Quality crimp connections, the right tool makes all the difference

I think we’ve all heard the wisdom about the right tool for the job and how much easier it can make it to complete your task. I have something of a tool habit, so I frequently use this wisdom as an excuse to go buy another. But, sometimes the cost of the “right” tool is sufficient to cause me to try some intermediate steps first. Heat-shrink crimping tools are a prime example of my hesitance to buy the expensive “right” tool out of the gate. What follows is a visual illustration of the results.

Years ago as I was first researching how best to make connections on my boat I learned that nearly every method of connecting wires I knew from projects at home was inappropriate for the boat. So I needed to learn some new tricks. I found out that crimping was nearly always the preferred method of joining conductors or attaching terminals and further that heat-shrink crimp connectors were likely to be best for nearly all my applications.

But, to crimp these connectors I needed a heat-shrink terminal crimping tool. Heat-shrink terminals, as the name implies, have a heat-shrink outer jacket around the metal terminal or butt splice. To crimp these connectors properly the tool needs to squeeze the barrel of the terminal sufficiently to grab the wires without cutting, crushing or otherwise destroying the heat-shrink jacket. I looked at the Ancor tool above and then did a little search on Amazon. The Ancor tool was just shy of $100 while the visually similar Tool-Aid (far right in the top picture) “Professional Ratcheting Crimper” was only about $20. So, figuring that they looked similar enough I went ahead and bought the Tool-Aid crimper and began my crimping career.

Imagine my surprise and frustration when many of my early crimps pulled out immediately after crimping them. I did learn that I could frequently get better results by sizing down one color (crimp a blue, 16-14 gauge, connector on red and yellow, 12-10 gauge, on blue) but that only worked for blue and yellow since there wasn’t a size smaller than the red (22-18 gauge). So, off I went in search of a better crimper.

I’m not sure why at this point I didn’t just pay up for a good tool but I didn’t. Instead I went back to the Amazon well despite my previous failure. This time I picked a Titan Tools ratcheting crimper for heat-shrink terminals, (Thanks to Beth for noting in her comments below that this crimper is not advertised as being appropriate for heat-shrink terminals. Though I was quite certain it was marketed as such when I purchased it I can’t find anything that shows that and now question if I made a mistake when I purchased this or the description has changed) thanks in large part to several thousand reviews averaging 4.5 stars. The results were better, but hardly great. ABYC specifications call for a 14 gauge wire with a crimp connector to resist 30 pounds of pull force. If half of my crimps with this tool withstand that I would be surprised.

Added 3/11/2020 – What I’d not yet realized (but should have) was that while both crimpers I’d tried were visually similar to the Ancor tool their jaws have important differences. The Ancor jaws are designed to squeeze without hurting the heat-shrink jacket while the Tool-Aid and Titan use a jaw design suitable for insulated terminals but not heat-shrink terminals.

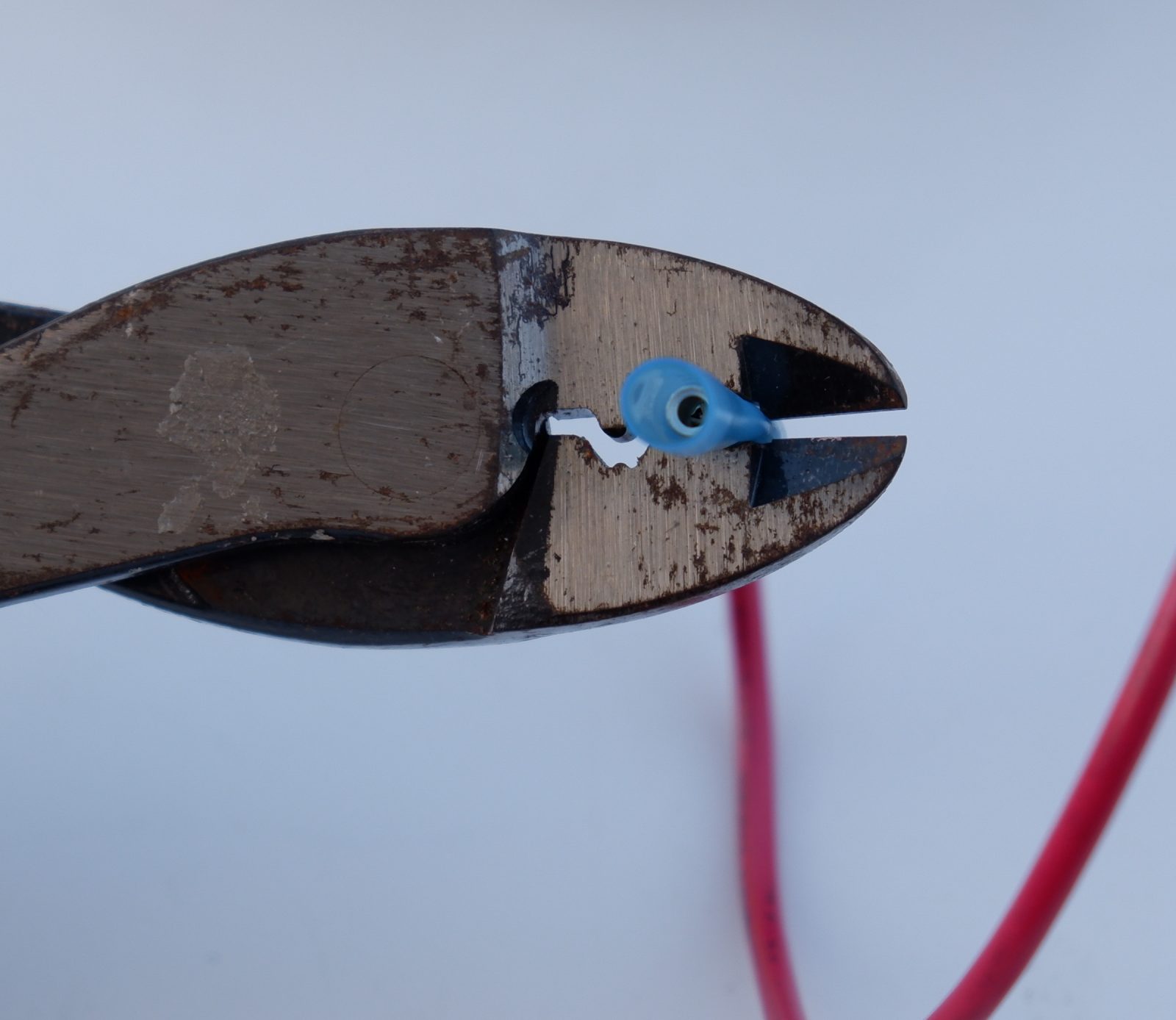

Next up in my search was a tried and true, non-ratcheting, Channel Lock #909 crimper. This is a general purpose crimping tool, not specifically deigned for heat-shrink terminals. So, it runs the risk of damaging the heat-shrink jacket either by cutting it or squeezing it too hard and breaking through with the jaws of the tool. The Channel Lock has worked pretty well for me; well-enough that I decided to give up on ratcheting crimpers. But it does have a couple of weaknesses. The first can be seen above as the right edge of the heat-shrink jacket is being squeezed into the cutting surface of the crimper. This means that each crimp usually has at minimum a scoring of the jacket right at each crimp point. The second issue is one of consistency, because there’s no ratcheting mechanism to control the crimp it’s all about how much force you put into crimping. I’ve found my crimps with this tool are uneven. Sometimes, I don’t squeeze hard enough and the wire can slip out. Other times I squeeze too hard and cut fully through the heat-shrink jacket. But I learned to manage these issues and produced pretty reliable results, though probably with a 10-20% percent failure rate.

Then, while reading an article on proper crimp connections on Rod Collins’ excellent Marine How To, I learned he is selling two heat-shrink crimpers. There’s both a DIY model ($37) and a professional option ($147 – HST-Pro). At this point I crimp a lot of connections, at least a couple of dozen a week, so I justified the expense of the professional tool to myself (I’m a professional, right? OK, sort of) and ordered one up. Let me just say that though there’s a roughly seven fold price premium between the cheap Amazon crimpers and the model Rod sells it is very easy for me to justify that premium. Gone are the poor crimps with no explanation.

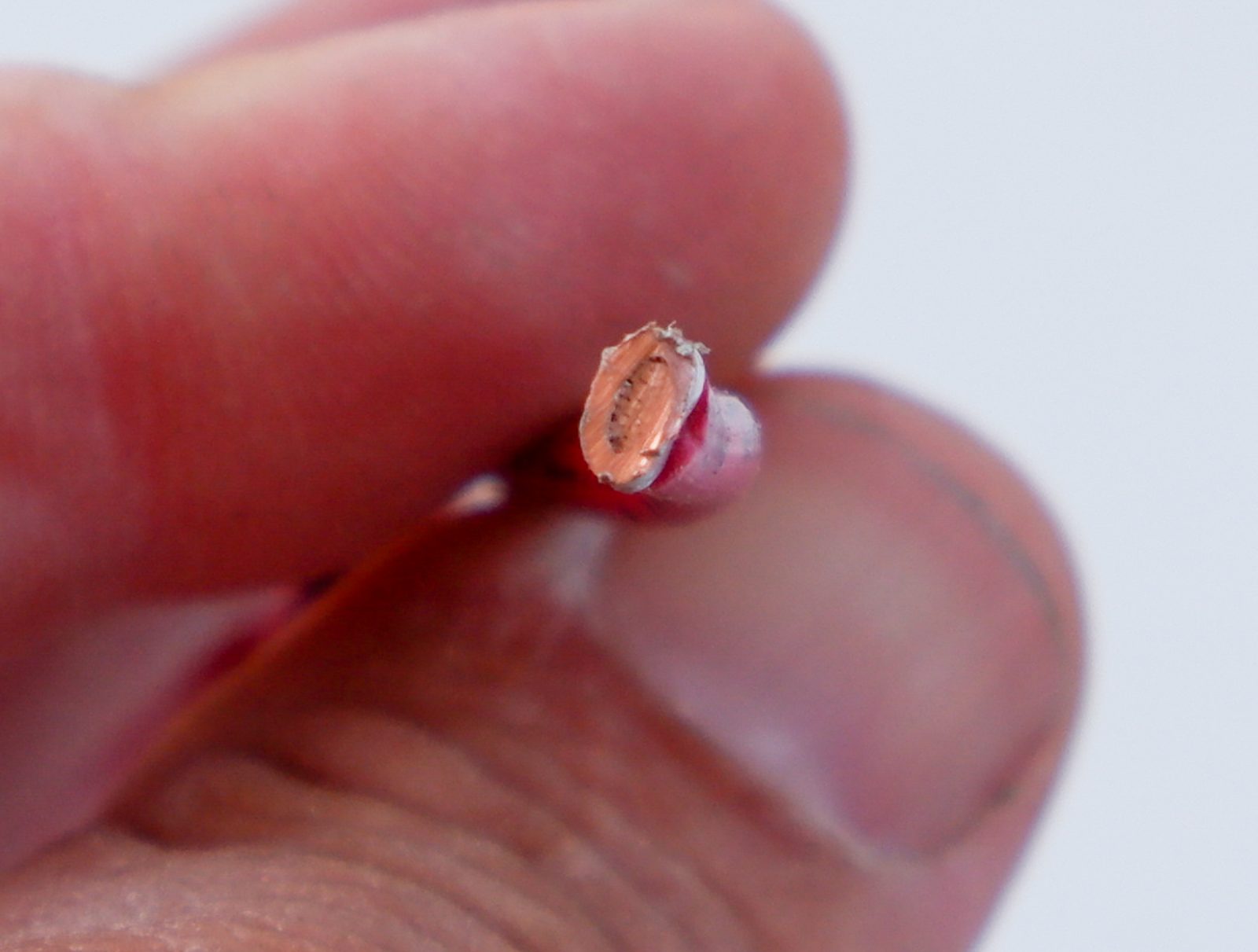

If I take my time, insert the wire fully and fully crimp I get a high quality crimp each time. That 30 pounds of pull that ABYC specifies? I’ve lifted myself up using a loop of cable I made with a butt-splice. When I cut away a crimp made with the Titan (above right) I found I could still see the wire strands with the body of the splice squeezed around them. The HST-Pro crimped end was basically mushed into a single, thinner block where I could no longer distinguish the wire from the body of the splice. Also, I wasn’t able to get a picture of the cut away with the Tool-Aid crimper because of the five or six that I tried the wires pulled out before I could cut through the splice.

I certainly recognize that not everyone is going to be interested in spending the $150 or so an HST-Pro costs. But, before you run out to Amazon and pick up a $20 (not really) good enough knock-off I’d encourage you to try out the DIY tool that Marine How To sells. I haven’t had the opportunity to try one myself but Rod Collins says it does a good job of making reliable crimps without damaging the heat-shrink. For over $100 less if you’re just going to make an occasional crimp it’s probably a good compromise.

The last video shows the process of heating the heat-shrink jacket so that it shrinks down around the wire. I’ve often used a small torch or even a lighter to heat the splice but a heat gun provides a more consistent result without risking burning the wire. I’m using a Milwuakee M-18 cordless heat gun that while not super powerful is hot enough to melt the jacket and neatly finish off the splice.

As you can see in the videos above the results really speak for themselves. If you have the right tools and take your time you can achieve results far in excess of what I’ve ever seen with solder, wire nuts or any other ABYC non-approved means of connecting wires.

Insulated terminals and heat shrink terminals are different. Insulated terminals do not have heat shrink and are meant to be double crimped. The first two crimpers you tried will crimp insulated terminals. Look at the tools and you will see two little crimping surfaces of different heights. The insulated terminal will have a ridge and a fatter side. You have to use the tool in the proper orientation to crimp successfully, and it won’t do a proper job on a heat shrink terminal. The final tool you mention, in its expensive version or the inexpensive one, will work beautifully on heat shrink terminals, which are meant to be single crimped. Of course, always tug hard after crimping.

Beth,

You’re definitely correct that insulated terminals call for a different crimping tool than heat-shrink, but that’s not the whole story here. Neither of the two Amazon crimpers mentioned here have differing heights between their two crimping surfaces. Additionally, the Titan tool is specifically sold as a heat-shrink crimper, despite the double crimp setup.

-Ben S.

That’s funny, because before I posted my comment I checked thatAmazon link you provided and that Titan tool specifically says it is for insulated terminals, and not recommended for heat shrink terminals. Perhaps you posted an incorrect link, but it certainly looks like the same tool and is very similar to an Ancor tool I own ( the Ancor tool picture you posted is different than mine, and does look like it is a single crimper.

Beth,

Mea culpa, you’re absolutely right. That link I posted is for an insulated crimper and not a heat-shrink crimper. I bought mine several years ago and I clearly recall that it was marketed for heat-shrink terminals at that time. Given the length of time it’s possible my recollection is mistaken or I made a mistake in the variety of crimper I selected (this one has four different models under the main listing).

While reviewing Amazon for this story I noted that there are crimpers that appear to be double crimp for insulated terminals sold as appropriate for heat shrink (https://amzn.to/3aMZbn8 is one such example) still sold on Amazon.

So, part of the story should be to be pay more attention to the type of crimper you purchase and not make the same mistake I did!

-Ben S.

Ben – I see you photo of the Ancor. Did you ever purchase that one and how well did you find it worked?

I didn’t purchase the Ancor tool so I can’t speak to how well it works.

-Ben S.

I had a surprise when “saving money” by buying my adhesive heat shrink connectors in a Walmart RV section. They were high quality 3M connectors. There is only one thing wrong, their outside diameter is smaller than marine connectors and my crimpers (yes, multiple different ones) didn’t squeeze down enough. I had to use the Channellock pliers to completely affect the crimp. Of course, there are automotive crimpers which work fine.

This entry motivated me to take an honest inventory of my own crimping tool history, and it’s not pretty. Few of mine even have brand names. And, yes, I’ve sometimes used a crimper meant for insulated terminals on heat shrinks — thanks, Beth, for the accurate detail — though the results can be reasonable when done with care.

In recent years I’ve been using an inexpensive BSP heat shrink terminal crimper that looks similar to the DIY-HST tool that Marine How To sells. And I think it’s worth consideration for light DIY use, especially when purchased as part of the for the kit I bought at Defender:

https://www.defender.com/product.jsp?id=1960417#

I’ve used most of the shrink wrap terminals included with results that have held up, and all three tools work OK. Admittedly, there’s no “BSP” branding to be seen, just “Made in China” labels.

Ben, this is the kit I recommend to my students, and it is my go-to when I venture into the bowels of the boat to rewire anything. I cram a pair of cable tie cutters and good wire strippers into the bag so everything I need is right there. I restock the zippered compartments as needed.

Good to hear, Beth. In real use, my BSP bag also includes a selection of the solder sleeves I’ve come to like for thin wires:

https://panbo.com/heat-shrink-solder-sleeve-butt-connectors-great-for-skinny-boat-wires/

Have you messed with these? Also, I see one of your courses and it looks great:

https://www.womensailing.org/events-education/marine-electrical-systems-workshop-for-women/

Those crimps look very cool for data wire connections. I shall have to get some to play with.

I have the Ancor tool somewhere but I haven’t used it in a long time. I also have a YYT1, and an Ideal Crimpmaster. But my go-to tool for…maybe a decade…has been a 3M TR-490 – in fact I have two of them. And my TR-490 looks a LOT like that HST-Pro except for perhaps the head which is squared off like the TR-440. And that slotted “ratchet stud nut” on the lower handle of my TR-490 is field-adjustable in 5 pound increments – does the HST have that feature?

The TR-490 looks nice – has crimping options for non insulated crimps as well. Although the literature never mentions that it’s made for heatshrink terminals – it does look identical to the ProHST. You use yours for heat shrink?

It’s quite obvious that in both the cases of the Tool-Aid and the Titan crimpers that they are not adjusted properly and hence the crimps are very weak. You need to unscrew the Phillips screw on the adjuster, and turn it in the + direction to add some tension. It’s very clear in the video of the Tool-AId crimper in action that it’s not applying enough pressure just buy how easily you’re able to get the tool to the release point. I agree that you generally get what you paid for in tools, but a $20 ratcheting crimper can produce very strong crimps 100% of the time if it’s properly adjusted.

Jake, but even with the tension adjusted up these tools aren’t crimping the connectors in the way they’re designed to be crimped. Heat shrink terminals aren’t designed to be double crimped and those terminals that are designed for a double crimp should be crimped at two different depths. These tools don’t do that so the best case is that you’re going to apply more force but not the right force in the right place.

-Ben S.

I guess you do realize there are different die sets for different terminals. I have the too aid ratcheting crimpers and have ten different die sets that can be changed out. In particular the 18942 die set is designed for 8-22 heat shrink terminals. That may be the one your using not sure. If you look on page six of this link you will see the die sets and what terminals they are designed for.

https://toolaid.com/sites/default/files/tool-aid-catalog-2020.pdf

It’s a little off topic but since we’re discussing electrical tools I thought I’d give a shout out regarding a nice (yet reasonably priced) clamp-meter I bought last year:

Uni-T B4Q094 UT210E True RMS AC/DC Current Mini Clamp M W Capacitance Tester

Learn more: https://www.amazon.com/dp/B00O1Q2HOQ/ref=cm_sw_em_r_mt_dp_U_NQrJEbWWK6QGB

I checked it against a HP/Agilent 34401A bench multimeter, a Fluke 87-III and HP/Agilent E3632 power supply readout; The UT210 read within less than 1% of all the others over a range of DC voltages. It seems fairly well made. Not bad to get a fairly accurate clamp-meter with True-RMS AC for under $50.

Mic, I’ve got the same current meter and it recently checked out fine on my boat’s battery cables, charge or discharge, versus the installed Victron BMV shunt. Also, I’ve recently been impressed with an inexpensive battery analyzer that measures internal resistance and cold-cranking amps. It’s been startling accurate on batteries I know the specs of and think are in good shape, while also definitive about a couple that I thought to be marginal:

https://www.harborfreight.com/digital-automotive-battery-analyzer-66892.html

A power pro I know is very keen on this meter, saying that internal resistance is a key value and that measuring it usually costs much more.

Funny, I have that meter and a more traditional one (https://amzn.to/2Rmu6PX) that I find a real pleasure to use. I’m sure a properly calibrated Fluke is more accurate but I’m yet to be able to detect that difference and I’ve definitely had better results with these meters than what you might buy at a big-box home improvement store.

-Ben S.

As always, Thanks for the tips!!

I’ve used the same set of Klein Tools 9-3/4″ OAL Crimping Pliers with great success for going on 15+ years now. I’ve almost completely rewired both my current and my previous boat with them, having brought the set home after using it in professional tower work. I don’t think I’ve ever had a bad crimp that wasn’t blatantly my fault. They are similar to your channel lock tool, but importantly different in they have the insulated and bare crimp dies positionally swapped from yours, which means the cutting edge doesn’t score the insulation, and the insulated die is closer to the jaws which provides more crimping force. If you like the channel lock ones, you’ll love the Klein version, it’s subtly but significantly better yet.

https://www.mscdirect.com/product/details/01831858

I enjoyed reading this post. Now I am looking for a pair of the CMI Pro-HST wiring crimpers and I cannot find a pair anywhere. Rod Collins from Marine How To, has had a stroke and his store is down. If you know of a source, I would appreciate it.

Thank you

Joseph,

I’m not sure of the answer right now. I’ve reached out to Rod to see if he has any ideas but his responses are delayed as he works through his health challenges. I’ll keep you updated if I hear anything back.

-Ben S.

Thank you Ben. I appreciate it.

I am also looking for a pair of the CMI Pro-HST wiring crimpers. I can’t find them anywhere. If anyone knows where to buy them I would really appreciate it. Or any suggestions of a pair of same quality that would be great. Thanks Randy,

I found the seller of them but he will only sell locally because he had a stroke. He is in Maine and I live in Ohio. Wish I knew someone in Maine that could ship a pair to me.

Thanks Joseph, I appreciate the reply. I know a couple of airplane mechanics, so I’ll just bite the bullet and get recommendations from them. Although the crimpers will be more money, but they will work like the should.

I am going to pull the trigger on the Knipex half round crimpers for heat shrink terminals. I am hoping that the different die sizes help me get a good crimp without damaging the insulation.

https://www.kctool.com/knipex-97-72-180-half-round-crimping-pliers-for-end-sleeves-ferrules-multigrip/

I have a few of the HST-Pro crimpers available if anyone needs them.

I’ve been working Rod on a few things recently. As you may know, Rod suffered a serious stroke last year. He’s made a remarkable recovery, but some things remain difficult for him. As a result his web store is permanently closed. I have his remaining inventory which is a small number but I’m working on getting more on hand.

Two and a half years later I use these crimpers every day. I couldn’t begin to count how many crimps I’ve made with them, but I do know that in that time I’ve ordered far more than 4,000 crimp connectors. They work as well today as they did the day I took them out of the box.

-Ben S.

Ben – if you still have any HST-Pro – I would be interested.

Hey Ben, I’m looking for a pro-hst if you have any left. Please drop me a line! Thanks

Hi Ben, Would be interested in the HST-Pro crimpers and would also be interested to know what else you have from Rod. Lost my boat and all tools in the Mattapoisett Boatyard fire two weeks ago and would like to rebuild my toolkit. I had purchased several items from Rod in the past and never regretted it.

Thanks.

Brien

Ben,

I am willing to pay, to get a pair of the HST-Pro Crimpers. Please let me know

Thank you

Joseph Augustine

Ben,

Interested in a pair of HST-Pro crispers if available.

Thanks,

Greg

interested in the HST-Pro crimpers if you have anymore.

thanks.

Hello Ben,

A colleague turned me on to Rod’s article, “Marine Wire Termination” – an awesome read! I have been looking into the “new” (read that: “new” to me) heat shrink splices. As I researched them, I found that I needed a completely new and different crimp tool, and my favorite vendors (T&B, Amp, etc.) didn’t seem to have the right tool. So I shelved the idea. This has me excited again! Please let me know if you have any of the PRO-HST crimp tools available.

Thanks,

Drewsky

Great news! I have more crimpers on the way. Rod helped me get my hands on some additional crimpers. Currently, 20 of them are en route to me and should be here soon. I have put up a web store for these (https://webstore.panbo.com). Please let me know if you have any troubles placing an order.

-Ben S.

Awesome. I ordered 2. I’ve been wanting these for along time.

Thank you

Something is wrong with the check out. Won’t let me pay. Can you check on this please. Thank you

Hi,

I’ve checked things on the store and was able to place an order. I did clean up the design a little to hopefully make it easier to use.

-Ben S.

Had to mention Klein make a crimper much like the Cannel Lock 909 but with the indent and circular sections in opposite positions. Think you will find these a bit easier on heat shrink terminals.

Dave in Darwin NT Australia

Interested in these tools but I’m more of a hobbyist, is there any chance you are able to source the DIY version of Rod’s crimper? Thanks