Upgrading to lithium batteries & testing an all Mastervolt DC power system

Like many boaters, I treasure the peace of a serene anchorage, but not the sound and smell of a generator. So the high energy density and fast charging abilities of lithium batteries got me interested, and eventually led to an all-Mastervolt system that should also improve my 12-volt DC house power system in many other ways. This is part one of a series detailing the reasons for that decision, the installation, and how well it performs.

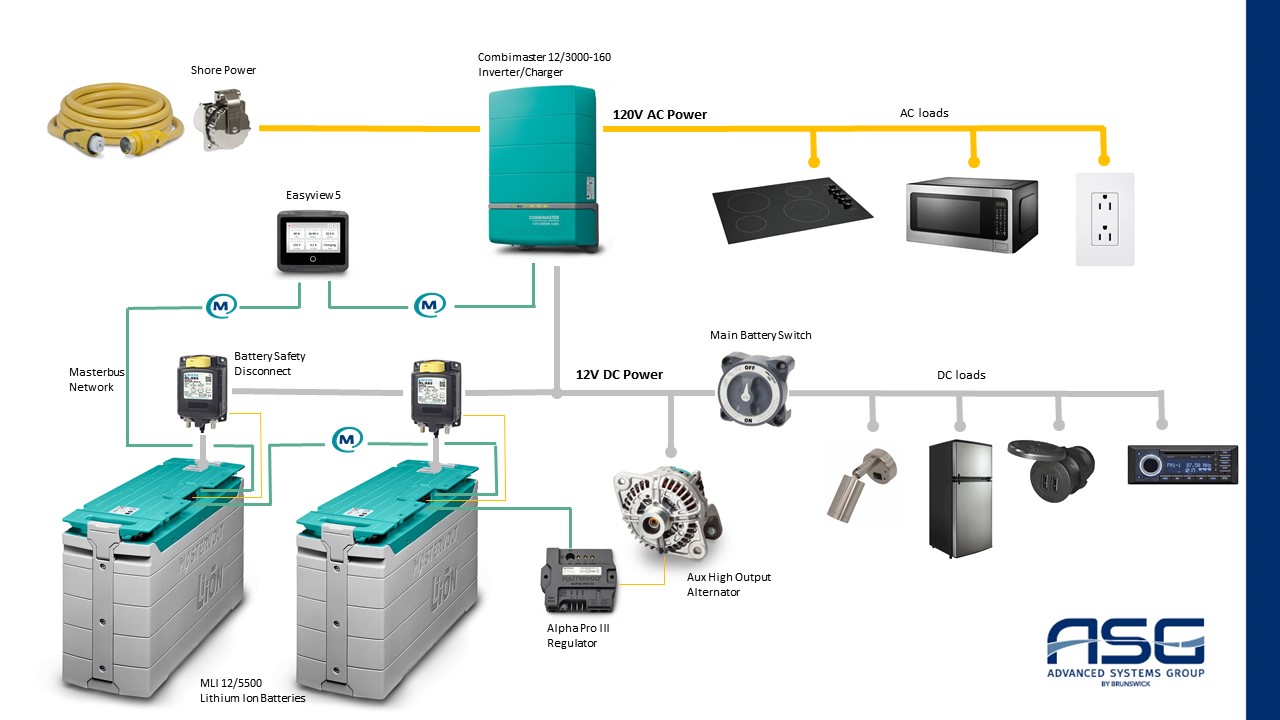

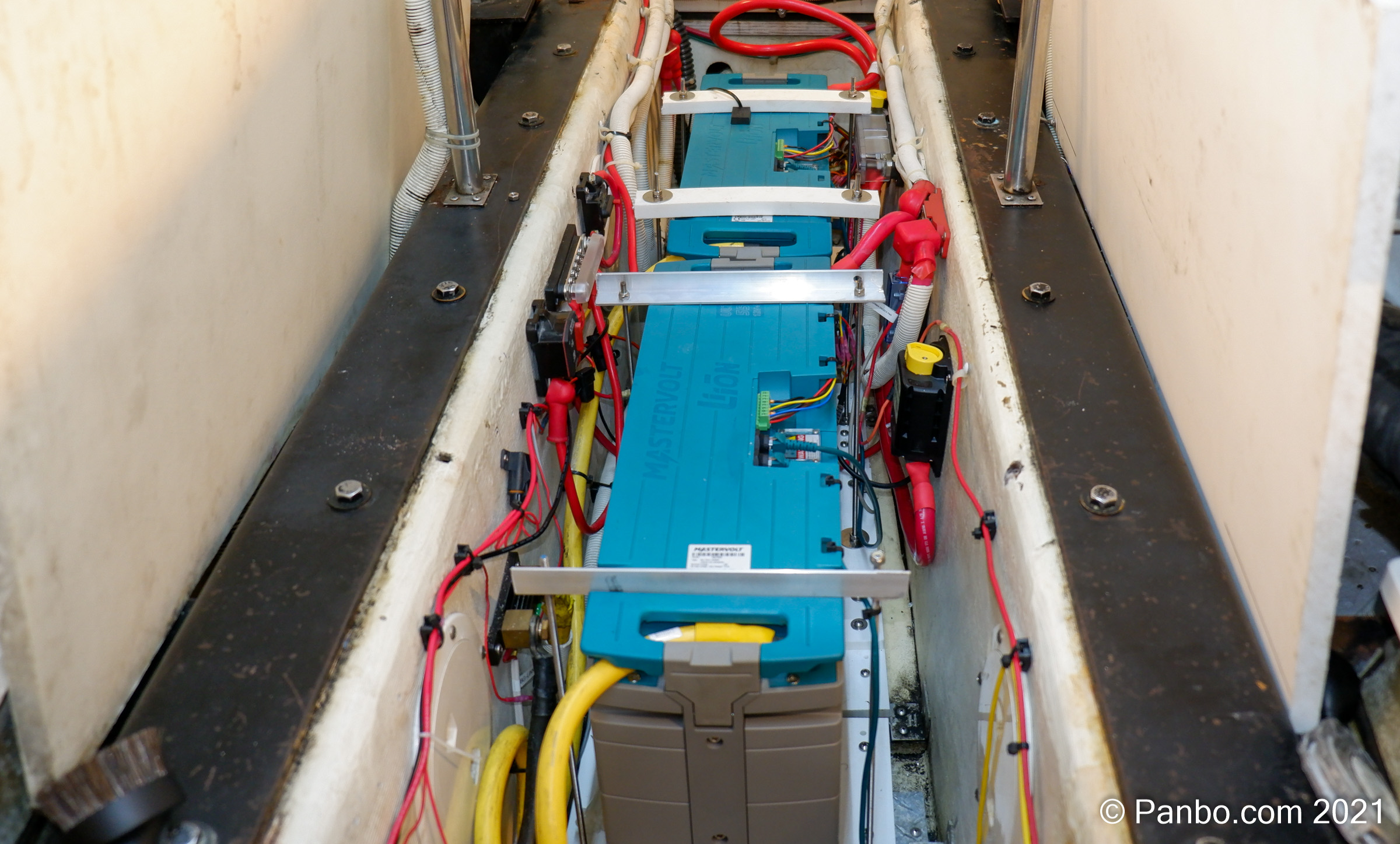

Actually the install isn’t finished, but when done, I’ll have upgraded or changed all of the sources and storage on Have Another Day‘s 20-year-old house power system. The new component list is a CombiMaster inverter/charger, two 400 Ah MLi series LiFePo4 batteries, an EasyView 5 display, a 200 amp Alpha Compact alternator, and an Alpha Pro III external regulator — all from Mastervolt. So far I’ve replaced her original inverter and installed one of the lithium iron phosphate (LiFePo4) batteries, but I’m already seeing the fruits of my labor and investment.

Why LiFePo4?

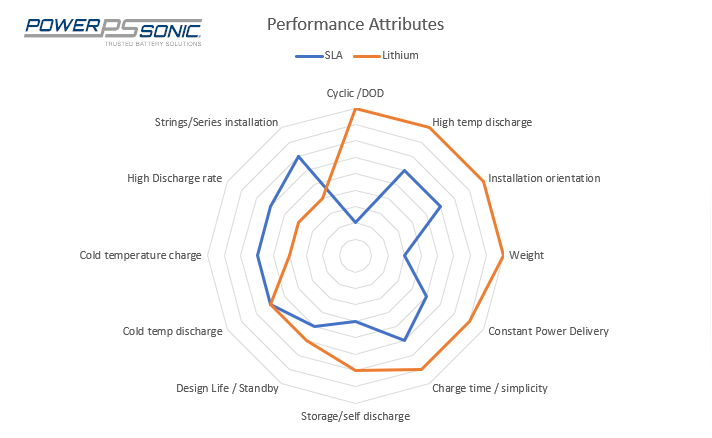

Lithium batteries — specifically the popular LiFePo4 type that is meant throughout this entry — offer boaters many advantages over the various lead-acid types (that Luis Soltero explained in depth):

- High current charging — low internal resistance mean that lithium batteries can be charged quickly, and they’re often rated to accept their entire capacity in an hour.

- Higher energy density — they generally store double the energy in the same physical space.

- Lighter weight — they weigh less than half of a comparable lead-acid battery.

- Depth of discharge — LiFePo4 batteries can be safely discharged to 80% of their capacity while lead-acid batteries are typically discharged a maximum of 50% to protect their longevity.

- Constant power delivery — these batteries deliver a very steady voltage until they’re nearly completely discharged, even under large loads.

- Longevity — manufacturers claim that lithium batteries can be used ten times more than lead-acid types, and thus last ten times longer. (And that may be longer given that many lead-acid banks die from an event like getting discharged too far.)

LiFePo4 batteries have other benefits: they are maintenance-free, can be installed in multiple orientations, and self-discharge at a lower rate. But lead-acid outperforms lithium in some ways, the most obvious being the upfront cost. An 80 amp hour, deep cycle, group 27, flooded lead-acid (FLA) battery can be purchased for as little as $80. In contrast, the least expensive reputable 100 Ah lithium I could find costs $800.

At first glance that suggest the FLA battery storage costs $1.00 per amp hour versus $8 for LiFePo4. But because only half the FLA amps are usable, so it’s more like $2 per usable amp hour, while LiFePo4 usable amp hours cost about $10 due to its 80% depth of discharge. Although that still makes the new technology five times as expensive as FLA, the investment will work out in the long run if they really do last ten times as long (and you don’t kill them prematurely).

But as you likely know, some lithium battery features are also safety concerns. While a subsequent entry will dive deeper into this subject, I can tell you now that a lot of research has led me to this conclusion: LiFePo4 is the safest of the lithium battery chemistries and it rivals or exceeds FLA safety, especially with the safety systems built into Mastervolt’s batteries and overall power system.

Why Mastervolt?

Installing lithium batteries isn’t as simple as a move from flooded lead-acid to AGM or gel; on an existing boat, their use often requires modification of charging sources, circuit protections, monitoring abilities, and more. And while there were many ways I could have solved all that, Mastervolt and Victron stand out because both have developed extensive marine power product lines that include their own network protocols for deeply integrating the various components. It’s darn compelling to get an advanced power system under the single warranty and guidance of a company with deep marine roots.

But Victron and Mastervolt have different strengths, and I like how the latter can even supply their own alternators. I also appreciate Mastervolt’s deep lithium battery experience — as in the around-the-world racing fleet Panbo covered in 2015 — and the reduced financial pain resulting from their nice trade/test discount. (Plus, though not planned, it looks like Ben Ellison will be installing a Victron lithium system, so readers will eventually get a comparison.)

Rod Collins does an excellent job diving deep into the details of installing LiFePo4 batteries on boats. One of the main points he makes is the importance of coordination between the batteries and their charge source. Mastervolt’s MasterBus (MB) communications bus enables communications between all the Mastervolt components on the boat and helps ensure that minor issues are caught before they become major issues.

Existing DC system

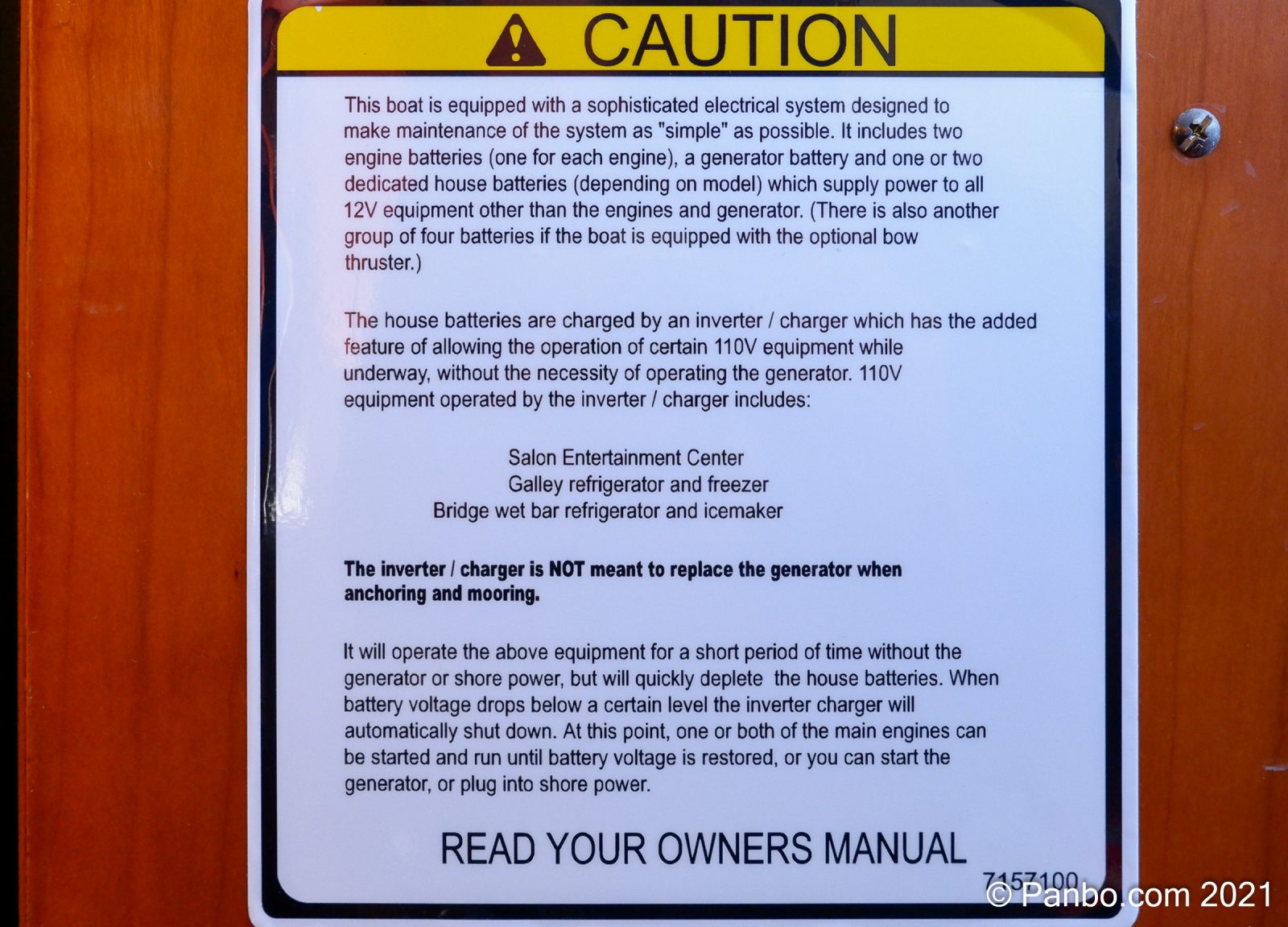

Have Another Day was built with a residential 110 AC voltage refrigerator and freezer in the galley, so they are dependent on an inverter to run from the house batteries (unless shore or generator power is available). Carver equipped her with the Charles Industries 93-ACP1226C quasi-sine-wave inverter/charger seen above at the factory in 2003.

When Have Another Day was built there were many fewer options for power away from the dock, and the sticker above drives this home. Carver’s advice about only powering loads with the house batteries and inverter “for a short period of time” doesn’t match my desire to enjoy an anchorage in peace without the generator running. Fortunately, advances in technology since 2003 enable much better options.

The refit begins

My move to LiFePo4 meant the Charles inverter/charger had to go. It was built before lithium iron phosphate power storage technology was used on boats and hence its charge profiles don’t support the chemistry. The last thing I’d want to do is hurt my brand new batteries charging them with the wrong profile.

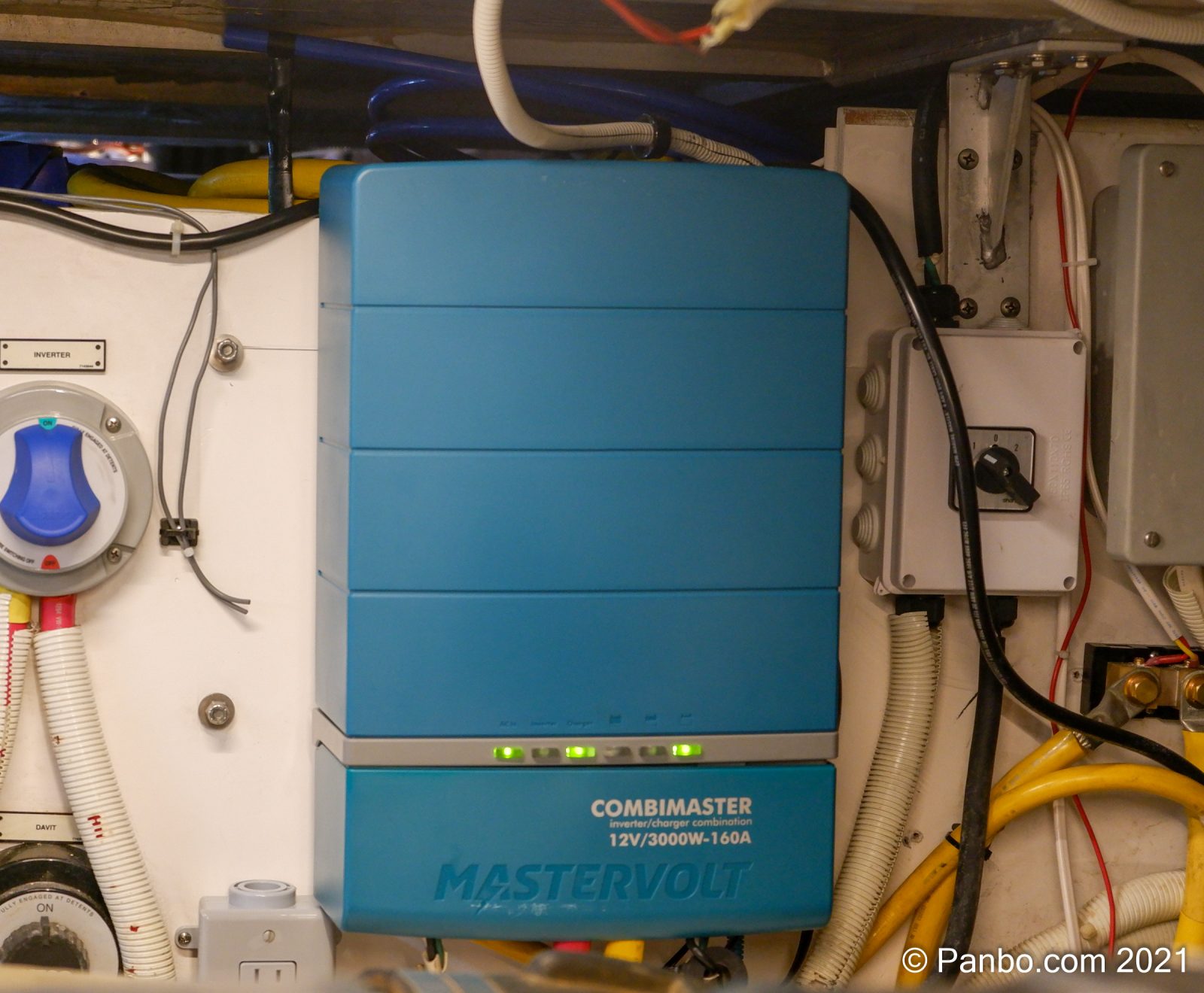

Also, the Charles had always struggled to reach its rated 120 amp maximum charge current when powered by my generator (and its modified sine-wave output never gave me much confidence either). One of the biggest benefits of these new batteries is their ability to accept extremely high charge rates and so I’m hoping that the Mastervolt CombiMaster’s higher 160 amp rating and its claimed ability to reach full charge amperage on generator power will help with my goal of minimized generator runtime.

Replacing the old Charles unit quickly made the physical differences noticeable. Despite greater inverting and charging capabilities, the CombiMaster is barely over a quarter the weight of the old one, at 20.5 pounds versus the Charles it a backbreaking 79 pounds. The new inverter/charger is also a little smaller at 17.6 x 11.2 x 6.1 inches versus 17.5 x 14 x 8.4 inches for the old one. Plus, the inverter portion is rated for 400 more watts and true sine-wave output.

Enjoying the benefits of the new inverter

Have Another Day spent a recent weekend on anchor enjoying an unseasonably warm winter weekend in southwest Florida. But it wasn’t all play; our time at anchor was also an opportunity to test out the new inverter and one battery (while logistics challenges delay the second’s delivery). Even with only one 400 Ah LiFePo4 battery installed, the fruits of the upgrade tasted good.

Faster charging

I think the CombiMaster’s 160 amp charging capability is the most significant upgrade for my use. Plus, it has had no troubles delivering all 160 amps on shore or generator power as well. The Charles charger was sensitive to the frequency of the power; if it was faster than 60 hertz, the charger would output well below its rated charging current.

I’ll discuss way more detail about the battery performance in a later article, but our weekend at anchor verified that the combination of MasterVolt CombiMaster and MLi battery will improve family life at anchor, when it is common for us to wake up with the house batteries down about 250 amp hours.

With the previous inverter and FLA house bank, the peak charge right after starting the generator was only 80 amps, and within an hour or so this would dip to about 60A. Because FLA batteries charge acceptance tapers significantly as they approach full charge — and charging them fully is the best way to treat them — a typical 250 Ah charge cycle would take six or more hours.

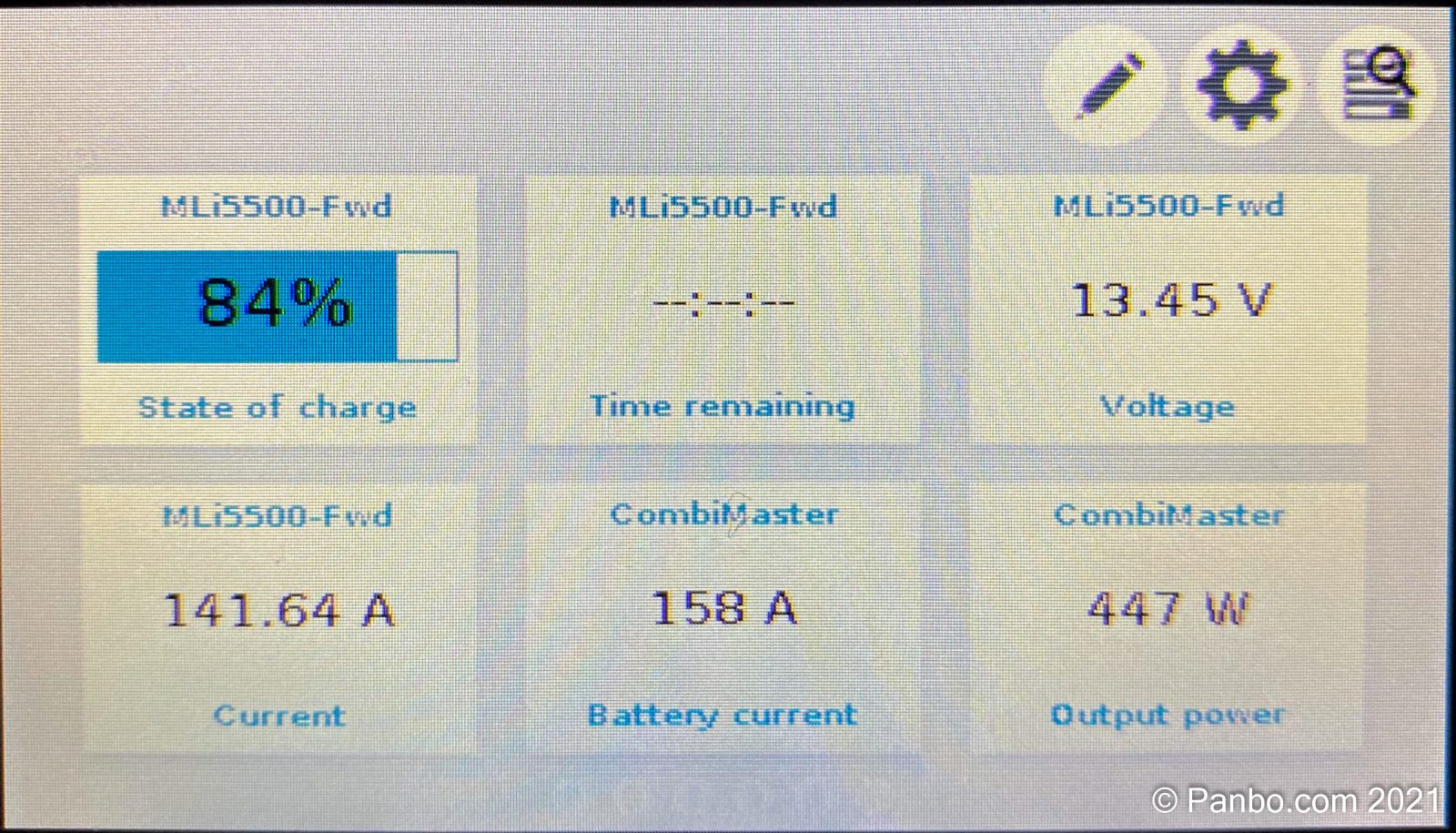

With the CombiMaster, I see steady charging around 140 amps with the full output from the inverter/charger at nearly the maximum rated 160 amps. The exact amount of current making it to the battery fluctuates as other 12v loads vary between 10 and 20 amps. The single lithium battery reached full charge in under two hours at anchor, and that’s a game-changer for us! Reducing our generator runtime by two-thirds is a massive difference. Plus, knowing that I can quickly replace any energy used with a short evening generator run means we can enjoy more time without the generator running.

Less power lost

Before removing the Charles inverter I measured its power consumption and found some surprising results. The reader comments to that entry seemed to reach a consensus that most of the “missing” power was likely power factor losses, but I’m pleased to report that there are no mystery issues with the CombiMaster’s power efficiency. Instead, I see around 100 watts being consumed by the inverter most of the time with some of that going to run the cooling fans and some to losses in the 120-volt to 12-volt conversion. Mastervolt says the inverter is 93% efficient and that’s in line with what I’ve observed.

What’s Next

There’s still more install work to do and plenty more to talk about. But, I’m going to save that discussion for future entries. I’ve just received the second battery and will get to work installing it. Then, I’ll be able to report on the performance of the full capacity battery bank, the install of the alternator, and the monitoring and reporting capabilities of the whole system. Plus, if there are areas you’d really like to hear about, please speak up in the comments section below. I’ll be sure to highlight anything you’d like to know more about.

Final thoughts

I still have a lot of work to finish up the full refit. But, if the rest of the work is as rewarding and smooth as the start I am confident I’ll be very happy with the final product. Getting the second battery installed will give us enough capacity to anchor for a full day with no generator runtime. Plus, once the 200 amp alternator is installed we should be able to fully recharge the battery bank with just a few hours of cruising. As I mentioned, I’m already enjoying the benefits of the work I’ve done so far, but I know there are more benefits to come with the project completed. Plus, once I finish this project I can figure out where to fit Solar on the hardtop and further reduce our generator runtime.

No solar/wind generation?

Solar is on the list for upgrades. However, I don’t have too much hope of getting the boat to be able to generate all her power from solar or wind. The boat draws enough, primarily because of refrigeration loads, that I doubt I can get enough solar to make all the power I draw.

Do you still have a separate Lead Acid starter battery?

Carter,

I do still have separate 24-volt engine start banks.

-Ben S.

Very interesting Ben. I would like to install Lithium on our next boat possibly.

Hi Ben – I’ll be very interested in your installation and operating experience with your new high capacity alternator. I did an alternator upgrade 4 years ago to a 180A small case unit with external mounted diodes powered by our Yanmar 6LY2A-STP engine with new pulleys and 10 rib serpentine belt. Our initial install was somewhat problematic as the belt occassionally rode over the water pump pully. Numerous alignment attempts did not solve the problem. Finally the alternator bracket was removed, bolt hole slotted and with the addition of a idler pulley hopefully resolved. So exact pulley alignment is critical and addition of an idler pulley necessary to maintain belt tension. I think a major contributor to the belt overriding problem, along with imperfect alignment, is the low shoulders on the outer ridges of the Balmar replacement pulleys which allowed the belt to easily ride over thos outer ridges. The alternator pulley has higher shoulders and we have never had an override at that pulley.

I hope your pulley replacement kit has better designed pulleys as that should make for a smoother transition. I’d also seriously consider a spring loaded idler pulley if you have space. We did not and are using a fixed pulley.

We have eliminated the need for a generator on our boat with the 180A alternator, 400 watts of solar panels and 4 Firefly carbon foam 100 Ahr house batteries. While not year round livaboards, we do cruise our Ellis 36 for 6 month seasons with 2-3 months summer cruise to Maine each summer.

Hi Ben,

Just curious if the Mastervolt system has NMEA2K interface or some other output that would allow for feeding various “power parameters” into a signalK server. I will need to replace my similarly aged Xantrex inverter soon and this will be an important feature so I can consolidate data in one place or on multiple displays around the boat that are being driven by the SIgnalK/Influx/grafana setup.

Thanks for a great article

Hi Ben. I like your focus on generator time as a game changer. That is exactly the phrase I have used. We are a 24 volt MasterVolt system with (2) Mass Combi and (2) Ultra 25/5000 180AH batteries. On Generator, both chargers run full blast and replenish 24 hours heavy battery use in about 90 minutes.

And, just wait until you start messing with the power sharing features available for A/C loads. When you have the ability to use batteries to cover short term high amp draws like microwave or coffee maker, it’s just incredible how little amps you need from shore to run and charge the boat. You only need to provide for average load from shore, not peak.

Mastervolt makes a MasterBus to NMEA 2000 adapter. This has the ability to output almost any of the parameters from MasterBus to NMEA 2000.

I’m planning to cover those capabilities in a later entry, but here’s a panel from Grafana through my SignalK server:

-Ben S.

awesome. Look forward to future posts

I have a Mastervolt installation on my sailing catamaran and I love it. My goal is to minimize battery charging from the alternator as I like the peace of running the boat from solar. In this scenario, I currently have just over 1kW of solar and I plan to increase that to nearer to 2kW and what I have learned from trying to switch to solar power is that you must be able to take all the amps you can get when the solar panels are working at their maximum output. My current panels peak at about 80A@12V when the sun is bright and overhead, so I am hoping that my additional panels will increase this to around 150A. Lithium is also a key contributor to weight reduction, which is a hot topic on a sailing catamaran. If all goes to plan, I think I will be able to run my water maker (12V dc, 60A), my two fridges, the small chest freezer, all the navigation gear, washing machine, USB charging for personal devices, lighting etc without ever needing to start the engine to charge the batteries except in cases of extended overcast weather. With the current solar, I can operate in sunny conditions at anchor (we spent three months in a marina in Ecuador where the shore power was very sketchy and we never once needed to do anything to run the boat, but once I start all the navigation gear and autopilot, the system cannot keep up and it can’t handle anything other than very sunny conditions, so I hope that the extra capacity will increase my options and allow me to sail 24/7 without needing to start the engines (I don’t have a generator or AC).

Looking forward to the rest of your comments about your new system.

Hamish

P.s. although it’s quite user unfriendly, the Mastervolt MasterAdjust software is very useful and provides detailed system control.

I am wondering if the Mastervolt system has the ability to charge the batteries bases on in/out going current. Not just voltage.

Yianni,

I’m not exactly sure what you mean by in or outgoing current. Batteries accept charge based on their state of charge and the incoming voltage. I don’t believe it’s possible to control the battery cells and tell them to accept more charge at a lower voltage.

-Ben S.

Ben, hi

I think we are both describing the same issue. What I meant to say, up to this point Charging regulators were able to charge batteries based on voltage alone. Recently though companies such as Wakespeed (WS500) have been able to monitor and adapt the battery charging cycle based not only on voltage alone but on the current measured at the battery level.

@Yianni,

Yes, the Mastervolt system is able to do this. With the Lithium batteries you don’t need a shunt as the battery BMS has a built in current measuring system. With non-Mastervolt lithium or any brands traditional batteries you need a MasterShunt.

With the shunt connected to the charger or charger controller via MasterBus the charging is based on net current into and voltage at the battery, not what is measured at the charger source.

This is not new: my boat has had it since 2010 and the tech has been available since the mid 2000s.

Hi Kees,

Thank you for making it crystal clear!

Cheers

Yianni

Yup,

The integrated nature of the Mastervolt system really works well. The battery tells the charge controller when to stop charging and when to reduce charging. Beautiful.

I cannot find any documentation on this “telling the charge controller when to stop charging”. Do you configure “events” on the masterbus? Or is the Shunt on its own trotteling the charger when SoC reaches 100%?

Hey Ben, did lfpo4 13 yes ago with twin victron multiplexes that would charge my bank at 240 max amps. All reduced my genset run time to < 1/3rd from year before. All good. The multipluses had 4 programmable relays and customizable charging profiles. Offer power match supplementing of meager shore power.. which permitted us to cruise in comfort when glomming inadequate power from a garden out or other 15 and source. All cutting edge at that time. I am still a fan but know little about what Mastervolt offers. Currently doing that to my small boat however using Firefly batteries as did know how to control the outboard charging systems. Interested to see the comparison with Ben E. Warmest regards, to you and family, Joe Pica

Amazing thanx for sharing information.

Hi Ben,

I see in your diagram that you don’t have any lead acid batteries as buffer batteries.

I was told by Mastervolt that you still need these. Was he mistaken? or was it just left out of the drawings?

Sorry Keith, it’s only six months later but I’m finally responding.

In house uses I’ve never heard talk of buffer batteries in the mix. I am wondering if yours was a starting role? Or if the buffer batteries were suggested for alternator charging with an unregulated alternator?

I’d be curious to hear more and better wrap my head around hybrid battery bank designs.

-Ben S.

Hi Ben,

Yes a late reply indeed. Better late than never I guess.

Anyway yes I was talking about the alternator charging. Yes it’s usually recommend to use buffer batteries to absorb possible voltage spikes that could potentially destroy the alternator should the lithium batteries suddenly open circuit due to the BMS activating it’s protections.

The general recommendation is,

Alternator ~> Lead Acid Battery ~> Charge Relay or B2B Charger ~> Lifepo4 batteries, which is ok if the starter batteries are the same voltage as the house batteries but otherwise it somewhat defeats the purpose of installing lithium if you also have to install extra lead acids.

Victron have recently approved the Wakespeed WS-500 regulator for charging their Lifepo4 batteries without buffer batteries with the future possibility of Can-Bus connection. When I saw your diagram I thought perhaps Mastervolt was doing something similar with the Alpha 3.

Thanks for sharing. I have purchase the same MasterVolt inverter charger because of it 160AMP charger and I will be using it ith non-Mastervolt lithium.

Hi Can you expand on your success with this. I have a Multiplus 12/100-3

A bit late to the party but i hope you are still monitoring this thread, we have two Mastevolt Lion 24/5000 batteries on board. All great, problem occurred when shorepower failed and we were not able to visit the boat for a long time during lock down. The batteries charge went down to 13% and has been reset by the dealer. We are experiencing much reduced times between charges suggesting the low charge level has impacted battery performance. Could that be the case you think and can this be reversed in hour opinion ? Thanks. Jan

Jan,

This sounds like damage might have been done to the cells resulting in less capacity. But, I’m sort of surprised that noticeable damage would have been done to the batteries from a single discharge to 13%. Do you know how long the batteries were held at this state of charge?

Also, have you been in touch with Mastervolt? There’s quite a bit of data that can be read from the batteries and the BMS and I would expect you could gain some clarity about the health and operation of the batteries from that data.

-Ben S.

I have some concerns about the alternator and the belt used. When the generator produces 200A at 12V it’s equivalent to a load of 2400W = 3,22 horsepower (HP).

From the picture of the alternator I can see that a v-ribbed belt is used and they are usually not able to transfer more than 1,5 – 2 HP. Using them at this high loads will wear them out very quickly.

A recent installation with litium batteries was made on the Swedish sailing boat Ran II, currently on its way on the Biscaya Bay, France. They installed Lithium batteries this summer in Sweden, half the capacity of what’s described here. From Sweden they sailed through the Kiel Canal and when in France (English channel) the alternator belt had to be replaced. In this case it was a v-ribbed belt.

To avoid to replace belts a couple of times every season, tooth belts should be used. Hyundai and Solé uses tooth belts that has better performance and last longer than v-ribbed belts. They are much thinner and since they have teeth they doesn’t need to be tightened so hard.

Are toothed pulleys required to avoid belt slip with toothed belts? Belt slippage should be less with greater contact area, V belts, than ribbed belts, or not? A properly fitted V belt in pulleys in good condition properly adjusted should be virtually slip free. If belt driven loads are causing slip pulley size should be examined.

Butch we went to a microgroove pully (Balmar Altbelt serpentine system) to eliminate our belt slip. Before had one v belt which was adjusted properly however would slip badly under the load of our lfp04 bank demand on our Yanmar 100amp alternators. Overtightening on ours would have side loaded the fresh water(antifreeze) pump and raw water pump bearings causing premature failure and leakage. That load was on the top edge of what a single v belt can take.