Mostly successful docking despite runaway bow thruster

There’s probably no good time for a bow thruster to get stuck in ON mode, but it happened to me while backing into our marina slip on a windy day. Moreover, that maneuver included a 90-degree turn with numerous nice boats tied up close by and rocky shallows not far downwind. While the cause of the thruster failure turned out to be minor, the possible perils and the lessons learned were not.

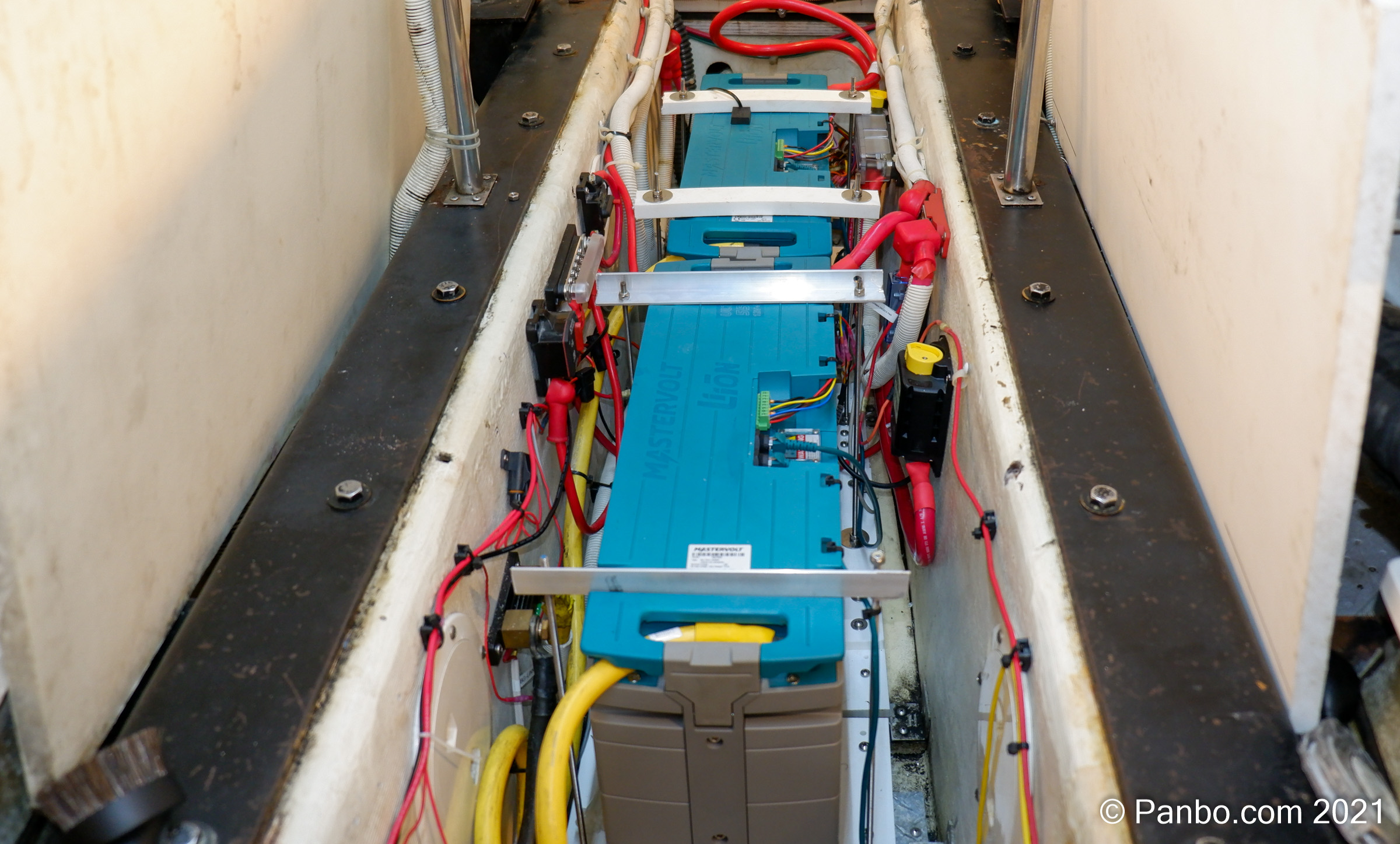

After a successful weekend of testing our new LiFePO4 batteries, I noticed the winds picking up and decided to head for our B Dock slip deep inside Legacy Harbour Marina. By the time we’d reached the three-legged entrance channel, the southwest winds were gusting above 25 miles-per-hour, which is perpendicular to our slip and also meant we’d be pushed sideways toward a fairly close and unprotected seawall.

But no big deal, I thought; I’ve docked in winds like this plenty of times. While our Carver Voyager 570 Have Another Day may have lots of windage with little keel mitigation — see my Seakeeper install entry for more detail — she also has two 675 horsepower diesel engines plus 24-volt bow and stern thrusters.

So as we reached the end of the last fairway — seawall dead ahead — I maneuvered to starboard so the boat could be blown to port some as we did our 90-degree backing turn into the slip. I tapped the bow thruster to starboard a bit, but when I heard a thruster running without my hand on the control, I looked around wondering who else was maneuvering their boat so nearby.

But it was my thruster stuck to starboard even though the control stick was in the straight-up neutral position when I checked it. I also turned off power to our Dockmate remote control system in case it was the culprit, but it wasn’t. At this point the boat is barely moving — the thruster helping against the wind (though I don’t think I’d really processed this) — but things were quickly getting out of control. My first thought was to pull out of the marina and assess our options, and that’s the plan I communicated over our headsets to Laura, who was on deck ready to handle lines with the girls.

The more I thought about it, the more it seemed like a bad idea to maneuver back through a marina full of boats with both a thruster and wind pushing the boat around. The better choice, I decided, was to immediately stuff the boat into the slip as best we could, and it was great to then realize that I could stop the thruster by pushing the control stick to port.

So I got my daughter Molly — who recently finished her Florida boating safety course — to come up and hold the stick over while I attempted to dock. But as I backed in, the wind pushed the bow towards shore and my neighbor’s beautifully maintained Tollycraft, and so I tried to correct with more reverse starboard engine throttle meant to pull the bow to port. Unfortunately, the stern was already pretty close to the floating dock, so the added speed mainly meant that the swim platform hit it harder.

The bad news was some damage to the platform. The good news was how we’d gotten most of the way into the slip with the port bow laying on the center piling and the starboard stern against the finger dock. We were then able to use the engines and dock lines to walk the boat into her correct position and get her properly tied up, all in a fairly calm manner.

What went wrong? Plenty!

With Have Another Day safely back in her slip, it was time to assess what happened. First, though, I learned that a marina dockhand had attempted to fend off the stern with his hands, which meant dropping his end of a stern line into the reverse suction of our starboard propeller. Fortunately, the prop instantly cut the line instead of wrapping it.

Also, once we were tied up, I had Molly let go of the thruster control and it immediately thrusted to starboard again. So I turned off its battery switch in the engine room, and that’s when I began to figure out that the problem must be in the solenoid.

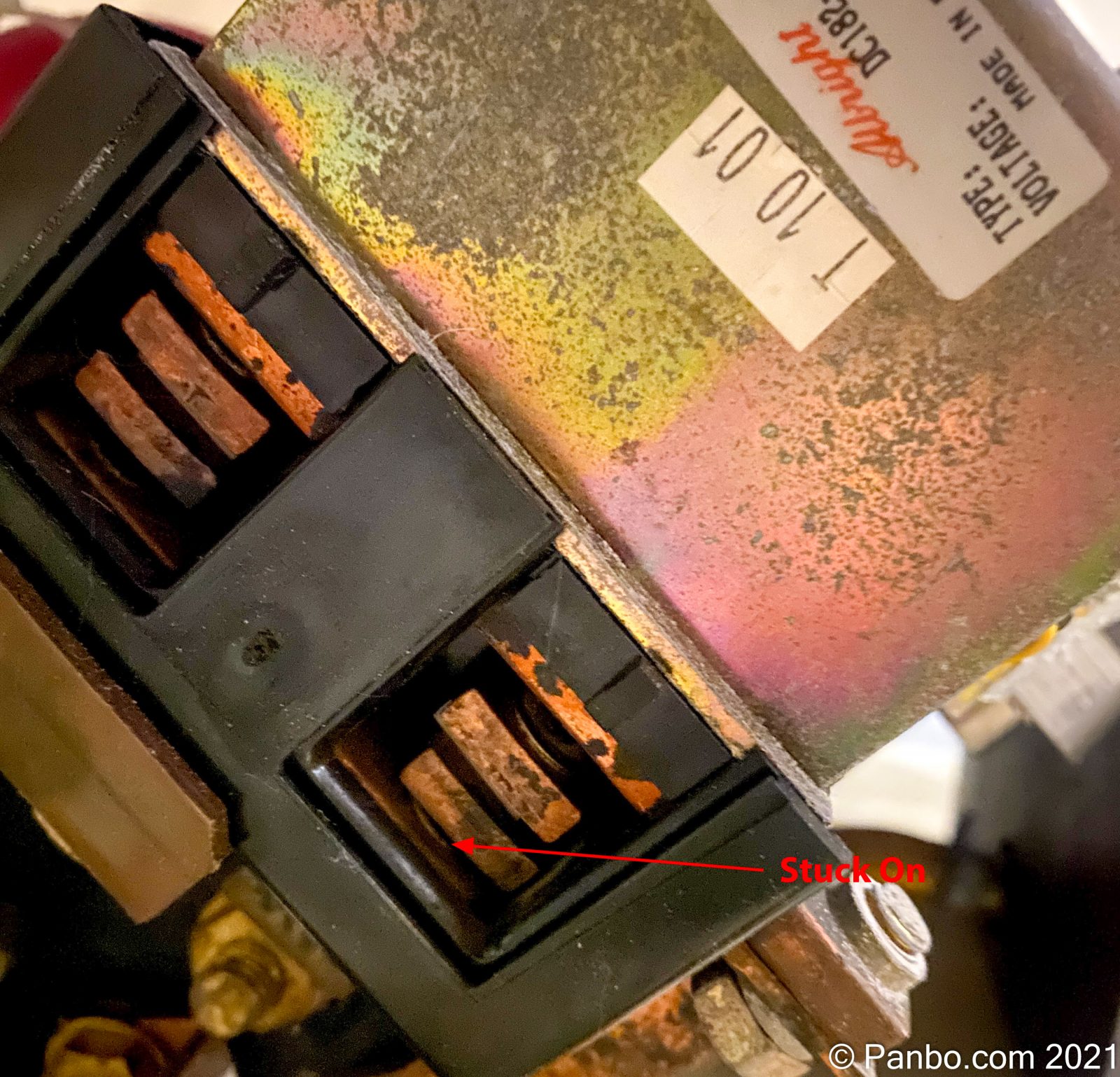

It took me a day to cool off enough for diagnostic work, but finding the culprit was quick. I took the photo above by sticking my phone into a floor hatch above the thruster and blindly snapping away. What I was then able to see was that one contact stuck in the up position. Fortunately, the solenoid is a readily available off-the-shelf part, a huge relief because Volvo-Penta stopped making Have Another Day’s QL bow and stern thrusters quite a while ago and stocks no spares.

When I fully removed the failed solenoid, I discovered evidence of sustained arcing on the contacts, most noticeable on left in the photo above. I believe that the arcing effectively tack-welded that contact in the closed position so it did not spring back to the open position when I released the control. Once removed, I could easily break the “weld” free and the solenoid now seems to work normally. But it will never see service again, as the arcing build-up makes it a ticking timebomb for another failure.

Failures at the helm

This entire episode was a reminder of how quickly things can go wrong and how difficult it can be to make good decisions in the moment. The first realization I had — after we were tied to the dock and the damage was done — was that the thruster was actually stuck to starboard, which would have fought the wind had I asked Molly to release the stick. But in the moment, I just knew the thruster was broken and wanted it stopped.

Also in hindsight, I wondered if I should have tied the boat up at an easier berth elsewhere in the marina. But I’d decided to maneuver as little as possible because I didn’t know if the thruster “solution” was stable or if its motor would suddenly turn back on, or turn on in the other direction, or otherwise surprise me. And I still think this was the right decision. I saw a path to getting safely tied up and it seemed the least risk to the boats around us. Ideally, I’d have loved to get back out on the river, drop the anchor and assess; but that trip would have had us passing hundreds of boats in narrow fairways with two 90 degree right turns and a 180.

In challenging winds I typically try to maneuver into the wind so that I can control the boat’s movement with the main engines. Unfortunately, my slip’s orientation and the day’s wind direction didn’t leave that option available. Also note that it’s only 40 feet from the land side of my slip to the mangroves and rocks. With a boat nearly 60 feet long, I didn’t have the room to go past my slip and head into the wind before backing into the slip.

Overall, I think the biggest mistake was violating my number one docking rule: never approach one any faster than you want to hit it. But the boat wasn’t responding as I wanted it to and, in the stress, I applied too much throttle and thus hit the dock faster and harder than I would have liked. The swim platform paid the price, but I’m okay with the outcome overall. The damage is relatively easily fixed and the only my boat was hurt.

So I guess I’ll be content with a bit of wisdom from Chuck Yeager: If you can walk away from a landing, it’s a good landing. If you use the airplane the next day, it’s an outstanding landing. I’ll call this a good one, dust myself off and get back on the water.

Been there, done that except my port engine remained in gear as my engine controls failed and the manual backup would not move out of gear. Shut off the engine but could not stop drift into dock. My wife is very good about telling dockhands to get a line on a cleat as many think they can control or push our 62-foot boat around by holding a line. Not going to happen. They don’t seem to understand the leverage gained with one wrap on a dock cleat. Unfortunately, the dockhands were deer in the headlights. If they would have done as told the lines would have slowed or stopped our forward progress. Lesson learned but it is a helpless feeling.

Good morning, Ben. Sounds like you did a great job in battlefield conditions! On our 64′ Grand Alaskan, we have an “Off” switch at the controls for our bow and stern thruster. Maybe there is a control panel that would give you the ability to quickly turn the system off. Was there not a breaker on your DC panel that could have been shut off?

Bob,

I do have an on/off switch at the helm but that only turns the control system for the thruster on and off. It’s not a battery disconnect and in this case, that’s the only thing that would have shut down the thruster. Because the solenoid was stuck, the control system had been defeated.

Also, large loads like thrusters and windlasses typically don’t have breakers on the main DC panel. They may have a large, plunger-style breaker near the panel or just T-class fuses and a battery switch in the engine room (that’s what I have).

So, my only choice was to spring to the engine room from the fly bridge. With the winds and close proximity of other boats the engine room seemed awfully far away.

-Ben S.

Been there, done that #2 – Same boat (53′ version), same thruster, same fused solenoid, – only our incident happened while “floating” in old Lock 52 on the Ohio River in the middle of a lock-thru. Luckily we were the only boat in the lock at the time and had been told by the lock master to just “float in the middle” during the process. Was using the bow thruster to keep the bow straight in the lock when it stuck ON in the stbd position. My wife was in the cockpit and had few panicked words over the headset (“What the hell are you doing??”) as we rotated around perpendicular to the lock. As I recall, no amount of joystick movement had any effect. I finally made a mad dash to the ER and turned off the breaker. LIke you, I found enough nameplate data on the solenoid to identify the manufacturer and replaced it for much less than a BOAT unit. Not sure what PM could be done other than making sure all the cable connections are secure and clean to prevent this, but it looks like a pretty common failure. Also experienced the same boat bite on the swim platform corner in other incidents on that boat. We finally rigged a deflated ball fender (about 18″ diam) with one side pushed in to form kind of a bowl shape that offered some protection to those very fragile corners. The order was “rig the bra fenders”. Regardless, we thoroughly enjoyed the 12 years we owned our Voyager 530. It was a great – Great Loop boat!

Very interesting to hear about the same failure on the same boat.

There’s no question the swim platforms on these boats are pretty fragile, especially considering the platform is the widest portion of the boat and hangs out there quite vulnerable.

-Ben S.

Maybe you could rig a Blue Sea Systems remote battery disconnect switch. My boat (a Back Cove 37) uses these for all the batteries and main functions: house bank, engine bank, generator, and each thruster. The actual Blue Sea battery disconnects are in the engine space, with the remote switches on the starboard bulkhead at the helm. My former Back Cove 34 had a very similar setup with the battery disconnects just inside the cabin and 1 step from the helm. Very handy!

We have the same contactors on our sailboat for hydraulic motor control. A contactor welded shut and unbeknownst to me kept the intermittent use high power 1000W 24 VDC motor running to the point it got very very hot and caused a minor fire. I replaced the contactor and the motor and since then, I service the contactors every season to make sure they are in good condition. I also installed additional high power breakers I can manually trip to cut power to the motors should a welding occurrence arise. The sad truth is that contactors used for DC applications are prone to welding closed.

Thanks for the story and comments. My boat also has breakers for the thruster motors at the helm. However in a run away situation, I might not have had the presence of mind to shut off power at the breaker.

This story now makes me more aware of the solution if the problem occurs on my boat.

This reminds me I should probably get better acquainted with the power circuits for our bow and stern thrusters. There’s not a shut off or breaker for either of them in an immediately accessible location.

Hi, thank you Ben for the article and the good comments from others.

My Cheoy Lee Offshore 41 (1980) is currently on a mooring in Pittwater, Sydney. I run the motor every couple of weeks and give the windlass and thruster, a Max Power, a spin.

Last time I did, a couple of days ago, the thruster kept pushing to port no matter what I did with the, no name, lever. Surreal, spinning around, and so glad I was not entering a marina etc, sounds like most of you who were managed very well!

Then the thruster stopped.

After the event, I found the battery selector switch had burnt out. The fuse for the thruster, in the bow, was intact. The on/off switch for the thruster is also in the bow and, as usual, under berths piled with sails etc.

Ok, it is an old boat. But clearly I need to improve the system. You and your commentators offer lots of good knowledge and advice. Nigel

Hi Ben! I am Serafim and I live in Porto Portugal. Looking for a “Relay 12V QL Ref. 41100185” I found this wonderful post of yours which is a copy of what happened to me a few days ago!!!! I didn’t hesitate to sign up on the forum and send you this message asking for help if you can tell me where I can find a “Relay 12V QL Ref. 41100185” (your Relay looks similar) or compatible in Europe. I am having a very hard time finding it. Thank you in advance for your kind attention.

Serafim Borges (+351962676990) whatsapp – you can use it if you want it please. Thank you so much

Hi Serafim,

I was able to order a new solenoid based on the sticker on the solenoid itself. It’s a Curtis Albright solenoid part number DC182-491. I found one on eBay here in the U.S. https://www.ebay.com/itm/394540102303?hash=item5bdc6c329f:g:cx4AAOSwv-FkJeFy&amdata=enc%3AAQAIAAAA0Ohz8cZx3uUundSmhoeuR3CONpchBsfkJzBGEeDiLq6tfzs5QMDizfLQR%2BkCL79aG8LZkXjQo9fuwXNRQPXzX6fDWDoBLNJ8vxdkSA8EBN%2Bz8wMEwmIwIAoidxudwLu3jE8uI7AwWnZEeDhG1HXDlmne5OAnR4%2FIS1PgywUxmLE5hp5qwMOOJlb0l6k%2BSb7c3DT698Fm2NArBXM2mQQxJI2l9U2SYewMBhi1AiMMvWPH5sRNRDTw63AEa72SL1sL46aMw4tqQJu1rZ%2F8p%2FgYfgw%3D%7Ctkp%3ABk9SR4Ks5ci-Yg.

Hopefully, armed with that information, the search will be a little easier.

-Ben S.