Dymo XTL labeler, premium quality labels at a premium price

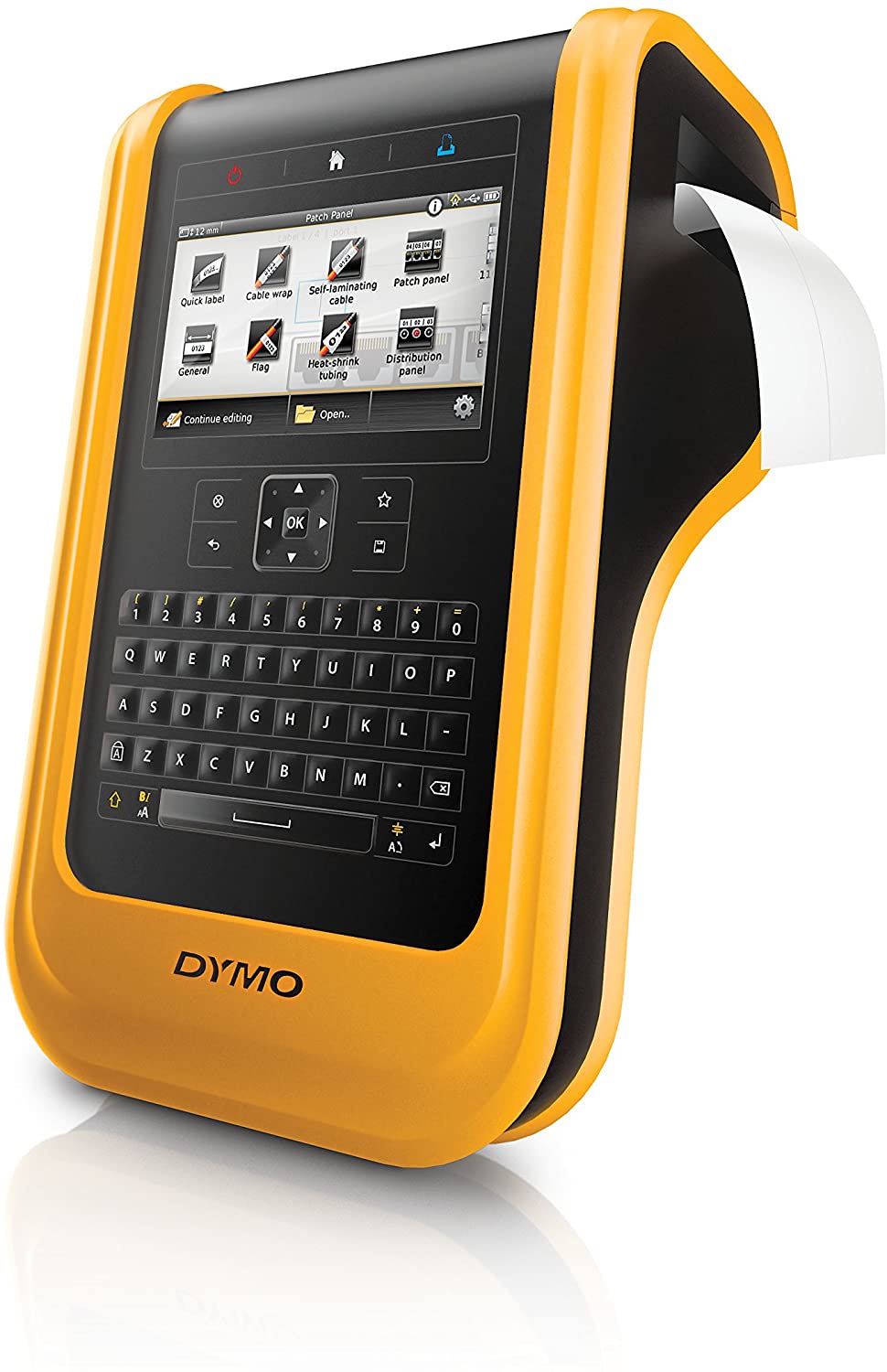

Several weeks ago I shared a few pictures of me working in an engine room with Ben Ellison. He used those pictures in his recent entry and in a caption asked, “Wait, is that yellow/black thing an exotic cable label machine or what?” Well, it is indeed a (somewhat) exotic label machine, the Dymo XTL 500 and I think it’s definitely improved the quality of my installs. The XTL series of labelers print on a broad range of labels including several very well suited for work aboard a boat.

Previously, I’ve used a Brother P-Touch labeler with heat-shrink tubing to label wires. This is a great strategy for wires with small enough connectors (or bare wires) to slip the heat shrink over. But, it’s embarrassing how often I remember to label a wire only after I’ve crimped a connector onto the end. Plus, my recent work on DC house systems has involved a lot of work with large diameter cables the Brother labeler’s heat shrink won’t fit around. Before the XTL labeler, I used label flags for cables I couldn’t get heat-shrink around. I’m not a big fan of flags because I think they look messy, are easily ripped off, and are frequently pinched in bundles of wires. So, I was quite excited to discover the Dymo XTL labelers while searching for some label supplies.

Brother P-Touch labelers produce laminated labels with a clear cover over the label itself, with the exception of a few specialty cartridges like heat-shrink tubing and iron-on labels. The XTL labelers print directly on vinyl and don’t laminate the labels. I’m not sure if one method is better than another, but I have noticed the XTL labels do seem more durable overall. I’m not alone, LabelZone — a UK label specialist company — tested XTL label durability by placing a label on the floor of a high traffic warehouse.

There are two XTL labelers; the XTL 300 prints a maximum of 1-inch tall labels and the XTL 500 prints up to 2-inch labels. Both come as kits with the power supply, USB cable, carrying case, 1/2-inch labels, and 1-1/2 x 1-9/16-inch cable wraps. The XTL-300 kit sells for around $350 and the XTL 500 kit is around $500. One comment I read online described them as hands-held rather than hand-held and that seems accurate owing to their chunky size. But, they are also solid, well-built machines with extremely long battery life. I’ve had mine for about four months now and only charged it twice despite some pretty heavy use.

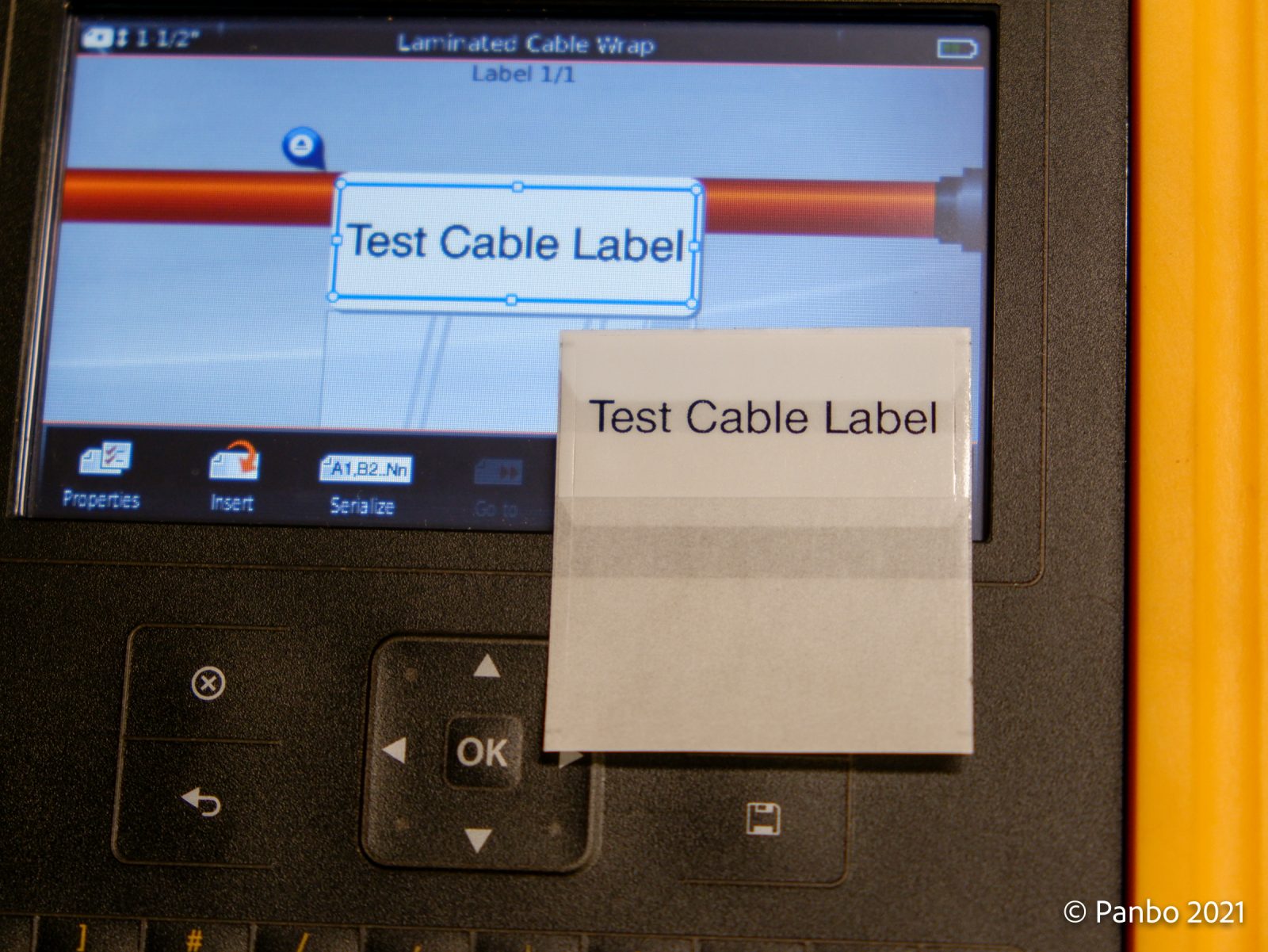

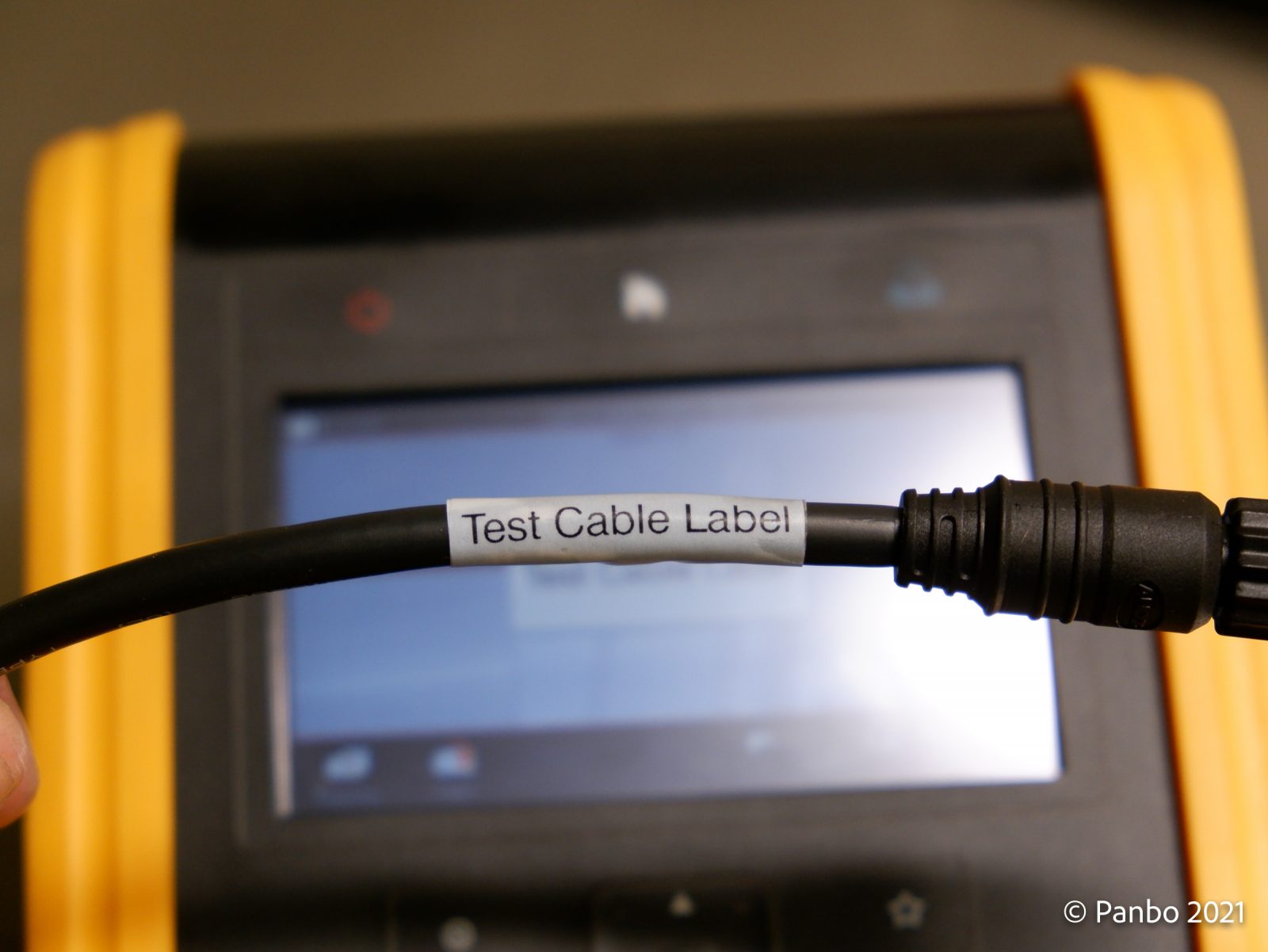

For my use, the biggest upside of the XTL 500 is the array of sizes and types of labels it prints on. Especially the “Laminated Wire/Cable Wrap” labels. These labels have an opaque white section a the top of the label and then a clear portion of the label that extends down to wrap around the cable and cover the printed section of the label. I’ve used around 100 of these labels so far and had no trouble with them peeling. Durability can only be proven over the long haul, but what I’ve seen so far leads me to believe these labels will hold up very well.

The cable wrap labels solve the difficulty of labeling large diameter cables and cables with large connectors that I can’t get heat-shrink tubing over. The cable wraps also mean that I can label my cables at any point in a project and don’t have to remember to slip heat-shrink tubing over wires before I’ve connected or put ends on them.

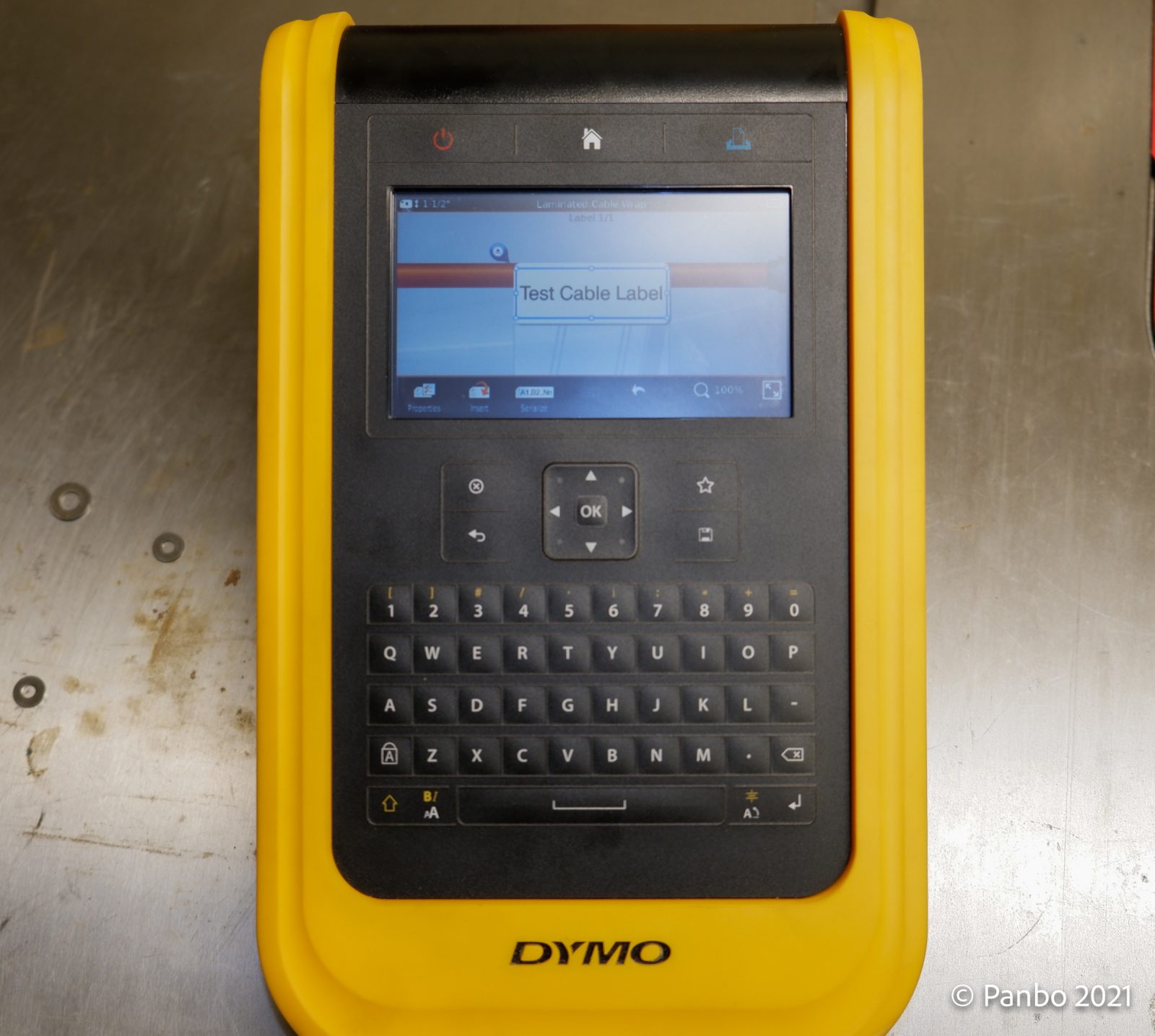

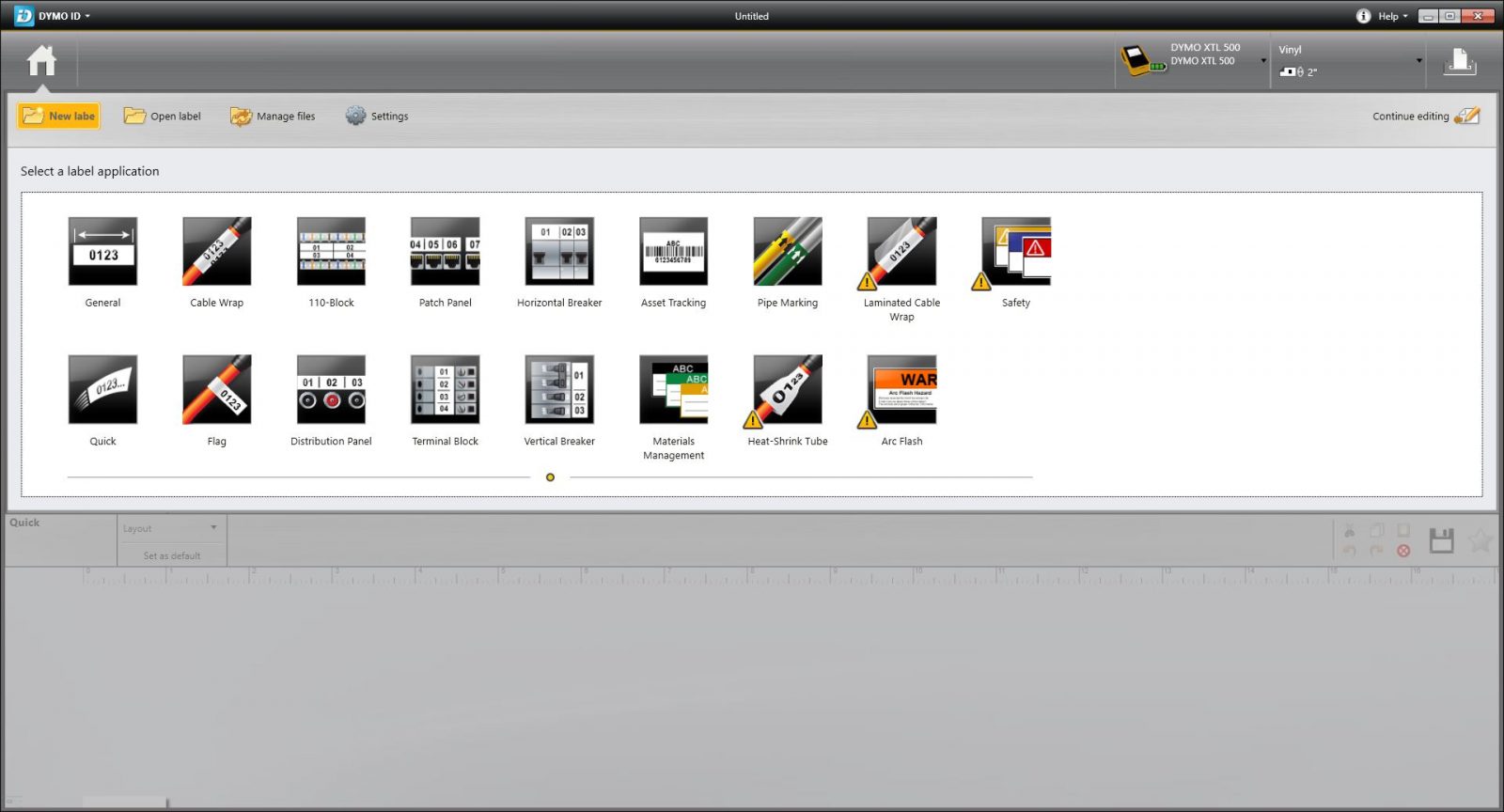

Labels can be easily created using the keyboard and touchscreen of the XTL or, for more complex or involved labels, you can use DymoID software to design your labels on a computer and send them to the XTL. DymoID can be used to add images and other more complex elements and also to import labels from spreadsheets and databases. For example, if you have a full wiring plan for a boat, you could export the wire numbers from your plan and print labels for each wire. Labels designed in DymoID are sent to the labeler via a mini USB cable that is included with the kit. So far, I’ve only used the PC software to print labels with the Panbo logo. But, the ability to create lots of labels on a computer and send them to the XTL may well come in handy.

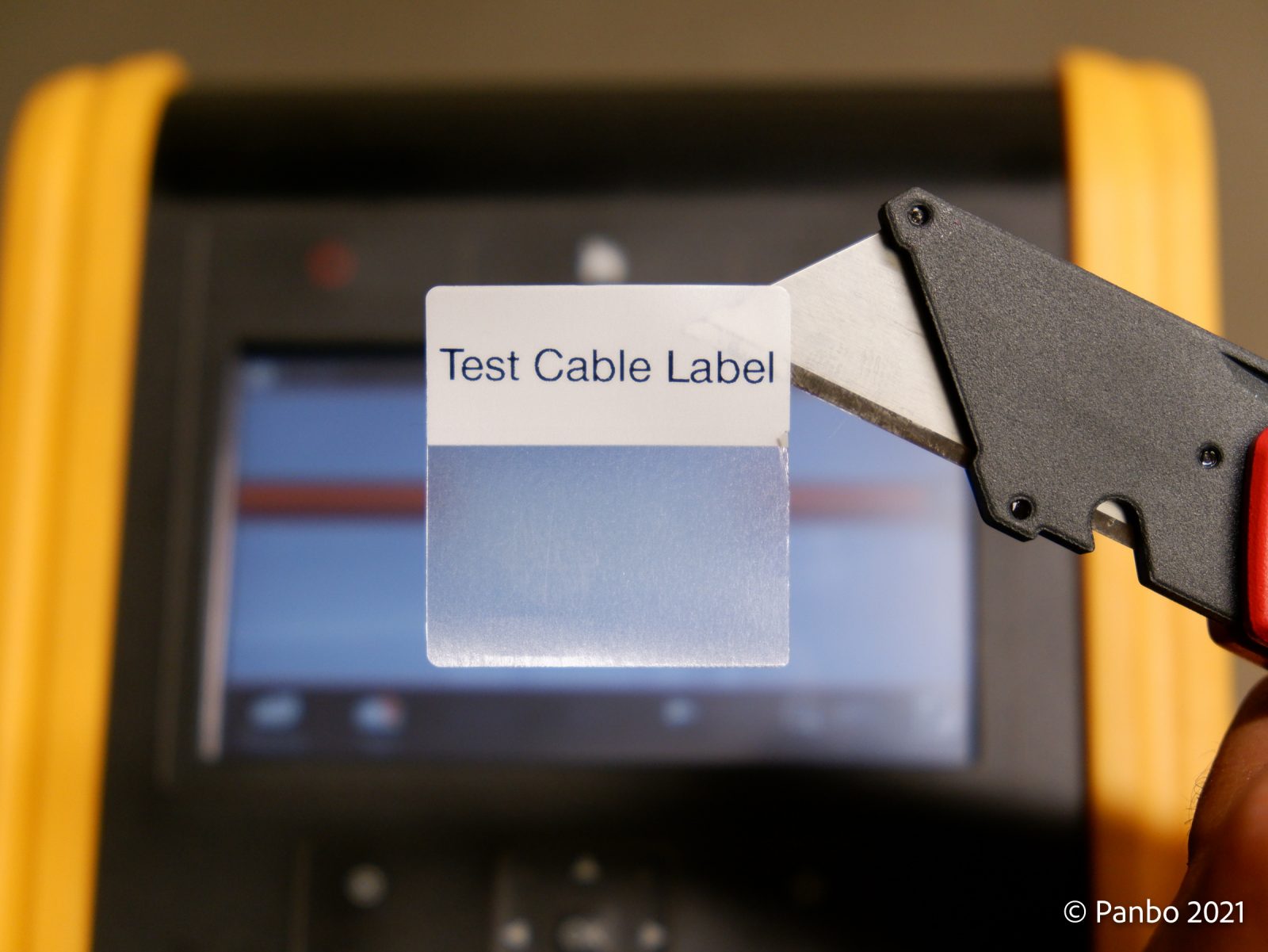

There are a few quibbles to note with the XTL labelers. Boot up takes longer than my Brother P-Touch labelers. It seems like the labeler is running a full operating system which needs to boot up. I’d guess it takes about 20 seconds to boot from powered off. The cable wrap labels are tough to get off their backing paper. The only way I can reliably get them off is with a knife between the label and the backing paper and even that usually takes a few attempts.

The single largest reservation I have with the XTL system is the cost of the labels. I used the cost of Brother’s P-Touch labels to compare with XTL labels. A 1/2-inch P-Touch label cartridge with 26.2 feet of tape costs $13.99 on Amazon or $0.53 per foot. A 1/2 inch XTL label cartridge with 18 feet of tape costs $20.10 or $1.16 per foot. Comparing heat shrink yields similar results. Brother’s 5.8 mm heat shrink cartridge with 4.9 feet of tubing is $23.70 or $4.83 per foot. Dymo’s 6mm cartridge with 9.5 feet of tubing is $54.98 or $5.79 per foot.

Dymo’s XTL labelers aren’t the cheapest option out there and they’re a little larger than some of the competition. But, they’re flexible labelers that offer options no other portable labeler I know of does. So far, I’m very pleased with the durability of the labels they produce, the battery life of the labeler, and the build quality of the machine itself. I still keep a P-Touch labeler in my toolkit and will continue to use it for many tasks where the smaller, cheaper option is appropriate but the XTL sure does make my work easier and neater.

Stay away from the 3rd party generic labels. The Dymo labels are almost twice as expensive, but they take the printer ink properly. The generics allow the ink to be smeared and often the print is not as solidly readable. The Dymo can make very small print.

These label printers don’t use ink…… they print using heat.

I have an older Dymo, this looks like a compelling upgrade – now I’m trying to rationalize the 1″ vs 2″. I can’t come up with an immediate need for a 2″ label, but certainly the 4″ cable wrap for large cables / hoses would be useful. But I think I can achieve the same with “3M 850 Polyester Film Tape – 1″ x 72 yds, Clear” wrap. Ben? Have you produced a 2″ label yet other than a cable wrap?

Keith,

I have found it useful to have the larger sizes a few times and, if I understand correctly, a lot of the specialized labels would be out on the 300. The 300 says it prints up to 24mm labels. I believe something like the 1 1/2 x 1 9/16 cable wraps (https://www.dymo.com/en_GB/XTL-Laminated-Wire-Cable-Wrap-1-1-2-in-x-1-9-16in.html) would be out with the 300. That’s the most common size of label I’ve used so that would be a big problem.

I also used the 2-inch labels to make warning labels for an electrical panel where I’d fit an inverter. The large label tape and graphics capabilities of the XTL made for a pretty professional-looking warning.

Plus, I’ve made Panbo logo stickers on 2-inch tape to stick on my tool cases.

-Ben S.

Hi Ben – have you noticed the en_CA site? https://www.dymo.com/en_CA/labels/xtl%3Csup%3Etm%3C%2Fsup%3E-%28xtl%29?q=en_CA&prefn1=DY_LABELING_NEEDS&prefv1=Wires%20%26%20Cables

Oddly, en_GB and en_US don’t mention this…but the en_CA site…it does not mention anything for 1868708 but it does say “Only compatible with XTLTM 500” for 1868712.

As part of expanding the N2K network and adding new instruments, I got a LABELWORKS LW-PX400 Industrial Label Maker.

https://www.amazon.com/dp/B08JQNSWL4/ref=cm_sw_em_r_mt_dp_2120HJG0XB7VYKXVWAMZ?_encoding=UTF8&psc=1

It has a large variety of label types including laminated labels and heat shrink labels, I really like the laminated labels because you can add them to existing wiring or N2K cables with pre-made connectors.

You use your phone to control it. Overall I am happy with and my wiring is well labeled.

It’s not cheap, but less expensive than the

but less expensive than the Dymo XTL models.

[Sorry, pressed return too soon]