Raymarine 2014: science, cadence & “IReverywhere!”

This frozen aSeries MFD has almost finished a two-day low temperature test, but that’s only the beginning of its suffering. Next it will run another two days in a high temperature cabinet with 85% relative humidity, and there’s still 19 more days of torture to Raymarine’s ERT (Early Reliability Test) Qualification Process. The quality of the testing tools and seriousness with which they’re used was as impressive as the Raymariner on-the-water lab, and I’m publishing more photos below because it’s reassuring to see what proper modern marine electronics have to go through before reaching our boats. But I’ll also attempt to describe the product innovation processes in play at Raymarine’s R&D center, which seemed equally impressive though much harder to photograph or quantify…

This frozen aSeries MFD has almost finished a two-day low temperature test, but that’s only the beginning of its suffering. Next it will run another two days in a high temperature cabinet with 85% relative humidity, and there’s still 19 more days of torture to Raymarine’s ERT (Early Reliability Test) Qualification Process. The quality of the testing tools and seriousness with which they’re used was as impressive as the Raymariner on-the-water lab, and I’m publishing more photos below because it’s reassuring to see what proper modern marine electronics have to go through before reaching our boats. But I’ll also attempt to describe the product innovation processes in play at Raymarine’s R&D center, which seemed equally impressive though much harder to photograph or quantify…

Some of Raymarine’s environmental testing was difficult to see in action, like the Red Sea level sun, humidity, and spray aging possible within the Q-Sun Xe-3 Xenon Chamber, but I did think of how little the RD418HD radome on Gizmo’s mast has faded or yellowed since I began testing it in 2009. Similarly, they couldn’t safely show us what happens in the Near Lightning Strike (NLS) closet, but while I doubt they can prevent all forms of lightning damage, I’m glad that they seek out fixable weaknesses. Meanwhile, the 250 kilograms of salt tablets stacked along a hallway suggested how the salty fog chamber reaches Icelandic levels.

The shock and vibration testing was more dramatic. In this scene the new a12 MFD on the shaker table is undergoing a protracted sine sweep with the PC graphing the vibration of both the table and the display. Thus, frequencies that cause harmonic reactions stand out so either the MFD mount can be modified or the device tested further with the more difficult vibes. Trade Only’s Chris Landry nicely videoed this test along with the nasty machine that delivers measured impact whacks to screens and other parts.

Chris’s video also features the water jet and spray booth, which is purposely the last stop for devices that have been frozen, baked, vibrated, etc. Apparently, testing to IP (Ingress Prevention) Standards should be done with “aged” equipment and besides, according to Raymarine’s Director of Engineering Gordon Pope, they test beyond IPX6 and 7 because the ultimate goal is to avoid major warranty issues. He noted, for instance, how an aged MFD with failed gasketing might survive the IPX6 100-litres-per-minute jet at 100 kPa from 3 meters because the pressure actually resealed the unit, but the same unit might fail the lesser IPX3 spray test.

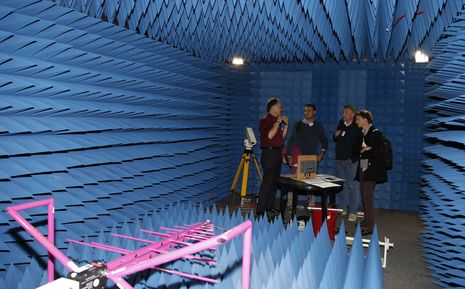

That’s Pope explaining one of Raymarine’s several EMI (Electromagnetic Interference) test chambers to some of the visiting journalists. The sounder module on the table, which is powered up and receiving transducer data, is being targeted with EMI that might emanate from other gear on a boat, while the test engineers use that white camera to watch what happens on the screen of a networked MFD that’s on the floor. The module will also spend time in a chamber that looks very similar, except that a receive-only antenna will measure any EMI the sonar throws off, so hopefully it passes whatever FCC, CE, etc. standards it’s meant to meet (which Raymarine is qualified to ascertain).

Pope is passionate about the testing process and often emphasized the word “science” during our tour. Both he and Director of Product Management Chris Jones previously worked for Motorola and other mass consumer electronics companies, and they can vividly describe the engineering precision and discipline it takes to, say, quickly design a new and different smartphone and then manufacture millions of them glitch free.

So while Gordon Pope likes to talk about the science of product assurance — incidentally, Raymarine maintains subsets of test engineers and equipment at its contract manufacturing facilities in Hungary and China — some of Chris Jones’s favorite terms involve the “pace” and “cadence” of product development. For instance, how did Jones’s small team of sonar engineers march from unusual concept to finished DragonFly hardware/software? A good conference room helps, as do nearby prototyping and testing facilities, but a whole lot of the challenge is prioritizing goals and dividing the tasks into doable chunks. At Raymarine, they call the three-week development sprints “scrums” (as in rugby), and they’re followed by three weeks of evaluation and then another scrum, etc. etc. (While the marketing dept. dreams up alluring terms like “visionality” and someone tricks out a Hobie fishing machine because Ray has ambitions in that exploding market.)

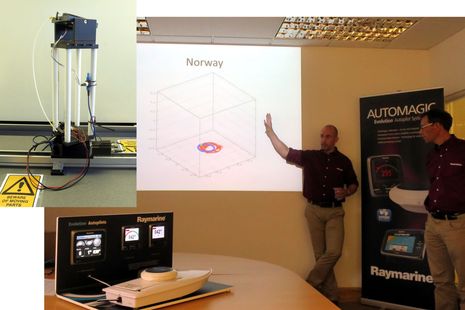

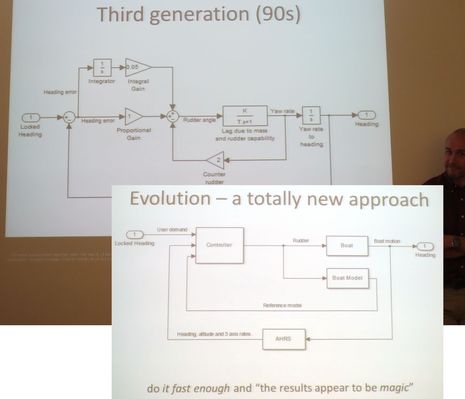

While each team at the R&D center gave an interesting presentation, perhaps the deepest involved the Evolution Autopilot system. That’s Ian Matt, who worked on helicopter and formula one race car electronics before Raymarine, and Mark Johnstone, who first cofounded Tacktick and engineered the wireless instruments that Ray sells today. They’re explaining some of the algorithms that made the EVO 9-axis AHRS — that’s an attitude and heading reference system with 3-axis magnetometer, 3x gyroscope, and 3x accelerometer — into a marine “compass” that can be mounted most anywhere without calibration. Apparently, it can pull off that trick most anywhere on the planet, too, even areas of extreme magnetic dip like northern Norway. The diagram shows in red the raggedy raw magnetic heading data collected, while blue illustrates how the EVO extra sensors and smarts resolve the data into something much more accurate. The photo inset at left shows a gadget the team used to move the AHRS in multiple ways at once.

Once they were confident that the EVO sensor really can feel a boat’s motion well, the developers were able to use it as a data collection tool to see how well their autopilot logic was working on some 50 beta test vessels. They can even turn the data into graphic simulations that showed test boats steering better and better through waves as the code writing scrums proceeded. And development did not end when Evolution went to market. Evo is thought of more as a platform than a product, much the way all the MFD series (and even DragonFly) run LightHouse software that is updated about every three months. The first major Evolution update came in February; Hydro-Balance can purportedly sense and correct variable hydraulic issues like air bubbles and hose flexing that can cause poor pilot performance, and it’s just software.

Incidentally, I used the Evo AHRS as a heading sensor on Gizmo much of last season and I’ve only seen better performance from a Furuno SC30 satellite compass that’s bigger, more expensive, and fussier about where you put it. Installing the rest of the Evolution autopilot system would be easy except that my solenoid-driven steering means I have to exchange the working Simrad rudder sensor with a Ray one – a tight-quarters job I don’t relish. But I was motivated by the presentation in England and also some positive reader reports. Can Evolution handle following seas better than Gizmo’s current AC60 course computer and RA42 rate compass? Maybe it’s time to find out.

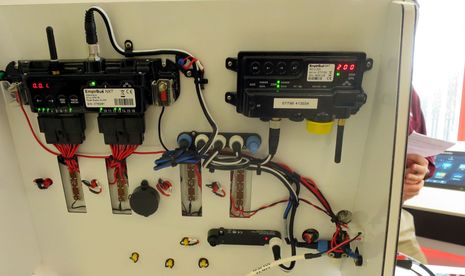

I haven’t heard much about Raymarine’s support of Empirbus NXT digital switching since the Miami 2013 announcement, but it’s purportedly attracting the interest of European boatbuilders. I also learned from the Empirbus product manager that the main DC module (left above) can handle almost any switching or monitoring task on its 16 channels and also supports a wireless, battery-free switch technology that I’ve been hearing good things about from another marine developer. There’s much to study here.

How much did FLIR have to do with the Raymarine turnaround that’s seemed obvious as the product lines rapidly evolved over the last few years? One conclusion I reached in the UK was that FLIR (and Garmin, which also made a bid) saw value well beyond the brand name and distribution network. The R&D facility in Fareham may be relatively new, but the engineering and boating culture within often stretches back to the Autohelm days. I did laugh, though, when told that the guest WiFi password is “IReverywhere!” FLIR is a very determined company, and apparently they did make some changes at Raymarine, mainly in terms of key managers and guiding the “pace” of development.

While the Ray crew is also disciplined about discussing not-yet-announced products, they did say that there may be interesting MFD integration possibilities with FLIR’s new FX line of wireless daylight cameras. And who knows where the company’s tiny Lepton IR sensor may end up (besides the FLIRone iPhone cam)?

I’ll close with a bigger thought. Obviously the Raymarine visit impressed me a lot, but I also saw some excellent R&D science and cadence when I visited Garmin a few years ago. And while I once characterized Navico as “firing on all cylinders” (which still seems true), I’d now say the same of Raymarine and have long admired Furuno with its powerhouse hardware developers in Japan and software team in France. We live in a good time for marine electronics, people! Thus the collage of handsome Discovery 57 with FLIR M-Series cam serving lookout on mast, e12 MFDs at helms, and yours truly thumbs up about everything.

They don’t just call it scrum at Raymarine. It’s a well known methodology in agile software development.

Scrum is the name of the daily meeting, not of the development iteration (which is officially called “sprint”).

Scrum-managed projects don’t have a project manager, just a Scrum master who is not a manager but a moderator/mediator between the project sponsors and the team and is a servant-leader to the team.

http://en.wikipedia.org/wiki/Scrum_%28software_development%29

Interesting. Kind-of makes you wonder why the old C-Series classics failed like one-legged pole vaulters…

With the apparent focus of Raymarine on product quality, perhaps you’d care to comment on the “orphaning” of the E-wide series of MFDs.

The original “new E” series MFDs (Lighthouse I) worked flawlessly with the E wide series. My combination of an E7 at the helm and a data master E120W under the dodger was sublime.

Then came Lighthouse II for the “new E” series that dropped support for networking with the E wide series. Raymarine, if you believe them, said that there wasn’t enough RAM in the new E series to support the E wide protocol. OK, if I don’t upgrade to Lighthouse II, the E7/E120W combo still works. I can live with that.

Then Navionics drop support for Lighthouse I in their mobile apps. So, if you own an E wide device, iPad sync, a wonderful feature, goes down the drain.

Raymarine technical support is aware of problem but says it isn’t their fault. They even had a work arournd: When I want to sync with an iPad, upgrade the E7 to Lighthouse II, sync the devices, and save the user data. The downgrade the E7 to Lighthouse I and reload the user data. Uh, maybe not.

I bought my E120W when Raymarine was tottering on the brink of liquidation with the belief that excellent technology will find a way to survive. The FLIR intervention demonstrated that irrational hope sometimes works.

No, post-FLIR, Raymarine is going out of their way to screw the customers that stuck with them when things were tough. It is very hard to believe that Raymarine couldn’t upgrade Lighthouse I to support Navionics (they have the source, I hope), couldn’t upgrade Lighthouse II to support networking with the E wide series, or Navionics couldn’t support the new and old synchronization protocols.

No, I don’t think it is technical problem. Either Raymarine management is indifferent to their customer base or they are actively trying to orphan pre-FLIR devices to force upgrades to almost-as-good “new E” MFDs.

Thanks, Henning. Navionics recently told me that their development process is now organized in three week sprints and that we could expect more frequent iterations of the app software.

Dave, I still see a lot of C-Classics on boats. In fact, a C12 came with Gizmo when I bought her in 2009, I sold it locally and I believe it’s still operational.

That’s not to say that Raymarine (or anyone) builds perfect gear. For instance, despite all that elaborate testing during development and manufacturing, many original e7’s developed touchscreen issues after a couple of years. I understand that Raymarine had to hire outside engineers just to figure out what was going wrong, but they did the right thing once a consistent corrosion problem was identified. Even owners who don’t yet have e7 trouble can get a replacement:

http://www.raymarine.com/view/?id=9095

Also, yesterday I got a call from an installer who’s seen several Ray AIS650 Class B transponders with antenna issues and wondering if I’ve heard of that. I haven’t, and I ran a 650 on my boat for quite a while without any problems. Anyone?

He did say that as a certified Raymarine installer — working at the “pointy end of the stick” as he phrased it — he’s gotten much better support since FLIR arrived on the scene, and that he too thinks the equipment is much improved.

I’ve used the AIS650 for several years without antenna issues beyond those I inflict on myself. I am curious what the antenna issues might be.

There was on antenna issue I had in the sense I had a near lightning strike that wiped the AIS650. Raymarine kindly repaired/replaced it and I now have coax surge protectors on all antennas. Seems to work so far.

Cheers

Don

I got a little confused, Don, but I think the issue is that the 650’s software sometimes senses a poor antenna and shuts down transmissions even though the antenna is fine. The installer is Dave Skolnick, who has particular expertise with radio issues. I just emailed him to hopefully clarify what he’s seeing.

Jim, in a sense the E-Wide orphan situation is worse than you state. When Ray introduced its high end CP450C Chirp Sonar it wouldn’t work with the E-Wide even though the latter was still being sold (if I have my chronology is correct). I’ll bet there were some fishermen who didn’t feel good about that.

But I think you’re making a lot of presumptions about the motives behind the scenes. I’m pretty sure that LightHouse was a start-from-scratch software replacement, and backward compatibility often suffers in that process. I’m not a coder but I think it’s perfectly possible that E-Wide compatibility was hard to maintain and they had to drop it as LightHouse moved forward. New features like two formats of Lighthouse Charts and the ability to use unlimited sonars must take up some memory and processor space, wouldn’t you think?

Also, I think you’re confused about the Navionics app. Version 7 is not syncing routes with LightHouse II either. This surprised me too but apparently it’s just temporary; see comments here:

https://panbo.com/archives/2014/05/navionics_boating_app_now_with_free_us_charts.html

At any rate, Jim, I don’t see any actual evidence that “post-FLIR Raymarine is going out of their way to screw the customers that stuck with them when things were tough” but no doubt the transition to the new platform was painful, as it was for other companies like Navico.

I’ll add that while I personally like to punish companies when their products disappoint me, this rebuilding situation with Raymarine and other marine manufacturers may be the wrong place to apply that principle. Customers with E-Wides did get a particularly poor deal in terms of product updates and compatibility with new gear, but now all the displays, sonars, autopilots, etc. are running on a clean unified platform that Ray seems able to improve in big steps at a nice pace.

Until/unless Raymarine offers broadband radar, I will remain a Simrad guy. It’s apparently a patent issue, but for someone who needs Navionics charting and solid-state radar, Simrad remains the only choice (and Lowrance, obviously).

As another poster implied, the FLIR acquisition has hastened the obsolescence of existing RM stuff in an effort to force upgrades…reminds me that I need to clean out my garage…

Thanks for the reply.

The current version of Navionics US & Canada is 7.0.1, released June 10th. It starts to sync then displays a message box to the effect that my E7 must be upgraded to the lastest version to sync. So, while they may have addressed syncing with Lighthouse II, it still leaves us stranded with Lighthouse I high and dry.

As it turns out, I am a code and have been doing Internet data transfer protocols longer than the Internet as existed. It is the industry norm — and not at all difficult — to maintain backwards compatibility with a protocol negotiation step during the initial handshake. I’m also an Apple developer, and there is technical reason for Navionics to rip out support for the first generation plotter sync protocol.

But perhaps more to the point, there is also no reason that Navionics could not resubmit earlier versions of their mobile apps to the Apple store under different names. This would cost nothing, require no engineering work, and should only take a few days, plus or minus Apple store bureacracy.

But, I fear, neither company seems very eager to solve the problem to even to state they the problem will, eventually, be solved.

Meant to add in the comment to Jim that just last year — well after the introduction of the CP450 — Ray introduced the middle-of-the-road CP300 sonar that’s compatible with “legacy Raymarine E Series Classic, C Series Widescreen and E Series Widescreen displays”…which doesn’t make sense with the “forced upgrade” theme:

https://panbo.com/archives/2013/07/fingers_on_raymarine_a65_and_hello_a68_a75_a77_a78.html

Impressive. This why a consumer tablet or smart phone will never be my primary nav source.

Interesting to see Agile adoption within the marine electronics industry.

Karl, FLIR already has FMCW Radar (called Broadband by Navico):

http://gs.flir.com/surveillance-products/surveillance-technology/frequency-modulated-continuous-wave-radars

I think Garmin also has solid state radar (aviation type) and rumor suggests that Furuno is working on it. My recollection is that Navico doesn’t claim to have invented it, but did spend a lot of time and money getting it to work well on the a boat at an acceptable price.

Just as a counter point to some of the above comments I have a C140W and a C90W (the middle age C’s) hooked up to HD digital radar, an even older Autohelm Autopilot I could also be hooked up to a digital sounder black box the DSM 300 or CP 300 (I am not in my installation), all of this is 2009 vintage [except the CP 300] or earlier equipment. I could upgrade in 2014 to the new c or e MFD’s and all of this peripheral equipment is still compatable. Raymarine make adapter cables so I can re-use the high speed network cables and make a re-fit bezel for the C90W. I think that is fairly impressive for at least 5 year old electronics equipment.

I find all this fascinating especially in light of my recent last few weeks.

Customer purchased entire new Raymarine system. Two plotters, helm and nav station, HD radar and all associated cables per my specs, I am very happy he insisted on supplying the product BTW. I then installed the system.

After the boat was launched and the mast stepped I showed up to hook up the radome to the rest of the system.. No go… Hmmmm that’s odd? Another trip to the vessel for three hours of trouble shooting.

“Hello Ray tech support this is RC I need the pin-outs for the new round plug Raynet wires.”

Silence…

“Ah I don’t have those?”

“What?”

“I don’t have those yet.”

“Can you please get them from engineering I am on the boat trouble shooting a brand new system and need the pin-outs to test these cables.”

“I’ll try”

Two billable hours later I call back and 30 minutes later I have the pin outs via email, but not for the radar cable.

All is good on the boat end regarding Raynet wires & jumpers. I swapped plotters from helm to nav station because there is apparently no way to diagnose a bad Raynet board from the unit itself. Both units do the same thing. Not the units. Check email, still no pin-outs in my email inbox from Ray? I go home.

I tell Michael my customer that we either have a bad dome or bad cable, dome would be better as it entails NOT unstepping the spar to run a new cable. D’oh…..

Customer BUYS new radar cable. Up the bosuns chair, plugs it in and what do you know the cable works. Wish it was the dome…. D’oh….

His appointment to de-rig, un-step, re-run in mast cable, re-step & re-rig is scheduled for July 11 at Brewer’s So Freeport. I post this just in case anyone wants to see what all this “testing” relates to in the “real world”…. $$$$$$$$$$$$$$$$$$$$$$$$$$$$$

Oh and I need to go replace three e7D’s (touchscreen alignment issue recall) in the next few weeks, which I as an installer, can not charge anything for. The customer loves that they are getting a brand new plotter but as the installer I get BONED. I suspect Ray probably wonders why I am buying less and less equipment from them. I mean they do plenty of “testing”.. Wink…

Sorry you caught me in a sarcastic mood but I find the timing of this pretty laughable right about now….. Tongue only partly in cheek on this one Ben…

Back to the 650 in particular, the issues I discussed with Ben are several. The underlying issue as an installer and repairer is that integration time and troubleshooting time is out of hand. Very often we simply can’t pass those costs on to a customer.

With respect to integration, I recently upgraded a customer from an AIS 500 to an AIS 650. The boat is all Raymarine and has three E90W chartplotters. The AIS 500 worked fine. The 650 would go into silent mode within seconds of power-up regardless of switch position or chartplotter controls. This ultimately turned out to be a software problem in the chartplotters. Why was the 650 more susceptible than the 500?

I fully understand that with the number of new and legacy products making sure that everything talks to everything is hard. There is still a lot of support requirement passed to the installers. Warranty allowances of 15 or 30 minutes don’t help much when stacked against hours of troubleshooting.

In the same timeframe another customer had an AIS 650 that reported very high VSWR through the dealer version of ProAIS – huge numbers like 65:1. Of course the AIS 650 did what it was supposed to and went silent. The problem was that using an external antenna analyzer (an MFJ-269 for those that care) the VSWR was right around 2:1 through the AIS 100 splitter and 1.5:1 direct to the antenna. My little “known good” VHF antenna on deck measured 1.1:1 on the antenna analyzer but the AIS 650 thought it was 62:1. Unhook everything and ship to Raymarine for repair. *sigh* SWR measurement and output foldback circuitry isn’t rocket science and really should not fail. 15 minute warranty allowance – about 2 hours of work.

All that said (and I do have more examples), Raymarine technical support under FLIR has been pretty good and turnaround at the service center has been pretty fast.

When we get a work order that includes an AIS 650 my management and I cringe as we fully expect that the time we have to eat is going to make the job a money loser.

I’ll be the first to admit that the problem jobs stick out in my memory.

73 es sail fast de dave

S/V Auspicious

“15 minute warranty allowance – about 2 hours of work.” You’re right about that Dave!

Warranty work is always a loser, some more than others. Try dealing with West Marine’s extend warranty company if you want to experience Dante’s 8th circle of Hell (the 9th circle is reserved for DirecTV, Verizon, AT&T, and Sprint). I start to lose warranty claim related money the moment the phone rings.

I’m very happy with Ray’s tech support. Although the wait times have increased, when I get through the staff is always pleasant, honest with me about issues, and knowledgeable. My issues with everybody’s gear is lack of diagnostic tools especially when dealing with “Black Boxes.”

It appears that current thought of marine manufacturers regarding warranty repairs has drifted toward the big-box store model….namely if it doesn’t work and its in warranty, the customer should return it no questions asked. Marine installers are among the few people left who still seem to wonder why it doesn’t work. Sadly, the value add-ed of marine installers may boil down to saving the original packaging for warranty work.

Bill – wait times on the Raymarine Certified Tech line aren’t too bad. It’s worth the study time!

I agree Dave. Rays tech support is good, much better than it was 7-8 years ago. However one issue is that if & when you need to go test something, and report back, you have no ability to direct dial the tech you were on the phone with and getting back to that particular tech person can sometimes place you back into “phone hold Purgatory”….

I guess my frustration is that Ray tech support guys are often not given the tools they need to do the job at the level needed for well served tech support..

I understand that things such as cables change from time to time but simple things such as the pin-out diagrams should be loaded into their computers for a quick email out to techs in the field.

Hi RC!

It isn’t just tech support that doesn’t have the tools they need.

I want a box I can plug into my laptop with NMEA 0183, NMEA 2000, SeaTalk-1, SeaTalk-ng, and Ethernet (for Furuno and Raymarine) and software that can at least give me sentences and preferably a time-domain voltage display. If I can get better data I can do more without calling tech support. If I can collect better data tech support can help me better and faster.

sail fast and eat well, dave

My two computer chart plotters work flawlessly. My digital RM radar & DSM 30 both run perfect. Plotters update daily plus the computers have bells and whistles that no MFD has. I got tired of chasing rainbows.