Is now the time for a move to 48 volt DC systems?

For as long as I’ve been covering marine technology, I’ve heard consistent talk of a move to a higher voltage than the defacto 12-volt standard. 48 volts is often cited as the sweet spot between efficiency, safety, and reduced weight. But, why make a change? 12-volt has served boats well for a long time, why change? Let’s take a look at the reasons for a change and perhaps some reasons to move cautiously.

There’s no doubt that higher voltage comes with some advantages. These advantages include smaller wires, less voltage drop, and for many devices, greater efficiency running at a higher voltage.

The amount of energy a load requires is measured in watts. Watts equals volts times amps. For example, let’s look at a 600-watt load. At 12 volts you will need 50 amps of current to get 600 watts (12*50=600). At 48 volts it’s only 12.5 amps to get 600 watts (48*12.5=600).

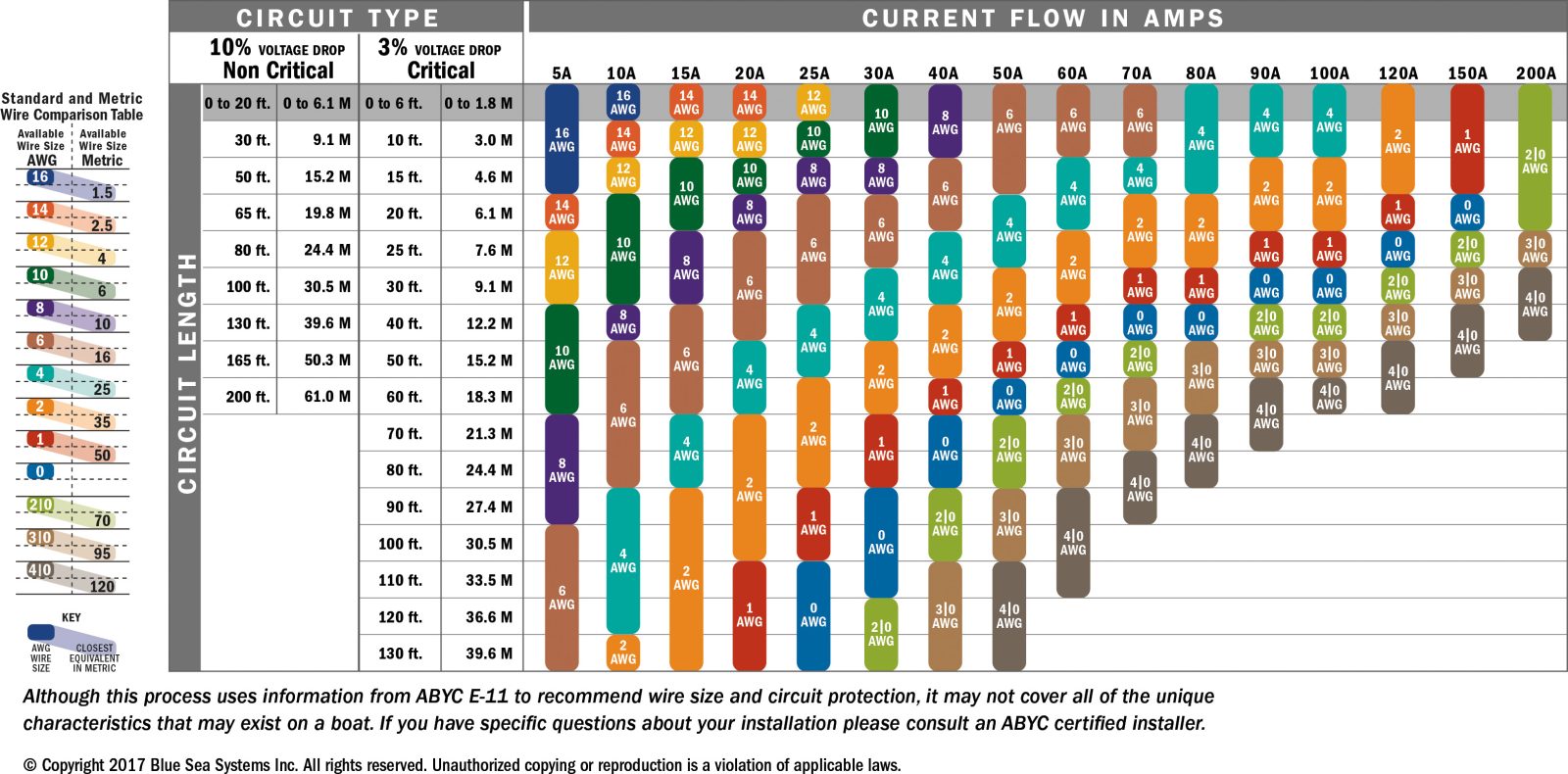

Since wire sizes are determined by the number of amps they carry, reducing the amperage reduces the wire size. For example, at 3% voltage drop over a 25 foot circuit length we would need 4 AWG wire at 12 volts and 50 amps. Our same load at 48 volts would require 12.5 amps and hence only an 8 AWG wire. If you run to your local West Marine to purchase the wire, 4 AWG will cost $3.39 per foot compared to $1.39 per foot for 8 AWG.

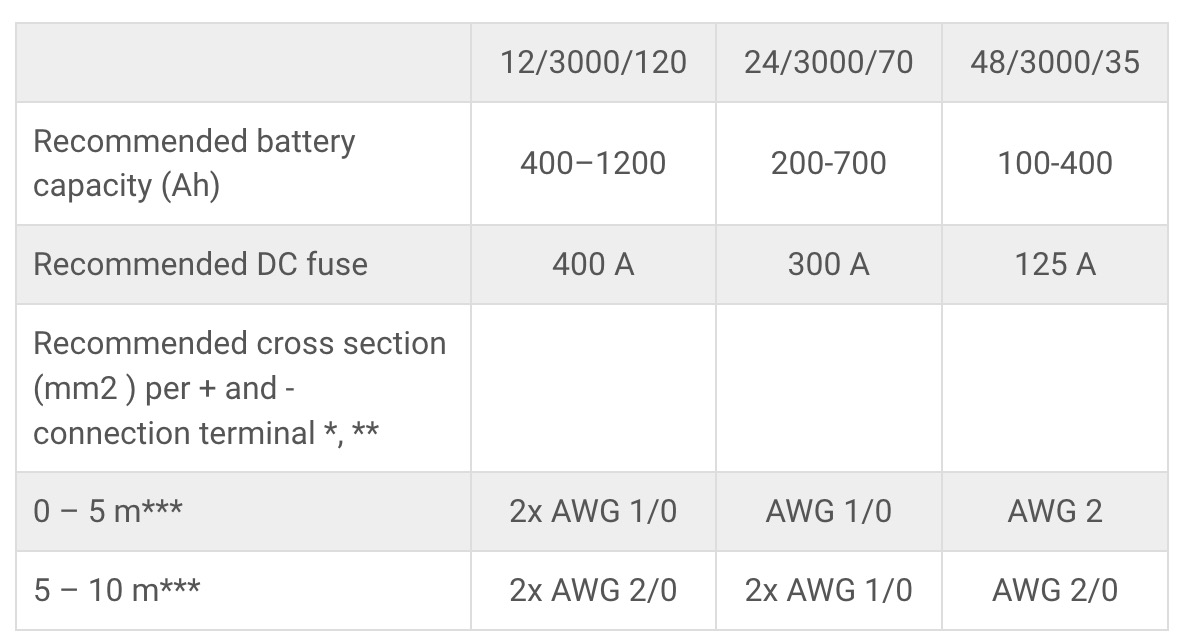

As you can see in the table above, Victron’s recommendations for battery cable size vary greatly depending on the battery bank voltage. A 12-volt, 3,000-watt inverter will require either 1/0 or 2/0 battery cables, depending on the distance from the batteries to the inverter. Victron recommends two positive and two negative cables. 1/0 cable weighs over just under half a pound per foot and 2/0 is just over half a pound. 1/0 is $6.89 a foot and a foot of 2/0 will set you back $8.89. Since you will need positive and negative, that’s one side or the other of 2 pounds a foot and either $27.56 or $35.56 per foot..

Now, consider a 48-volt inverter. Jumping to a 48-volt system cuts the cabling needs down pretty dramatically. Take a look at the cabling needs if your battery cable run is less than 5 meters. Instead of 4 1/0 cables at 2 pounds and $27.56 a foot, you need 2 2 AWG cables at half a pound and a total of $8.88 a foot.

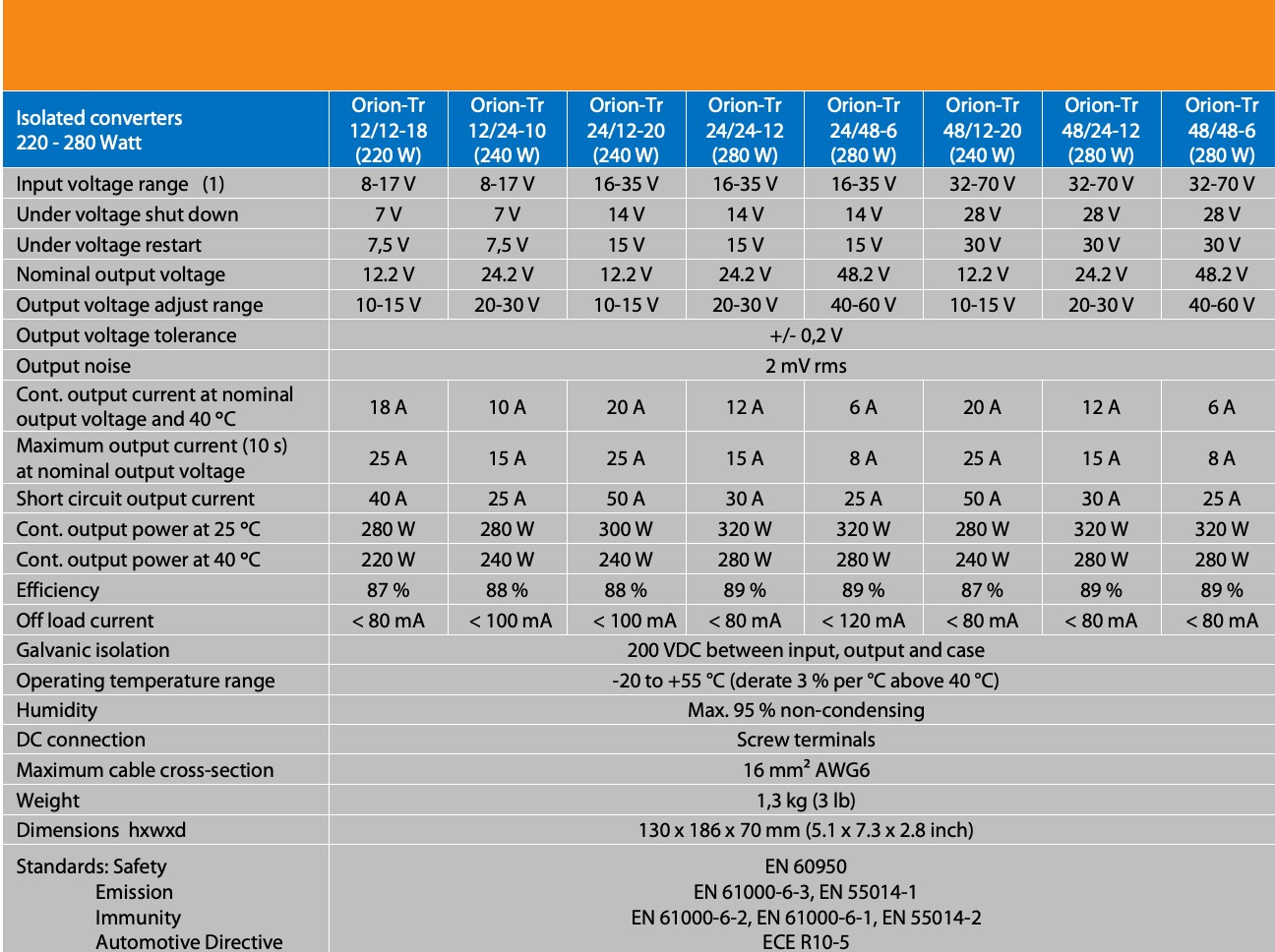

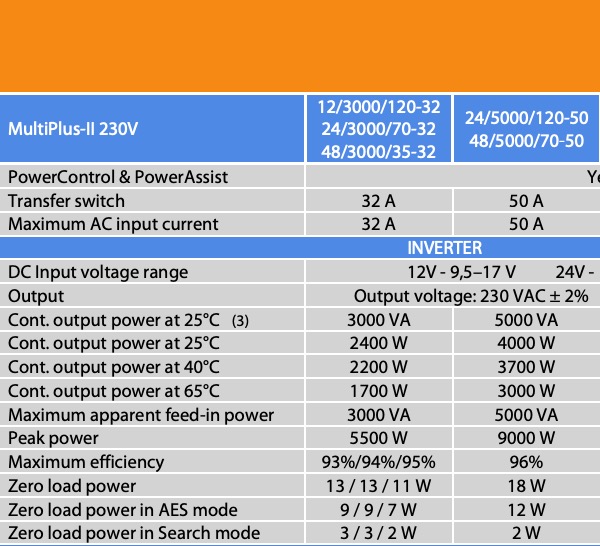

But, battery cables aren’t the whole story of 48 volts. The Victron MultiPlus-II inverter spec sheet shows the increasing efficiencies of higher DC voltage units. The 3,000 watt inverter is available in 12, 24, and 48 volts at 93%, 94%, and 95% efficiency. A 2% difference in efficiency may not sound like much, but it’s reducing your total energy lost by 29%. Lastly, using higher voltage battery banks means smaller solar charge controllers. 1,000 watts of solar at 12 volts would need MPPTs with a capacity of 80 plus amps. The same 1,000 watts at 48 volts only requires 20 amps of MPPT capacity. That means, smaller, cheaper, and cooler running charge converters.

48 volt considerations

So far, we’ve only talked about the benefits of moving to 48-volts. But, there are some reasons for caution. FIrst, I think we’re a long ways from being able to convert an entire boat to 48 volts without a 12-volt system.

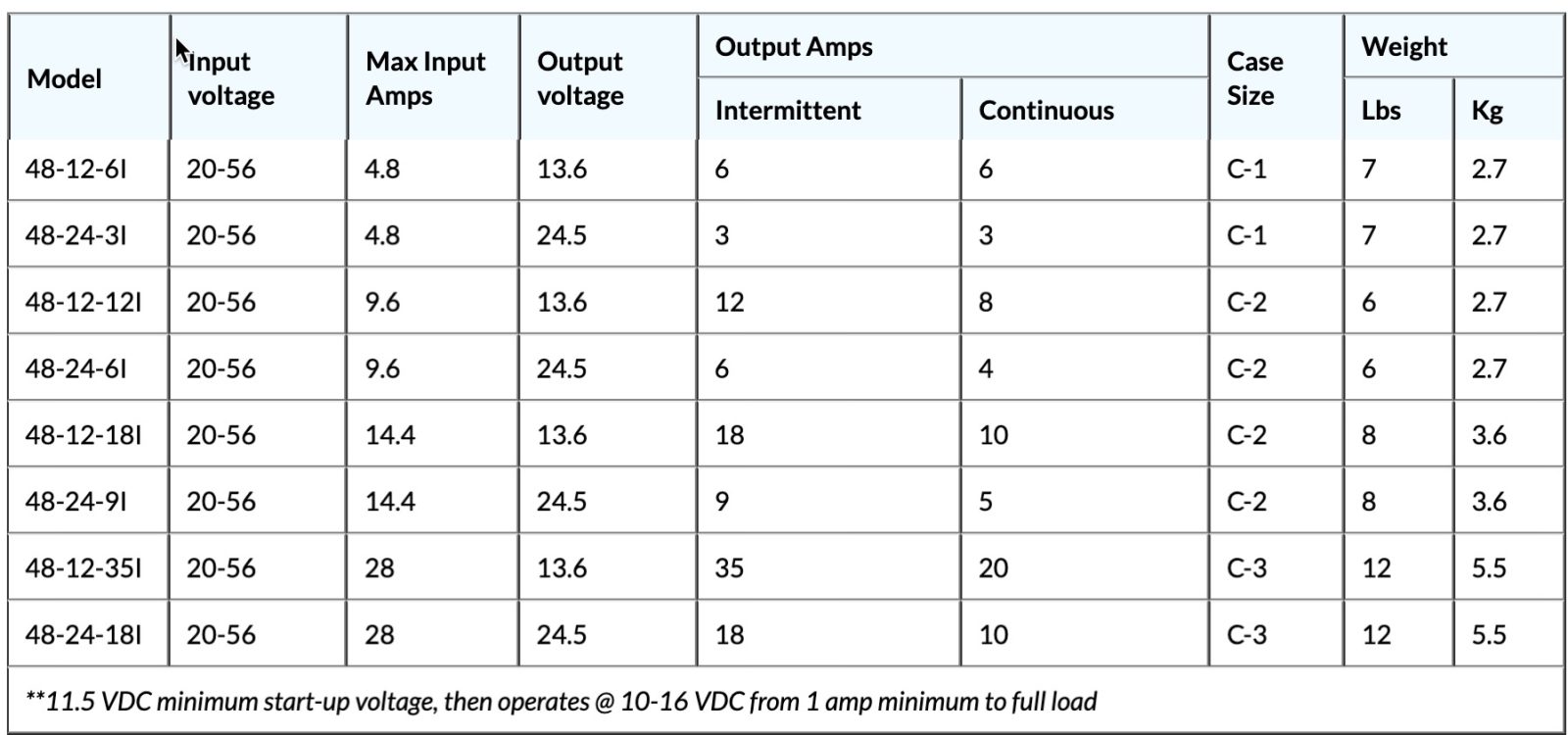

I’ve heard people make the case that it’s simple to use voltage converters when 12-volt power is needed. Unfortunately, I haven’t seen large step-down transformers available. The largest I can find is the Newmar 48-12-35I which supports 35 amp intermittent loads but only a 20 amp continuous load. The 20 amp continuous rating matches the largest units available from Victron or Mastervolt.

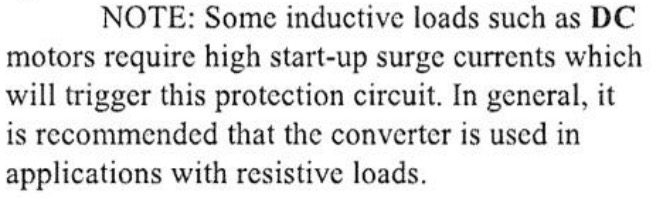

Sizing a converter might seem to be as simple as just adding up the loads and ensuring you’re under the maximum of the converter. But, that’s not the whole story. DC motors require much more power to start than they do to operate steadily. For example, I measured a small, freshwater pump on my test bench. When the motor is running it draws around 3 amps. But, at startup, the inrush is over 12 amps. In fact, the highest measurement I saw (but didn’t get a picture of) was nearly 14 amps. That’s a 4 to 5-fold increase over steady running. As you can see in the snippet from Newmar’s instruction manual, they don’t recommend their converters be used with inductive or motor loads.

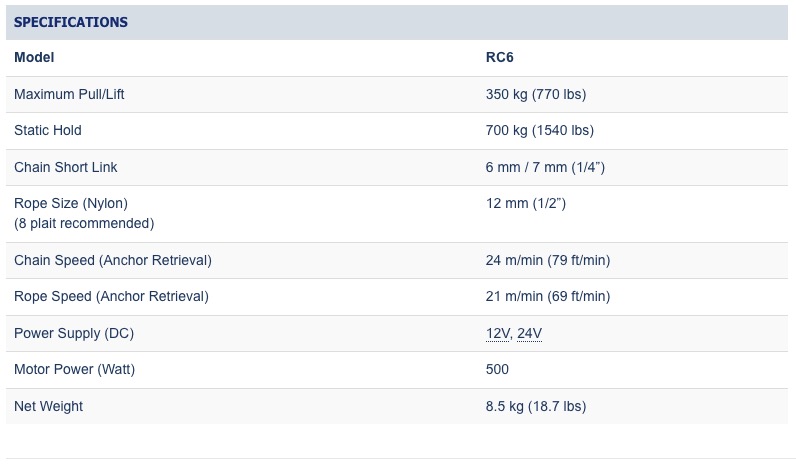

Inrush loads become very difficult (or impossible) to meet as the size of the loads goes up. The specs above are for a Maxwell RC6 windlass. Maxwell’s specs list the RC6 for a 15-25 foot boat. At 12 volts the 500-watt motor draws 42 amps. Inrush will be 3-5 times that or well over 100 amps. There’s no 48-volt to 12-volt DC-to-DC converter in the marine marketplace that can handle that load.

Hybrid solutions

The picture of the battery bank at the start of this article is from an upcoming article on a boat with a very modern approach to power and air conditioning. The boat has both 12-volt batteries to service traditional house needs and a 48-volt battery bank dedicated to a 48-volt inverter. Right now this seems like the only practical approach to introducing higher voltage DC systems on boats.

Without a 12-volt house system, everything not available in 12-volt models will have to be supported by a converter. This can lead to significant challenges in finding the appropriately sized models and significant expense. As mentioned, that’s not always possible. 24-volt components are fairly widely available, but often at a significant premium. Nearly every 24-volt boat I work on also has at least a small 12-volt system for navigation electronics. The NMEA 2000 spec calls for 12-volt power to the bus. Many electronic components will run on 10-30 volts of power but there are also plenty that only operate on 10-16 volts.

The reality is that the cost of converters and specialized components will dwarf any savings from reduced wire sizes or greater efficiencies. Thus, I believe, the best option to capture the benefits of higher voltage is via a hybrid approach.

I used to do some system design. If a boat was system heavy I would always pushed people towards 24VDC with 12VDC converters (basically for electronics). I think if all the motor loads and inverter loads (etc) are at a higher voltage, then a converter makes sense for electronics. Lot less complex then a split system and if everything over a couple amps is on 24 VDC it makes sense. We did quite a few boats this way in the 40-80′ range. At the time we ran the electronics off Newmar or BEP 20 amp converters.

48 VDC is a bit more problematic and you will (for now) end up with two systems. The reason for this is basically pumps. 48VDC thrusters and windlass’s are now not that uncommon, but finding a potable water pump, bilge pump or marine refrigeration designed for boats is a challenge. Which then means that all your charging sources have to handle both 12 VDC and 48VDC (or have some method of bank to bank charging) .

There are some larger DC to DC converters out there. Meanwell being a common one, and I think analytic systems offers one that can do over 50 amps marketed at commercial marine. But if you have heavy enough draws that those are required the cost to have a split system might be similar.

So shorter thought. 48VDC will make a lot more sense when you can buy more marine equipment in that voltage, which I have a feeling will come.

“finding a potable water pump, bilge pump or marine refrigeration designed for boats is a challenge”

On my current boat these all run on AC anyway.

There is a DC bilge and housewater backup pump(s), but these could well be 12VDC if no 48VDC unit is available.

I would love to see a marine electric systems manufacturer develop a comprehensive solution to the all electric (or mostly electric) boat. A solution that handled high power loads, inductive loads, and low power devices (electronics), and charging sources equally well with a systems approach. 48 volt systems have been on the drawing boards of automotive manufacturers for decades. And hopefully, as they become more common the builders of marine electric systems will be able to leverage those economies of scale to the advantage of the marine industry.

48 volt has indeed been on automaker’s drawing boards for a very long time but, except for hybrid and electric propulsion batteries, we haven’t seen it come to reality yet. I think this is in large part because of the challenges of sourcing 48 volt componentry and the sheer amount of 12 volt equipment out there. My hybrid Ford Fusion has a high voltage hybrid propulsion pack and a totally separate 12 volt system for entertainment, comfort, and control systems. I think there are real benefits to be realized from a move to higher voltage, but it’s also proved harder than many might have thought.

-Ben S.

I think another large concern with the 48 V systems is safety. Working in telecommunications rooms was an eye-opener a decade ago when one of my guys dropped a screwdriver on top of a bus bar, which shattered the plexiglass cover, which meant the pliers that he dropped about 10 seconds later shorted out between the positive in the negative. I don’t know what was more traumatic watching the pliers turn red hot in about a second, or watching the red hot pliers explode into the molten metal. 48vdc on boats will increase the risk of fire, but then again maybe the move will lessen the risk of fire because no as many “undersized” wires would be used in 12v systems. Either way I think we are still 20 years away from a major change in the vast majority of vessels on the water.

Pliers shorting a battery turn red equally well on a 12VDC battery.

Its the current that heats them, not the voltage…

I saw the exact same thing happen in a tandem switching office. Someone dropped a crescent wrench across the terminals of a single 2V cell in a string of 24 drum-sized 2V cells making up a 48V battery. The voltage was 2 measly volts, yet with more than a 1000 amps of current, that wrench went up in smoke.

I’m pretty sure that what Charles saw was the exact same thing – 2 volts, not 48 volts (unless it was a really small system!).

What I’ve noticed on some high-tech boats is 48v for main DC storage and generation — or much higher voltage if electric propulsion is involved — and then both 24 and 12 volt subsystems for standard loads, like all those pumps Colin mentions. That sounds overly complex, but I can see how it makes sense given all the factors being discussed.

Also worth noting is that virtually all the distributed power / digital switching systems I know of can handle both 12 and 24v. And also that 50v DC is apparently a threshold when it comes to safety requirements, or so I’ve heard.

“also that 50v DC is apparently a threshold when it comes to safety requirements, or so I’ve heard.”

Interestingly enough, in Europe the threshold for safety is 120VDC.

That is scary high, I think.

No it’s 50 V AC or DC for EU

Negative. It is 50V for AC, but for DC it is not harmonized yet. But most places it is above AC, as it should be, as AC is RMS voltage anyway.

Low Voltage Directive states 75V for DC, but many countries like Finland still has 120VDC limit.

I personally think 80V would be a good compromise, as it would permit running 72VDC batteries legally, but it is what it is.

One great advantage of 48V involves charging. Carrying much greater power through the same size wires means you can have an alternator produce much more power. So a 100 amp alternator at 12V would give you 1200 watts, but at 48V you get 4800 watts from a reasonable size alternator.

With larger Lithium battery banks arriving on more new boats it is very nice to be able to charge them up quickly with a powerful alternator.

Paul Shard

Power generation is measured in watts, and wire is sized to the current carried. Comparing a 1200W alternator with a 4800W alternator is apples and oranges equivalent to comparing a 20A 12V alternator with a 120A 12V one. Even less applicable when the same size wire is used for both.

As an example, consider Victron’s inverter/chargers. The 48V model specs for charging amperage is half of the 24V model’s, while the output specs are identical.

Not when 1200W and 4800W alternators output the same current?

And Victron ’s inverter/chargers are limited by the AC/DC unit, not the DC current. Remember AC voltage and current remain the same.

I should bring up one more item here which is engine staring and charging. I don’t think I have seen an option for anything bigger then 24V for a marine diesel starter. Which means having some lower voltage system or possibly a closed system with a super cap to handle the engine.

There are a lot of reasons higher voltage aren’t that common yet.

I would say if I was going to design say a 45′ motoryacht from scratch, I would go with a 24V main system that would cover engines pumps refrigeration and lightning (with 12V converter as required) then a 48VDC system that would run the thrusters, stabilizers, windlass and inverters. I would leave standard engine charging for 24VDC, and add a second alternator (possibly PTO driven for 48 VDC.) to allow for running heavy loads under engine with out a generator, I would also feed solar into the 48VDC bank. I would have a 48VDC to 24VDC charger for times when the engine was off (If this was my personal boat I would like to monitor this part for a while and then automate it later on once I was comfortable with the best possible operation) .

I think the big question for a system like this is if you need a generator would you go for a small AC generator and battery charge or go custom and build a 48VDC generator. The other possibility is no gen if you keep HVAC loading low.

48VDC starters are available on automotive side, depends on the engine size of course.

Though as it is wise to have a separate starter battery with its own charging anyway, it does not really matter if the voltage is different, that much.

But an optimal solution would be to have a PTO bolted BLDC generator with starting capability. Maybe airstarter as an ultimate backup.

Btw, what is the reason to have 24VDC in a boat where the big loads are 48VDC?

I think 48VDC for big loads and 12VDC for navigation, VHF, N2K etc which does not need much power makes more sense, and “only” two voltages is required.

Actually every 24VDC boat needs 12VDC as well today, so it does not add any more complications compared to today.

Mostly due to things like refrigeration and pumps, but also keep wire sizing down for things like lighting. Really it would be 24VDC for everything except electronics that can’t run on 24. Ideally if you could get 48VDC refrigeration, bilge pumps, engine starters, I would just go that way.

I would leave the engine starters out of the discussion, as they are typically separate batteries anyway, can be trickle charged from DC-DC or AC-DC charger or something.

But for fridge, there are 48VDC units available, or could be an AC unit. Pumps can also be AC driven, and backup could very well be 12VDC.

I just don’t see a point on _three_ DC voltages, too much complexity. 12VDC is still needed for N2K, VHF etc, so it is a good choice for backup voltage.

“Unfortunately, I haven’t seen large step-down transformers available.”

How big you need?

Schaefer C5632 takes 48VDC and outputs 240 A at 12VDC, and you can parallel many if more is needed.

There are more options available, but maybe best is to have a 12 VDC critical load battery charged via DC-DC or AC-DC charger, latter with options for from genset, shore and/or inverter.

Meanwell SD-1000 is maybe more handy form factor, and outputs 60A at 12VDC, and also supports multiple parallel units for more power and/or redundancy.

I think one point to note is the main driver for 48VDC is off grid and off grid solar especially. There 48VDC is getting more popular fast, and that is why Victron provides most all their models at 48VDC as well.

On boats is the electric propulsion.

I now have a 38kw 48v system.

1000ah onboard…

Boat is now all electric off-grid.

Not looking back…

Can you share the details? Brand of batteries, charging, usage etc?

EG4 8x48v100aH

Signature Solar 4x450v bifacial

Victron MPPT, charger and inverter

Recent trip from Kemah to Hitchcock, TX 35 NM starting capacity according to the Electric Yacht monitor/computer 26.4hrs runtime

At destination 5.5 hours later 24hrs runtime remaining with about 30% reefed jib.

Battery bank at: 65% remaining capacity.

David what other sources do you have you have to keep your bank charged, to fill up a bank that size you will need crazy amounts of solar. Do you have a dc genset or 60-100amp alternators?

As originally stated I have 1.8kw of bifacial that on a day like today easily hits (or peaks) at 2000w…

Generally run the motor at least once a day to keep the barnacles and growth off…

Today I ran the motor at 800 and 1000RPM forward and reverse for about 30-45 minutes…

After shutting off the motor for the day the 48v bank was back at status: Float…

When sailing I get regen charge with much better recharge and range…

No need for a genset…

Great write up!

We installed a hybrid 48V Victron 48/10000 Quattro System complimenting our legacy 12V system, on our boat the Elli-Yacht. Instead of fussing with DC toDC converters, we just let the legacy 12V Charger and Battery Bank serve that function…

All of our 120/240V loads are on our 48V Inverter so the 12V System is constantly supplied/floating by being powered by our 48V system. Or, the 12V charger/power supply can be turned off to extend our power use by drawing from the 12V battery bank and replenish when we run our mains or the genset recharges the 48V LiFePO4 Battery Bank.

Originally being a California boat, the Elli-Yacht was outfitted with all electric systems. 4 AirCon/Heat Exchangers, electric hot water and now, induction cooking. This creates significant loads that were simply out of the question on a 12/24V system which can now become common place on a 48V system.

Here is more info on how we skinned the 48v ‘cat’. Cheap Used Valence Lithium LiFePO4 batteries + Victron 48/10000 Quattro = Off-Grid boat life (EP 8)

https://youtu.be/-y91NGWaLV4

Earlier today there was an article about nVidia’s new 12-pin power supply. GPUs in general are quite power hungry, and so are some CPUs. Why are we still using 12V internally in computer systems? Going to 24V or 48V would lower current requirements in cabling, and could increase efficiency in power supplies and power regulators.

Problem is mostly the chips that run internally on very low voltages, like 1.x volts, and relatively huge currents, and DC-DC conversion has its quirks. Its a complicated issue.

Pleased to notice that Maxwell has 48v windlass models that fit medium size boats:

https://vetus.com/usa/news/48v-is-now-available-for-the-maxwell-ps-range/

That could simplify cabling a windlass except unless you’re also powering a bow thruster up there, because 48v thrusters only seem to come in large sizes. Unless I’m missing something?

Why am I researching windlasses? Well, our first Gizmo cruise since 2020 started with a windlass failure and a lost anchor. Damn!

Anyone feel especially positive or negative about any windlass brands? I’m looking at Maxwell, Lofrans, Muir, and Lewmar vertical models, rope & chain gypsy plus capstan. It will be 12v but Gizmo already has 4/0 cable to bow.

I would personally consider a AC driven unit with VFD control. Unbeatable torque and silky smooth speed control, and thin cabling, if AC is available onboard. Maxwell has DC, AC and hydraulic versions of most their windlasses.

VFDs are crazy cheap today, few hundred usd in this context, if even that.

I did miss something! Vetus also offers Bow Pro 48 VDC bow thrusters as small as 1.2 – 1.6 kW:

https://webshop.vetus.com/en/products/thruster-systems/bow-pro-48-vdc-series

Chris from Balmar here. We introduced two 48V alternators and a regulator a few years ago, and are starting to see some traction in this direction. We have some early adopters that are using our 48v alts with great success on their boats.

A few years ago, I wrote a white paper outlining the case for 48V systems: https://www.balmar.net/wp-content/uploads/2020/07/CASE-STUDY-Silent-Running-A-Case-for-48V-Systems.pdf

RV Manufacturers are embracing 48V systems, and I think in a few years we will see this in the marine market as well.

Chris

Can you give an estimate on the efficiency on these 48V alternator + regulator combos?

@ChrisWitzgall – thanks for sharing – super interesting to consider!

Very interesting efficiencies on 48 volts:

https://secureservercdn.net/50.62.88.87/gj7.932.myftpupload.com/wp-content/uploads/2017/10/DC-Technical-Datasheet.pdf

The toughest part of making a 48v (or 56v if you are targeting some higher performance POE++ devices) is fusing/circuit breakers. Not many fuses, fuse holders, or circuit breakers are rated for those voltages. The circuit breakers that are have really high amperage for what the draw of an average marine device would be. I’m looking for the equivalent of the 12 circuit fuse block from blue seas for a higher voltage bus and not finding it. I found some fuses and inline fuse holders, but those aren’t as easy as having a block that might be stashed somewhere. It’s not so much an issue now since we need 24 or 12v for most marine electronics still, but no clear “future proof” power distribution for the day that chartplotters , etc.. Separate breakers for each VHF, chartplotter, and the NMEA bus?

There are plenty of circuit breakers rated for 48DC, they are not hard to find.

Both automatic type and conventional blow once types.

For higher currents, ones for PVs and EVs are for way way higher volts and amps.

The problem is lower currents. Devices fused at 3/7.5/10 @12v don’t have an option at 48v for single digit amps

There are glass tube and blade type fuses starting from 1A.

But what device would you put that to exactly? The ones you mentioned won’t work with 48V anyways, NMEA, VHF, maybe chartplotter etc require 12VDC anyways. Have a dedicated, small nav battery for them or use DC-DC converter, and fuse them on 12VDC side?

Littelfuse 314/324 Series L covers 0.125A – 40A and is rated on DC up to 125V DC.

If you want even smaller – why would you? – there are pcb mount ceramic fuses all the way to nanoamps, but they need some soldering.

There are so many options available, its not a problem really.

As an example of million types available:

Nader NDB1-125 or ABB SU201M-K6