Heat shrink solder sleeve butt connectors, great for skinny boat wires

The small gauge wire connections usually required when installing NMEA 0183 data sharing often fail because normal boat wiring techniques don’t work well at this scale — or at least not in my clumsy DIY hands. So I was intrigued at first sight with this relatively new type of heat shrink butt connector that uses low-temperature solder instead of a crimping sleeve, and so far I’m quite impressed with the results.

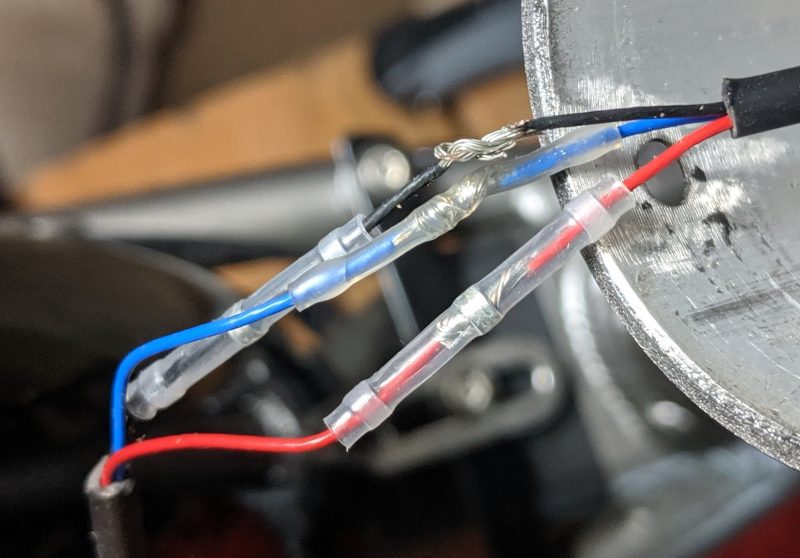

The three skinny wire splices above may not look neat and tidy, but I’m confident that they’ll hold up to a lot of abuse. And the heat shrink solder sleeves were fairly easy and quick to use. But they do involve a few issues that I’ll discuss, and it’s possible that readers will have more to add. Boat wiring may seem mundane, but it’s important and to some extent controversial.

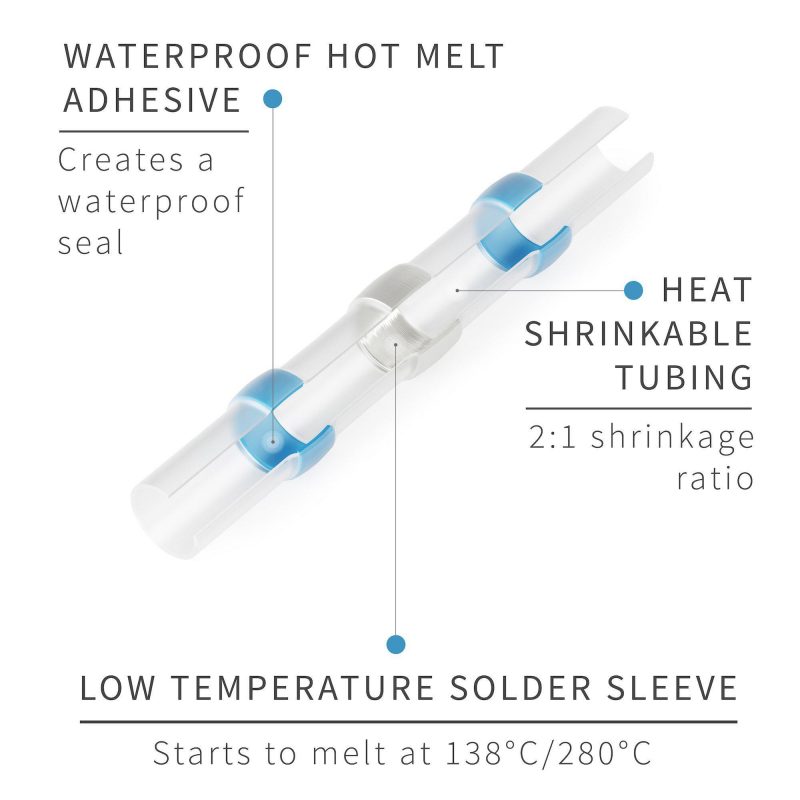

These clever connectors are called solder seals by some manufacturers like Wirefy, which is also responsible for this helpful illustration of the various components involved (though the bottom line should read “Starts to melt at 138° C / 280° F”).

Before we get into further details, however, I can almost hear informed readers muttering something like “Wait a minute, soldered wire connections are not allowed on boats!” That’s only a partial truth as best I can tell. The actual wording of the ABYC Standard for Boats E-11 (excerpted here) goes “Solder shall not be the sole means of mechanical connection in any circuit” and Ed Sherman further suggests the standard’s flexibility in this ABYC blog entry.

I’d argue that these heat shrink solder connectors with waterproof adhesive provide a lot of mechanical connection beyond the solder, especially when compared to what’s otherwise possible with wire gauges thinner than 22 AWG. Heck, ABYC E-11 also states that “Conductors shall be at least 16 AWG…” and the smallest Ancor heat shrink butt connector is for 18-22 AWG, but smaller gauge NMEA 0183 wires are still in use on a great many boats. And while 0183 is slowly going away, many of new boat monitoring systems use various sensors like magnetic door intrusion detectors that work fine with skinny wires, except when you need to splice them.

I’ve vented about thin wire difficulties before, and have also had good luck with 3M Scotchloks and similar mechanical connectors (though several issues came up in the comments to that entry). Could solder seals be the best solution?

Here I tried to illustrate the steps required for this type of butt connector, aside from stripping back the two insulating layers. Note how one black wire is already fished through the heat shrink tube and twisted together with its mate, but the connector has not yet been worked along the joined wires to position the solder sleeve over the twisted bare strands, as I have done with the red pair.

Lastly I carefully applied heat to the black and red connectors until the pre-fluxed solder bonded with the wire strands and the adhesive end bands flowed as the tubing shrank, as evident in the blue wire splice. It’s great that an installer can see the results well, but I wasn’t completely happy with mine (check top photo), and — mainly because one of those 3-wire cables had zero slack available — I was also reluctant to apply more heat and possibly torch the job.

Therein lies what may be the real issue with this connector design. If you dig into the more negative reviews of Amazon’s many solder sleeve brands, a fairly common complaint is how easy it is to overheat (torch) the shrink tube before melting the solder. And we’re talking about the smallest and likely most fragile sizes, like these Sopoby white-bands (sizes are color-coded to at least a vague standard). Ben Stein has also had these issues, but I have a theory that it may be about manufacturing quality than connector design.

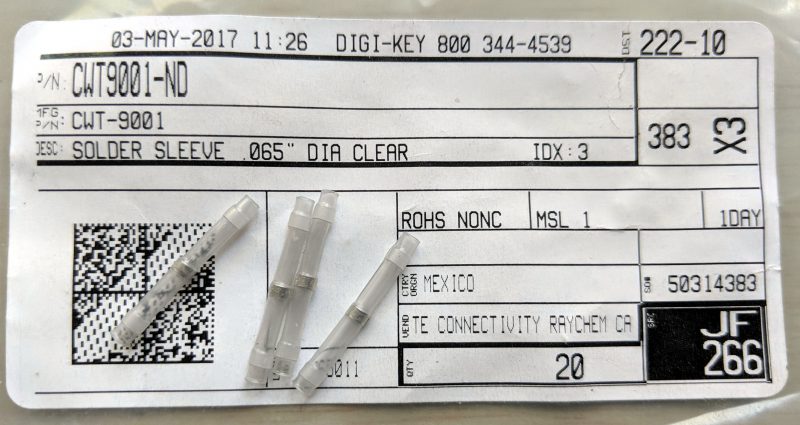

Two summers ago a Mazu Marine engineer kindly left me a small bag of white-band size solder seals at the end of a Gizmo install visit, but I only realized how kind today. These TE Connectivity brand solder sleeves cost 82 cents each in small quantities, which is far more than the brands already mentioned and many others I’ve seen.

But maybe that’s why they’ve worked so well for me? I’ve used about a dozen for various projects without any problems at all. None burned, for instance, despite my using a questionable variety of butane heat sources, even a cheap Bernzomatic utility lighter. In fact, the most recent three seen above are the worst looking (and I did, in fact, add more heat shrink tubing around the whole cable splice for extra mechanical strength and waterproofing).

So can these little widgets that all look almost exactly the same actually be quite different in construction and hence in how well they work? I don’t know, but it does seem like we’re seeing more and more inexpensive knockoffs that are not really the good deal they seem to be. The good news with solder seals is that you will very likely know a badly made one when you use it, and maybe some readers will report on experience with less expensive brands.

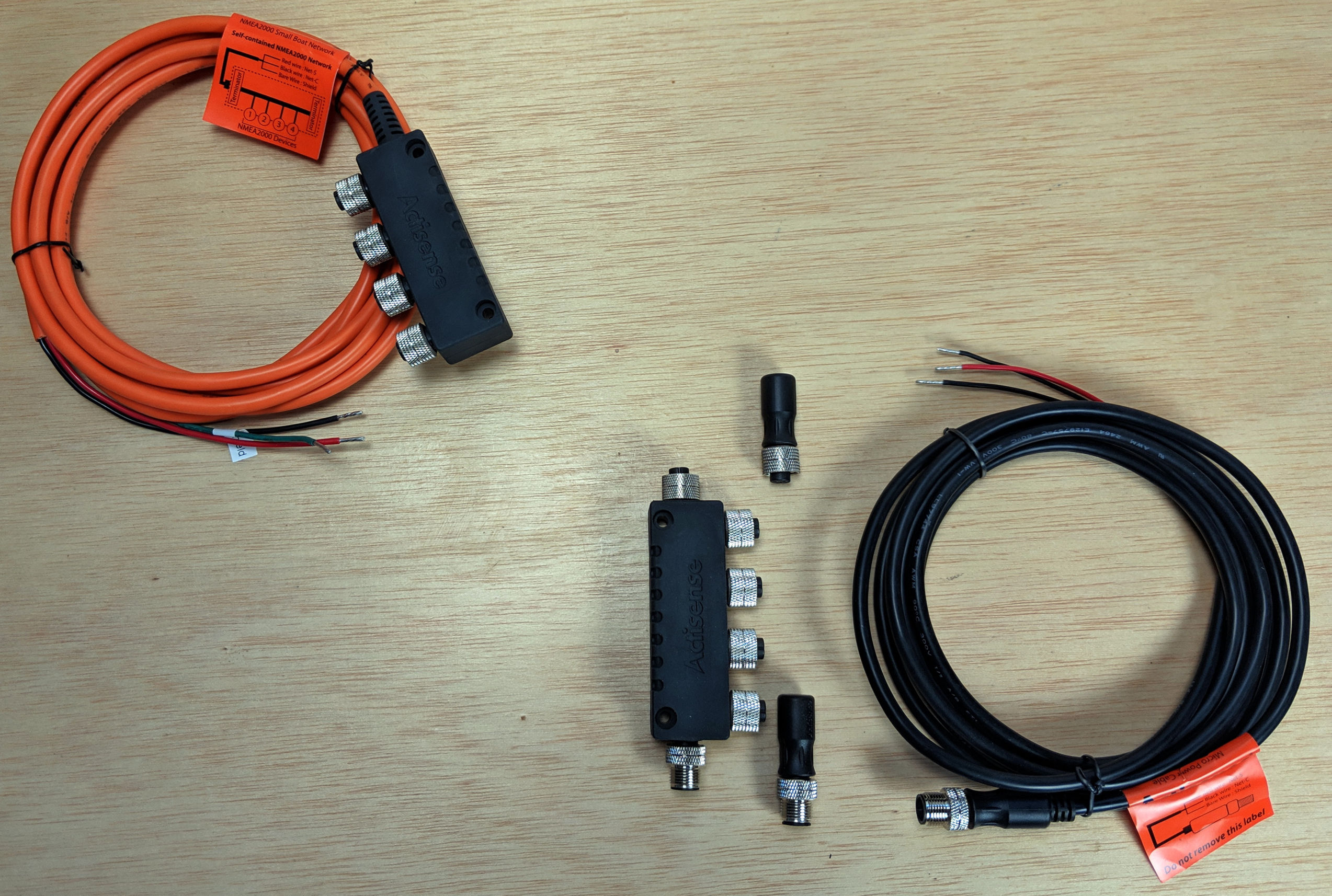

The project I used to illustrate this entry could have involved a GPS cable that barely extended beyond the end of a center console T-Top tube, but in fact I was turning the Flash V1 ebike I discussed last summer into what I think is the even better Flash Commuter design. So those red and black 26 (or maybe 28) AWG wires are powering a 60 lumen LED rear light while the blue data wire tells it whether to be a safety flasher, a brake light, or a turn signal. That’s possible because of the bike’s 36v DC power system, and I won’t be surprised if many boats move to even higher voltage main DC systems eventually, and thinner wires.

Speaking of neat modern tech, I recently learned that the Flash team can track my battery usage thanks to the bike’s associated app, and that’s quite helpful because I’ve only put it through 15 cycles due to my fat tire preference and I want to sell it. So consider this: you could visit beautiful Camden Maine, try out an extraordinary ebike, and maybe go home with it at a steep discount that in this case makes sense.

Ben, how about using euro block style connectors with ferrules crimped on to the wires. https://www.practical-sailor.com/issues/37_50/features/Out-Out-Brief-Wiring-Terminals_11614-1.html by yoiur neighbor RC Collins As much as you change out devices these may be proctical.

Practical Sailor evaluated these no lead solder butt connectors and found them to not be secure or as effective.

Thanks, Joseph; that’s a very useful article.

But note that in the ferrule kit Rod recommends “The terminals are color-coded: red, 22-16 gauge; blue 16-14 gauge; yellow, 12-10 gauge.” They are not designed for extra thin wire gauges, I’m not sure ferrules small enough exist, and I think most of us would also need a small delicate crimping tool as well.

Ben, the kit I have does up to 28 ga. and includes the crimper.

https://tinyurl.com/yymr56dv

Thanks, Joseph; I may have to add that or similar to my collection. I do like ferrules for screw type terminations, but think solder sleaves have their place too.

Hi Guys – just back from the Bahamas and late to the discussion. I, too bought a kit of ferrules (Chinese, of course) with a crimper and they are the bomb for the euro-style connection blocks (that are very popular with sailing instruments, it seems). I also used them on the #6 connections to my Victron MPPT controller, so they’re not just for big stuff.

If I was connecting wire-to-wire and didn’t want to put in a connection block, I would use the IDC (AKA “Scotchlok”) connectors, the silicone grease-filled ones. No heat source needed!

This is a really neat way to deal with small wire connections. I have used the 3M scotchloks, Dolphin connectors, and the terribly unreliable high heat butt connectors with shrink tubing. Out of all of those the 3M ones are the most reliable and easiest to use, but these seem like they could be easier for my fat clumsy fingers and not be as bulky as the 3M’s.

I wouldn’t use the solder shrink type. You can get really tiny ferrules for using in connector blocks. When they are that small, you can crimp with the flat bit of combination pliers. In UK we have Wago 221 connectors which are reliable on small wires. They come in 2, 3 and 5-way common, ideal for an easy NMEA split. Best used in a small box so you can tie down the separate cables coming in.

Why not solder sleeves? I think there are cases where the connections you’re talking about can be done more compactly, more waterproof, stronger and faster with these connectors (assuming you get ones that work right). What am I missing?

Don’t get stuck on the fact that the butt connectors have two ends. Strip the wires, twist them together, and then crimp in one end of the connection. When heat shrinking, when it’s still soft, pinch the heatshrink down around the wires. Put dielectric grease in other end, shrink and pinch. Use something to protect your fingers, that heat shrink adhesive is like molten lava.

Thanks, William, that sounds like an excellent way to make an oversize crimp connector work with thin wires, and the technique probably also works well when connecting two wires with substantially different gauges. I’d say it’s obvious except I’ve never seen it done and never thought of it myself. Too much linear thinking!

I like nylon cap splices, if one has the room. Twist wires together, cover with appropriate size of cap splice, crimp… done. You can squirt glue or sealant into the open end to waterproof them.

For more detail on how precisely engineered TE Connectivity’s solder sleeves are, check out the “B-155 SolderSleeve One-Step Wire & Cable Term Install” PDF you can download here:

https://www.digikey.com/product-detail/en/te-connectivity-raychem-cable-protection/CWT-9001/CWT9001-ND/573479

They also illustrate some unusual uses, like using solder sleeves to connect wires to long pins that come on some parts like some temperature sensors I’d like to add to my Victron Venus system 😉

Monster Bolts has a great suggestion of waterproof crimp and seal, and also crimp and solder connectors.

https://monsterbolts.com/collections/electrical-connectors

There is really nothing wrong with this technique, even per ABYC, it could be improved slightly by the manner in which the two wires are twisted together prior to applying the solder connecter. ABYC says that solder will not be the “sole means” . The “Western Union splice” is a mechanical splice that was developed to take a considerable mechanical strain. Using that technique and then improving it with the solder for connectivity and shrink seal for moisture protection should exceed ABYC.

https://en.wikipedia.org/wiki/Western_Union_splice

On a tangent ABYC and NMEA are great organizations for manufacturers in insuring standardization and minimum quality, However they are not friendly towards owners. Both organizations push that you should always get a “certified” technician to do the work. Their standards are not openly published and are prohibitively expensive for the average owner to obtain. In my opinion this ends up counter productive to safe maintenance and modification after manufacture.

Ben, a second thought that does not need posting…

The 16 awg minimum ABYC recommendation is for single conductors. Once bundled into a “cable assembly” there is no minimum I am aware of. The mechanical strength gained by the outer jacket and very often a nylon center cord prevents the smaller conductors from being stretched to their breaking point. So some method of splicing these small conductors is important. And most of these are signal circuits today not power carrying. An overall adhesive shrink tube restoring the “outer sheath” would restore the mechanical strength of the “cable assembly”.

As I stated ABYC sets minimum and best practices for the recreational boating industry. Yet they still approve the ridiculously outdated 30 amp twist lock shore connector a demonstrated electrical fire source. Time and technology moves on.

I started in the 1980s as a USCG Machinery Technician. I have completely re-wired numerous military and Auxiliary civilian boats. We always soldered every crimped eye terminal to ensure electrical connectivity and prevent moisture corrosion, adhesive heat shrink wasn’t even invented yet.

I’m sure we’ve both seen dozens of boats that were hacked by mostly well meaning but ignorant owners. It’s mostly a matter of education. Access to proper techniques is difficult even today as so many of these “standards” are kept restricted. The link provide to ANCOR only publishes “excerpts” of E11 because they are not allowed to reprint the entire section.

Just my 2 cents…