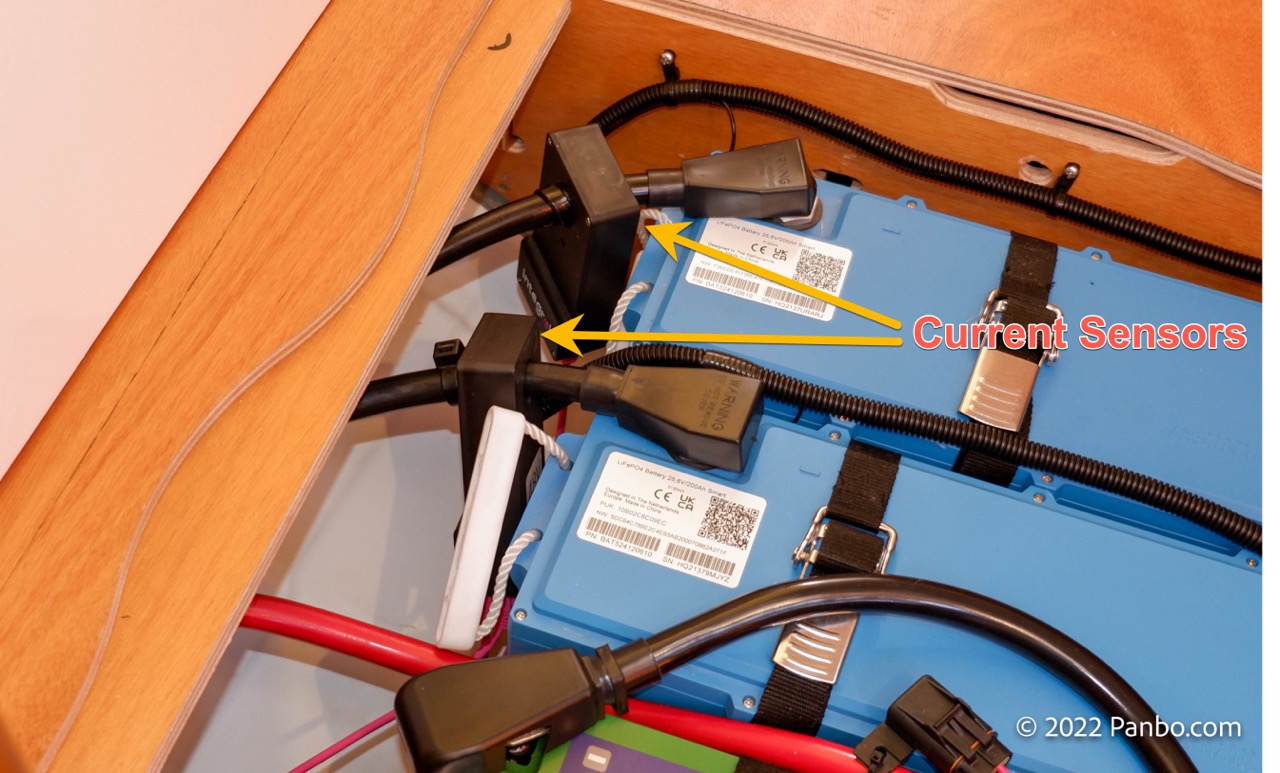

Cinnamon Girl has two separate lithium iron phosphate (LiFePO4) battery banks. There’s a 48-volt bank composed of four 25.6-volt, 200 amp hour Victron Lithium Battery 25.6 Smarts. Connected in serial and parallel, the total capacity of the bank is 400 amp hours at 48 volts or roughly 20-kilowatt-hours. There’s also a 12-volt parallel string of Kilovault 100-amp hour batteries providing a total of 3.6-kilowatt-hours.

The 48-volt battery bank services just the inverter but has a plethora of charge sources. When connected to shore power, the inverter charges the batteries at up to 70 amps continuously. That’s an impressive 3.36-kilowatts of charge current or the equivalent of 280 amps of charge at 12 volts. The 48-volt bank will also be charged by 1,000 watts of solar via Victron MPPT controllers. Lastly, and far from least, the Integrel system will also charge the bank at up to 9 kilowatts or a somewhat staggering 188 amps at 48 volts.

In normal operation, the 48-volt bank sits at the top of the DC food chain. This bank accepts charge from the sources outlined above and then shares power with the 12-volt house battery bank, engine battery, and bow-thruster battery. This power sharing happens through Victron MPPT chargers used as DC-to-DC converters. Phil Gutowski explained they selected MPPTs rather than Orions because of the greater voltages supported and size configurations available.

But, even without the 48-volt bank, the 12-volt bank isn’t suffering from a lack of charging options. BoatRX installed four Victron MPPTs employed as DC to DC converters charging the 12-volt house batteries from the 48-volt bank. There’s also a 240-volt AC to 12-volt DC battery charger to charge the 12-volt house bank, engine start, and bow-thruster batteries. Lastly, the Yanmar 4JH’s 120-amp alternator, paired with a Balmar MC618 regulator, charges all three banks.

Integrel power generation system

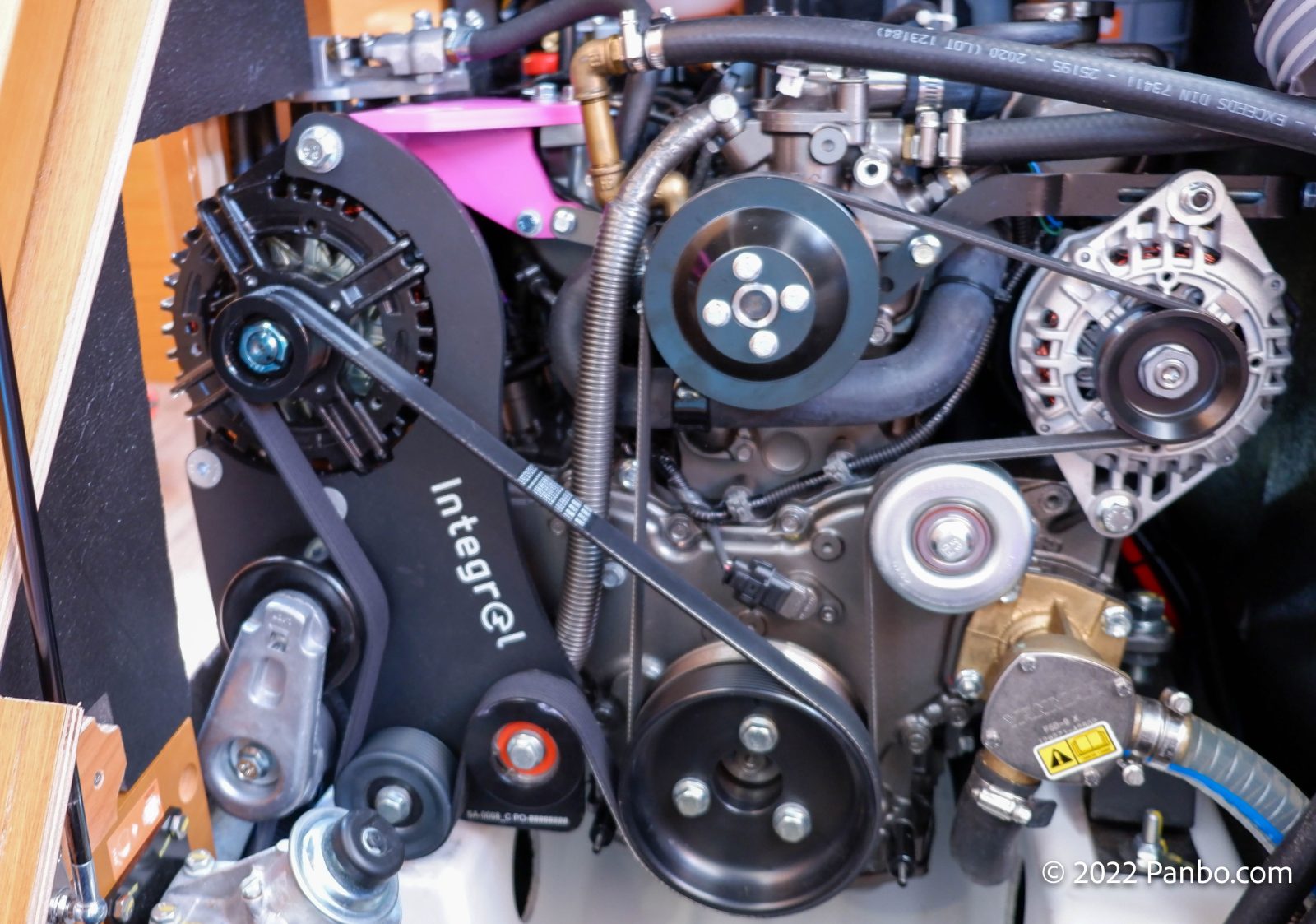

Integrel’s power generation system can generate up to 9 kilowatts of power from the main propulsion engine. On Cinnamon Girl it’s mated the Yanmar 4JH57. Originally developed by Nigel Calder, Integrel utilizes an extremely high output alternator producing around 56 volts to charge a 48-volt battery bank. They call the system an engine-mounted generator to better convey the quantity of power the system can produce.

Integrel’s advanced control system utilizes numerous sensors and a J1939 connection to the engine’s control unit to regulate the system. The control system utilizes engine load information so that it can dial back the load it places on the engine. This ensures there’s sufficient propulsive power available but allows Integrel to harness power that would otherwise be wasted.

Fitting the large Integrel alternator into the engine compartment was a tight squeeze. In fact, it was so tight a hole had to be cut alongside the engine to make room for the alternator. The hole will get an access plate in the final stages of installation.

Air conditioning

The biggest driver behind this entire project is the extended air conditioning run time powered by batteries. To do that, two things are necessary: a large battery bank and efficient air conditioning. But, more efficient air conditioning means smaller battery banks or longer runtime off of batteries.

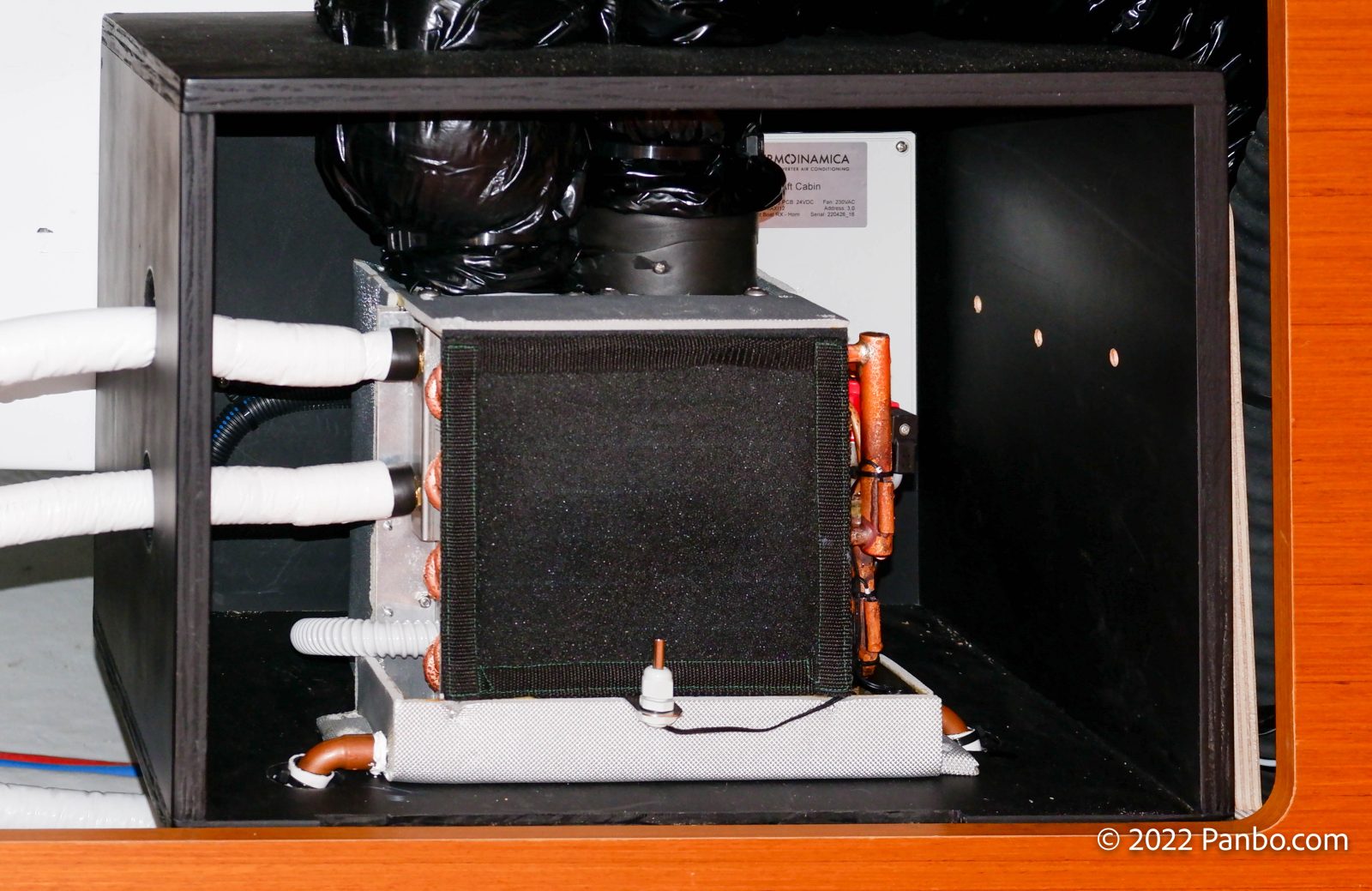

BoatRX selected the most efficient air conditioning system in the market. Termodinamica’s Compressor Box and air handlers. Although Termodinamica relies on proven technology, they’ve put it all together in a way the marine market hasn’t seen before.

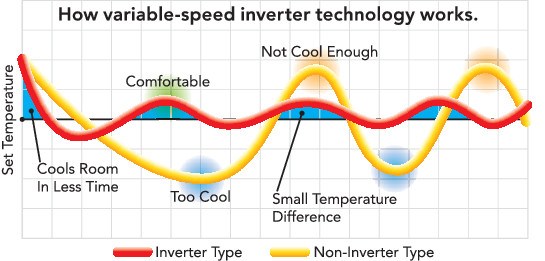

Variable capacity

Combining a variable-capacity compressor with variable speed fans and a sophisticated control system deliver peak efficiency. The illustration above shows some of the benefits of variable capacity AC systems. Traditional, fixed capacity, AC systems are either on or off. As a result, they blast cold air until the set point is reached. Then, they shut off and let the room’s temperature climb until it’s high enough to cycle back on. Variable speed systems simply reduce the compressor’s speed to match the call for cooling. As a result, the room’s temperature is more consistent. Additionally, because the system runs consistently, humidity is more effectively controlled by being evaporated out of the continuously cooled air.

For many of us, our first exposure to variable capacity air conditioning systems was probably from a mini-split system. Most mini-split systems use variable capacity to deliver quiet cooling at just the rate needed to keep the space comfortable. Variable-capacity is also marketed as inverter or VFD (variable frequency drive) air conditioning. Inverter and VFD refer to the actual technology used to vary the capacity of the system.

Termodinamica employs a variable capacity mechanism called VRV or variable refrigerant volume (often called VRF or variable refrigerant flow) to deliver carrying amounts of refrigerant based on the load. This is done by varying the speed at which the compressor runs. To vary the speed of an alternating current motor, you vary the frequency of the power. In North America, alternating current alternates at 60 hertz, or 60 times per second. To slow down an AC motor you slow the frequency with which the power alternates. An air conditioning compressor is essentially an AC motor, so to slow it down and hence reduce its capacity, we slow the frequency of the power. To do this, incoming alternating current is rectified to direct current (DC) and then inverted back to AC at a different frequency. Conversion losses are relatively small at each step, but it’s still likely that 10-15% of our power is lost to conversion.

In their marketing materials, Termodiniamica claims a minimum of a 50% reduction in power compared to traditional systems. We’ll see Cinnamon Girl’s results a bit later and can compare, but based on what I’ve seen, the claim seems accurate.

Distributing the cool

Now we really get into the heart of what makes the Compressor Box system different than what we’ve seen before. In concept, Have Another Day has a similar system to Cinnamon Girl. The compressors (or condensers) on Have Another Day are in the engine room while air handlers (or evaporators) are spread throughout the boat. But, my system lacks the flexibility and efficiency of Termodinamica’s. I have a 48,000 BTU compressor for my salon. That compressor serves two 24,000 BTU air handlers. It’s all controlled by one thermostat and when the thermostat calls for cooling, both air handlers run at full capacity. I can’t only run one evaporator at a time and I can’t run them at anything less than 100%.

Each air handler has an electronically controlled expansion valve to precisely control the refrigerant that passes through the evaporator coil. There’s a control box connected to each air handler that controls the expansion valve and communicates the air handler’s cooling demand to the Compressor Box via ModBus.

Mix and match flexibility

The beauty of this approach is the flexibility it affords. If only one air handler needs cooling, the compressor will produce appropriate cooling for just that unit. The compressor’s ability to match its capacity to the demand from the air handlers affords flexibility in designing the system. If Cinnamon Girl had been ordered with air conditioning, it would have come with a 16,000 BTU unit in the salon. That unit would be sized according to well established formulas that deliver the best compromise of cooling capacity and humidity control. We are all programmed to think a bigger unit is inherently better, but that’s not the case with traditional air conditioners.

A larger unit may be able to reach your desired temperature faster. That sounds like a good thing, and for meeting your temperature requirements, it is, but much of the comfort we get from air conditioning is from cool dry air. Air conditioners dry the air by blowing warm, humid cabin air across cold coils. The humid air meeting the cold coils causes the water vapor in the air to condensate on the coils, drain down to the condensate pan, and be drained overboard. But, it takes a lot of air flow across the coils to drain all that humidity. If the desired temperature is reached too fast, the air will be cooled but not dehumidifier.

The variable capacity of the compressor and air handlers in the Termodinamica system mean that, within reason, the air handlers can be oversized a little. If it takes 16,000 BTU to cool and dehumidify the space most of the time, that’s where the system will run. But, if you’ve just returned to the boat on a hot day and the system has been turned off, additional capacity will be available to get rid of the excess heat quickly.

The flexibility capacity gives the system designer Lego like mix and match options. A boat could be outfitted, again within reason, with more air handler capacity than compressor capacity. Many boats’ use patterns suggest there will never be a time when all the air handlers will run at full capacity at the same time. So, if you know that stateroom systems only get turned on in the evening, when the salon system isn’t working hard, you can size the compressor box appropriately.

The Compressor Box supports up to five air handlers with its internal power supply. With an external power supply, the limiting factor will be the total cooling capacity of the compressor.

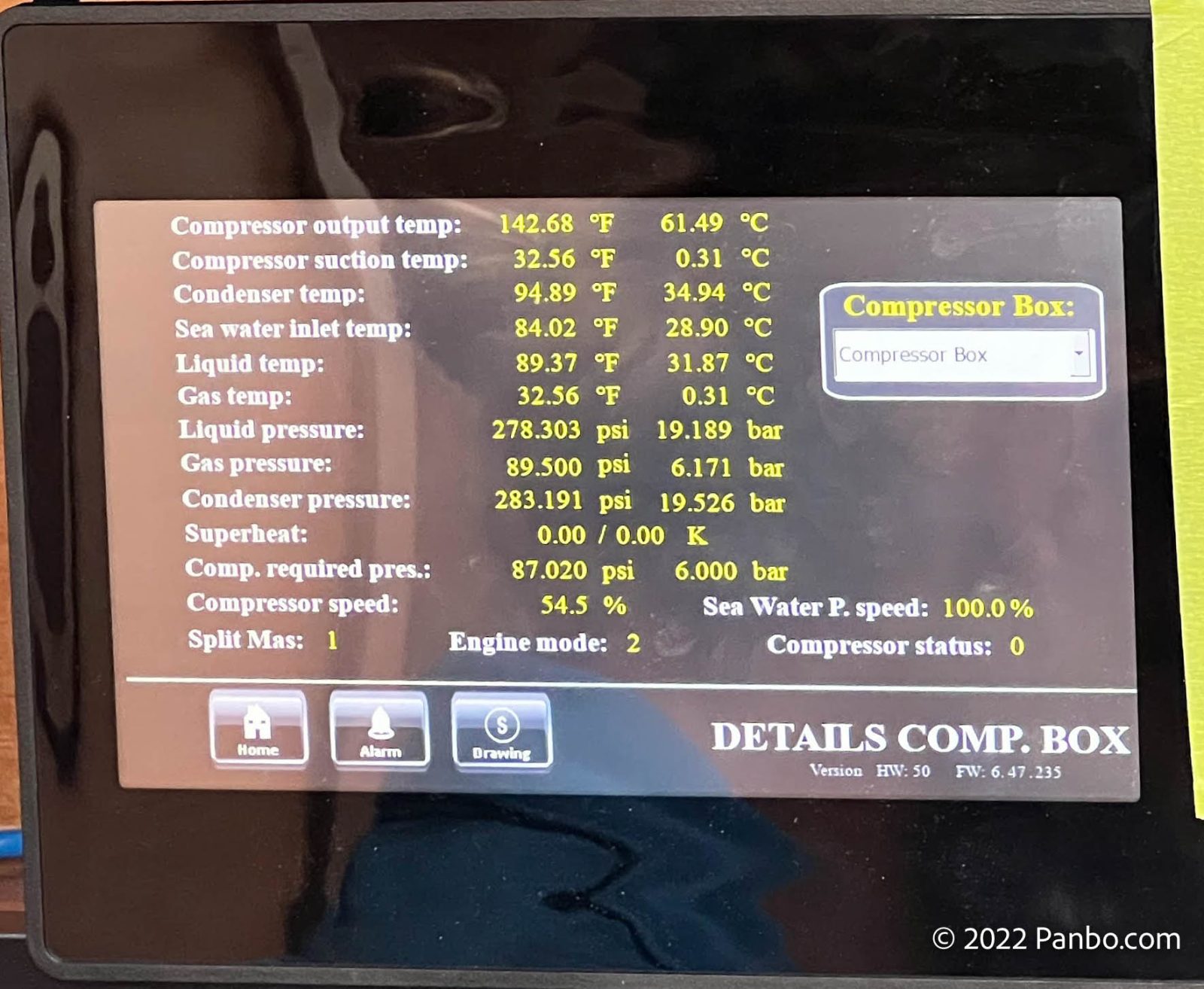

Precise control

Termodinamica achieves its efficiency by precisely controlling the system’s operation. The fans in the air handlers have 250 speeds, the compressor speed is highly variable and all aspects of the system are monitored. Having spent too much time troubleshooting my own system, I’d love to have all this information at a glance.

Why 48 volts?

I’ve written a piece discussing the merits and downsides of a 48-volt DC system afloat. But, for this project, Integrel’s ability to rapidly recharge its 48-volt bank determined the voltage of the battery bank. In my other entry, I point to the architecture BoatRX used as the most logical based on 48-volt component availability. By using a split system BoatRX was able to take full advantage of the benefits of 48-volt while minimizing the downsides. Also, 48-volt is the foundation of Integrel’s capabilities. I don’t think there would be any chance of generating 9 kilowatts of power at 12 volts from a single alternator without massive cooling and a physically much bigger alternator.

Running the system

I arrived at Cinnamon GIrl well into the commissioning phase of the project. It was a warm and humid day on the Chesapeake, so I was quite happy the air conditioning was working. Coincidentally, the day I arrived the local power utility was doing work that required turning off the power at the marina. Fortunately, I was visiting a boat with battery-powered air conditioning. Between battery-powered air conditioning and all loads — except for the hot water heater — powered by the inverter, the loss of utility power was a non-event.

Efficient cooling

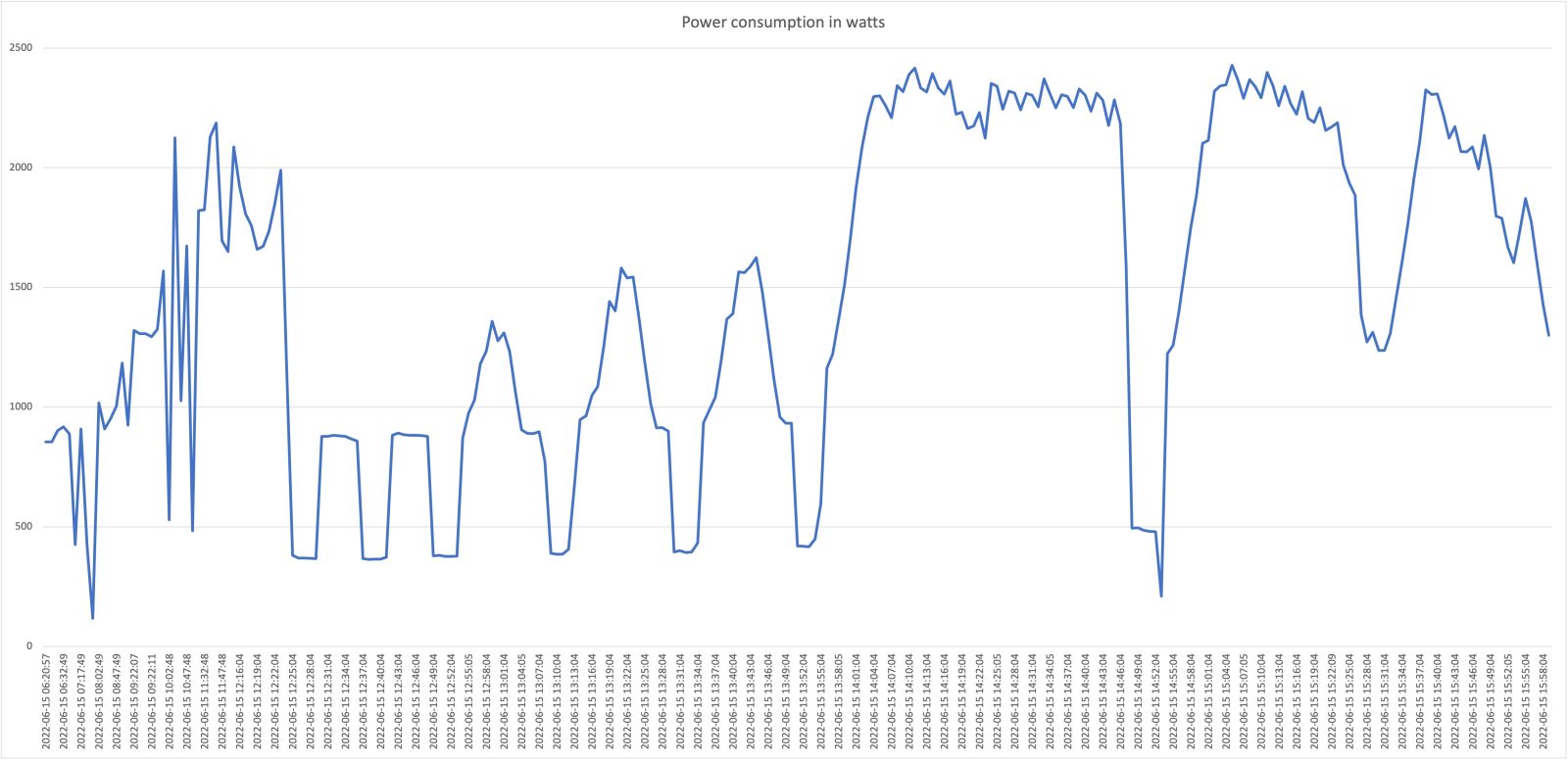

The graph at the start of this section shows power consumption through the inverter on the day I visited. This was measured and recorded via Victron’s VRM. The inverter feeds all loads except the hot water heater, so it’s a full accounting of all power consumption on the boat. Because there was a lot of commissioning work being done on the boat, the companionway door was opened frequently, which meant the air conditioning had to work harder. According to VRM, for the nearly seven hours I was there, the system average just under 1.5 kilowatts of power consumption.

Based on the 20-kilowatt battery bank, 1.5 kilowatts would give a total runtime for the system of about 13 hours if you discharge the batteries to zero percent. Or, just shy of 11 hours if you discharge to 20 percent state of charge. But, I was also there for the hottest part of the day and I was there before the solar installation was completed. The boat will be fit with 1,000 watts of solar. The beauty of solar as a power source for air conditioning is that the times when the most air conditioning is needed are also the times when the most solar energy can be harvested. Even just 3 kilowatts of solar will likely add a couple of extra hours of runtime to the batteries.

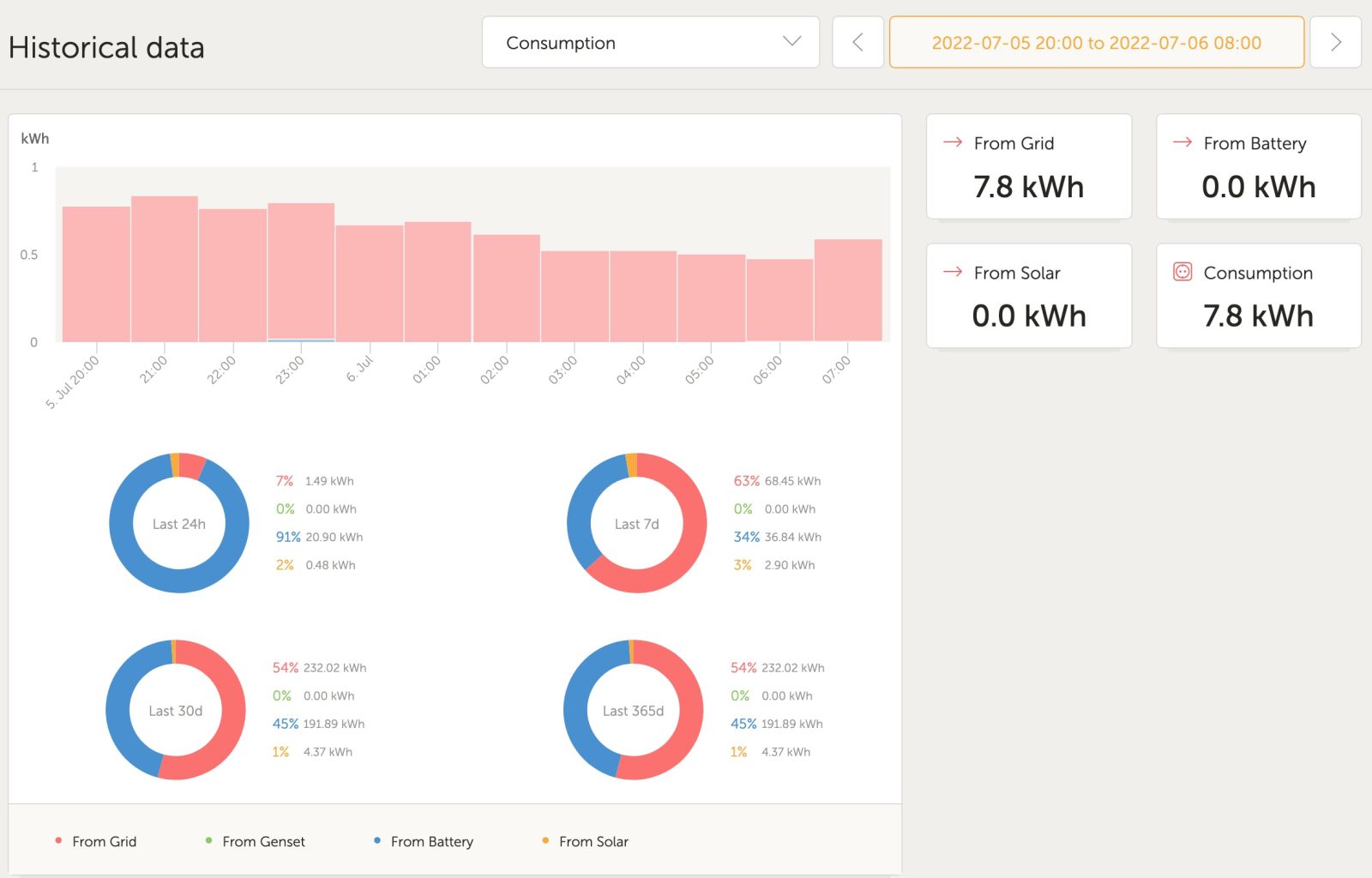

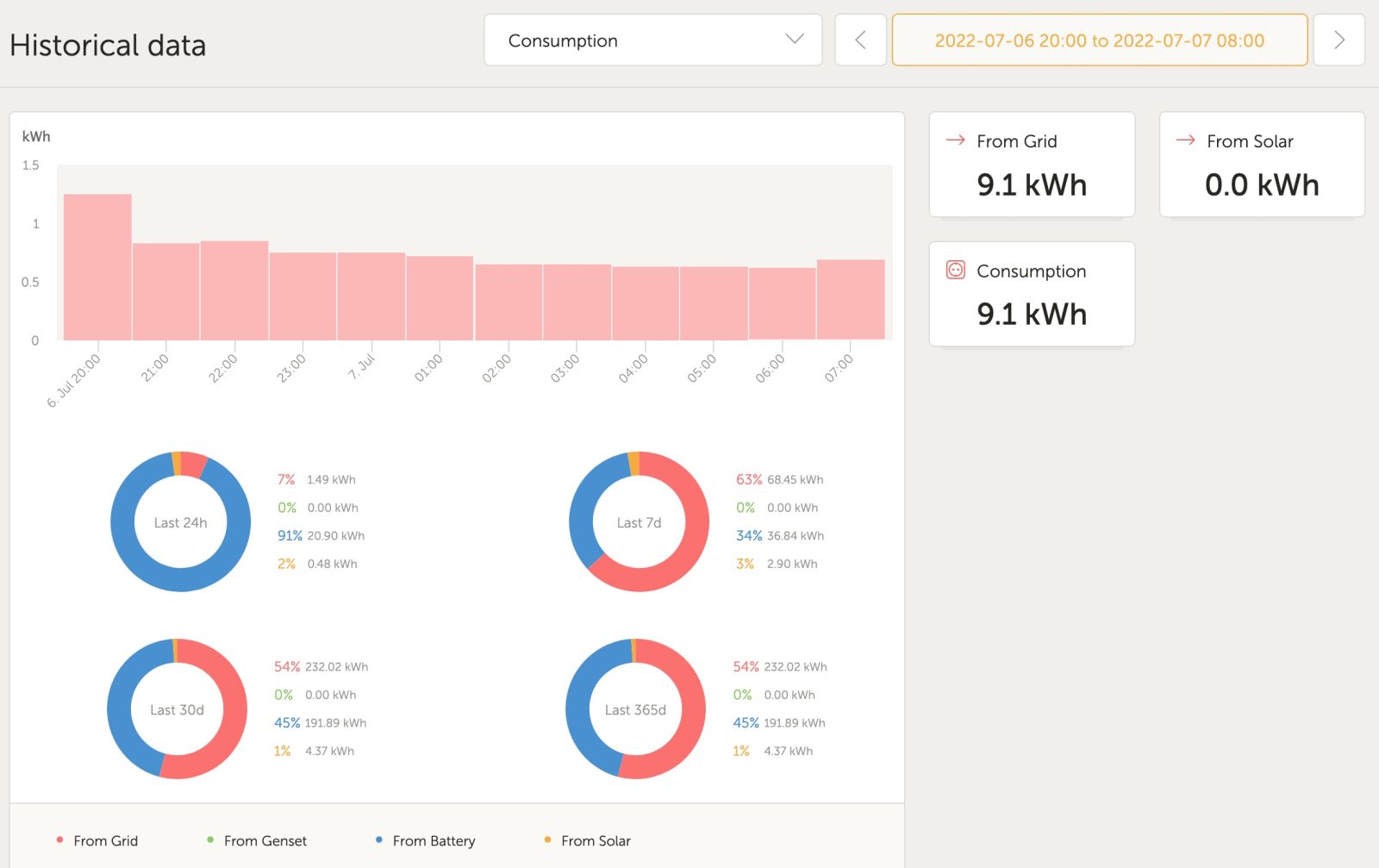

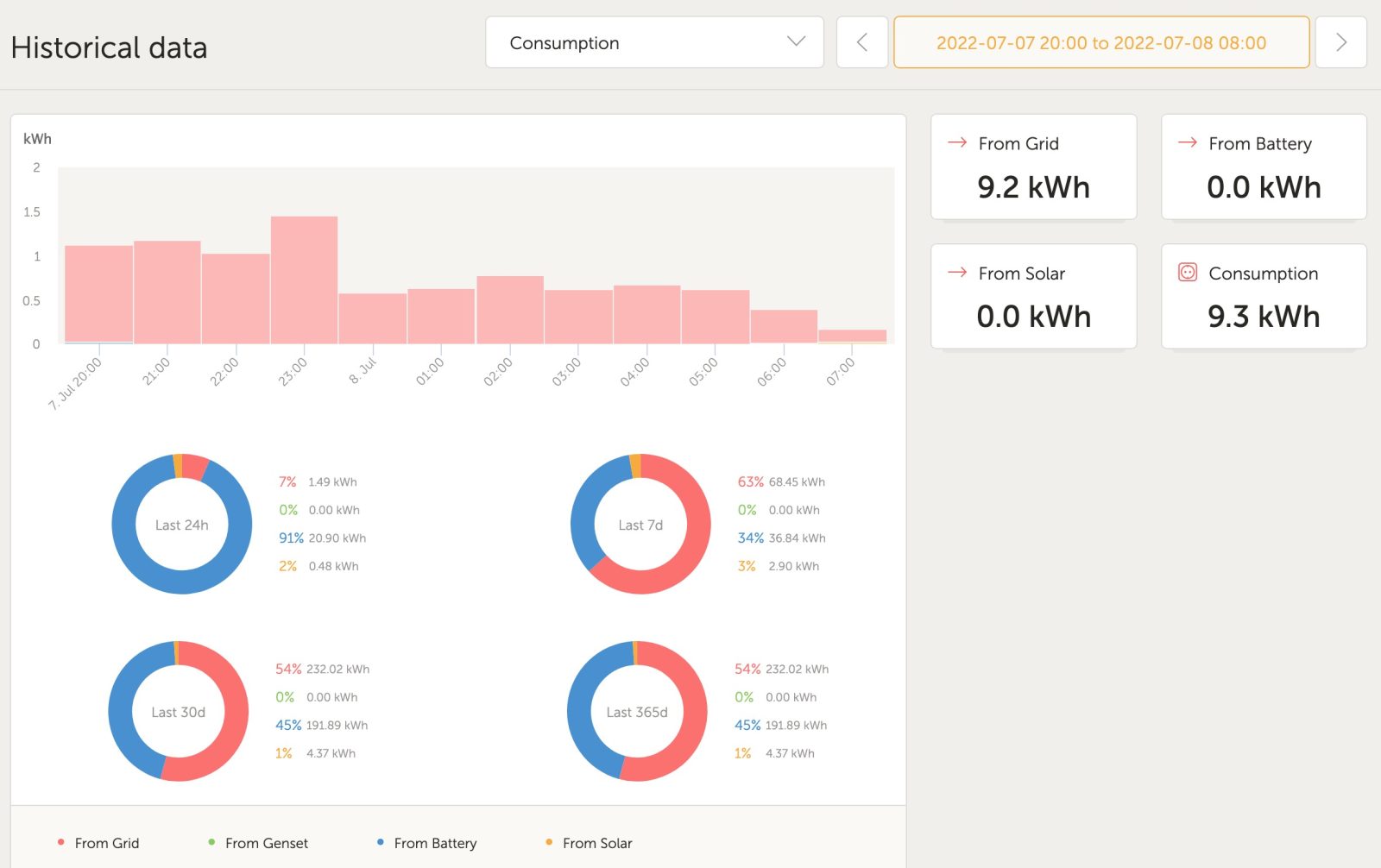

Remember, the owner’s original requirement was to be able to run the air conditioning overnight from battery power. Power usage overnight will be a fraction of the daytime totals. So, I think it’s very safe to say the overnight requirement will be a piece of cake for this system to meet. Indeed, three recent nights’ consumption, shown above, average just under 9 kilowatts of power consumption from 8 pm to 8 am. At that rate, and with the support of some solar production, it seems that 24 hours of runtime is within reach.

Massive power generation

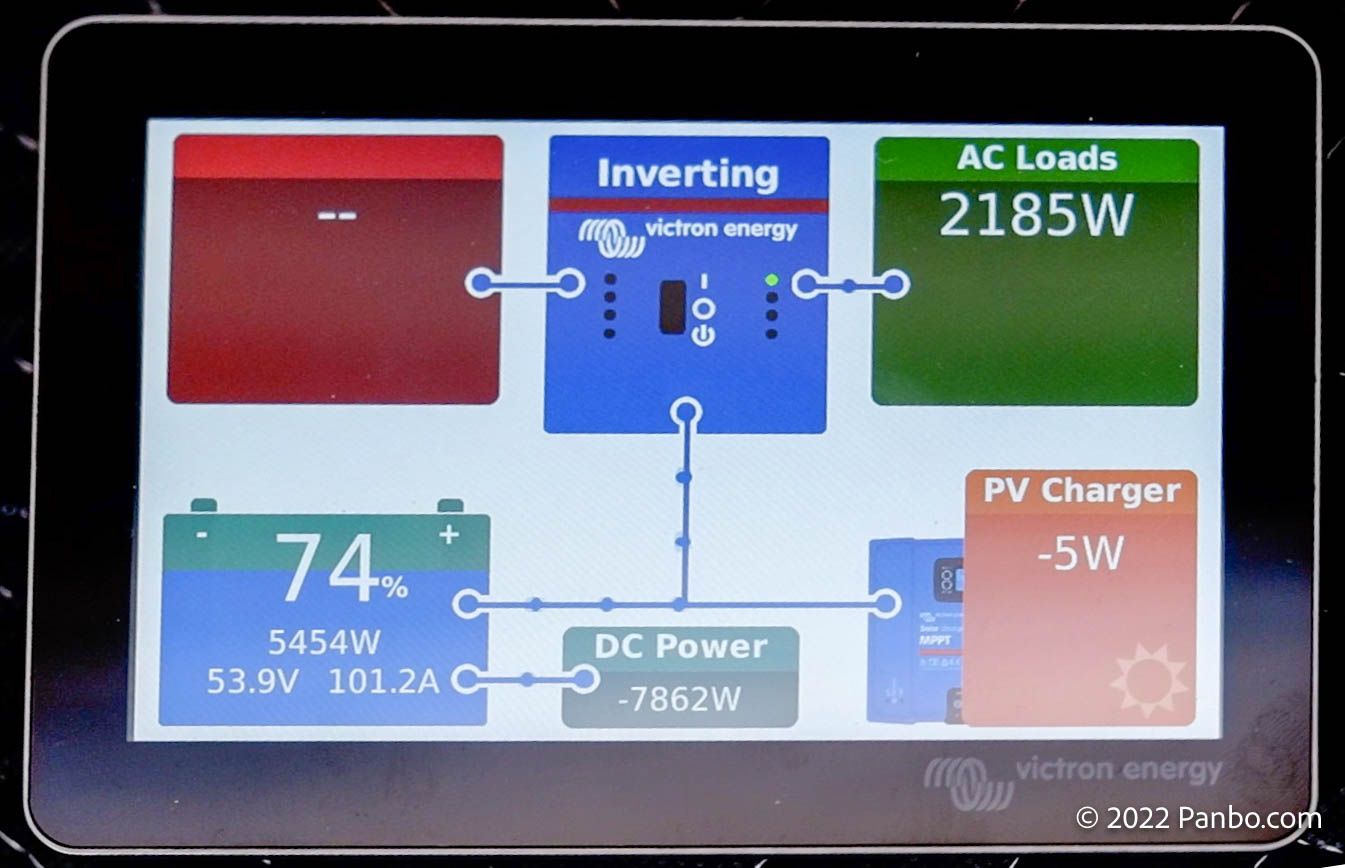

I realize that at first, the image above doesn’t look too odd, but the little box in the center bottom that reads “DC Power” has a huge number displayed. When this picture was taken, the engine was running at 1,600 RPM and Integrel was generating just short of 8,000 watts of 48 volt DC power. That’s a ton of power! Take a look at the battery icon on the bottom left of the image. The batteries are getting charged at 101 amps. But, remember, these are 48-volt batteries. That’s the equivalent of a 12-volt bank being charged at 400 amps.

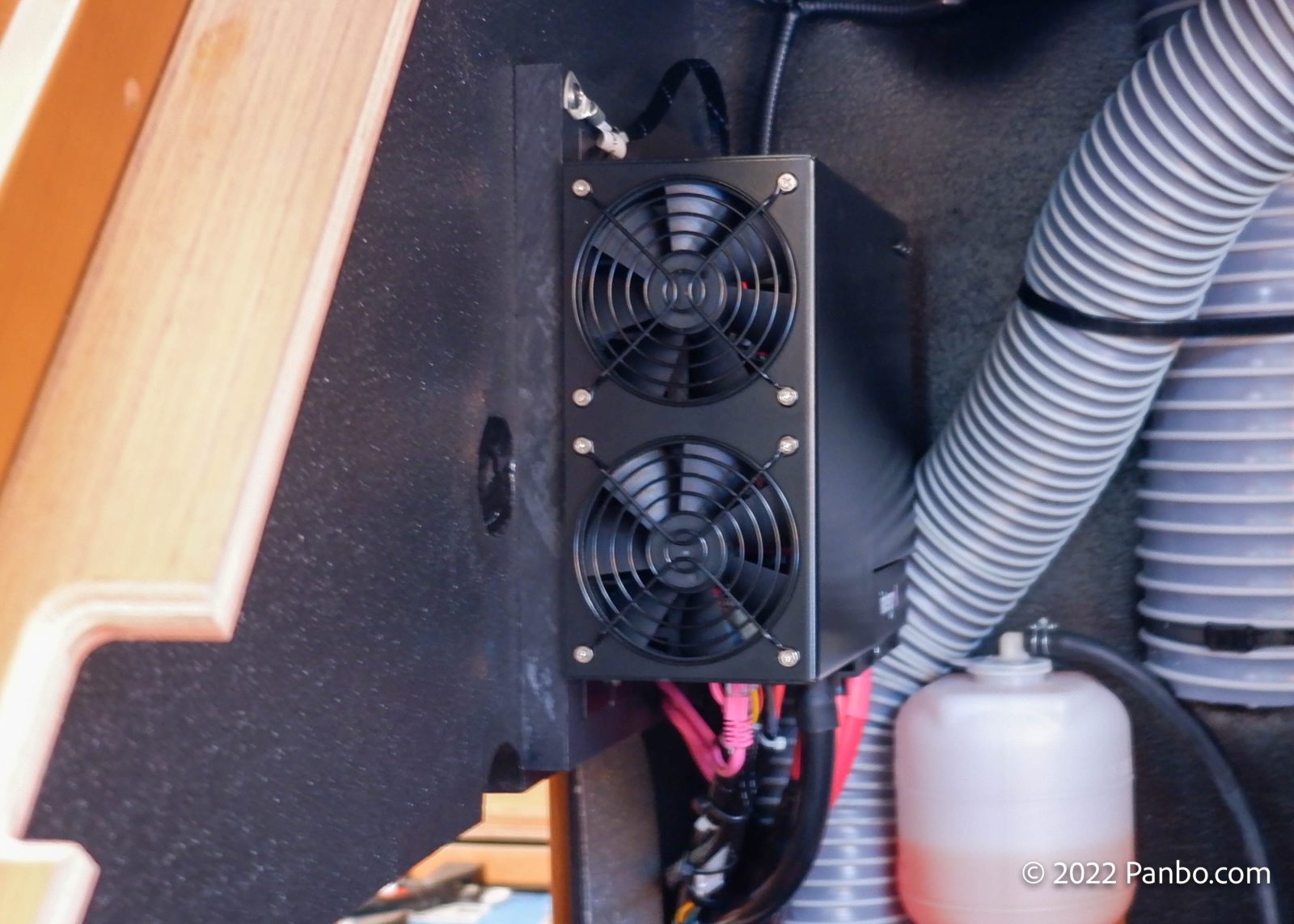

The air conditioning was running while the engine was running and Integrel was charging the batteries. So, 2,200 watts of energy were going to power the air conditioning. If we’d turned that off, we could have dumped an additional 40-45 amps of charge current. With a 400 amp-hour or roughly 20 kW battery bank, Integrel is theoretically capable of charging a fully depleted bank in under three hours. The one caveat to this is that the Integrel alternator generates significant heat and the engine compartment is pretty small without a ton of ventilation. That means it is likely that Integrel’s controller will dial back the power production a little to keep the alternator cool.

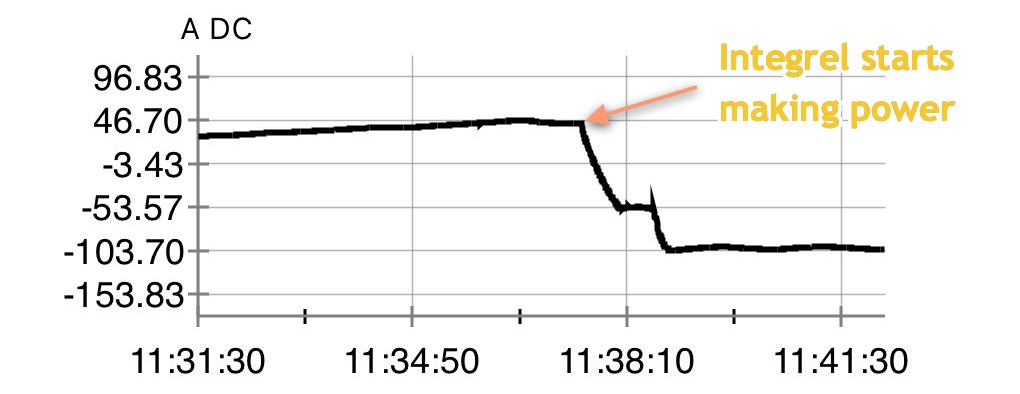

The numbers were so good coming from Integrel that I felt compelled to do a little independent verification. The chart above is from Fluke Connect, the measurement app my Fluke 376FC uses to record measurements. I put my meter on the main battery cables so I could measure all current in and out of the batteries. The chart shows power being consumed as a positive number. In this case, that was the air conditioning running, drawing just under 50 amps. Then, the engine is started and after a brief delay Integrel starts making power. That climbs to about 5 kilowatts of production — from just under 50 amps of consumption to 50 amps of charge — before engine RPMs are increased from about 1,000 RPMs to 1,600 RPMs and power production increases to a total of just under 150 amps.

Silent cooling and plentiful power

I spoke with the owner of Cinnamon Girl after he’d taken delivery of the boat and had the opportunity to use her on a few shakedown cruises. Our conversation made clear how satisfied he is with the boat and the systems. He reported that their first weekend on the boat they went a day and a half without shore power, running the air conditioning when they wanted, and still had 40 percent battery state-of-charge remaining when they returned to shore power. His only real lament was the lack of app-based control of the air conditioning system. On the other hand, he couldn’t say enough nice things about working with BoatRX. He was thrilled with the craftmanship of the work and the job they did making all these systems simply disappear into the boat.

Cinnamon Girl isn’t the first boat with air conditioning and she’s not the first boat built without a generator. But, she is the first boat I’ve been on with battery-powered air conditioning, ample battery capacity, and the ability to rapidly recharge her batteries. I’m going to be watching her VRM portal carefully to see how it works in real-world cruising, but I suspect the owner will rarely have to fire up the engine just to charge the batteries. Solar power generation and an hour or two of motor runtime should be all the boat needs to keep the batteries topped up and the cabin cool.

Great article!

Good article and would be very interested in seeing a followup when the system has been used more. It would also be interesting to know the type of cruising the owner does as it appears that the system could support less than two days at anchor without firing up the main engine for about four hours to get back to 80% SOC. Did the owner have any rationale for only being able to run the water heater on shorepower?

Great article. I have a similar victron setup 12v. Can you tell me what the (dc power) represents?

Thank you

Clay

Clay,

I think you’re referring to DC power in the picture of the Touch 50 towards the bottom of the article. If so, that figure represents the DC power the Victron GX (Cerbo on Cinnamon Girl) has calculated. It’s calculating this based on the points in the system it can measure. So, on Cinnamon Girl it can see how much power is flowing into or out of the batteries and how much power is coming from the solar controllers. But, there’s not a VE-connected meter on the output of the Integrel alternator. So, that’s calculated as part of the “DC System” and represented by that box. Incidentally, when that picture was taken, Integrel was generating power which is why the number is negative (and large).

-Ben S.

Having worked in the background with BoatRx on this project (providing the Integrel), we at OPE can say that they are awesome installers!

Whether Integrel or other high-power alternator/regulator DC charging system, generator removal/replacement is becoming a popular option, and a growing percentage of our distribution business.

Note that these systems are generally not DIY installations. We highly recommend only having such systems done by an experienced installer like BoatRx!

..high tech over expensive systems that will require a 5 dwarf team of electrical engineers on board at all times to maybe keep it working.

Inspiring. Looking for smallest cost installation to be used for a smaller 24-30 ft sailboat.

I’d be very interested to know how BoatRX have overcome (assuming they’re aware?) the one major, and potentially catastrophic; issue with using Victron MPPT’s as DC-DC chargers?

Under certain circumstances, a Victron MPPT will deliberately short the PV input terminals to protect the battery bank.

This is completely safe if a solar panel is connected to the input, but not so with anything else.

This behaviour is documented here under Err 38 and 39:

https://www.victronenergy.com/live/mppt-error-codes

Can you please check with BoatRX and come back to me?

Ben,

I reached out to Victron to understand this issue before I published this article. As you mentioned, in certain circumstances the MPPT can short its output terminals. Here’s what I learned:

If the output side stops accepting current rapidly (like a BMS disconnect event), the MPPT has to do something to stop the inbound energy flow. To do that, it will short the input terminals. If solar panels are connected to the input, that would just drop panel voltage to 0 and all would be fine. But, if the inbound source is a battery or other high current source, that won’t work. So, there’s an internal fuse in the MPPT that will trip in order to avoid bigger issues. Once that fuse opens, the unit is done, as it’s not economical to replace the fuse.

I asked about potentially providing overcurrent protection external to the unit so that when the terminals are shorted that overcurrent opens first. They thought that could work but the magic is in the timing of which overcurrent protection goes first. In my conversations, Victron didn’t know the size or blow speed of the fuse used on the boards so it might take some disassembly or experimentation to figure it out. It’s also not likely to be an issue unless there’s a shutdown event during charging.

Further, during my conversation I learned that Victron has plans to expand the DC-DC lineup with more 48-volt options (among others) but that the supply chain issues have consumed their product engineering resources in refactoring existing products for available components.

-Ben S.