Interactio Optio Fuel, easy installation and accurate fuel flow

{Editor Note July 2022: Interactio has apparently gone out of business and the Optio fuel flow system is no longer available.}

Interactio’s Optio Fuel flow system is a tidy little box that delivers gas or diesel consumption information to your phone. The system’s app collects performance data about your boat and then makes recommendations for the best cruise speed to help you run your boat as efficiently as possible. Can a little box communicating with your phone via Bluetooth really help you run your boat more efficiently?

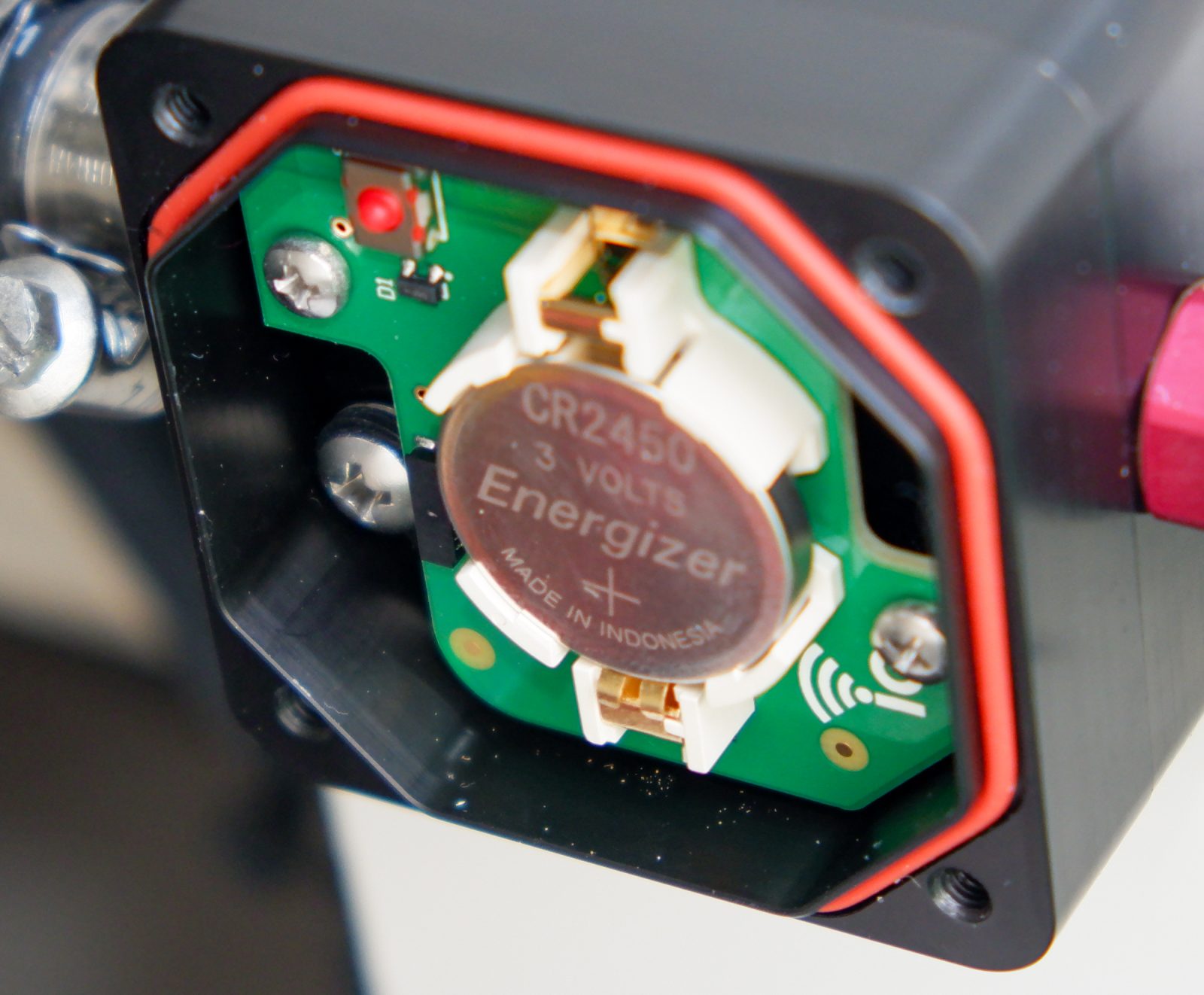

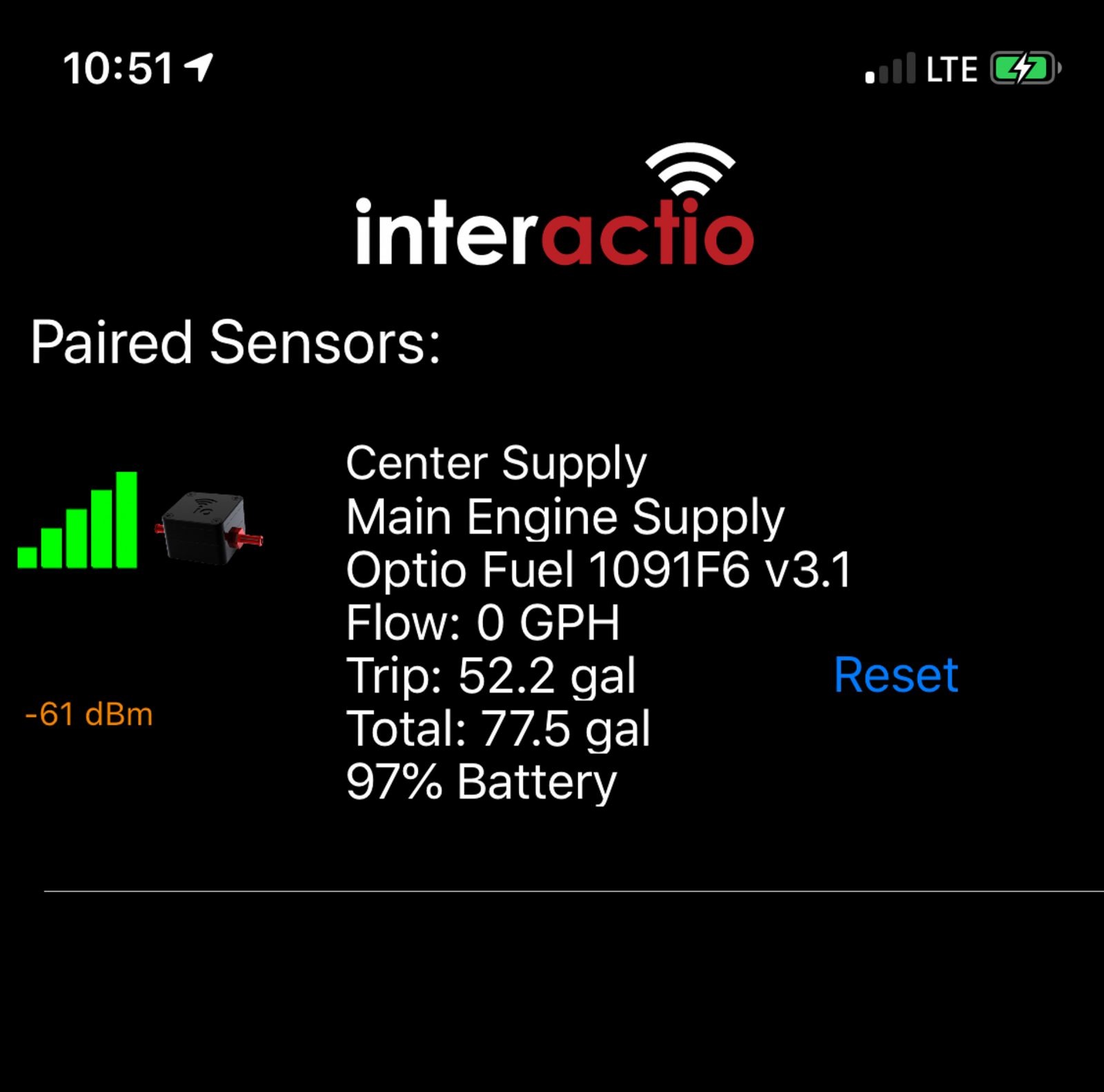

On a gasoline engine without a return fuel line — most gasoline engines — the Optio Fuel flow system consists of one small (roughly 2″ x 2″ x 1″) black box with input and output ports on opposing sides. This about $400, tidy, battery-powered box is all you need to measure fuel flow and send the data via Bluetooth low energy (BLE) to your mobile device.

If the Optio Fuel is being used to measure a diesel engine with supply and return lines, two Optio Fuels will be needed (available in a bundle for about $750), one to measure how much fuel goes to the engine and another to measure how much comes back. The app will then do the math to calculate the difference between these two numbers to calculate the actual amount of fuel burned.

Installation

I installed a single Optio Fuel on Panbo(at)’s 150 horsepower Yamaha F150 gasoline engine. Installation was quite simple; requiring mounting the sensor, moving the fuel line from the priming bulb to one side of the Optio Fuel, and then adding a section of fuel line to connect from the priming bulb to the other side. It doesn’t matter which port is used as the input and which one is used as the output so you can plumb it however works best for your physical installation.

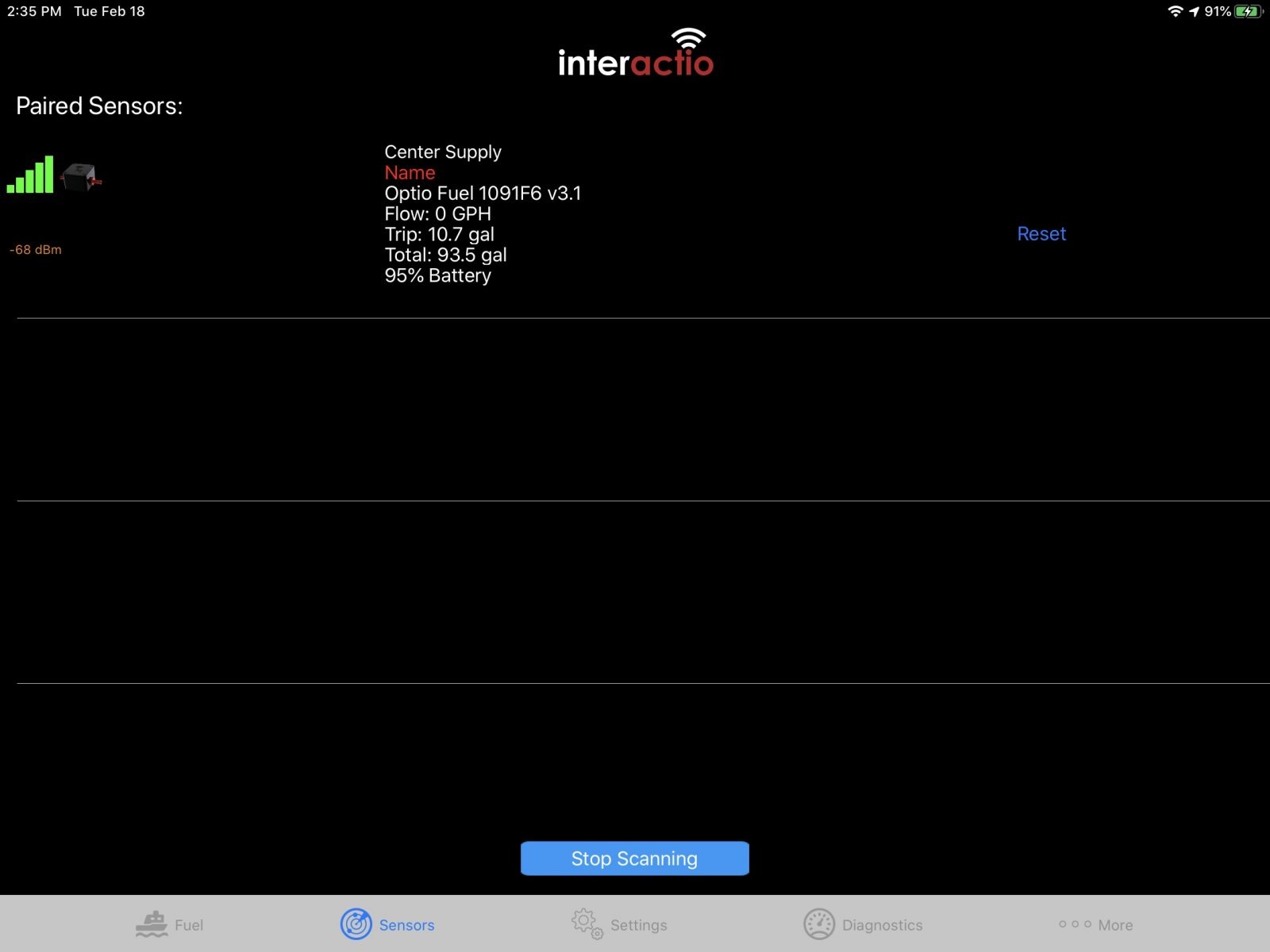

With the physical installation done, the Interactio app needs to be installed on a mobile device and paired. Pressing the red button on the circuit board of the Optio Fuel wakes it up, but if you’ve already closed the unit up fuel flow will also wake the unit.

The sensor was quickly detected, and then I only had to input boat information to complete the install. Including taking my time and photographing, the entire installation was well under an hour.

Measuring fuel flow

Once installation is complete, it’s time to start collecting fuel flow data. I started up the engine expecting to quickly see fuel flow numbers appear, but none appeared. I was confused, the app just stared back at me showing all zeros for fuel flow. Eventually I revved the engine in neutral a couple of thousand RPMs and the sensor registered two gallons per hour. Once I returned the engine to idle the Optio Fuel continued to show fuel flow for a few seconds before returning to zero.

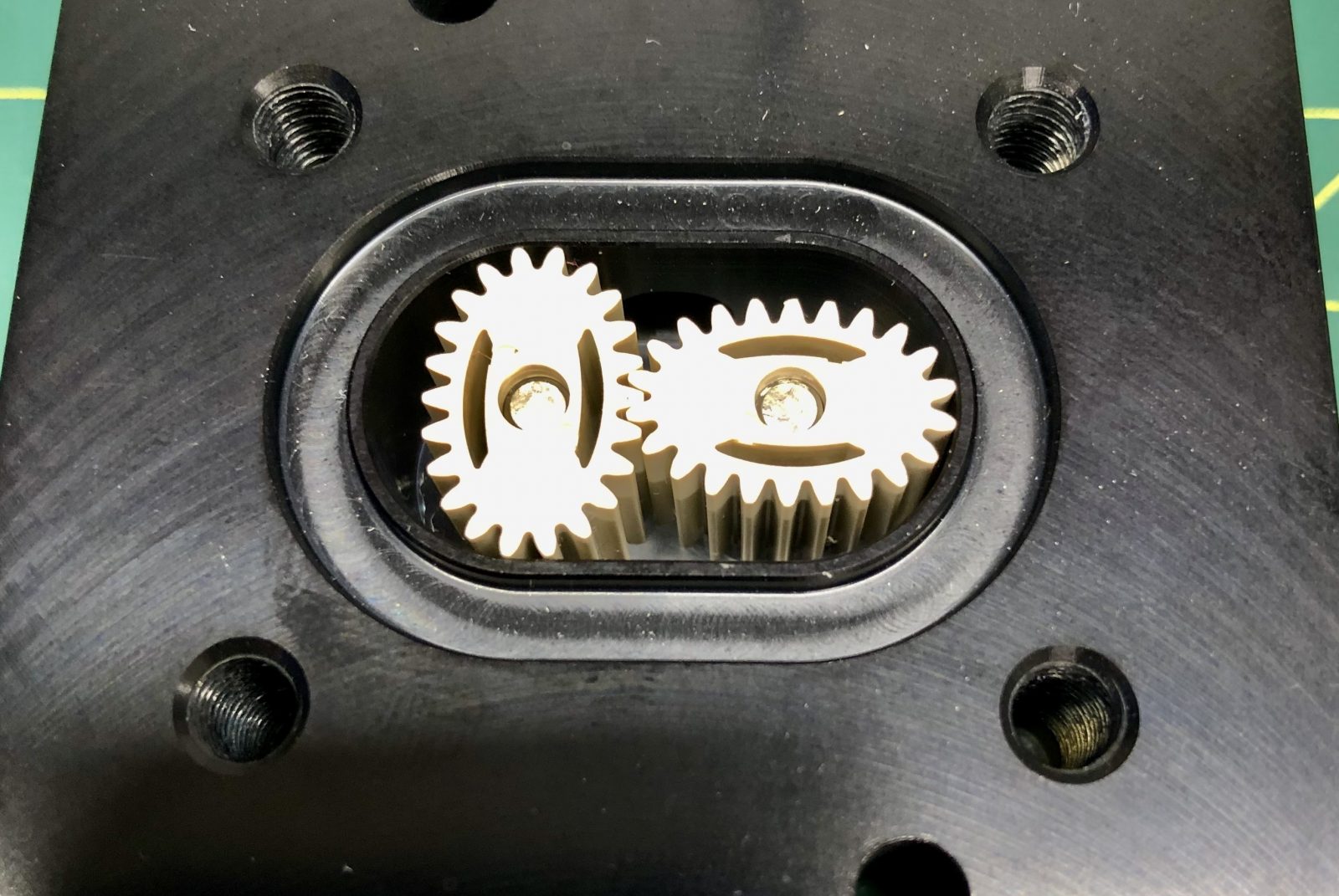

My first reaction was a little concern, how accurate could this sensor be if it couldn’t read anything at idle? At this point I realized it might be time to read a little more (I can read, it’s just that sometimes I choose not to). I found Interactio’s FAQ which includes an answer to “Why does Optio Fuel’s flow range start from 1 GPH not 0?” Interactio explains that the sensor is designed to bypass fuel at low flow, both to ensure the engine will receive fuel even if the gears in the sensor are jammed and to minimize the reduction in fuel pressure through the sensor. A little sheepish about my lack of research, I pressed on.

The trouble with low flow rates is largely limited to gasoline engines. Diesel engines draw and return a lot of fuel, as Ben Ellison discovered when he installed Maretron’s FFM 100 fuel flow system. Diesel engines cool the injector pump with excess fuel passed through the pump and returned to the tank. So, to measure actual fuel usage for a diesel engine you need to measure the rates at which fuels is supplied and returned and then subtract the return fuel quantity from the supply.

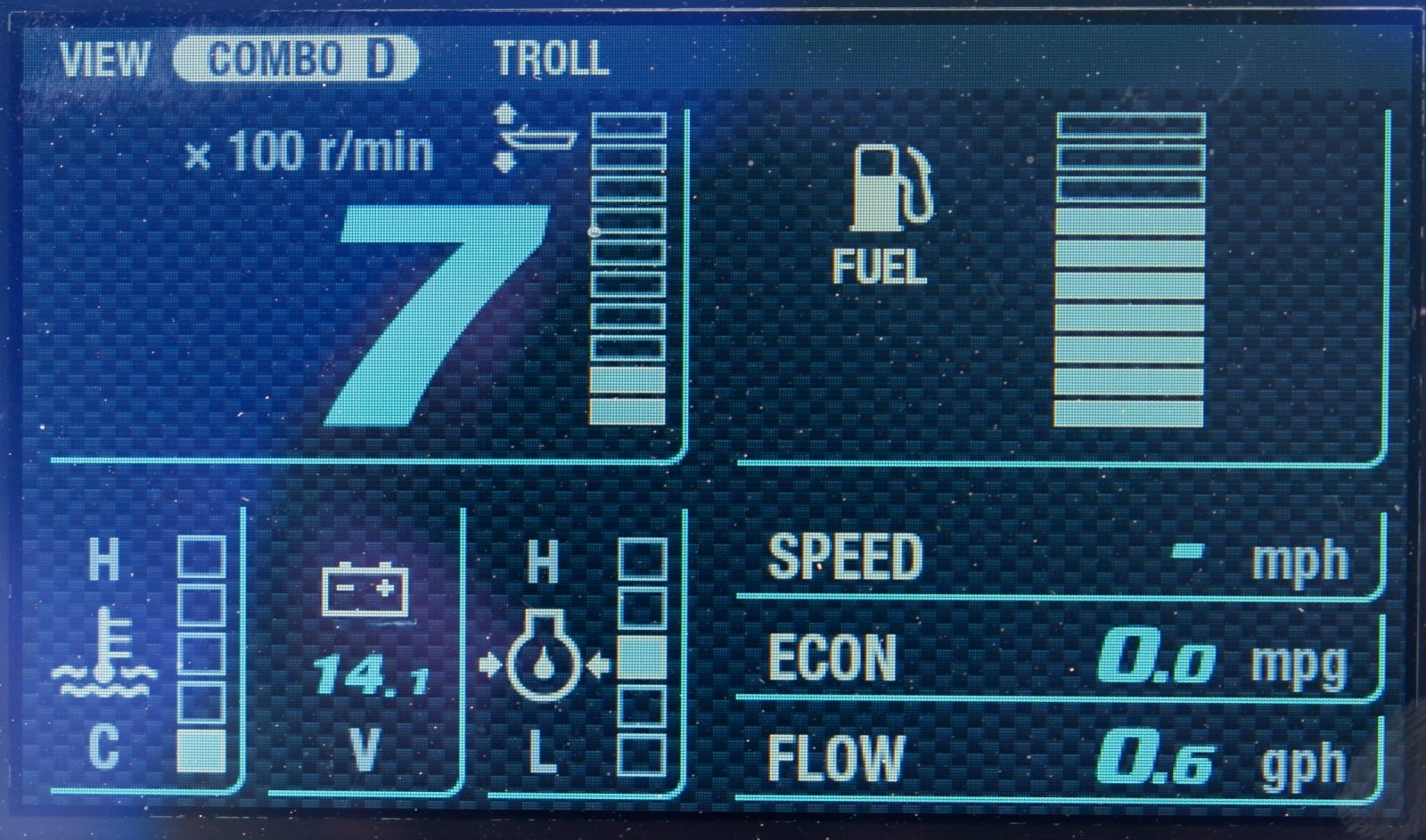

Now that I understood the behavior of the sensor at low fuel flow rates I got off the dock and tested the sensor at higher fuel rates. What I found was wide varations between what the Optio Fuel read and what the Yamaha display showed. This isn’t too shocking to me since I knew that the Yamaha display isn’t measuring actual fuel flow; instead it’s counting pulses of the fuel injectors and using math to determine the current flow (Ben E. has written about this method of fuel measurement for diesel engines as well).

Most modern outboards utilize both low- and high-pressure fuel pumps. The low-pressure pump draws fuel out of the boat’s tank and delivers it to a small reservoir on the engine that is used to pressurize the fuel rail of the engine. The low-pressure pump typically pulses off and on to keep the reservoir full. This system means that instantaneous measurements of fuel flow may not reflect how much fuel the engine is actually burning, instead showing how much fuel is being delivered to the internal reservoir of the engine. But, that won’t affect the overall fuel measurements because the fuel delivered to the motor’s reservoir will eventually be burned and then replenished giving you accurate overall fuel burn information.

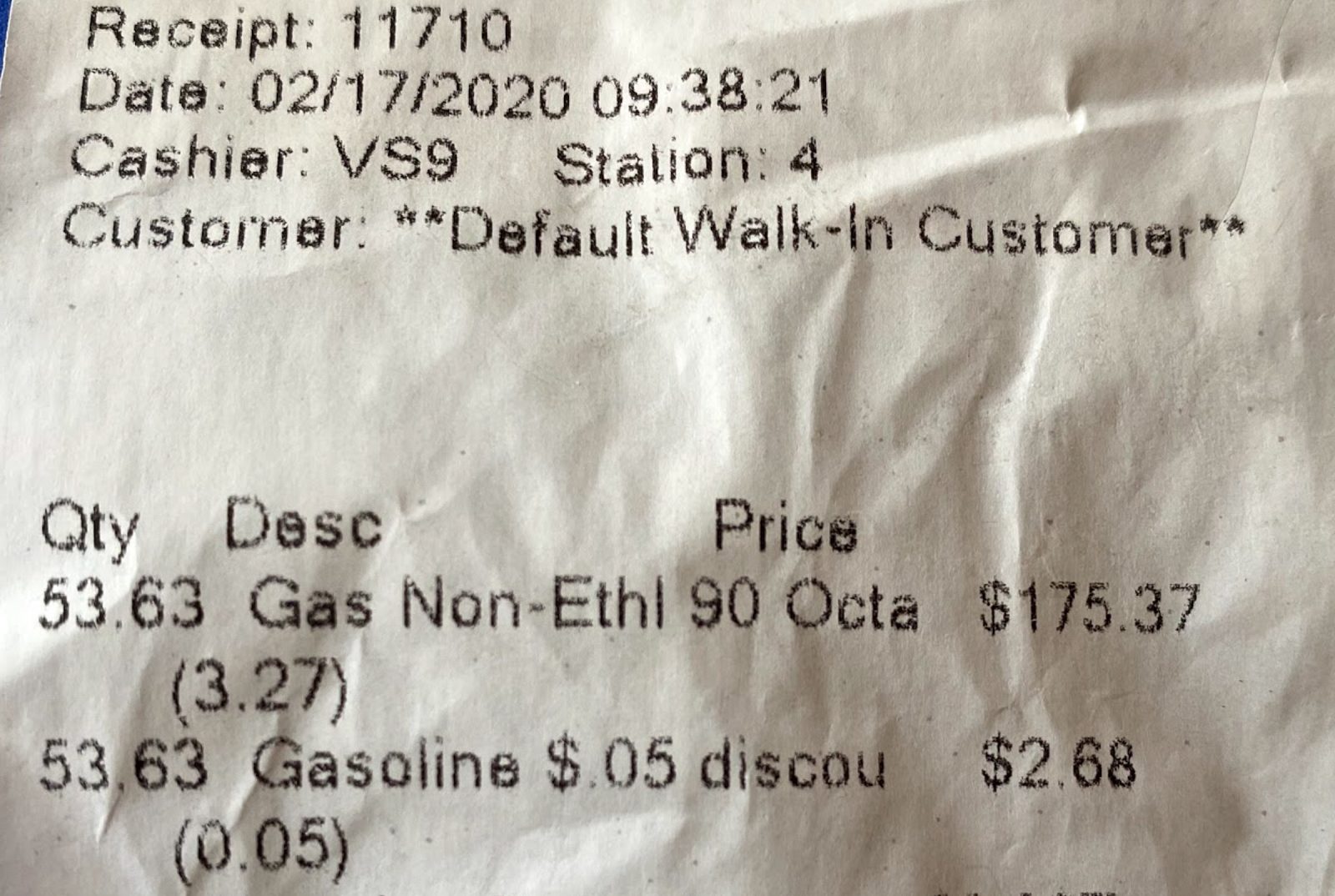

Overall accuracy

So far I’ve described multiple reasons the instantaneous fuel readings shown by the app might not be accurate. So, it would be reasonable to infer that the Optio Fuel isn’t very accurate, but that’s not the case. It turns out the Optio Fuel is very accurate, in my testing through three cycles of burning fuel and then filling the tank I’ve found the Optio Fuel to be much more accurate than the Yamaha Command Link display. The Yamaha display usually overstates fuel burn by about ten percent while the Optio Fuel has been about two to three percent under actual numbers as reported by the fuel pump. I should note that my testing methodology isn’t up to laboratory standards, I’ve used the same fuel dock for each of the three fill-ups but if the calibration of the fuel dock pump is off that could introduce issues.

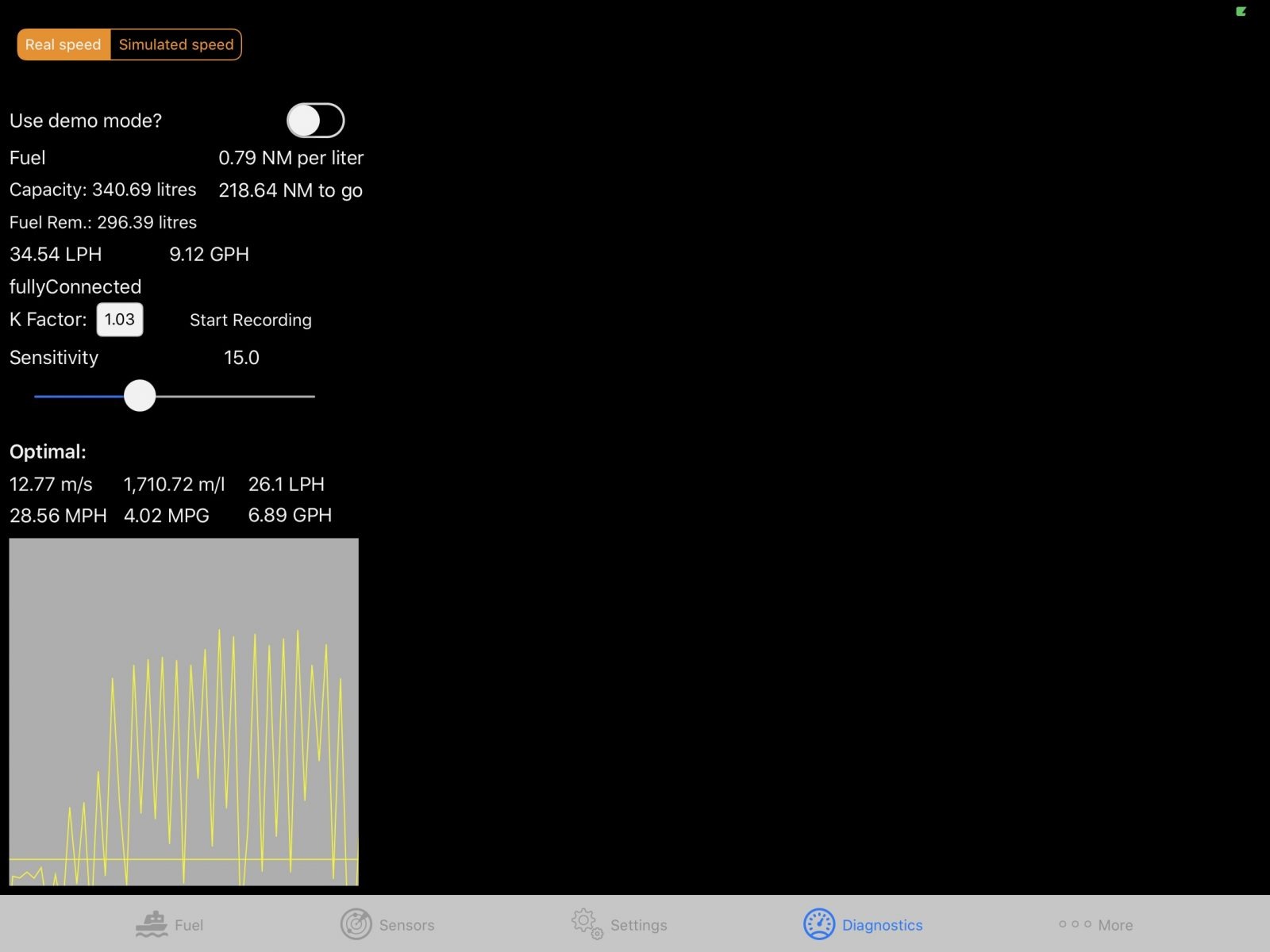

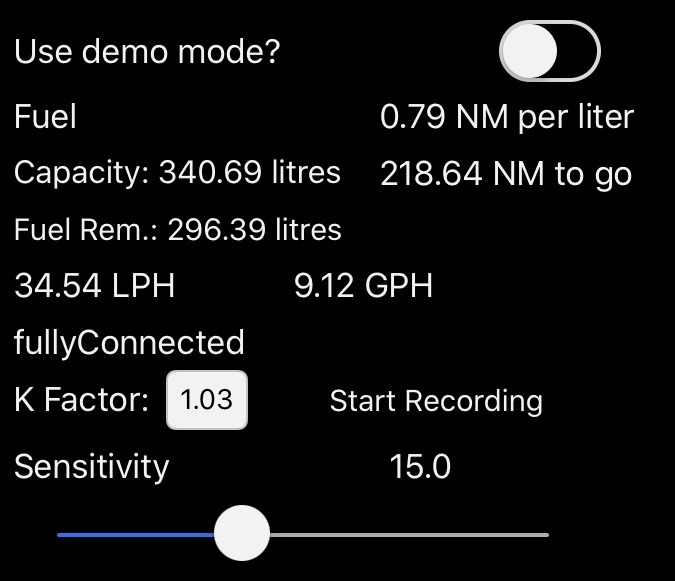

The Interactio app’s diagnostics tab includes the ability to edit the K factor utilized by the application for fuel calculations. K factor is the Optio Fuel’s calibration adjustment; setting the K factor to 1.03 as I’ve done above adjusts the burn up by three percent. K factor can be used to adjust for long periods at idle — and hence below to 1 gph threshold for the sensor — or for approximations of other uses of fuel not measured, like a generator.

Optimal cruise speed

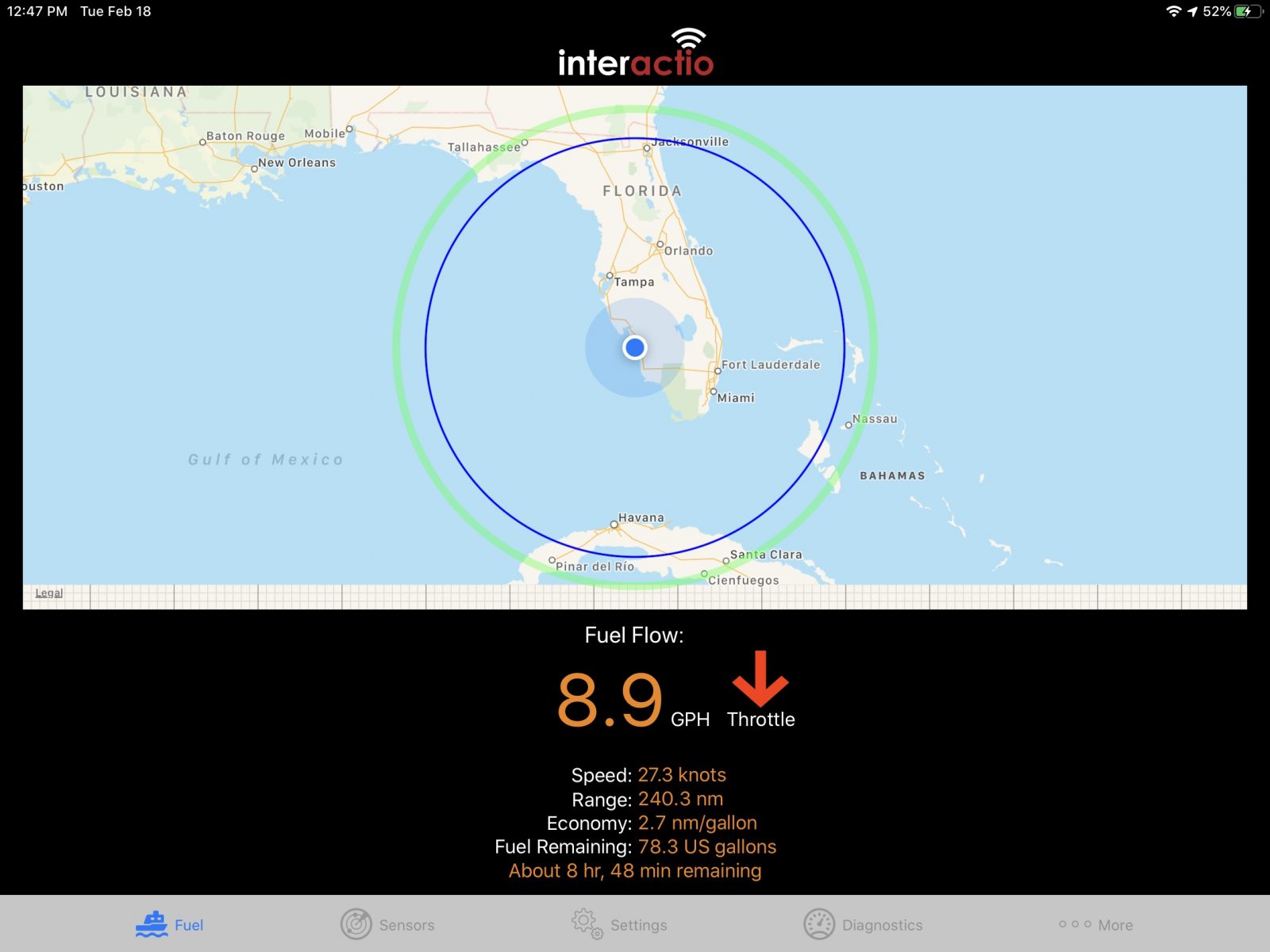

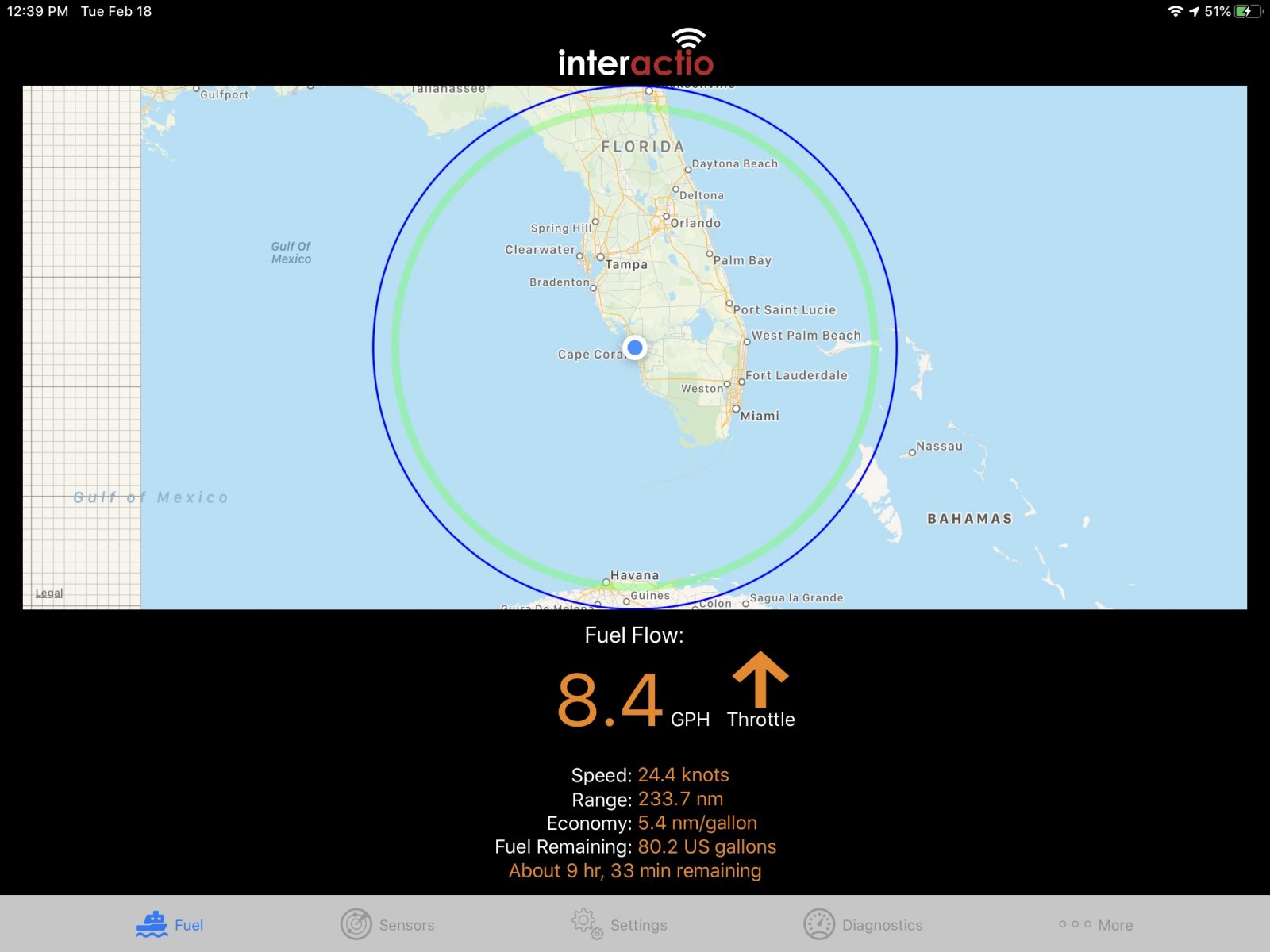

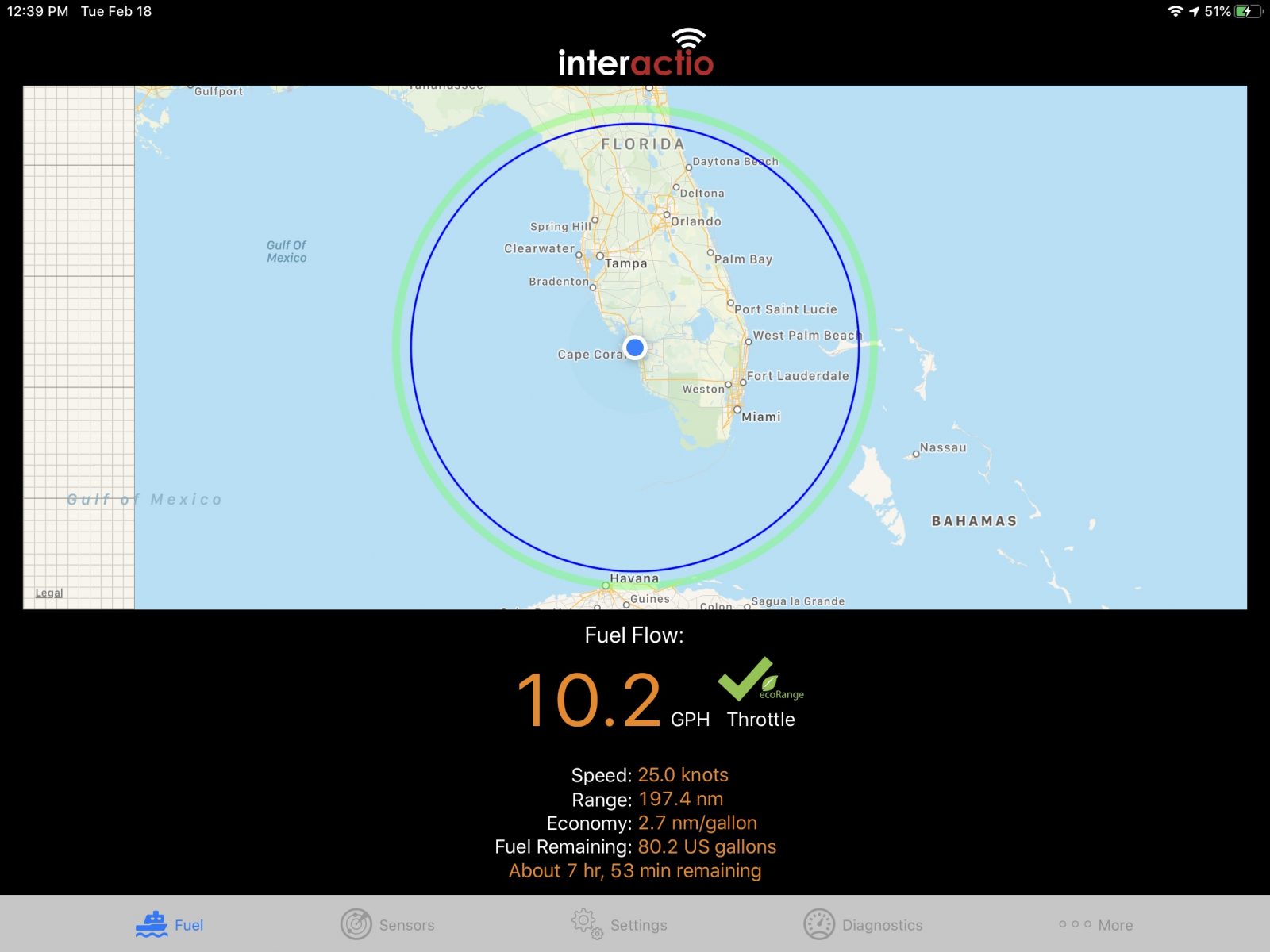

The Interactio app home screen displays current fuel flow, efficiency, and range data. The green circle represents the app’s calculation of your range at ideal efficiency based on your current quantity of fuel and the blue circle shows your current range based on your efficiency at that moment.

When I spoke with David Burton, Interactio’s founder and CEO, he explained that the app is measuring economy at each fuel burn rate and building a map of the most efficient cruise. Unfortunately, I’ve found the efficiency calculations and recommendations confounding. For instance the screenshots above show that at 8.9 gallons per hour and 27.3 knots I’m being told to throttle down for more efficient cruising; 27.3 knots burning 8.9 gallons per hour corresponds to just over 3 nautical miles per gallon (nmpg) — though the app is calculating this at 2.7 nmpg. The second screenshot shows 24.4 knots burning 8.4 gph for 2.9 nmpg, but the app is showing 5.4 nmpg and suggesting more throttle. In the final screenshot the boat is travelling at 25 knots and the Optio Fuel is measuring 10.2 gallons per hour of fuel flow for a calculated efficiency of 2.5 nmpg, though the app is showing 2.7 nmpg and ideal throttle.

The recommendations frequently seem to be flawed, but in fairness to Interactio, what they’re trying to do is quite difficult and it’s made a lot more difficult by the way the low pressure fuel pump draws fuel. I suspect these calculations can get more accurate, but I fear the goal of making accurate efficiency recommendations based only on GPS and fuel flow numbers may be unattainable. Without access to information like speed through water and engine RPM — especially in areas with strong current — I think there may simply be too many factors the app doesn’t know about.

Battery life

Interactio says that each CR2450 battery is good for about 1,700 hours of active fuel consumption and that this should easily equal or exceed a year of real world usage. The sensor goes to sleep when no fuel flow is detected and automatically wakes back up when it sees flow. Thus far I’ve used the sensor for about 35 hours underway and it’s still showing 95 percent battery life. These returns make me think the sensor will easily last the advertised time and make the tradeoff of installation simplicity versus having to replace the batteries periodically seem like a very good one.

Pricing compared

Fuel flow sensors seem to be available at several different price points. A Maretron FFM100 with two flow sensors — which use the same gear system to measure flow — capable of reading .5-25 gph carries a list price of $1185, which makes two Optio Fuels for about $750 look like a good value, especially if this is your first Maretron equipment and you also need to purchase a USB100 or other device to configure the FFM100. But if you compare a single $400 Optio Fuel to a Lowrance fuel flow sensor for $200 it can look a little more expensive. But the reality is that Lowrance, and similar inexpensive fuel flow sensors, use less accurate turbine to measure flow and doesn’t have the ability to join two sensors for supply and return calculations.

NMEA 2000 compatibility

The one thing both the Maretron and Lowrance sensors have going for them is NMEA 2000 compatibility. And though this can make installation more difficult since a NMEA 2000 drop cable needs to be run to the sensor, it also means the sensors’ data can be displayed on any compatible display. Interactio has plans to offer a hub that will, among other features, provide an interface between Bluetooth Low Energy and NMEA 2000. This option strikes me as the best of both worlds because of the flexibility in placing the hub while maintaining the ease of installation of a fully wireless sensor.

Final thoughts

The primary job of a fuel flow sensor is, not to state the obvious, to measure fuel flow. This sensor accomplishes its primary mission, at least in my testing, with great accuracy and I believe that’s what’s important. The inaccuracy of the efficiency recommendations doesn’t subtract from the great results measuring fuel flow. Plus, I believe that feature is easily improved upon with future software releases. Based on the attention to detail and execution of the hardware design I think it’s likely that we will see just that happen. I think Interactio’s solution is already pretty good and will get even better when the NMEA 2000 hub is available allowing the Optio Fuel to connect to other onboard electronics.

David Burton from Interactio got in touch with me and clarified a little about the economy optimizer’s operation that might clarify some of the results I saw.

David said, “The optimizer is continually learning and needs 6 values in each “bucket” in order to average an economy recommendation (to compensate for variances and changes) so even though you have run for several hours, at some flow rates it may still not be reporting accurate values since it may not have 6 values which is min to perform the calculation.”

While I think this makes sense it seems like the app might need an indicator that the optimizer is still learning. Otherwise users may well conclude (as I did) that the optimizer isn’t accurate before it’s had a chance to learn enough to make good recommendations. I’ll continue to watch the results of the optimizer and see if it gets more accurate. At this point I’ve run over 100 gallons of fuel through the Optio Fuel and spend about 30 hours on the water with it so I’m thinking it should be getting close to having enough data at nearly all the ranges I tend to run the boat.

Interesting little tool! I´m still searching for an affordable but NMEA2000 compatible fuel flow system for my twin John Deere 6068 equipped Trawler.

I miss an alternative Windows program to access the InterActio system via BlueTooth. If the company decides to alter it´s product or worst case fails, users are not able to step up with the Apple/Google operating systems evolution getting an unusable piece of expensive hardware.

well – I´m i just same situation.

There are many MDF´s that gives the opertunity to show fuel flow but it is – as far as I know – not possible to connect them to Bluetooth.

Only via N2K.

Also I have problems with recieving the signal from the two censors due to metal film in the engineroom insulation.

There are travel recorders only using N2k (eks. from Yacht Device -ydvr) where af travel can be analyzed, and widthout the posibility to connect Interactio Optio Fuel via N2K, this funktion is unavailable.

Therefore an cabeled connection with NMEA2000 signal is strongly needed and wanted.

(I love cabeled connections more than wireless – I find, it provides a more secure connection without electrical disturbtion).

–

I have been informed from the compagny a couple of years ago, that a N2K connection has been developed, but not put into produktion yet.

–

I think, that we are many owners, that would be happy with a N2K connection from Interactio Optio Fuel meeter.

I realy hope, that this N2K-converter will be put into production soon.

With kind regards.

By the way:

It seems, that the compagny does not exist any more.

I cannot find any website or contact informations at all !!!

I’m sorry to hear that. The last time I talked to David Burton from Interactio he mentioned that he was thinking about pulling the plug on the company. He hadn’t gained the type of traction he was hoping to achieve and sounded frustrated with some of the challenges. It looks like he followed through and has indeed thrown in the towel.

-Ben S.

Looks like the company may resurface at some point under new ownership.

Old link states that the company is in the process of being acquired.

https://shop.interactio.co/password

Tks. for this information.

let’s hope it’s true and there will be some possibility to get help – also for earlier buyers – and that there will come a N2K – interface.

I need help, because I have readings on my Android tablet, that I find unreliable.

They are not stabel and makes no sense.

I have been thinking: Should it be possible to pick up the bluetooth signals from the sensors and convert them into N2K so they could be send to and used by a MFD??

But let us see, what happends and hope the best.

Kind regards.

I’m not aware of any fuel management systems that attempt to improve their fuel efficiency estimations with running experience. But wouldn’t the learning challenge be much easier with access to other boat data like engine RPM and Speed through the Water (STW)? Which makes me wonder of Optio’s NMEA 2000 will be bi-directional and if they hope to use such data in their calculations?

Also, measuring low flows is really hard in real-time (especially if it’s the differential between large diesel in and out flows). I remember well when I complained about the jumpy flow I was seeing at low speeds with a Maretron FFM100 system on Gizmo’s 450hp Volvo Penta, and Rich Gauer suggested that I go to the galley sink and try to take an entire hour to fill a one gallon jug. Which is why learning fuel efficiency over real boat time is an admirable endeavor.

Isn’t that why the fuel rate displays driven by data from the engine ECM are inherently more accurate especially at lower flow rates? My experience over 12 years of electronically controlled engines, which was with Volvo D series common rail Diesels and now with Cummins QSB engines is that the fuel rate data from the ECM is accurate within 2%. That’s based on comparing the measured total fuel consumption with how much fuel it takes to fill up the tanks many, many times. The displayed fuel rate readings at idle and along the rpm curve up to WOT are also generally consistent with the manufacturer’s published fuel rate curves.

It would be somewhat of a pointless expense to add something like the Optio on a boat that has electronically controlled engines that can display real-time fuel rate data. That would make for an interesting comparison, however. I wonder if Optio itself has ever done that.

Hi Quitsa, my sense is that engine-measured fuel burn has varied in quality over the years. It’s hard to find out exactly how it’s being done, and when I researched the issue years ago I got the impression that at least some engines are only guesstimating. The technology could be much better now.

This summer I will hopefully check this hypothesis thanks to a Yacht Devices Engine Gateway YDES-04

https://www.yachtd.com/products/j1708_gateway.html

It can read the fuel flow coming out of my 20-year-old Volvo Penta — which I’d only seen before when a VP tech with a special tool was on board — and bridge it to NMEA 2000. If it is as accurate as the Maretron FFM system I already have, it would certainly be a much less expensive and easier-to-install choice.

Quitsa,

Though I haven’t done the comparison on a diesel engine I’ve done just that with my Yamaha 150 hp outboard and found Interactio’s numbers to be (somewhat surprisingly) more accurate than the fuel calculations done by the ECU and Yamaha display. The Yamaha display overstates consumption by at about 10%. On the other hand I’ve found the Optio to be within 1-2% of the total as measured by the same gas pump.

-Ben S.

Interesting. Is the 10% differential visible in the current rate readings across the rpm range or just what you determine comparing totals when you fill up the tank? My guess is that the a modern Diesel with common rail is likely to give more accurate fuel rate readings from the ECM than a fuel injected outboard without the complications of spark timing and other factors that affect a gasoline engine. But perhaps Ben will find out when he installs the Yacht Devices gateway in the summer.

Interesting. Is the 10% differential visible in the current rate readings across the rpm range or just what you determine comparing totals when you fill up the tank? My guess is that the a modern Diesel with common rail is likely to give more accurate fuel rate readings from the ECM than a fuel injected outboard without the complications of spark timing and other factors that affect a gasoline engine. But perhaps Ben will find out when he installs the Yacht Devices gateway in the summer.

Real time readings have a tendency to vary quite a bit between the Yamaha display and the Optio’s. Yamaha is counting injector pulses and deriving a number from that, so the Yamaha readings tend to be quite consistent. The Optio is watching how much fuel travels from the tank to the engine. Because there’s an electric fuel pump in the engine that is providing fuel to the high pressure pump that feeds the injectors there can be a disconnect between how much fuel is being burned right now and how much is being drawn into the engine.

For instance, when you advance the throttle the Yamaha display immediately shows more fuel burn, but on the Optio there’s a delay because that immediate demand for more fuel is met within the engine. But then the electric fuel pump is activated and for several seconds after that the Optio shows more fuel than the Yamaha display. My understanding is that this is the electric fuel pump replenishing the fuel drawn out of the engine. Then, after a few seconds the readings stabilize and come a little below what the Yamaha display is showing. Though periodically they will drop way below the Yamaha display or spike way above. I believe this is because the electric pump may meet the fuel demand by running for a period, then shutting off, then running again. Meanwhile, all the Yamaha display is doing is counting injector pulses and reporting on the math it has done.

Also, bear in mind that Ben’s engine, like my own 2002 era Volvo-Penta D12s, is not a common rail engine. So, there’s not a fuel rail being charged the same way there is with a common rail, so it’s likely that his engine will behave differently than a fully modern common rail engine. I would expect there’s a good chance the common rail engine would behave closer to what I’ve described with my outboard, but I’m kind of guessing.

-Ben S.

Your description of what is happening with fuel flow on the Yamaha outboard sounds 100% correct. I have one of those as well on my small boat, an F115. The fuel rate is shown on my plotter via a NMEA 2000 interface.

At least with the common rail injection system on my Cummins QSB 6.7s, I am reasonably certain it would not exhibit the cycling phenomenon you see with the Yamaha outboard or if it does, it would have a much lower amplitude. The net measured fuel flow from the supply and return should track the ECM output very closely. I confess I have no idea what would happen with an old D-12 with electronically controlled unit injectors. Might be really accurate.

Great questions and comments on here. I would add to what Ben described (very well) that Optio Fuel is measuring actual fuel flow whereas the numbers you see from most engine management systems is not measured – it a calculated value of what the engine should be burning. That calculated value does not take in to consideration boat loading, weather, tides, currents, etc. etc. so is an approximation, which is one of the main reasons I started Interactio and built Optio Fuel. Great discussion!

I have to say I’m very impressed with the service I just received from Dave at Interactio. I was having trouble with my Interactio fuel flow sensor and so sent it back for service. Turns out I made my own problem by using thread sealant on the fuel line barbs. (Not supposed to do that as the sealant breaks off and gets in the gears) Not only did they upgrade my circuit board and housing. They tested the whole unit and were happy to do this at no charge! Customer for life… Thanks Dave. Ron W 1999 Sea Ray 230 Overnighter.

Our experience with David Burton and his Optio fuel management system was nightmarish. We have twin Yanmar 6LYA-STE engines which required 4 optio fuel flow sensors. On arrival we activated and installed the items sequentially only to find the last unit to be activated was DOA. On further inspection I found one battery terminal had not been soldered to the board. On contacting Mr. Burton he offered to send a new board, but did not have any and said to would be weeks before a board could be sent and suggested an on site repair which I successfully completed.

After getting all four units on line we found that the optio fuel sensor app said we were making fuel, rather than providing fuel burn information. Mr Burton said “that’s every boaters dream” and that “the android app isn’t as far along as the IOS app”. He was never able to provide a resolution.

We then found that he had shipped sensors with old firmware which was impossible to update.

Finally the sensor that he had shipped with the bad circuit board also began leaking diesel fuel from its case. Mr Burtons suggestion was another on site repair or that we should simply return the units to him.

At this point the units were leaking diesel, provided no meaningful data and there was no apparent resolution to the software issues. We elected to take Mr Burton up on his offer to return the items, which we did at our expense.

At that time he stopped communicating, never providing a refund or offering a repair.

When we asked our credit card company to help with the matter. He did respond to them with a lengthy letter basically saying that there was debris in the gears, (we have Racor 2 micron fuel filters on each primary engine filter and any debris in the gears would have been present when he shipped the sensors), that we had somehow downgraded the firmware in all of the items, that we had used power tools to install fasteners (they were all hand tightened) and that his return policy is only 30 days,

Judge for yourself but never again for us.

David Burton provided some of the worst customer support and service I have ever received from a company

I am not going to turn this great forum into Mr. Martin’s dispute mechanism. All I will say is what he reporting is not the complete picture. He did have issues and his sensors were not working for him, but there are a lot of variables in a fuel system that can cause what he was seeing and we were trying to work with him to understand the issue when he suddenly returned them without a RMA (return to manufacturer). He did not read, understand or follow the return policy and sent them back incorrectly. They were damaged and sending them without an RMA caused us to pay customs and duty on our own product. For anyone interested, I have videos of taking apart the damaged, returned sensors. Those who have worked with me know that we provide excellent customer service. Anyone wanting to know the real story is welcome to call me.

Dave. Where can I get the app for the iPhone? I just bought this last year and switched from galaxy to iPhone and now I can’t use this sensor. Please help

David my comments are simply an honest review of your product and customer service. We truly wanted to make the product work and invested a lot of time, and effort doing so. The condition of the sensors on return was the same as when you shipped them. Trying to shift blame for a faulty product to your customer really isn’t fair

At this point, I’m going to ask that we bring this conversation to a close. It’s unfortunate that things worked out this way but I don’t think continued conversation here will change the outcome.

-Ben S.

I’ve had a very positive experience with this product and support from the company.

I’ve had this fuel flow system installed for a few years now on my 1986 twin diesel Tollycraft.

It was easy to install and David Burton provided great customer support and feedback even on weekends and holidays.

It’s been one of the top 5 upgrades to my boat.

HI david.

I need to get a 2 sensor kit ASAP .

HOW CAN YOU HELP ME ??

I have two for sale if you want to contact me. Is that ok Ben?

Fine by me.

https://grandrapids.craigslist.org/bpo/d/grandville-interactio-bluetooth-fuel/7427760807.html

Here is the link. (Ben, I can delete if he buys them so your forum isn’t full of links. Thank you!

I has an awesome Experience and David was awesome to work with. I did swap out for a nmea one but only because I got a new simrad and it came with the fuel sensors.

Hello Ben Stein

I have talked with you for several days ago. I am drom Denmark. It´s about the Interactio Wireless fuel flow sensor

I have found only one company, who still does sell this sensors. I want to buy 2 of them. I have an older sailboat the engine is A FORD 2712E diesel 4 cyk 80 HP, I need 1 sensor from tank to engine, and 1 sensor back from Engine to tank. I kow when i sail with my engine on max power 1700 omdr pr minut , mY engine takes about 5 LPH – 1,33 gallon pr Hour ore about 5 Liters Pr. hour, but that is what Ny engine is using to go about 1700 revolutions per minute. It can go for a shurt time 2200 revolutions per minute. But I am not sure how muth Diesel the Pump does pump from tank to engine, and I am not sure how muth diesel again goes from Engine back to tank. But my Big question to you. Do you know the minium gallon pr hour the sensor can messure.

When I look at the Maretron FFM100 and look at the fuel sensor Maretron Partnumber M1AR, this sensor goes from: 2 LPH to 100 LPH (0.53 GPH to 26.4 GPH) .So I can use the Maretron System, because the sensor does show my diesel flow, but what about the Interactio Wireless fuel flow sensor, what is the minium LPH, because i want to buy this System. I have tryed to go on the internet,but I can, not find anything about thes Interactio system. Can you help mee please, ore any body els who knows about this system. kindly Henning Denmark

Hallo Henning

Ich hätte noch einen neuen Original verpackten zu verkaufen! Bei Interesse bitte melden. LG. Peter

[email protected]

As an owner of a couple of systems on my Cat engines I am hoping the optio equipment is picked and if so they would contact current owners

Henning in Denmark,

I found this in a prior correspondence with the previous owner who was very responsive re this product.

I believe this was also posted on his site and answers your gph low end operating range question. Seems to indicate it would work for your engine:

“the important factor is pressure drop, i.e. what is the pressure now compared to what would it be if the sensor was not there. In the case of Optio Fuel, it’s approx. 1psi through our operating range of 1-46 GPH….So in summary yes there is a pressure drop and it’s about 1 psi, which is not significant for most marine engine fuel systems.”

Does anyone know where I can download the Interaction app for iOS. The Apple link seems to be broken. Got a new phone and thought I could download. Now I have the fuel sensor but to app to view it!!!

Same thing happen to me.

Where can I purchase?

Johnny, in June 2021 the company said it was being acquired by a large manufacturer and that “Many interesting things are in the works.” However, their website is shut down and there’s no sign of new Optio sensor.

Also, apparently the Apple app needed to use the Optio is no longer available, though the Google version is:

https://play.google.com/store/apps/details?id=co.interactio.smartboat

Here’s the Interactio site as saved by the WaybackMachine:

http://web.archive.org/web/20210615001915/http://interactio.co/

I have a new unused sensor for sale. 12 volt connection. Price € 280 excluding shipping. lg.

I have been using the Interactio fuel flow sensors now for two years and initially I found that they were highly inaccurate. I wanted a flow sensor for measuring how much diesel I was using because the classic resistive level sensor was useless due to the shape of the tank. The level gauge is mounted in the deepest part which caters for about 25% of the volume so the gauge either shows full or nearly empty.

Getting back to the fuel flow sensor it indicated that I was using about twice as much fuel than I actually was. But this season I compared the Yanmar and found that I run my engine at about 2600 rpm which consumes 2.2 litres and the device recommends 1us gallon/hr which is 4.4 litres so adjusting the K factor found on the diagnostic page to 0.5 I am now getting a more meaningful usage reading.

Since David Burton seems to have gone out of business there is no support and the Android version returns some really weird readings. I run IOS but as an experiment have been trying out the Android version.

I purchased this sensor last year. I switched from galaxy to apple and now I can’t find the app. Can anyone advise where I can get the app for my apple or an I now the proud owner of a $500 paper weight. Thanks

The android app is still available on google play so I purchased a cheap used android phone for $25 on eBay. Now I just keep it the boat for the single purpose of using the Bluetooth connection for my fuel flow display.

Good morning

we are a startup based in Verona (IT) that produces electrolysers, that we mount as a retrofit on internal combustion engines (MCI).

we are looking for precision flow meters that allow us to accurately read the consumption of diesel fuel, checking the delivery pipe and the return pipe. The motors we control are motors with displacement +/- 4000L (cc), they are auxiliary motors that are used to produce energy. The consumption varies from 2L / hour (operation without electric load) to 4 L / hour (operation with electric load).

Do you have any FM between your products that can read these values?

We look forward to your reply

Kr – Stefano

Stefano, we don’t sell any products, just test and review them. But I suggest that you consider Maretron’s highly accurate and temperature-compensated diesel flow meter system. Using their displays and gateway, you’d be able to monitor and log flow into and out of the engine along with rpm and other engine data if it outputs NMEA 2000 or J1939, or you add something like Actisense’s EMU-1 analog to N2K gateway. It’s all proven and well supported gear.

https://www.maretron.com/products/ffm100.php

Very interesting product. Searching the net I found this other flowmeter. Works on diesel and petrol engines what do you think?

I forgot the link to the site, sorry.

https://www.naviflow.it

Thanks, Emiliano. It looks like Naviflow has developed an extensive line of gas and diesel flow meters at reasonable prices, even with the NMEA 2000 option (that I would recommend). I do wish they were more specific about the type of flow meters they’re using and I’d also like to see a claimed accuracy (like Maretron does).

Anyone have applicaton for android?. APK goes well

Did you look in the App Store? Last time I looked about a year ago it was still there. My problem is I switched to an Apple phone and they no longer have apps for it.. I had to pull my unit out of the boat and throw it in the garbage since the company shut down. What a waste of money.

App is out of google play. I am asking some one To Copy app from Phone ( android) and post it to me.

I have the app on my phone, but I don’t know how to copy end send it.

I would like to help

Send me a watsup message if you can help. +358 40 5200 178

Easiest way is. Istall Google file, open it, search optifuel app. And send via e-mail.

[email protected]

H-J Brehmer. Thnx for reply. I try to get instructions somewhere. Appriciate Your feedback

H-J Brehmer. Share&Update apps with friends offline. Google play help.

It is easy Way to share. I would be highly grateful for your help if it is possibe. A little time and patieence. If you can help. I put my Phone number here To start share.

Hi everybody

Thx for giving the hint to share , via Google, the apk file.

I was able to save it om my computer.

So if sombody need the file – sent a message.

Can anyone explain what the K factor is for and how to use it?