Ode to hydronic boat heating, and Sure Marine Service

It seems appropiate to kick off 2018 with a discussion of heating technology, specifically the diesel-fired hydronic system I installed on Gizmo last year. It was a significant purchase and a major install, but the 66 degree pilothouse temperature seen above certainly made my early December ICW trip a lot more pleasant. I’ll explain why I chose hydronic, detail how the system went together, and profusely praise Sure Marine Service, a marine heating equipment distributor par excellence…

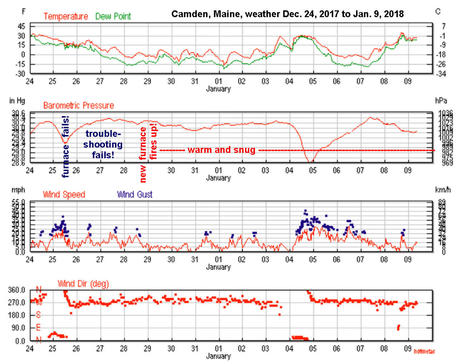

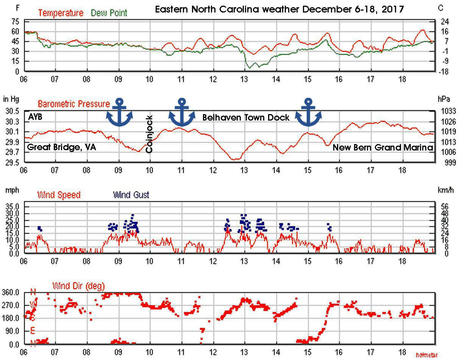

This Weather Underground history graphic is annotated with Gizmo’s locations starting when I rejoined the boat on December 6th at Atlantic Yacht Basin. The air temperature was falling into the 30’s and while many southbound cruisers were heavily bundled and looking glum, I relished the chance to finally try my new boiler in earnest, and soon the boat was a warm, snug shelter. Further proof of concept came a few nights later comfortably weathering a dank and howling Norther in a remote anchorage (I later added to ActiveCaptain), and by the time I left Gizmo at the New Bern Grand Marina, I was quite confident about the system’s heating abilities. (And a boat visit later this month may be quite a followup test given that snow is still visible on the Dock C live cam as I write!)

(Aside: You may notice that this was not an ambitious trip in terms of miles, even solo. While I knew that the days would be short and sometimes harsh, I’m also learning to appreciate a “go slow” cruising style. If you drill into Gizmo’s inReach MapShare tracking you’ll see that I only logged 190 nautical miles during this leg, and achieved a similar snail’s pace from Annapolis down to AYB in October. It means lots of time for boat projects, Panbo work, and sightseeing on the folding ebike I was “researching” a while back, but it also creates more opportunities to notice living aboard discomfort.)

When I researched heating options in late 2016, the goal was a quiet system light enough on battery power that I could use it while moored or anchored, and the Webasto TSL17 I purchased from Sure Marine Service does the trick. Installed in Gizmo’s sound-proofed engine room, it often takes a glance at the Boiler Exhaust temperature above to know if it’s running.

Wiring an EGT Probe to the boat’s existing Maretron TMP100 got me that useful readout, and also note the pleasingly high temperature being measured at the output of the hot water tank that used to be heated with engine coolant or shore power. A major benefit of the hydronic system is ample shower and wash water without running the engine or being tethered to shore power.

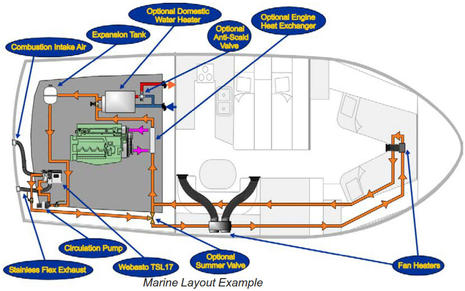

However, a marine hydronic heating system is not just a boat-size boiler (my little one is also marketed as the Webasto Thermo Top C and apparently used in over a million trucks). Not even close. As suggested in the Sure Marine diagram above, there are many components to even a fairly basic system. For instance, the boiler needs external air for combustion and also an external high temperature exhaust port, with both runs limited in length and total bends. And this diagram — which happens to be quite close to the component system I installed — doesn’t even include the fuel, electric and control subsystems.

However, a marine hydronic heating system is not just a boat-size boiler (my little one is also marketed as the Webasto Thermo Top C and apparently used in over a million trucks). Not even close. As suggested in the Sure Marine diagram above, there are many components to even a fairly basic system. For instance, the boiler needs external air for combustion and also an external high temperature exhaust port, with both runs limited in length and total bends. And this diagram — which happens to be quite close to the component system I installed — doesn’t even include the fuel, electric and control subsystems.

Given Gizmo’s vast electronics array — see the Smörgåsboat series for examples — you might think that I have a high tolerance for complexity, but actually I value simple boat systems as a welcome contrast to the work I enjoy. In fact, I might have installed a basic diesel heater or even a tiny wood stove if the boat had an acceptable place to mount either, and I also considered a fairly simple propane-driven forced air heater or fixing the reverse cycle CruiseAir AC unit still installed under the boat’s forward berth (though that wouldn’t satisfy my quiet and marina-independent criteria, especially without a generator).

You’ll find good overviews of boat heating systems in this 2012 Steve D’Antonio Passagemaker article, in this recent SV Cambria blog entry, and — especially if you’re headed to truly high latitudes — at Attainable Adventure Cruising. I also benefited from serious liveaboard and fellow Mainer, Matt Garand, who installed a large Sure-sourced hydronic system and well documented the selection, the preparation, the install, and the performance.

While a modest hydronic heating system made sense for Gizmo and how I use the boat, I was quite reluctant about the cost and complexity until I realized how thoroughly Sure Marine surrounds the various heaters they sell with accessories, information and support. In fact, I purposely put their name in this entry’s title instead of Webasto’s because I think that Sure has much more to do with the total system success.

While a modest hydronic heating system made sense for Gizmo and how I use the boat, I was quite reluctant about the cost and complexity until I realized how thoroughly Sure Marine surrounds the various heaters they sell with accessories, information and support. In fact, I purposely put their name in this entry’s title instead of Webasto’s because I think that Sure has much more to do with the total system success.

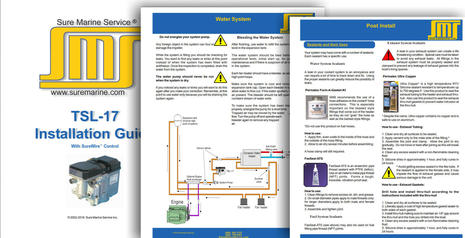

For instance, I believe it was the very specific and detailed step-by-step manual I collaged above that finally persuaded me that I could install this system myself. Note how the Sure manual writers even explain how and why to use the various sealants they recommend, which they can also supply along with every other piece needed, right down to high quality, double-band hose clamps.

You can get a good sense of what a system like mine entails, and the retail costs, in this TSL17 kit PDF, though I suspect that most orders end up custom like mine, fairly easy to do using a combination of the online shopping cart and phone consultation with the knowledgeable sales desk in Seattle. And you’ll learn below that several important components are not just distributed, but also designed and manufactured by Sure Marine.

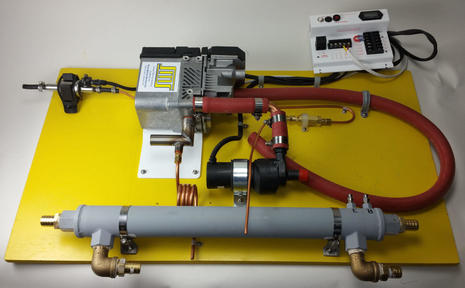

Here’s the boiler panel I was thankfully able to assemble in my shop before mounting it on a bulkhead in Gizmo’s somewhat cramped engine area, and it’s worth clicking to full size to see core system details. Every part was supplied by Sure, but that 22mm stainless exhaust elbow with condensation drain is also Sure made, and so is the white Surewire Water control board that organizes all the electrical connections and much more.

Here’s the boiler panel I was thankfully able to assemble in my shop before mounting it on a bulkhead in Gizmo’s somewhat cramped engine area, and it’s worth clicking to full size to see core system details. Every part was supplied by Sure, but that 22mm stainless exhaust elbow with condensation drain is also Sure made, and so is the white Surewire Water control board that organizes all the electrical connections and much more.

For instance, if you look closely you’ll see that the little fuel pump and filter are not yet piped to the boiler. That’s because the Surewire let me easily prime the fuel system into a waste container before the final hookup, hopefully also clearing any contaminants that may have gotten into the diesel pickup plumbing. The other components seen above are the “coolant” circulation pump and the optional heat exchanger, that means I can use the engine instead of the boiler to heat domestic water and the boat when underway.

Before further install details, let me note two misconceptions Sure Marine tech support had to talk me through during the system design process. The big one was my desire to run the 60/40 mix of hot water and low-silicate antifreeze right through Gizmo’s 450hp Volvo Penta engine, much like the engine coolant used to run through the water heater and a noisy “bus heater” installed in the lowest step to the galley. It would be like having a giant radiator under the main cabin, I thought, maybe even like the radiant floor heat I so enjoy in my home!

My Sure contact was polite but firm: running boiler output through an unlubricated engine and significantly extending its normal cooling system run were both really bad ideas. I’d also hoped to use the fuel feed left in place from the old generator install until I learned that the included Webasto pump is very particular about its plumbing.

On the other hand, Sure did supply a fuel pickup with a nifty weldless bushing design that also doesn’t require access to back of the hole for a nut. But, yes, I did find myself drilling a 1-inch hole in the top of Gizmo’s port fuel tank and I was questioning my DIY decision. Moreover, in classic DIY fashion, the heating system I first pictured in use last winter when the boat sometimes sat in Camden ice did not actually get fired up until one hot day in July. In short, you may want to consider a marine professional (who may also appreciate the services of Sure Marine).

Sorry that I don’t have a photo of the installed boiler panel, but picture it fastened to the fore-and-aft bulkhead that separates the port fuel tank from the engine space. That puts it under the port settee and hence a fairly short upward run for the intake and exhaust tubing visible above where they exit Gizmo’s cabin side.

Sorry that I don’t have a photo of the installed boiler panel, but picture it fastened to the fore-and-aft bulkhead that separates the port fuel tank from the engine space. That puts it under the port settee and hence a fairly short upward run for the intake and exhaust tubing visible above where they exit Gizmo’s cabin side.

The exhaust tubing — only 22 mm in diameter, and one reason I chose the little TSL17 — is inside a high-temp insulation sock, but this install was still so close to the recommended stand-off tolerances that instead of a stock 22mm exhaust thru hull, Sure made me that 90-degree triple wall beauty. The center tube does get quite hot, but I rarely walk that side of the deck anyway and I’ve detected no dangerous heat levels in the wood or fiberglass near the system.

Now you’re looking at the same tubing inside the settee along with the expansion tank, its overflow container, and a bit of the actual hydronic hosing. Also visible is the large oval hole I cut through 3/4-inch cabin sole, two layers of 1-inch Soundown insulation, and the 1/2-inch engine room ceiling.

Now you’re looking at the same tubing inside the settee along with the expansion tank, its overflow container, and a bit of the actual hydronic hosing. Also visible is the large oval hole I cut through 3/4-inch cabin sole, two layers of 1-inch Soundown insulation, and the 1/2-inch engine room ceiling.

Measuring for that hole was harder than you might think, but a Steven Roberts magnet trick helped me out (magnets like these can find each other through all that material, but try hard not to let them make direct contact ;-). Also, the 3/4-inch plywood I used in this project is inexpensive Sande from Home Depot; I’m sure it doesn’t quality match the marine ply used elsewhere in the boat, but it’s almost as light and an unfinished test piece did survive 48 hours submerged in water without showing any breakdown.

I took the main photo above late last winter when I finally flushed and filled the completed hydronic system. The boat’s water system was drained by then — um, because it didn’t have regular heat yet — and the marina water was long shut down, so I modified that bucket to gravity feed the Sure-supplied drain valve that’s plumbed into the lowest point in the system, just aft of the old bus heater spot under the galley steps.

I took the main photo above late last winter when I finally flushed and filled the completed hydronic system. The boat’s water system was drained by then — um, because it didn’t have regular heat yet — and the marina water was long shut down, so I modified that bucket to gravity feed the Sure-supplied drain valve that’s plumbed into the lowest point in the system, just aft of the old bus heater spot under the galley steps.

The Sure-made REAL Heat 6400B — just one of a large family — is similar to what it replaced, but thanks largely to computer-type fans, it uses about 10% the amperage, and may well be that much quieter, too. It also pushes warm air just where it’s most effective, starting at floor level toward the head, galley, and sleeping cabin, then rising up into the main cabin. (I installed a second, smaller fan heater in the engine room — mainly to protect systems in extreme conditions like winter in Maine — and it would be fairly easy to redirect that unit or install another.)

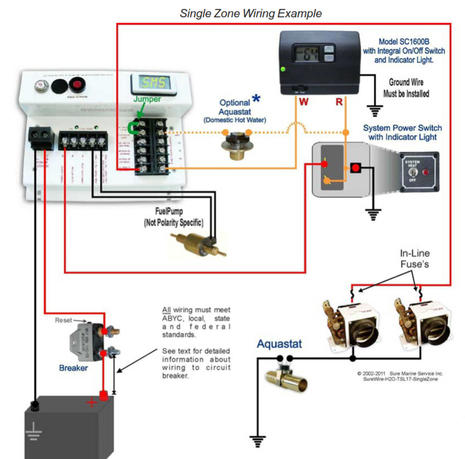

But I didn’t get to try the heating until I wired the controls, and that goal got elusive once spring broke. The task for Gizmo’s system is almost completely described in the Sure manual diagram above — there are also Off/High/Low switches for the two fan heaters — along with further illustration of Surewire talents. I did install the optional aquastat on the domestic hot water tank so it can be automatically managed even with the thermastat heat off, as well as the fan heater aquastat which prevents them from blowing cool air.

But I didn’t get to try the heating until I wired the controls, and that goal got elusive once spring broke. The task for Gizmo’s system is almost completely described in the Sure manual diagram above — there are also Off/High/Low switches for the two fan heaters — along with further illustration of Surewire talents. I did install the optional aquastat on the domestic hot water tank so it can be automatically managed even with the thermastat heat off, as well as the fan heater aquastat which prevents them from blowing cool air.

More than six months for the total install? In DIY defense, I did prioritize carefulness over speed — no leaks so far — and I also improved numerous unrelated hose and cable runs that were in reach as I spent hours in various obscure boat nooks. Still I managed a small control error.

More than six months for the total install? In DIY defense, I did prioritize carefulness over speed — no leaks so far — and I also improved numerous unrelated hose and cable runs that were in reach as I spent hours in various obscure boat nooks. Still I managed a small control error.

Instead of the main System Heat switch seen in the cluster of heating controls now lower right on Gizmo’s breaker panel, I should have ordered the System Heat / Engine Heat Switch that I could use to run the circulation pump and fan controls without the boiler once the diesel has warmed up. (Preheating the engine coolant is possible, but that requires another pump and a different switch, and Gizmo’s system can get similar results with the engine room fan heater anyway.)

I did figure out a (wire nut!) workaround to activate Engine Heat on the Surewire until I install the proper switch, but let’s get to the bigger picture. Because this breaker panel is located next to the galley steps, my new cool weather morning routine begins with goosing up that thermostat before making coffee, getting dressed and so forth. I like seeing the boiler come alive on the Maretron display, and I love feeling the first results on my tootsies.

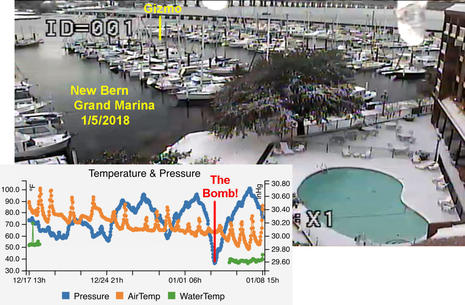

If I’d stayed on the boat in New Bern, I would have had a surprisingly good opportunity to test how much cold the fairly small 17,000 BTU Wesbasto boiler can combat. The deep cold snaps that bookended the historic Bomb Cyclone shut down this normally temperate little city and reportedly caused a lot of anxiety for boat owners.

I was certainly using the various boat monitoring products I’m testing to follow the situation, but was already so confident about the Sure system’s safety that I left the heat on at the thermostat’s minimum 45° when I left in mid December. I can’t quite tell if it ever kicked in, but even if the marina had lost power — especially possible because so many reverse cycle systems have been working so hard on the docks — Gizmo would have had heating power for days, thanks to the Firefly battery bank, and days more, thanks to the fully automated EFOY Comfort fuel cell I look forward to detailing soon.

But the New Bern Grand Marina’s power never did fail, nor the useful live cameras nor the WiFi, which is why the FloatHub I purchased via Kickstarter was able to continuously track barometric pressure and inside temperature. And note how the (green) Water Temp came back on last Friday (1/5) when the excellent new marina manager Jeremy McConnell kindly took the time to check out Gizmo and turn the NMEA 2000 network on.

One lesson learned: The normally mild water temperatures in highly protected and shallow areas like the Neuse and Trent rivers can plunge very quickly, as in 36 with ice chunks on Saturday. And aren’t the “shoulder seasons” getting less definite, even more reason for many of us to install good boat heating?

Onboard testing will resume when I return to Gizmo later this month, and I can take better system photos if there’s interest. One project on my list is fixing some issues with the boat’s wonderful but 17-year-old Force 10 propane cooking stove, and wasn’t I tickled to realize that Sure Marine Service may well offer more support expertise and easier parts ordering than the manufacturer.

PS: Bye bye Polaris!

I have more reason than a new boat system to think about heating technology, perhaps a good postscript. On Christmas evening at my house we realized the hot water was going, and that meant our beloved radiant floor heating would soon follow. I put a new igniter in the Polaris high-efficiency propane heater to no avail, and then we fired up the basement/shop woodstove as well as the propane “fireplace” that replaced the living room woodstove last year (yay for that decision).

I have more reason than a new boat system to think about heating technology, perhaps a good postscript. On Christmas evening at my house we realized the hot water was going, and that meant our beloved radiant floor heating would soon follow. I put a new igniter in the Polaris high-efficiency propane heater to no avail, and then we fired up the basement/shop woodstove as well as the propane “fireplace” that replaced the living room woodstove last year (yay for that decision).

A heating professional and friend who knew my system well kindly devoted the next day to troubleshooting with yours truly assisting. I even bought an old Polaris for parts from another friend who’d finally given up on what all three of us knew to be a troubled design since we got involved with it in the 90’s. In fact it was my second Polaris, because it worked very well when it worked.

After night two of no central heat or hot water, and outside air temperatures below zero, we were at the troubleshooting stage of rebuilding the entire burner without confidence that it would fix the problem. Credit to American Water Heaters for providing patient telephone support, but we got different advice from different techs and none of it was in the documentation.

After night two of no central heat or hot water, and outside air temperatures below zero, we were at the troubleshooting stage of rebuilding the entire burner without confidence that it would fix the problem. Credit to American Water Heaters for providing patient telephone support, but we got different advice from different techs and none of it was in the documentation.

Still, I was ready to buy yet another Polaris because it would install easily — and, hey, maybe the latest version with touchscreen is more reliable — but my man Norman came up with an excellent and immediately available alternative — the HTP UFT-140 humming away below — and then gathered a gang of three who installed it in one long day.

Apparently, I was the last guy who might need spare Polaris parts in my area, and so it was mighty fine to see the once cutting-edge tech headed to the recycling center. In retrospect I wish I’d made the switch sooner. It’s also interesting that I was served so well by a solo contractor who doesn’t even have a business card, while the key to my boat heating success may be the biggest in the business. It’s not about size, it’s about quality. Oh, and heating your shelter well is important.

Funny or sad? The snow in New Bern — which stayed on the ground longer than it has in a very long time — mostly melted away today. I took almost as much time writing this entry as I did installing Gizmo’s new heating system, relatively speaking.

Ben – can you comment on the sensors that you’re using for the outside weather data and the refrigerator interior temperature? Thanks!

Congrats on the Hydronic!

We installed a Eberspächer D4 diesel air heater in July 2015 and we love it except for the noise the intake air pump makes (we have silencers on the warm air outlet ducts to the cabins).

Later that winter that we met Goldcrest of Lymington in Barcelona and it was quite an eye opener to see how silent their boat was while keeping quite toasty aboard… clearly if one likes one’s quiet, there is no option other than Hydronic heating.

Hi Evan, The outside temperature is coming from the LCJ Capteurs CV7-V wind sensor at Gizmo’s masthead, as discussed here:

https://panbo.com/archives/2017/10/smorgasboat_2_more_tasty_test_electronics_southbound_on_gizmo.html#LCJ-Capteurs-CV7

(With the barometric pressure added by the LCJ Windy Plug in the fly bridge cabinet).

The refrigerator temp is coming from a Maretron sensor via their TMP100 (same as the engine block and inside temps). I’m about to add another TMP-100 to get dripless shaft bearing, raw water pump, transmission and battery temps into the N2K network, and will write up. I’m not sure you can put enough temp sensors on a boat, especially if you can custom alert and alarm them as Maretron allows.

I’m also about to install a Yacht Devices humidity sensor that will hopefully add Hum Outside and Dew Point to that Maretron weather page at top, and perhaps even help predict fog:

http://www.yachtd.com/products/humidity.html

Ben – thanks for the info on the sensors. I also have a TMP100 which I use for engine EGT and engine room temperature. Still plenty of channels left and I’d like to add the fridge and ice maker internal temps. But still puzzling over how to route the sensor to the interior of these devices. How did you run the wires into your fridge?

Ben –

Great piece as always. This answered a lot of questions for me. Do you have a sense if the total current draw for this type of hydronic system is more or less than the current draw for the Webasto Forced Air heaters? (I know there’s various sizes that could affect current draw). By a lot? Or a little?

Thanks!

– Peter

Thank you, Peter. I did fudge the specific power needs of Gizmo’s hydronic system in the entry, but it is a complicated subject.

For instance, the Sure Marine Webasto TSL17 page shows Start-up consumption of 8.8 amps for 30 seconds and “Full” consumption of 3.8 — which I can sort of see on the boat’s Victron BMV. But there’s a lot going on with the little boiler given its ceramic igniter, combustion fan, and ability to adjust heat output. I can hear various cycle changes if I turn off the radio and pay attention, and that exhaust tube (exterior) temp I’m measuring rarely stays constant.

Plus there’s the circulation pump, the Surewire box, and the intermittent heater fans (though my Real 6400 reportedly only uses .71 Amp in high mode). I’ll try to do some careful overnight amp counting along with outside and inside temp monitoring when I’m back on the boat, but my gut feeling is that the heater consumption was like the refrigeration consumption during my ICW trip (and note that reefer would have worked less if the boat was colder 😉

Back to Peter’s question, Sure Marine shows the Webasto Air Top 55 — similar to the TSL17 with 18,750 Btu — with Start-up consumption of 10 amps and Full on consumption of 7.4. That’s more than the TSL but circulation pump and additional fans aren’t needed, and as noted actual heater consumption over time is hard to quantify. (Though I think that Simarine Pico monitoring could do the job, and maybe I should try it.)

Congratulations on the hydronic heater installation. You’d just finished up most of the initial installation when I met up with you in Camden last June (on a very hot day). Glad to hear it is doing the job as you’d hoped.

Best wishes

Stephen Hill

Tug’n (Nordic Tug 37)

I just want to second the nomination of Sure Marine as a great supplier. Replaced my rusted Trident propane solenoid with a SS one from Sure, plus a better pressure regulator & custom hose. Great help from Todd Glenn.

Thanks, Stephen, I remember. I think you noticed that I didn’t have the right switch to work with the engine heat exchanger, and maybe I can blame the hot day for forgetting that part.

Here’s a little YouTube fun, some guy bench testing the Webasto Thermo Top C, the glass jar of diesel fuel a nice touch: https://youtu.be/EErcbFNjQ_8

But the Top C does fire up the same as my TSL17 (though it comes with a circulation pump attached and may have different wiring on top). Its manual has more detail on amperage consumption in different modes:

http://www.techwebasto.com/documentation/heater/cargoapp/thermo-top-c.html?download=2301:thermo-top-c-operation-manual

Hi Ben:

Thanks for that additional info. I appreciate that the different parts of the system have different energy requirements. If you’d be willing to post your thoughts on current draw of the whole system down the road, I’d be super interested!

– Peter

Excellent article, Ben. A note for those on sailboats who are planning on sailing in high-latitudes and being on the hook for extended periods of time (and without a generator or a huge battery bank): take careful note of the power consumption of hydronic units. Our Webasto DBW2010 uses far too much power to run for days without a good charging source.

Ben. why did you selected Webasto, we have Kabola, and that runs quiet and also allows hotwater radiators etc.

Ben. why did you selected Webasto, we have Kabola, and that runs quiet and also allows hotwater radiators etc.

Jan-Kees, a big part of my decision was a system that could fit on my particular boat. Transom mounting the air intake and exhaust outlet were nearly impossible and access to the cabin side cramped.

At any rate, I don’t have comparative experience or opinions regarding other boiler brands, but it is comforting that the little Webasto I got has purportedly been used in over a million trucks.

Also, while I didn’t know it beforehand — and Kabola may have similar — there’s a sophisticated diagnostic app available for the Webasto if it has problems:

https://youtu.be/WrKQAlCT04U

PS I don’t think there is any reason that a Webasto radiant system can’t also run radiators, but again I didn’t have the right spots.

Jan-Kees,

A Webasto or Eberspächer hydronic is smaller, doesn’t use as much electricity, and can run of a 12V battery directly. However, it is also rated for only 3000 hours of operation and it doesn’t generate as much heat. If you live on-board in a cold climate and intend to run the boiler for long periods you’ll need to replace the blower motor on the Webasto or Eberspächer every year or so (3000/24 = 125 days.)

Ben’s TSL17 is 17000 BTU which converts to 5 KW. The size of the unit is about 4 L (232x105x165 mm).

My Kabola KB40 (the smallest Ecoline Combi) is 13 KW, but uses 182 W of AC current and is 515x655x450 mm = 151 L big and weighs 80 kg. It can make as much steaming hot water as you want for showers and doing the dishes, and it is *totally* soot free. Because it uses a much hotter flame it is also higher efficiency so uses less fuel.

So it is just a completely different proposition in almost every way.

So I think, that for the size of boat and intended use, Ben chose wisely.

For the USA read Espar for Eberspächer (identical).

For Kabola the nearest equivalent is Olympia, as used by Matt Garand in Ben’s reference above — see http://www.suremarineservice.com/olympia-boiler.aspx

For some reason the Olympia claims a much lower fuel consumption compared to the Kabola, which I don’t really understand — they both use basically ‘household’ equipment so should be somewhat comparable.

My friend has an Espar air heater on his boat, and it works very well. Seems to be lot simpler installation as long as you have the room to pass a 4″ duct throughout the boat.

As for the polaris replacement, I imagine that in addition to the new boiler shown, you also need another heat exchanger for the DHW, or a conventional gas water heater.

Thanks for all that solid information, Kees! I did not actually know about the 3,000 hour fan life on my Webasto TSL17, but that will likely be far into the future given the way I intend to use the (as you surmised).

Chris, I’ve never had a separate domestic water heater. During the decades I had the Polaris boilers, the radiant heat system was “open” — meaning the water flowing under the floors was the same as what came out the hot taps. That didn’t cause any problems at all, but is no longer allowed because some open systems did have issues with water contamination.

So the HTP is a true combi that heats domestic and heating water separately, and now my radiant loops are closed.

Thanks for the great write up and explanation of a hydronic unit.

In 1993, we were outfitting our Cal 46 for Alaska cruising, and had ordered the “new” Force 10 hydronic system. About 3 months before we were ready to sail from S. Calif., we were informed that Force 10 was not going to sell any (more?) of their diesel heaters, which we had ordered. (We were told there was a fire box problem) A quick check of products available revealed the Proheat truck heaters might work–and we ordered one. The X 45 is now sold by SureMarine as a boat heater, with some modifications, but basically the same unit. Ours even came in the diamond plate box. The 45,000 BTU unit was perfect for the Cal 46. We were able to get 3 of the “radiator boxes” with computer fans, and thermostats, which Force 10 had already built and shipped to us. One in the foreword stateroom, one aft stateroom and one in the main saloon gave excellent heat distribution. In the hanging lockers we used a single loop of bare copper pipes, as we did several loops of bare copper tubing in each of the two heads (under the towel racks).

It was a very simple system all in one box–fuel pump, (1/4″ lines), atomizer pump, forced draft blower, and coolant circulating pump. There were the air intake and exhaust which were concentric, as in the Webasto, and 3/4″ circulation output/input lines. There was a copper expansion tank included, with coolant fill cap. One switch for the on/off of the main ProHeat unit, and each radiator unit had its own thermostat for the 12 volt fan. There was a thermocouple in the main unit which kept the coolant between 150 and 180 degrees when the unit was running.

We did not include the water heater loop, since we ran either the generator or main engine daily; either of which heated water. When the engine was running we had a red dot radiator and fan under the companionway steps, which heated the main saloon and the center cockpit, which was fully enclosed with canvas.

The only issue was that the unit exhaust was fairly noisy. (More outside than inside). Our current draw averaged about 5 amps, and about 8 amps on start up.

Heat is wonderful… not doubtaboutit… I have Espar Airtronic 4 installed on a 36′ sailboat. 3 outlets keeps the boat toasty. Once design temps have been reached you can'[t even hear the heater… and barely as it’s warming up the cabin. It’s no louder than ambient wind and waves and passing boat sounds. Heat is dry and using diesel is convenient… no other fuel to deal with. Install was quite easy and running the trunk line was not a problem. I try to avoid pipes which can and do leak.

Ditto from me on the always outstanding Sure Marine. Their showroom is amazing, their inventory is extensive, and their seasoned advice has saved me plenty. Big sale or small, they have always gone above and beyond. And they’re so price competitive that I don’t shop out-of-state anymore. I just go to Sure Marine and they set me up. Can’t sing their praises enough.

Hi

Live in Norway. Bought a Benetti SailDivision 79 RPH. My wife and I live on board.having some problems with the existing AirCondition/ heating system.

We need to heat up living room, dining room, kitchen, hall, bridge, 5 cabins and the engine room.

We have a closed circuit, with glycol, running through all the rooms. This system is working perfect. This means, we want to use this system in combination with a new heater.

Ben,

I’m preparing to add heat to our Saga 43, anticipating a year of summer time sailing in the Canadian Maritimes (as far north as Newfoundland). Looking at “extreme lows” of upper 40’s. Sure has been exceptional on the phone already — but they recommend that I consider the 2010, which at 35,000 BTU seems overkill.

So, your little TL17 has serviced Gizmo well in temps into the 30’s, right? Are you still happy with the performance and durability?

I sort of think I’ve been steered toward (and willingly followed!) a system that is perhaps far more complex than my use-case suggests. After reading your post, I’m seriously considering dialing back the design.

Hi Harry. Yes, I’m very happy with the performance and durability of my hydronic heating system. I think it’s clocked well over 2,000 hours without any issues and I just used it quite a bit on a 10-day cruise, mostly for hot water showers and dishwashing but also to take the edge off chilly mornings.

With the boat in the water all last winter in Maine, I used the heater in some really cold conditions, but it was for work projects where I arrived already warm and well dressed, not for living aboard. I also let it run for extended periods to keep the unwinterized engine room above freezing in sub zero air temps with the harbor water near freezing.

I do understand why Sure Marine is recommending a larger boiler, but suspect you’d be pretty happy with the TL17 for summer in Maritimes. Note though that my main fan heater is at forward cabin floor level facing forward, which is ideal for heating the relatively small galley, head, and sleeping area, plus I have a propane cooking stove that can add significant heat for short periods. That warm air does rise into the main cabin with all its glass, but 17,000 btus has a modest effect up there with temps in 30’s or less.

I’ll add that Gizmo is going to spend this coming winter in a large drafty building in Rockland and I was pleased to learn that the yard will probably be OK with me running the boiler when I’m aboard for projects. They want to see and smell it in operation first, but I don’t think there will be a problem as it runs quite clean. In fact, I never see smoke and I’ve never had to clean the cabin side in the area of the exhaust output.

PS There’s no question that my TL17 was a complex installation, and maybe overkill for your one-time cruise. Maybe you should consider the propane system Sure Marine sells if you can determine that propane tanks are easy to obtain in the Maritimes?

https://www.suremarineservice.com/Heat/Propex-Propane-Forced-Air-Heaters/PRO-2800-KIT.html

Or a small solid fuel stove like lots of Maine cruising boats have. There’s nothing like a wood fire to fight damp chill:

https://www.suremarineservice.com/Heat/Solid-Fuel-Heater/00-NEWSF.html

Ben,

Thanks so much for the replies. The propane one looks pretty nice (and I hadn’t noticed it before), but getting an air duct from the back of the boat (a sailboat) to the front is a big challenge. Also, I only carry two 10 lb propane tanks. My old Cozy Cabin propane heater would burn about a pound a night (the boat is actually CNG, so the propane heater was cobbled together to use 1lb camp bottles — not ideal, I know) and so I could imagine not getting more than a week out of the house propane system. Still, have to think about that solution.

Thanks for your article and sharing your design and experience. Have you considered adding a chiller so you can leverage the same fan coil loop for AC as well? I’m considering that…