Dometic E-Actuator steering promises better outboard steering with no hydraulics

Dometic’s Optimus Electric Steering Actuator has had quite a successful show season since its early 2019 introduction. It’s won major awards at IBEX, METS Trade and from Boating Industry Magazine. But what captured the attention of those award committees? It’s the promise of more precise handling, reduced weight, easier installations, and reduced maintenance. A few minutes spent with Dometic Marine representatives makes clear the engineering and innovation required to make this system possible.

Dometic purchased Seastar Solutions at the end of 2017 and rebranded it as Dometic Marine at the end of this year. Seastar Solutions has long been the dominant provider of marine steering systems with around 80% of recreational steering systems coming from them.

Engineering an all-electric steering system

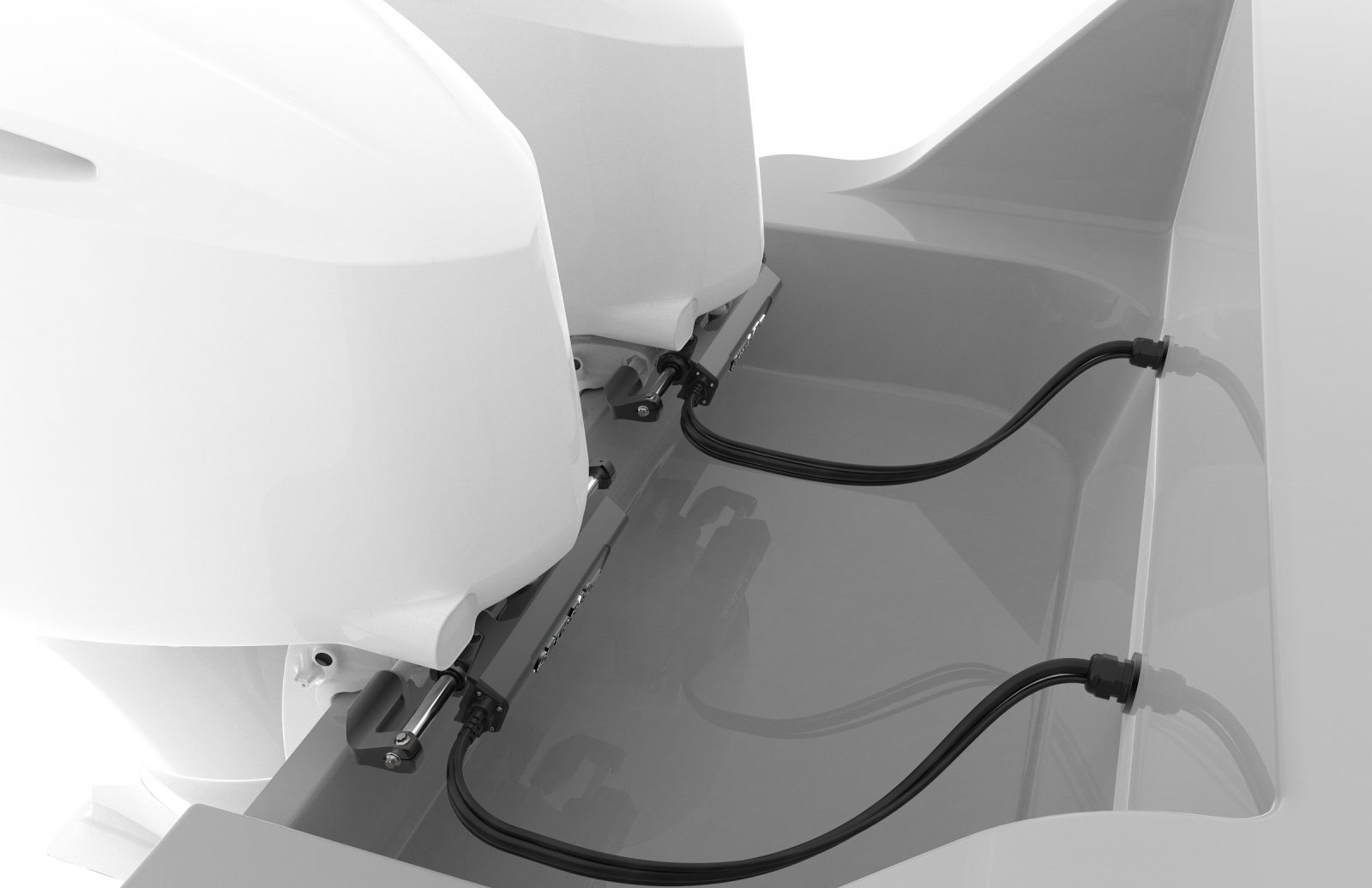

The previous Optimus EPS system was drive-by-wire from the helm to pump control module but then utilized hydraulic pumps, lines, and cylinder

The Optimus all electric system requires just power and CANBus wiring. There’s no hydraulics in the system

Seastar’s Optimus EPS electro-hydraulic system debuted in 2012 (and Ben Ellison tried it out) and utilizes drive-by-wire technology from the electronic helm unit to a pump control module mounted at the stern of the boat. Drive-by-wire from the helm to the pump means there’s no hydraulic lines or cable controls running from the helm to the stern, instead there’s just a couple of thin CANBus wires making the connection. The pump control module then controls hydraulic pumps that connect to a hydraulic steering ram attached to each engine. This system was a significant step forward eliminating long hydraulic runs and drastically simplifying the installation of additional steering stations, but it still required the rigging of hydraulics from the pumps to the steering rams.

Dometic Marine’s all-electric actuator removes the need for any hydraulic rigging and dramatically simplifies the installation of the boat’s steering system. Connecting the actuator only requires three CANbus connections and wiring power to the unit. A brushless direct current motor and roller screw drive system are contained entirely within the actuator. Dometic estimates the installation of the all-electric system will be two to four hours faster than an electro-hydraulic system.

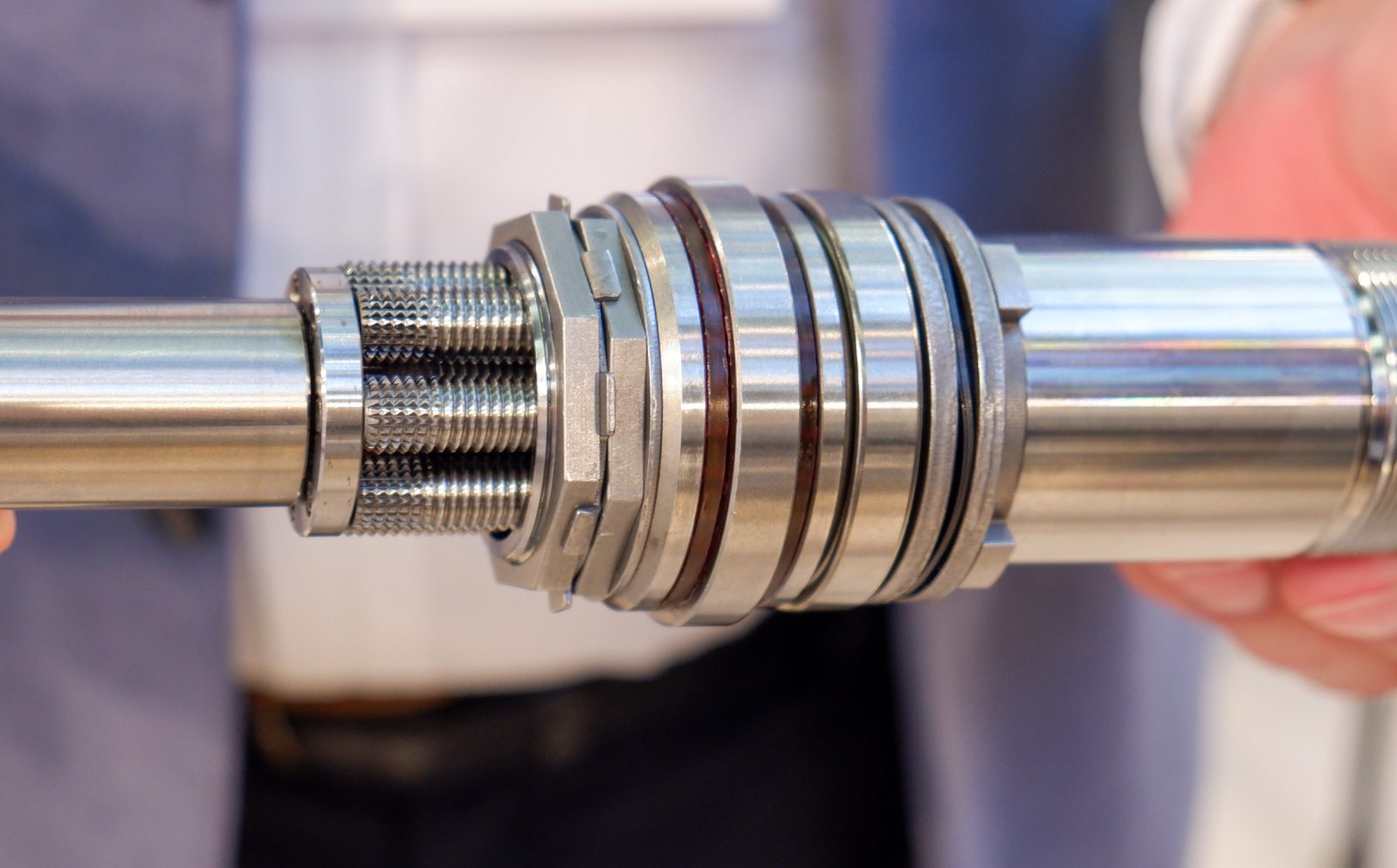

It’s almost unfortunate the actuator is covered by its protective housing because it hides the impressive and beautiful example of what’s possible with modern fabrication techniques. Dometic is justifiably proud of what they’ve accomplished in the design and manufacture of the Optimus Electric Steering actuator. Though they’re also a little tight-lipped about some of the exact techniques, they will proudly tell you that they’ve developed quite a few unique manufacturing processes to deliver the product.

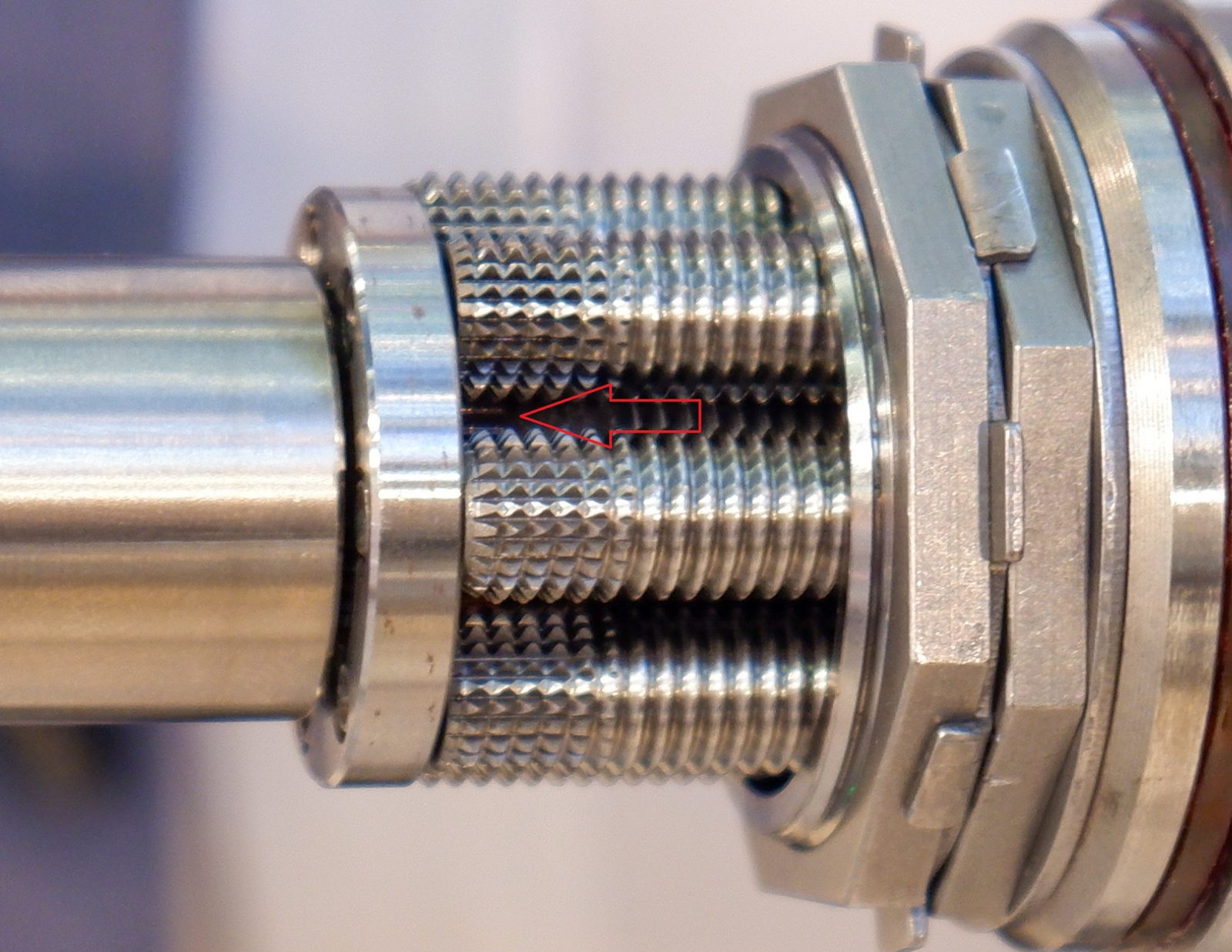

The actuator utilizes what Dometic describes as an inverted roller screw design. It contains 7 planetary rollers around a main center screw. The rollers mate with the threaded interior of the actuator housing to extend or retract the ram and control steering. I’m told that getting the high precision threads on the inside of the housing was one of the major challenges of building the actuator. The roller screws are made of hardened stainless to ensure durability. But, harder metals are also more brittle so the alignment of all those threads must be extremely precise to avoid fracturing any of the threads.

Dometic precisely machines the roller screws to tolerances of .0001 inches and controls the rotation of each roller by hobbing the end of each screw with a pattern that mates to an internal gear. The gearing on the end of each roller screw can be easily seen while the tooth of the internal gear can just be seen peeking out by the red arrow in the picture above (you may need to click on the picture to enlarge it). This internal gear meshed with each roller screw maintains thread alignment as the actuator moves to steer the boat.

E-Actuator on the boat

The promised result of all this innovation is a system that is more responsive, more precise, quieter, and easier to install. The all-electric Optimus system carries about a 25% premium over the current Electro-Hydraulic system. I suspect most of this premium can be made up in the reduced time and effort required to install a system without any hydraulics. Additionally, a twin-engine, all-electric system is 33 pounds lighter than it’s electro-hydraulic sibling. Maintenance is also reduced since there’s fluid to monitor and change.

Each Optimus steering system, whether electro-hydraulic or all-electric, utilizes redundant CAN networks to ensure reliable control of the vessel even in the event of a failed connection or cable. Optimus steering systems can control from one to four engines and the Optimus 360 joystick control system can be added to any engine configuration. The steering effort and a number of turns from lock-to-lock can be adjusted based upon the user’s preference, plus those parameters can be set to vary based on the vessel’s speed. An additional benefit of either the electro-hydraulic or electric system is the ease of adding additional stations. Rather than having to rig any hydraulic lines or cable controls to additional helm locations all that’s required is extending the CAN networks to the helm location. This cuts down significantly on both parts and installation labor. It looks like all the Optimus systems support up to three helms.

All of Dometic’s Optimus systems equipped with their Optimus 360 Joystick system can also be outfitted with SeaStation GPS dynamic positioning system and Seaways Autopilot. SeaStation has three modes, position hold, heading hold or position and heading hold. The Seaways Autopilot features heading hold, tracking mode or route mode. Both systems are controlled via Dometic’s color display

A steering ram probably isn’t something you think about too often, but the improvements Dometic’s all-electric system offers might be enough to change that. The benefits of the system are pretty easy to understand and the simplicity of installation and adding significant features like joystick, autopilot, and dynamic positioning systems make this system pretty compelling. If you’re building a new boat it seems pretty obvious this system deserves consideration. But, what about as a retrofit to an existing boat. Ben Ellison recently purchased a boat that might benefit from such a system and I’m in the market for one myself. Perhaps one of us will have the opportunity to give this system an extended on the water test.

You know I had actually thought this was already a thing. I know there are several kicker motor systems panther is the one I found with a quick search, but I had thought the Verado and E-tec G2 were actuator steering. After a quick look up both do have hydraulic components. The E-tec is an interesting system in that it’s basically self contained.

Overall this is a big trend with actuators replacing hydraulics. There have been teething pains including several Navy projects I have heard about, but the idea is as mentioned simplification, even if at first it may seem more complex.

I think I like the all-electric approach, but agree that the E-Tec G2 has cool build-in controls and note their claim that hydraulic means get-home steering if the main electronics fail:

https://panbo.com/new-at-icast-evinrude-idock-and-raymarine-axiom-pro/

I’ve also learned the electric steering actuator in the Yamaha 425 XTO is built by Dometic and very closely related to the Dometic E-Actuator. When that engine first came out I was most intrigued by the simplicity of rigging it (minus the complexity of lifting and fitting a 1,000 lb engine onto a transom).

Congratz, Brian and your team.